@agentgeorge Fortunately the one thing that you *won't* need to worry about is the wiring because there is hardly any! The eBus board has a socket on it and comes with a detachable plug that takes two wires (+/-) - you attach that to your eBus, plug in the board and you're good to go. + and - should be marked and the documentation claims that getting it wrong won't fry anything but I've not put that to the test. The board then broadcasts its own little WiFi network (SSID), you attach to that and a Web page should come up (if not then the IP address is in the documentation) and you can set parameters, the main one of which is to give it an IP address on your home network (static or DHCP). The firmware should be perfectly good enough to kick off with and once you have done that then once rebooted it'll be broadcasting eBus packets to your network till you unplug it.

What follows assumes that you are running HomeAssistant (HA). Unless you bought a pre-installed and configured HA box then, again, you'll have at least passing familiarity with Linux.

At this point you can telnet to the eBus card on its IP and port and all being well you'll see a load of digital junk coming back at you.

You next need to download and install an eBus daemon (software that runs permanently listening for stuff) called ebusd within the HA machine and tell it the IP address of the eBus card. This then catches the eBus traffic from the board, tidies it up a bit and looks for somewhere to send it within HA. A common way of handling that is to install an MQTT daemon in HA, another piece of software that runs permanently and is part of the MQTT integration for HA and handles messages from other software. Here, MQTT knows how to deal with ebus packets (I'd need to check where it got told this, possibly when the ebusd daemon was installed) but a collection of ebus devices and entities should then appear in HA which can be built into cards and histories.

Most integrations are installed in HA simply by selecting them from a table. The more experimental and niche ones are made available in collections like GitHub and appear in a separate HA collection called HACS.

I think my main problem with the documentation was that it gave you lots of detail but omitted the one thing that was so blindingly obvious to the writers and readers that they didn't mention it and without which nothing else made any sense. A lot of the time after extensive research I would come back to the original documentation and think. "Oh, so *that's* what they meant".

I am *not* going to claim to be an expert in this august company 🙂 and anything I have said may have been overtaken by newer and easier ways of doing it but I can help avoid some blind alleys.

There is or was a separate way into the Vaillant data via an integration called MyVaillant or MyPyllant. This, though interrogates the Vaillant servers and needs to be used with caution since it can flood them at which point you'll be suspended for an hour or two before it replies to further data requests.

Hope this helps and is mostly accurate!

Posted by: @agentgeorge@simonf no sensor is accurate unless calibrated, I ran the calibration cell in the test laboratory at Gaydon Proving Grounds for a few years; everything had to be +\- 0.1C at 20C stabilised for 1h with the test engineer in the cell, as entering the cell affects the calibration as the human acts as a heat source.

It makes me smile when I read posts on here with stats of room temperatures as 21.5C, without a tolerance and calibration certificate its meaningless and is just a random number.

I agree and that’s why I don’t believe a lot of the high COPs that get reported on Vaillant units.

It’s a shame Vaillant don’t calibrate the sensors. When I had them out to replace mine the Vaillant engineer had to go through 3 different sensors to try and get a pair which matched. They had no process for testing or calibration.

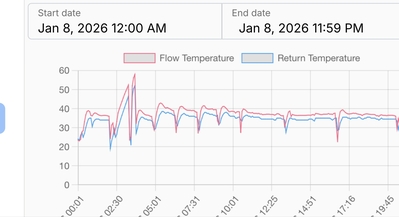

@adamk I'm observing my own system at low temperatures and it was useful to compare it with your history and some "Should my system be doing this?" posts. I have a 10kW Vaillant AroTherm Plus running as a hybrid with a buffer tank and a small backup oil boiler. Switch-over is at a bivalent point currently set at -2 C. Temperatures here since 1 January have been varying between +4 and -6 C and mostly below 0. Significantly, relative humidity was in the low 90s between Christmas and New Year, dropped to the mid 70s until a couple of days ago and is currently around 96% (Central Scotland isn't known for crisp snowy days). The correlation with defrost cycles is striking and I'm seeing one about hourly just now. When ambient temperature was below -2, the boiler cut in. Its thermostat is set to minimum (50-55C), applied in short bursts so held the buffer tank at pretty much the usual temperature of about 44 C. Once the temperature rose above -2 the boiler shut off and the buffer tank temperature can be seen to sag to 41 C between defrost cycles. It has now gone a bit high but probably temporarily. The difference between ASHP flow and return (and that to/from the radiators) is about 5 C. None of the temperature values are calibrated 🙂 but are a mean of multiple sources where possible (I'm reading eBus - see post and I installed other pipe sensors and temp/humidity gauges). I interpret this to mean that the system is beginning to feel the squeeze and trying to maintain the temperature between high demand and frequent defrost cycles but that the oil boiler is doing what it was put there to do. This house was practically designed to radiate heat despite my best efforts. I calculated a SCOP from the Vaillant app figures and for 12 months from 1 June 2024 I'm getting about 4.75 +/- 0.25. Right now it is telling me 3.2 for the last week.

ive got the installer coming Monday to fix an isolation valve the previous engineer damaged by not installing the strainer retaining ring in the right position. ive also got an issue where the hp pees over the path when doing a defrost even though it has a soak away, hopefully just some rubbish in the drain pipe blocking it. ive also asked them to sort the sensors as i have a 0.5c+ discrepancy between flow and return, though they said if Vaillant come out they might charge £98.

@agentgeorge if it is i need to somehow tweak it to match as its confusing the heat pump. 0.5c apparently skews the cop by about 25% up or down depending on the pipe the sensor is on.

So it seems probably most of the issues I’ve had are down to bad flow and return sensors. With them swapped around I’m now getting what I can only assume is an over inflated cop. What it has done as well though is to now show a clear separation between hot water and heating cop with heating now beating hot water.

what I don’t get though is in one position the gap is about 0.6c but when swapped it’s more like 0.9c. I wondered if one sensor was reading cooler and the other hotter so when swapped the gap is greater, or maybe some issue with the wiring. I’m now waiting for the installer to sort out how I get get 2 matching sensors that are at least close to a calibrated one.

@adamk In my experience the gap widens when the outside temperate increases, so could be that. Or maybe just down to the way the swapped sensors have been installed. With them being clip on sensors, the exact placement and way they are installed makes a difference. i.e. if thermal grease was used on the probe, if the any of the pipe insulation is in contact with the sensor. Hopefully your installer will get lucky and find some matching sensors.

@simonf I did try swapping them twice and in both cases the gap increased by 0.2 to 0.3 compared to the shipped position error of 0.5/6.

ive tried cleaning the pipe and sensor tip and it didn’t seem to make any difference.

what I could do with is a calibrated sensor and then a pile of these to find a good pair.

Posted by: @adamk@simonf I did try swapping them twice and in both cases the gap increased by 0.2 to 0.3 compared to the shipped position error of 0.5/6.

ive tried cleaning the pipe and sensor tip and it didn’t seem to make any difference.

what I could do with is a calibrated sensor and then a pile of these to find a good pair.

Its almost surprising that ASHPs don't feature a 'sensor calibration' mode. Absolute accuracy isn't that important, but relative accuracy affects measured COP so is. It wouldnt be beyond the wit of man to have an offset somewhere, which could be calibrated by swapping the sensors or just switching off the compressor so that flow and return are (more or less) at the same temperature

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 301 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Electricity price predictions

I am always impressed with how you keep abreast of so m...

By Batpred , 2 minutes ago

-

RE: Setback savings - fact or fiction?

I fully understand your reasoning, same steady inputs s...

By cathodeRay , 11 minutes ago

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

@majordennisbloodnok I’m glad I posted this. There see...

By AndrewJ , 33 minutes ago

-

RE: What determines the SOC of a battery?

@batpred I didn't write the Seplos BMS software, I a...

By Bash , 2 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@tasos and @cathoderay thanks. I have some history grap...

By benson , 2 hours ago

-

I am having my existing heat pump changed to a Vaillant...

By trebor12345 , 3 hours ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 3 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

Just to wrap this up here for future readers: The S...

By Batpred , 6 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 6 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 8 hours ago

-

@painter26 — as @jamespa says, it's for filling and re-...

By cathodeRay , 11 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 22 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 24 hours ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 1 day ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 1 day ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 1 day ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago

-

RE: DIY solar upgrade - Considering adding more panels

I know this is a bit old, but it made me wonder what co...

By Batpred , 2 days ago