Mitsubishi Ecodan 8.5kW installed April 2025 + hopefully soon getting 3.6kWp solar PV

Additional photos of the system here - you can see how hard it is to follow the pipes (but at least it's a nice compact install like I asked for!)

Mitsubishi Ecodan 8.5kW installed April 2025 + hopefully soon getting 3.6kWp solar PV

Hi CB, everything you are describing here is a lack of heat transfer, it will not matter if you have 24,21 or even 12/Lpm flow rate at the optical sensor if there is any kind of bypass as the system will just bypass and give you a low DT. The optical flow sensor will be on the return line of the ASHP pipework, if you don't move the heat through the radiators to exchange it you will get a smaller DT return to the external unit at any easy point to return, balancing is everything. Have you got the Ecodan pre-plumbed cylinder installed?

I will try to help and point you in the correct direction:

1) you must have a DT at 5Deg at every radiator https://www.heatgeek.com/balancing-heating-systems-the-ultimate-guide/ (this should have taken your engineers at least 30mins on every radiator, if your system was commissioned faster than 1 whole day something was not checked enough, balancing up to 10 rads often take over 4 hrs to do correctly and accurately with K2 sensors clamp sensors and every pipe checked.

2) it is essential that the system was power flushed, it is very likely that the system will have at least a small amount of debris and this can cause flow issues

3) Monoethylene Glycol is ok in the system, in fact Mitsi Ecodan still insist upon it for their 3 diamond care (we are not sure why that is, I protest often and I am know for it at Mitsi) Using the glycol will slightly reduce the efficiency say by 2 points so 3.9 rather than 4.1, this is acceptable for the protection it offers.

4) In my view this time of year running a flow temp of what looks to be 38 you should be getting 3.5 to 3.7 COP or better.

It is my view even when designed with radiators you should design the system so that it is open loop on as many circuits as possible to maintain the 5DT for milder seasons and only TRV solar gained rooms and bedrooms as a set back, so these TRV's would be set 2 Deg above your desired temp and potentially only ever close if the sun was shining through enough to over heat the room, set the system on weather curve and run it at your designed temp balance curve to allow the system to tick along.

The Ecodan by default will tray to always target 6DT until it no longer can, although the system is targeting (6) it designed to a true 5DT and all designs at the moment should be based on 5DT.

Can you share the design criteria and I may be able to help a bit more?

AAC Group Ltd covering the Kent Area for design, supply and installation of ASHP systems, service and maintenance, diagnostics and repairs.

Professional installer. Book a one-to-one consultation for pre- and post-installation advice, troubleshooting and system optimisation.

I cant immediately see anything wrong but I also cant follow the pipework.

As you say this is a poor time to test/set things up, but I would still be concerned about the COP. Ruling out the bypass is worth doing, I presume 0.5bar is the max it can be set to, personally I would want to shut it off entirely if that's possible, to expose any downstream faults.

I don't know exactly how auto adapt works, but your flow temperatures are reasonable.

Unless

- we are missing something,

- the bypass together with system back pressure is in fact causing recirculation (which @ashp-bobba is I think suggesting) or

- the two water pumps are fighting each other

Im struggling, based on the day plot you posted, to see why you aren't getting close to the rated COP for the flow temp and outside temp.

It is well worth eliminating the above before the installer returns, my hunch is its to do with the bypass or two pumps (the latter is a mystery - why do you need two pumps - its suggests again something wrong with the downstream system).

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

@cbrenewable is the return pipe to the external unit the pipe with the filter showing in the picture?

AAC Group Ltd covering the Kent Area for design, supply and installation of ASHP systems, service and maintenance, diagnostics and repairs.

Professional installer. Book a one-to-one consultation for pre- and post-installation advice, troubleshooting and system optimisation.

Posted by: @ashp-bobba@cbrenewable is the return pipe to the external unit the pipe with the filter showing in the picture?

Yes - the return pipe is the one with the filter and is showing in the picture.

Mitsubishi Ecodan 8.5kW installed April 2025 + hopefully soon getting 3.6kWp solar PV

AAC Group Ltd covering the Kent Area for design, supply and installation of ASHP systems, service and maintenance, diagnostics and repairs.

Professional installer. Book a one-to-one consultation for pre- and post-installation advice, troubleshooting and system optimisation.

@ashp-bobba - thanks for the detailed thoughts.

I'm aware that my rads upstairs seem to be working well and I have a reasonable density of rads in not that big of a space (small rooms) even if each rad itself is only type 21 and isn't that big. I know we're in April not Jan/Feb but worth mentioning that the upstairs gets perfectly warm at the lower flow temps of 30/35C that the system has been outputting. So far as I can tell the heating loop goes around the upstairs first before it goes downstairs though short of 2 rads I've not been able to find where the loop goes from 1st floor to ground floor. Downstairs is where I have the larger problem - larger rads and so far as I can see less flow rate since the larger rads aren't fully getting hot (see earlier posts about this). I was aware of downstairs likely needing some work going in to this project but I was intending to make some minor improvements myself over the summer and then see where that got me when the heating came on in Oct/Nov before doing anything drastic like replacing a load of radiators.

Worth highlighting that the room stat is in one of these upstairs rooms so it's not like the relatively poor downstairs heating is causing the unit to run harder/longer or anything like that.

Your points 1-4 covered here:

1 - Balancing - The installers did go around the house and bleed the system but this was probably 1min per rad rather than 30mins per rad so I find it unlikely they did any balancing. I gave a small amount of balancing a go but didn't really get very far with this. As previously outlined all the upstairs rads get hot and from running around and feeling them as this happens it feels like this happens somewhat evenly.

2 - The system wasn't flushed. I've already contacted the installers and they've said they're going to arrange for it to be some kind of flushed. Whether this would be a normal flush or a power flush or a chemical flush I don't know. For obvious reasons my preference would be a thorough power flush. I'm persuing this with them currently.

3 - A bit weird about the glycol point and I'm aware it slightly lowers efficiencies. A few points here/there lower in efficiencies I'm not worried about - just trying to get the system a bit closer to reasonable running costs.

4 - From my reading and research on places like Heat Geek etc I was expecting a significantly higher COP for this time of year. I'm not planning to get to the top of the SCOPs with this but I've worked out that assuming 80% oil boiler efficiency then I'll need a SCOP of around 3.3 to match the running costs like for like. I'll be happy with that and this feels like it should be achievable, even for a retrofit. Having contacted the installer they did sound concerned about the low COP and have just emailed me to say I can expect an engineer next Wednesday. Fingers crossed he can find the issue.

Other points:

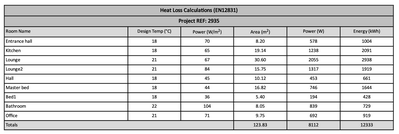

Regarding design criteria I've posted the Heat Loss Calcs for design temps etc. I'm not sure what ref OATs these were done at but I've heard they'd typically be about -2C OAT so I'm assuming (!!) mine are the same.

All the TRVs on Radiators were opened and I've actually unscrewed the top of the TRVs entirely hoping to get as much water through as possible.

Mitsubishi Ecodan 8.5kW installed April 2025 + hopefully soon getting 3.6kWp solar PV

I am initially thinking it looks like you have one pump pushing through the other if the flow and return are as I placed the arrows?

AAC Group Ltd covering the Kent Area for design, supply and installation of ASHP systems, service and maintenance, diagnostics and repairs.

Professional installer. Book a one-to-one consultation for pre- and post-installation advice, troubleshooting and system optimisation.

@jamespa -

Yes, 0.5bar is the max on that bypass valve. Range = 0.1 - 0.5 bar.

How would I validate that the pumps aren't fighting each other?

To cover off a question someone asked previously I'm not sure why I have two pumps - that's the sort of thing a homeowner, even a geeky one like me, would just trust an installer to get right I guess. Would 22mm plastic heating loop have something to do with this?

Not related to efficiency but the other oddity I've found is that my immersion is controlled totally independently of the ASHP. I have a dedicated programmer for this which I've set for 2hrs every Sunday night. I understand they can be wired in so the main controller can control the legionella cycles. Does anyone have any idea why an immersion might be installed this way?

Joule Cyclone CY250L Indirect Hi Gain Coil C

Mitsubishi Ecodan 8.5kW installed April 2025 + hopefully soon getting 3.6kWp solar PV

@ashp-bobba - your arrows on the picture are correct. I've followed the pipes just now and confirmed this.

How could I check the pumps are installed the correct way around/aren't otherwise fighting with each other?

Picture of pump included. They look like they're both the same.

Mitsubishi Ecodan 8.5kW installed April 2025 + hopefully soon getting 3.6kWp solar PV

What's the heat output each day for the last few days, and the input.

My COP is 6 and over at the minute.

The big rads not getting hot maybe an issues, as its not giving out the heat its producing, but with that you'd expect to see a bit more cycling than you have. Might be one to ponder......

-

Ecodan Zone 2 Mitshibishi thermostat Auto Adapt

1 week ago

-

Ecodan Pump Issues… Circulation pump turns off when heat pump compressor turns off

3 weeks ago

-

Running my new Nibe ASHP efficiently

4 weeks ago

-

New Mitsubishi Ecodan 11.2kW installation - L9 errors and maybe more

4 weeks ago

-

Ecodan with FTC7 - True Weather Compensation

1 month ago

- 27 Forums

- 2,475 Topics

- 56.9 K Posts

- 248 Online

- 6,165 Members

Join Us!

Worth Watching

Latest Posts

-

RE: If a heat pump can only heat DHW to 50C then what? Issue with 18KW Heliotherm heat pump

Hi, Nothing yet. I've asked customer to measure flow...

By errmm , 5 hours ago

-

RE: High Temp Heat Pumps for fast warm-up of house

I don't know exactly how long it takes to heat up (and ...

By JamesPa , 6 hours ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

OK. What Im seeing looks fairly normal TBH: 1 start ...

By JamesPa , 7 hours ago

-

RE: Vaillant Tech Support Flagged Low DT: UFH Return Cold, Suspected Zero Flow

@editor thanks for the tips which I will try before cal...

By DavidB , 8 hours ago

-

RE: Daikin 6kw setup with Dixell controller

@jamespa Many thanks for your reply, a very detailed an...

By CraigH , 8 hours ago

-

RE: Exploring the role of alternative clean heating solutions - Government Consultation

Despite reservations, I found some time to respond to t...

By Rusty , 8 hours ago

-

RE: New Vaillant aroTherm Plus in black - When will it come to the UK?

@crankplus, nope, still not, and I've followed up with ...

By Mars , 8 hours ago

-

RE: Octopus Cosy Heat Pump Owners & Discussion Thread

@agentgeorge Probably, but temperature change at -10 ha...

By AndrewJ , 9 hours ago

-

RE: External wall insulation - your experience

To be clear, my experience was very positive. The journ...

By Batpred , 11 hours ago

-

@foxesfan Re: ‘Servicing’ as @editor has covered in his...

By Toodles , 11 hours ago

-

RE: A Smarter Smart Controller from Homely?

@benson No idea why mine doesn’t work, all I see on ...

By Papahuhu , 12 hours ago

-

RE: Battery sizing - How low can you go!

It seems I am seeing something similar to what you do, ...

By Batpred , 13 hours ago

-

RE: Gaslighting in the heat pump industry – has anyone else experienced this?

Don’t know if this is relevant to this thread, but my A...

By Gruff2001 , 14 hours ago

-

RE: Bosch CS5800i 5kW - Experience So Far

@majordennisbloodnok While getting Home Assistant runni...

By Steelbadger , 1 day ago

-

RE: MCS - BS EN 12831-1:2017 – Heat Loss Survey

Since May 2025 it no longer a requirement in England to...

By JamesPa , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handel @jancold Manufacturer: Daikin Model: E...

By Jancold , 1 day ago

-

RE: Octopus Cosy 12 Heat Pump Regret: Incredibly Loud, Poor Heating & Constant Hum - Help!

@harriworld it was roughly 3am for an hour as that’s ...

By L2jad , 1 day ago

-

RE: Hoped for improvements not being realised on my Mitsubishi heat pump

I have been wondering that myself. The fact is that, ...

By JamesPa , 1 day ago

-

RE: Filtering Tap Water – Share Your Setup for Cleaner, Better-Tasting Water

I remember when I was in my early 20s I was introduced ...

By Majordennisbloodnok , 1 day ago

-

RE: Setback savings - fact or fiction?

But if it is recorded an an integer, which it seems it ...

By cathodeRay , 2 days ago