Why Buffer Tanks & Low-Loss Headers Can Sabotage Your Heat Pump's Efficiency

@ch_18, welcome to the forums.

On the principle first: converting a 4-port buffer into a 2-pipe volumiser on the return is a logical step if your goal is to reduce mixing losses and improve emitter temperature consistency.

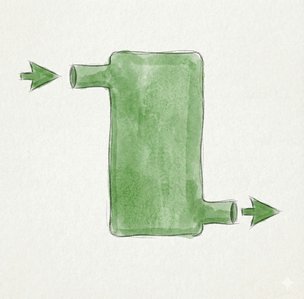

On your question about port orientation, in a true volumiser configuration (not decoupled) you’re not trying to achieve stratification in the same way as a buffer. So keeping both the emitter return and the heat pump return on the lower ports can be acceptable, provided the flow path through the vessel is continuous and you’re not inadvertently short-circuiting the top section.

In practice, like @judith alluded to, this is the more conventional way of plumbing in a volumiser.

On the pump question, a 7 kW Vaillant’s internal pump is generally capable of handling a typical single open circuit system provided the hydraulic resistance is reasonable. The fact that it’s currently circulating 1200 litres (I assume you mean system volume, not flow rate) is less relevant than the required flow rate and head. What's important here is whether, once you remove the secondary pump and decoupling effect of the buffer, the internal pump can achieve the required design flow at the actual system resistance. If it can't, you'll drown in flow errors.

Get a copy of The Ultimate Guide to Heat Pumps

Subscribe and follow our YouTube channel!

Posted by: @editorSo keeping both the emitter return and the heat pump return on the lower ports can be acceptable, provided the flow path through the vessel is continuous and you’re not inadvertently short-circuiting the top section.

Without doing some horrendous modelling, or fabricating some transparent tanks, I would think that there is quite a significant risk that the upper section is effectively short circuited if both connections are at the bottom, particularly if the erstwhile buffer tank was designed to encourage stratification.

There will be some turbulence of course, and a bit of a convection current (hopefully not much if the tank is well insulated) but not a lot really to stir it up. So personally I would go in at the top and out at the bottom even if it makes the plumbing more difficult.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

@editor Thanks for the reply. Yeah I thought in at the top, out of the bottom would be the best solution for converting to volumiser but was hoping to minimise repiping, just incase it doesn't work for example if the internal heat pump circulation pump can't cope.

If you look, I have a spare 2 ports on the left hand side of the buffer. One is about 2/3 of the way up. Would this be a better option? Or does it have to go to the top nozzle?

I have 2 circuits, both open loop. One is supplying approx 120m2 of UFH circuits and the other is supplying upstairs (2 floors) of rads? You think the pump would struggle supplying enough flow?

Thanks again

-

British Gas Heat Pump Installation Complaint

4 months ago

-

Heating Turned Off but Radiators Still Warm

4 months ago

-

Samsung Heat pump with Yonos Pico circulating pump running all the time

4 months ago

-

Samsung 5kW R32 Monobloc Gen 6 ASHP

5 months ago

-

Ideal Logic 10kW Heat Pump Pipes Noisy and Very Expensive to Run

1 year ago

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 548 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 49 minutes ago

-

RE: What determines the SOC of a battery?

Thanks. It is not clear how @bash concluded the chargin...

By Batpred , 58 minutes ago

-

Struggling to get CoP above 3 with 6 kw Ecodan ASHP

I've been using this heatpump for two winters now and a...

By GoodbyeGas , 2 hours ago

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

That would make sense. I've found the effects are prett...

By Majordennisbloodnok , 2 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@benson — as @tasos suggests, plotting multiple variabl...

By cathodeRay , 3 hours ago

-

@painter26 — as @jamespa says, it's for filling and re-...

By cathodeRay , 5 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 15 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 17 hours ago

-

RE: Setback savings - fact or fiction?

I also need to correct something I said by mistake earl...

By cathodeRay , 17 hours ago

-

RE: Electricity price predictions

@judith Thanks for sharing, and nice to see how the ...

By Batpred , 18 hours ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 20 hours ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 21 hours ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 21 hours ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 22 hours ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 23 hours ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago

-

RE: DIY solar upgrade - Considering adding more panels

I know this is a bit old, but it made me wonder what co...

By Batpred , 2 days ago

-

RE: New Vaillant aroTherm Plus in black - When will it come to the UK?

@majordennisbloodnok Daikin, take note! (In fact, I hav...

By Toodles , 2 days ago

-

RE: Midea ASHP – how to set weather compensation

@mk4 — good work! First, I agree, no evidence of cycl...

By cathodeRay , 2 days ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

I don't know about Solis inverters. It isn't a featur...

By Transparent , 2 days ago