Midea R32 Monobloc MHC-V12W in 1989 Detached House: Noise from Pipes/Airing Cupboard, DHW Schedule Not Always Heating – Advice Needed?

Hi all, I've been reading the posts in this forum with great interest for the last few days, especially @pash44pump journey. I've already had some golden nuggets of support from some of you on the MSE forum but was informed of this resource and wanted to share my own experience and ask some questions if I may?

House:

1989 detached brick build, 1900 sq ft, 4 bedrooms, 4 reception rooms, 3 bath, (unheated) double garage.

No cavity wall insulation that we are aware of. Loft appears well insulated but survey suggested it may not be quite up to current standards.

Located in Hampshire, England.

System installed October 2024:

Midea R32 Monobloc MHC-V12W/D2N8-B

Pump located on east side of house, 400mm away from the wall and mounted on rubber feet (albeit 2 of the 6 bolts appear to be missing and are being replaced).

Pipework goes up east side of house into attic space, from where it drops down into first floor airing cupboard. Heating is provided by radiators.

I believe that the existing gas boiler pipework was used but new radiators were fitted to all rooms apart from the lounge and hallway.

I bought the house a couple of months ago but have only just moved in. The previous owner had the system fitted but subsequently needed to sell the house and move up north so I inherited it just past its first birthday.

Heating

I'm generally happy with the heat levels I get across the house. The upstairs is slightly warmer as one might expect, and as the rear of the house is south facing it benefits from sun a lot of the time.

I'm confused about how to balance heating output with the lock shield valves though. Currently all my TRVs are open fully so not sure if I need to do anything further with lockshields. All the radiators seem to heat up to similar levels, although the lounge, which was one of only 2 radiators not replaced, is a bit cooler (probably exacerbated by not currently being able to close the door fully!).

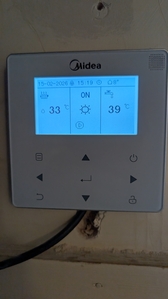

I have a weather compensation curve active which seems to do its job (typically 33 flow temp at 8 degrees outside temp and 38 flow temp at 3 degrees outside temp).

I've never lived my adult life in a property with a wet central heating system as I've always been in apartments with electric panel heaters, so I'm totally unfamiliar with the noises that one should hear from the heat pump. The outside pump itself makes a low whirring noise when the fan and compressor are active which can occasionally be heard inside through the adjoining wall to where it's mounted outside - but it's never particularly intrusive. However, I do hear noise inside the property which is louder than I was expecting. When the pump and/or compressor are active I hear a 'buzzy' noise through the inlet/outlet pipes in the loft and down into the airing cupboard. Hard to describe but like 'data scrambling' and, perhaps like the noises I remember my old central heating system as a child making.

Because the airing cupboard is sandwiched between my bedroom and one of the spare bedrooms I can hear the faint sound of the internal workings and what can only be described as a very very faint rumble like a wheelie bin being wheeled down a path. Very very faint and not audible in the loft pipes but only occasionally in the house itself. I do have exceptionally sensitive hearing so not sure if I'm overthinking what are perfectly normal noises.

As I hear it at night and I'm a light sleeper I wondered if it was worth considering setting back the heat overnight for a few hours or whether the re-heat efforts are not worth it.

Additionally, sometimes I hear an intermittent drip noise from the kit in the airing cupboard. There's no visible leak (and because I did have a leaking hot water tank replaced under warranty I'm super paranoid at checking every day). It's not audible elsewhere in the house and it's only occasionally from the pipes somewhere around the 2 expansion tanks. I can't work out if it's just condensation in the pipes or natural dripping noises from water going through the system. Only occasionally and I can't pinpoint it to a set time.

Domestic Hot Water

I was setting the DHW using the timer tab on the controller for e.g. 14:00-15:00 every day to hit 45 degrees, but I was finding it wasn't always heating up at these set times. Even though the 'squiggles' next to the tap symbol would turn on as planned the tank temp wouldn't increase.

I've just changed this to use the 'schedule' function instead and seem to be observing a similar pattern, maybe only every other day will the tank actually heat up. I wonder if this is because my 'tank reheat trigger' point hasn't been met yet (i.e. if my target temp is set to 45 on the timer, my reheat threshold is -5 then the timer will only ever kick in if the actual tank temp falls to 40 or below?) So, for example, at a current tank temp of 41 it wouldn't reheat even if the timer was instructing it to hit 45?

On the subject of legionella and immersions, I have the seperate immersion and TimeGuard clock fitted, however for the last few weeks the power and output LEDs don't light up on the timer, even though the display works and allows me to control it 'on and off' etc. I wonder if the timer is working off battery power and may have lost its electricity supply (I've recently had a new consumer panel fitted). If the electric immersion heater *was* actually running would the Midea controller reflect the increased 60 degree tank temp, or is it independent of the Midea temp detection?

I've read mixed opinions on whether running a legionella cycle is required. If the immersion heater is indeed not working could I just set one of my weekly timers on DHW to hit as close to 60 as possible? I believe that temps over 50 degrees will kill legionella over a couple of hours anyway? Does the legionella disinfect cycle on the Mideas require a seperate immersion heater or does it control the heat pump to increase the flow temp?

As an aside, I've signed up to Midea's MiCare scheme and awaiting my first service from them. Unfortunately, and I'm not sure how, they'd assigned my pump's serial number to another property record so I've been in dispute with them about convincing them I'm due the service which shows as already completed on their system.

I've attached some photos to show my set up.

@painter26 — welcome, and thank you for your clear description of what you have, and your questions.

First of all, I think you are largely on top of things. You are running weather compensation, which is the right way to do things given your setup. The importance of radiator balancing is sometimes over-rated, as long as it is roughly right, then it is probably good enough. You have all the TRVs fully open as you should, and if the heating just works with all the lock shields also fully open, that is fine. As it happens that is what I have, air flow between the rooms evens things out. Your lounge rad may be a bit on the small side, it may be worth considering fitting a larger one. If you have copies of the original heat loss survey and individual room losses, it should be easy to decide whether that is something worth pursuing.

You are on the right track with the DHW failing to reheat. The tank temp at the sensor needs to be below the the threshold. In your example, 45°C set DHW temp, -5 threshold (which by the way can be adjusted), at say 41°C for the tank temp sensor, a reheat won't be triggered. I find in practice (I also have a Midea heat pump) the tank temp sensor often needs to be a degree or two below the threshold to trigger a reheat. If you do need to do a manual reheat, the easiest way is to temporarily raise the DHW set temp, say to 50°C in your case, and then turn on DHW heating. You can do both of those things from the main home screen. Once the reheat has happened to the temp you want, you turn off the DHW heating, and reset the DHW set temp to your normal value.

I personally think the legionella risk in a closed (sealed) system in regular use is probably close to zero, and so don't bother with a legionella cycle. Having a resident with a pre-existing health condition might alter that assessment, but I doubt it. If you decide you do want to run a legionella cycle, you can use the heat pump, which will be more efficient than an immersion heater. I'm not familiar with it, because don't use it, but I believe Midea units have a legionella setting. Alternatively, you could run your own DIY cycle by setting the DHW set to maybe 55°C and make sure the tank stays at that temp for an hour or two (ie much as you suggest). There is a good Heat Geek article on legionella risk and how to manage it here.

The noises: not sure what to make of them. None of them sound (sic) particularly sinister to me. If they trouble you, you will need to do some diagnostics to narrow down where the noises come from. Using a night time setback is indeed another option to quieten things down overnight, but as you have already spotted these are controversial as to whether they (a) save or cost money and (b) recovery can be slow, because heat pumps aren't designed or meant to do sudden boosts.

I think I've covered all your question, let me know if I have missed anything out. And please do let us know how you get on!

Midea 14kW (for now...) ASHP heating both building and DHW

Thanks a lot @cathoderay - I've learned a lot from yours and others' posts on this forum.

Does the occasional 'drip' sound from the system sound normal in the airing cupboard? As I say, no signs of a leak and it sounds like it's coming from inside the pipework or maybe the expansion tanks - and only then occasionally.

Also, are you able to help identify what the purpose of the various tanks in my set up do?

I understand that the smaller cylinder next to the main DHW tank is the buffer. I'm not totally sure what it does and my installer did suggest that he felt it unnecessary but they're required to fit them.

The two expansion vessels - white one above the DHW tank I imagine is the cylinder's expansion tank? What is the purpose of the grey vessel top right?

I should also add that the pressure gauge when I moved in was reading below 0.5 bar. I believe the previous owner had an issue keeping pressure too with no evidence of leaks when the installer looked for them. In the last few weeks I discovered the hot water tank was leaking so has now been replaced (we suspect a potential pin hole leak which the manufacturer is now investigating). I've also got a leaky pipe valve into the bathroom towel rail which based on the amount of verdigris has been leaking for ages and I've temporarily turned it off at the TRV. Since these interventions it looks as though the pressure has stabilised so I'm hoping this was the cause.

Posted by: @painter26I've learned a lot from yours and others' posts on this forum.

Thank you!

Posted by: @painter26Does the occasional 'drip' sound from the system sound normal in the airing cupboard? As I say, no signs of a leak and it sounds like it's coming from inside the pipework or maybe the expansion tanks - and only then occasionally.

It doesn't sound alarming to me, given the context, occasional, no leaks and sensitive hearing. Maybe other can come up with a (benign) explanation? @transparent? @jamespa

Posted by: @painter26Also, are you able to help identify what the purpose of the various tanks in my set up do?

I understand that the smaller cylinder next to the main DHW tank is the buffer. I'm not totally sure what it does and my installer did suggest that he felt it unnecessary but they're required to fit them.

The two expansion vessels - white one above the DHW tank I imagine is the cylinder's expansion tank? What is the purpose of the grey vessel top right?

Buffers are for duffers, as you will know from your forum reading. Do you know if this indirectly a 'Freedom Heat Pumps' installation (ie they supply usually as a kit it to the installer who then installs it), quite likely as they are based in Chandlers Ford and you are in Hampshire. If so, they went through a period when they said some form of primary/secondary circuit separation was mandatory (I have a plate heat exchanger as a result, but low loss headers and buffers were also used). Long term, you may want to convert it to a volumiser which does what it implies, adds volume. I've kept my plate heat exchanger because it provides physical separation, meaning no rad crud in the primary circuit and glycol only in the primary circuit. Freedom have since been said to have relaxed the separation requirement.

The two expansion vessels: one will be for the hot water circuit. I can see what looks like a Caleffi pressure reducing valve (thing with the grey and blue caps on the vertical pipework by the main tank), the lower outlet on that valve will probably go to bottom DHW tank inlet, and one of the expansion vessels is likely to be teed into that feed, follow the pipework to work out which one. The other one is possibly for your rad circuit. You may be able work it out by following the pipework again. Faling that post more photos and we will see what we can make of them.

It also looks like you have an analogue flow meter, brass thing with two red valve handles on the right, another common Freedom feature. This is also used to fill the system, but the meter is a useful independent check on flow rate.

My primary circuit has a very small leak, such that the pressure will drop, but take weeks even months to do so. It must be a leak, but so small I am not sure it matters, and, like you, I have not been able to find out where the leak is. I just live with it, all the more so since I have never found a clear explanation of why the system most be pressurised to a positive pressure (obviously you don't want a negative pressure). Every now and then when I get round to it (twice a year?) I top it up using a temporary filling loop/adaptor which on my system can be temporarily connected to the rad filling loop, if that makes sense, I guess if you have been topping the system up, you have your own working arrangement. If anyone who reads this can enlighten us as to why the system needs actively maintained positive pressure, I am sure we will all be very grateful.

Midea 14kW (for now...) ASHP heating both building and DHW

Thank you @cathoderay .

The system was indeed supplied by Freedom (or at least the Midea handover booklet also has their logo on it!).

Now, I didn't realise the analogue gauge was a flow meter - I understood it to be pressure (although I'm not sure the pressure of what part of the system - and is this the same as the flow rate?)

The left hand expansion tank is an ExtraVarem unit which looks like it connects to the blue/grey valves. The top right expansion tank with the filling loop and gauge is connected by copper pipe to ond of the two pipes that come down from the attic. This tank is also connected to the blue/grey valves from another pipe.

I've attached an assortment of photos to try and illustrate. Ignore things like the isolation valve to the tank turned off - some of these were taken when I discovered the tank leak!

Posted by: @painter26Now, I didn't realise the analogue gauge was a flow meter - I understood it to be pressure (although I'm not sure the pressure of what part of the system - and is this the same as the flow rate?)

If you look at the side of it, you will see a glass observation port with with a scale marked on it, and behind that a little disk that moves up and down depending on the flow rate. Note it may be fitted upside down! Normally you read the value at the bottom of the disk, which is now at the top of the disk! The units are not the same (L/min) as the wired controller, but can be converted easily enough.

Posted by: @painter26The left hand expansion tank is an ExtraVarem unit which looks like it connects to the blue/grey valves. The top right expansion tank with the filling loop and gauge is connected by copper pipe to ond of the two pipes that come down from the attic. This tank is also connected to the blue/grey valves from another pipe.

I'm pretty sure the left hand one is the DHW supply pipework (ie what eventually comes out of your hot water taps). The other one I remain less sure about. If the circular gauge on the right hand expansion tank is the one you use to check the system pressure, then that means it is connected to the primary pipework, and if it is also connected to to the two pipes that come down from the attic, which I think are the flow and return of your primary circuit, that adds further support to that conclusion. The pig tail and two valves pipe is likely to be a filling loop coming off the rising main which then goes on to the Caleffi pressure reducing valve with the blue and grey caps. At least that is what I think the layout is, particularly if the rising main is as I have suggested it is.

I don't actually have an external expansion tank on the primary circuit (there is however I believe one in the main outdoor unit). I have the same DHW supply expansion tank that you have, but the other expansion tank I have covers the secondary radiator circuit. The difference may arise because of the plate heat exchanger I have, which physically separates the primary from the secondary circuit.

Midea 14kW (for now...) ASHP heating both building and DHW

The pig tail loop you refer to is what I was told by the installer to open both valves to increase the pressure (and thus the gauge that's attached to it). That's why I'm not sure what I'm actually increasing the pressure 'of' but it needs to be between 1 - 1.5 bar.

I've looked for this little flow gauge but can't seem to see anything.

Posted by: @painter26The pig tail loop you refer to is what I was told by the installer to open both valves to increase the pressure (and thus the gauge that's attached to it). That's why I'm not sure what I'm actually increasing the pressure 'of' but it needs to be between 1 - 1.5 bar.

This is absolutely standard for any sealed pressurised system (ie any system without a gravity fed tank usually in the loft). This is true whether boiler or heat pump so absolutely any plumber will know about it..

As @cathoderay says this is called a filling loop; its basically to allow you to let more water into the system (from the mains) if the system pressure drops because of a leak, because you have to bleed air out of the system, or for any other reason. The reason there are two taps and a non return valve is to prevent backflow of contaminated water in the system polluting the potable mains water.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 827 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

Actually, it’s better for wooden furniture – or at leas...

By Majordennisbloodnok , 4 hours ago

-

This is absolutely standard for any sealed pressurised ...

By JamesPa , 6 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 6 hours ago

-

RE: What determines the SOC of a battery?

@batpred Your BMS parameters will be the same as m...

By Bash , 7 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 8 hours ago

-

RE: Setback savings - fact or fiction?

I also need to correct something I said by mistake earl...

By cathodeRay , 8 hours ago

-

RE: Electricity price predictions

@judith Thanks for sharing, and nice to see how the ...

By Batpred , 9 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@tasos the OAT is incorporated into the control logic. ...

By benson , 10 hours ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 11 hours ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 12 hours ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 12 hours ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 13 hours ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 14 hours ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 15 hours ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 16 hours ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 17 hours ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 1 day ago

-

RE: DIY solar upgrade - Considering adding more panels

I know this is a bit old, but it made me wonder what co...

By Batpred , 1 day ago

-

RE: New Vaillant aroTherm Plus in black - When will it come to the UK?

@majordennisbloodnok Daikin, take note! (In fact, I hav...

By Toodles , 1 day ago

-

RE: Midea ASHP – how to set weather compensation

@mk4 — good work! First, I agree, no evidence of cycl...

By cathodeRay , 1 day ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

I don't know about Solis inverters. It isn't a featur...

By Transparent , 1 day ago

-

Daikin Altherma 3 H HT - Freeze Prevention Threshold

Hi. We have an Altherma 3 HT (18kW I think) which, now ...

By RICHARDF5033 , 2 days ago

-

RE: Passiv Smart Thermostat - Help & Forum Support

@petch We are not yet compatible with the R290 from Gra...

By Will H , 2 days ago