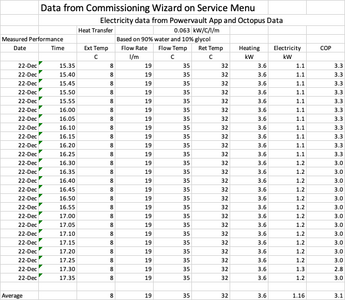

@f1p No Buffer, No LLH, Delta T is 3C, pumps are in proportional pressure mode, giving a fairly constant 19 l/min. There is glycol in the system and I have used 90% water 10% glycol for my calculations, I suspect that there is a greater concentration of glycol and hence the heat transfer is lower. The temperature sensors are the ones provided by Mitsubishi as part of the Flow Temperature Controller, the are 2 pumps in series both Grundfos UPS3, both set to Proportional Pressure 2. The flow is from the Mitsubishi Flow Temperature Controller. The commissioning wizard in the Service setting provides Flow Temperature, Return Temperature and Flow Rate at 5 minute intervals.

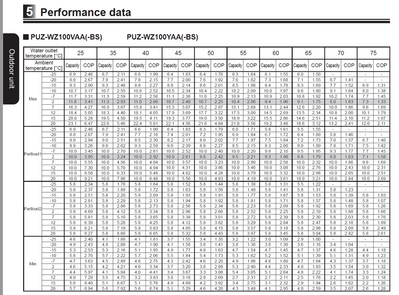

@sheriff-fatman I'm not sure why you have selected the Max figures from this table. Lower down the minimum figures are provided, these are more representative of the conditions, At 7C Capacity is 4.1kW with a COP of 5.04

Posted by: @ecoste@sheriff-fatman I'm not sure why you have selected the Max figures from this table. Lower down the minimum figures are provided, these are more representative of the conditions, At 7C Capacity is 4.1kW with a COP of 5.04

Wrong screenshot used, which I can't now edit. The commentary refers to the full datasheet and the range of COPs under different conditions.

Intended one attached. The one shown was a screenshot that didn't crop properly at the time, but it looks like I selected the wrong file.

130m2 4 bed detached house in West Yorkshire

10kW Mitsubishi Ecodan R290 Heat Pump - Installed June 2025

6.3kWp PV, 5kW Sunsynk Inverter, 3 x 5.3kWh Sunsynk Batteries

MyEnergi Zappi Charger for 1 EV (Ioniq5) and 1 PHEV (Outlander)

User of Havenwise (Full control Jun-Dec 2025, DHW only from early Dec)

Subscriber to MelPump App data via CN105 Dongle Kit

@sheriff-fatman The FTC7 with third party cylinder and pump does not control the pump speed, there is a menu item for pump speed and the value can be varied but the control unit does not have an output to control pump speed. Mitsubishi have confirmed this when I asked them.

@sheriff-fatman This is the table that I am familiar with. It shows a COP of 5.04 with a capacity of 4.1kW at 7C OAT and 35C flow. Which is why I think that less than 3 for similar conditions is failing to meet the specification, by a long way.

Does anyone know of one of these units that is operating at a reasonable COP?

Posted by: @ecoste@f1p No Buffer, No LLH, Delta T is 3C, pumps are in proportional pressure mode, giving a fairly constant 19 l/min. There is glycol in the system and I have used 90% water 10% glycol for my calculations, I suspect that there is a greater concentration of glycol and hence the heat transfer is lower. The temperature sensors are the ones provided by Mitsubishi as part of the Flow Temperature Controller, the are 2 pumps in series both Grundfos UPS3, both set to Proportional Pressure 2. The flow is from the Mitsubishi Flow Temperature Controller. The commissioning wizard in the Service setting provides Flow Temperature, Return Temperature and Flow Rate at 5 minute intervals.

Thanks for the further info.

Are the two pumps just because one wasnt sufficient, or is there anything between them. Have you got the Mitsubishi preplumbed cylinder which has a built in LLH?

all I am trying to do with the questions is to tie down whether you are definitely measuring COP at the heat pump (to compare with spec).

If you are definitely measuring COP at the heat pump then either

- the unit is underperforming relative to spec

- the rounding of the values is causing a miscalculation

- one or both of the temp sensors are out

- your electrical measurement is wrong

- the flow sensor is under reading

2. will become clear if you measure at several temperatures, because the rounding will work in different ways (there is a well known measurement technique when a readout has limited resolution which is to introduce white noise into the system and average the figures, this synthesizes extra 'bits' of resolution)

3. can be tested by swapping sensors and their connections

4 and particularly 5 are difficult to diagonse. Does the system measure electrical power. If so it would be worth capturing this figure also as it might give a handle on (4)

Hope that helps. I cant see why you should not expect COP measured at the heat pump on a long run to be close to the spec, given that Mitsubishi actually provide the spec at various power output levels.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

Posted by: @ecoste@sheriff-fatman The FTC7 with third party cylinder and pump does not control the pump speed, there is a menu item for pump speed and the value can be varied but the control unit does not have an output to control pump speed. Mitsubishi have confirmed this when I asked them.

Interesting. Thanks for the info.

That would explain the lack of movement in the flow speed and the delta T observations might just have been short-term variance, given the limited window.

130m2 4 bed detached house in West Yorkshire

10kW Mitsubishi Ecodan R290 Heat Pump - Installed June 2025

6.3kWp PV, 5kW Sunsynk Inverter, 3 x 5.3kWh Sunsynk Batteries

MyEnergi Zappi Charger for 1 EV (Ioniq5) and 1 PHEV (Outlander)

User of Havenwise (Full control Jun-Dec 2025, DHW only from early Dec)

Subscriber to MelPump App data via CN105 Dongle Kit

@jamespa The 2 pumps was a decision by the installer, I don't think that they are necessary but at the moment it is a small difference in energy consumption. They are in proportional pressure mode. I have a Joule Cyclone cylinder CY205L, no LLH.

I am measuring COP using the Mitsubishi temperature sensors and flow sensor. The flow and return temperatures are consistent with the entry and exit temperatures for the radiators, which I have measured independently. The temperature sensors track the hot water cycle, see the attached screen shot.

If I vary the pump settings the flow varies as expected, it is 27 l/min at the max setting.

The electrical readings have been validated against the data from my electricity supplier Octopus, I get half hourly reading data and can see instantaneous readings. I allow 300w for the background house usage, which is the maximum, it varies between 100W and 300W.

I recognise that the data is not very accurate, integer granularity, but even allowing for this it is a long way off the specification.

I would be very interested in any other Ecodan R290 users' experience.

@sheriff-fatman You may be able to vary the pump speed by using the controls on the pump.

Posted by: @ecoste@jamespa The 2 pumps was a decision by the installer, I don't think that they are necessary but at the moment it is a small difference in energy consumption. They are in proportional pressure mode. I have a Joule Cyclone cylinder CY205L, no LLH.

I am measuring COP using the Mitsubishi temperature sensors and flow sensor. The flow and return temperatures are consistent with the entry and exit temperatures for the radiators, which I have measured independently. The temperature sensors track the hot water cycle, see the attached screen shot.

If I vary the pump settings the flow varies as expected, it is 27 l/min at the max setting.

The electrical readings have been validated against the data from my electricity supplier Octopus, I get half hourly reading data and can see instantaneous readings. I allow 300w for the background house usage, which is the maximum, it varies between 100W and 300W.

I recognise that the data is not very accurate, integer granularity, but even allowing for this it is a long way off the specification.

I would be very interested in any other Ecodan R290 users' experience.

All noted, Im not doubting you, just trying to be certain (and hopefully help you be certain) that what you are measuring is real and representative of the heat pump itself not the system. Because its not as blatant as previously, you are going to have an uphill battle trying to get this fixed (if there is still a fault, which there may be), so absolute certainty is key. I would definitely check what the pump thinks power consumption is, neither Mitsubishi nor your installer is going to take any notice at all of 'I allow 300w for the background house usage, which is the maximum, it varies between 100W and 300W, particularly as it is well known that the national average electricity consumption is about 400W. I'm presuming that 'mixing tank temperature in the plot is a phantom.

To my mind if its that far from the spec under steady state conditions lasting 12 hours then its not working correctly. It might be worth reviewing the absolute numbers as opposed to COPs/Percentages just to take a view on margins of error.

I dont have an Ecodan R290 so cant add personal experience. There are however 5 Mitsubishi R290 heat pumps on openheatpumpmonitor, it might be worth looking at those

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

@jamespa I appreciate the questioning, you are correct it is important to have certainty. How would you check what the pump thinks the power consumption is? I do have 2 years of data to support my 300W assumption, but it would be better to have a measured value rather than a derived one.The mixing tank temperature is a Mitsubishi entry on the chart, I don't think that there is a corresponding sensor.

Thank you for the link to openheatpump monitor.

Here's a data set for 25 readings at 5 minute intervals from this afternoon.

Here's the Melcloud Hourly Temperature report, showing stability of flow and return temperatures

- 27 Forums

- 2,520 Topics

- 58.6 K Posts

- 461 Online

- 6,800 Members

Join Us!

Worth Watching

Latest Posts

-

Issue with a Grant Air Source Heat Pump & Tado Smart Thermostat

Hi all I'm having some trouble with a Grant ASHP and ...

By Renewables345 , 31 minutes ago

-

RE: Underfloor Heating Installation Issues with Heat Pump

We suffered a water leak last year in two rooms and had...

By MartinHook_UK , 42 minutes ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

Now seems a good time to summarise the costs and effici...

By benson , 50 minutes ago

-

RE: Heat Pump vs New Gas Boiler for Inherited House - Worth the Extra Cost?

*** I now see @jamespa has already posted but will stil...

By cathodeRay , 2 hours ago

-

RE: Tell us about your Solar (PV) setup

@mk4 Charge to 100%, discharge down to 10%.

By bobflux , 2 hours ago

-

RE: Daikin Altherma 3 LT compressor longevity question

This mess is intriguing: I wonder if this represent...

By bobflux , 3 hours ago

-

RE: Connecting Growatt SPH5000 over wired ethernet rather than wireless

The simplest wired option is usually the Growatt Ethern...

By Jonatan , 8 hours ago

-

RE: Peak Energy Products V therm 16kW unit heat pump not reaching flow temperature

ASHPs do have a minimum compressor speed. The minimum h...

By bobflux , 14 hours ago

-

RE: Electricity price predictions

@jamespa And it seems some of the nasty public cloud...

By Batpred , 15 hours ago

-

RE: Jokes and fun posts about heat pumps and renewables

Technology is rapidly advancing. BBC News reported th...

By Transparent , 18 hours ago

-

What matters for flow and pressure drop is internal dia...

By bobflux , 19 hours ago

-

RE: Do Fridges and Freezers have COP ratings?

@editor Thank you all for your replies and submitted in...

By Toodles , 21 hours ago

-

I know and yes. The secondary deltaT wont necessaril...

By JamesPa , 1 day ago

-

RE: Designing heating system with air to water heat pump in France, near Lyon

Just love the way you put it! 🤣

By Batpred , 2 days ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thank you for sharing. So it seems that your Schneid...

By Batpred , 2 days ago

-

RE: Forum updates, announcements & issues

@upnorthandpersonal thanks for the thoughtful, consider...

By Mars , 2 days ago

-

RE: Solar Power Output – Let’s Compare Generation Figures

@mk4 All 21 panels have their own Enphase IQ7a microinv...

By Toodles , 2 days ago

-

RE: Setback savings - fact or fiction?

Great, so you have proven that MELCloud is consistently...

By RobS , 3 days ago

-

RE: Mitsu PUHZ120Y 'Outdoor Temp 'error?

Thanks David & James It almos...

By DavidAlgarve , 3 days ago

-

RE: Surge protection devices SPDs

@trebor12345 - your original Topic about the right type...

By Transparent , 3 days ago

-

RE: Help needed with Samsung AE120RXYDEG

@tomf I’ve been sent this from a service engineer at Sa...

By Mars , 3 days ago

-

RE: Buying large amp bidirectional RCD and RCBO

Yes... I went through this particular headache and ende...

By bobflux , 4 days ago

-

O-oh! Let's take this as an opportunity to 'pass the ...

By Transparent , 4 days ago