Posted by: @catapult@derek-m The good old hand test suggests all 4 pipes are a similar temperature. I'll try and source a proper thermometer.

The three pumps have three set levels. Currently all running on the highest level. I think they can technically also run on "proportionate", or whatever the P stands for, but they aren't wired for that. I had a look at the Grundfos manual and it suggested proportionate wasn't suitable for systems with a bypass, which I think I have.

Current flow rate is 32.6lpm. Is that reasonable?

brendon uys has written an extensive article about this based on a lot of very scientific testing. https://renewableheatinghub.co.uk/how-to-correctly-install-heat-pumps-so-that-they-work-properly-and-efficiently

To solve this, its worth you drawing a pipework diagram. Focus on in/out of the buffer, if you have a bypass where is it, where are the pumps and which pump does what, and what flow rates are they running at (may not be the same) if they show that. then you can write on the diagram what you are seeing at each point.

It looks very much like you have a 4 port buffer setup from your pictures. This buffer is a point at which the hot water coming from the heat pump can get mixed with cooler water in the buffer. This leads to the temperature of the water going to the radiators from the buffer being a bit lower. This means the heat output of the radiators might be below target. So then the system asks the heat pump for more heat , in response to which it to turn up its LWT, which makes it use more energy. you get a warm house, but the COP drops.

some call this effect "distortion". see https://www.youtube.com/watch?v=mNcRx45DQ8M&ab_channel=HeatGeek . The "ideal world approach" as per the article would be to rebuild the system without a buffer, but obviously thats not something you can contemplate right away.

To prove this you need to know water temperatures and ideally flow rates, on the 4 pipes in and out of the buffer.

If you want to get into datalogging like a lot of the rest of us, then you can learn about the low-cost DIY tech that enables you do datalog the flows and temperatures of each pipe over time - plenty of other posts about that on this (and other) forums, I won't duplicate.

If you don't - go on amazon / ebay and buy some cheap fishtank temperature probes like these with metal ends https://www.amazon.co.uk/Thlevel-Thermometer-Temperature-External-Refrigerator/dp/B07TY6HRL4/

get inside the insulation of the pipes , on a straight bit after any branches, ideally around 30-50cm before it goes into each port of the buffer. align the thermometers metal head so that it is parallel to the pipe, better contact that way. apply a bit of heat conducting paste (like from heatsink assembly on a PC) if you have any (if not, don't worry about it). tape it to the pipe as tight as you can. then replace the insulation. Its fine to have the wire for the thermometer under the insulation until it can find a way out. try to keep the insulation back into its original place.

watch and write down the temperatures over time.

the suspicion / expectation is that the temperature on the buffer-to-radiators pipe is going to be a few degrees lower than the heat pump-to-buffer pipe. thats distortion loss inside the buffer. in response to that, your heat pump is raising LWT - which is reducing its efficiency.

My octopus signup link https://share.octopus.energy/ebony-deer-230

210m2 house, Samsung 16kw Gen6 ASHP Self installed: Single circulation loop , PWM modulating pump.

My public ASHP stats: https://heatpumpmonitor.org/system/view?id=45

11.9kWp of PV

41kWh of Battery storage (3x Powerwall 2)

2x BEVs

Posted by: @craig1980@catapult schedule overides the water heating. Mine heats up once for 1.5 hrs (often doesn't take that long) at 3am on our cheaper rate electric. When we get up the hot water is usually at least 48 degrees. We both have showers and there is still enough to wash up later and other small jobs with hot water through the day. You can set several on/off schedules.

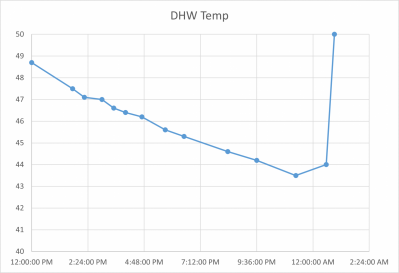

I stayed up til way past my bedtime to watch what the DHW does. Apparently drops at 0.46 degrees an hour, which seems quite high. So 11 degrees a day. I'm guessing the hot water was heated 3 times a day based on that. It also only took 20 mins to go from 44 to 50 degrees which is a lot faster than I expected. I've now set it up to heat automatically from 6am for 45 mins. I think that'll be the equivalent of using 2/3 of the electric. We'll see how that goes.

Does the schedule setting include a stop if it reaches set temperature, or does it just blindly heat for the set time?

Posted by: @catapult. Apparently drops at 0.46 degrees an hour, which seems quite high. So 11 degrees a day. I'm guessing the hot water was heated 3 times a day based on that.

seems a bit high. mines 0.275 degrees an hour on a new 300L unvented, running at much hotter temps (I'm charging it on off-peak immersion, thats another story).

Have a look at the insulation on the pipes in/out of the cylinder. Both the ones carrying the DHW, and the ones from the heat pump. Are any of them acting as radiators? Does the hot water exit of the cylinder go straight up? If so convection currents will carry heat out. insulation mitigates it but doesn't stop it. A short downward-facing loop in the pipe stops it. I insisted my plumbers put this in (they moaned lots) and it made a huge difference.

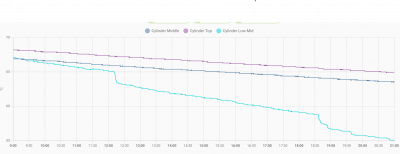

The other thing could be mixing of hot water at the top , with cold water at the bottom, leading to "medium" temp water that isn't usable. Again with the aforementioned cheapy thermometers, if you're cylinder has more than one probe location, track the behaviour at the different heights in the cylinder over time, to see if you are getting good stratification or not. this can be about the design of how the cold enters the cylinder - is it turbulent , or is it calm. what you should see is the hot water "moving up" the tank as hot is drawn off , and replaced by cold at the bottom - but the temperature of the hot "lump" not dropping.

My octopus signup link https://share.octopus.energy/ebony-deer-230

210m2 house, Samsung 16kw Gen6 ASHP Self installed: Single circulation loop , PWM modulating pump.

My public ASHP stats: https://heatpumpmonitor.org/system/view?id=45

11.9kWp of PV

41kWh of Battery storage (3x Powerwall 2)

2x BEVs

@iancalderbank The pipes around the hot water cylinder have no insulation... so that's a job for this weekend. The pipes around the HP in the boiler room are mostly insulated, but I think I can improve it.

The pipe out of the top of the cylinder immediately splits into two, one goes left, the other goes up and then left, but no downward loops. I think one is for the hot taps and one is for the shower.

It looks like there's only one temperature probe in the middle of the cylinder unfortunately.

@catapult ok, so glad in a way it wasn't insulated - diy fix for that is easy! see what gain you get from that first.

what model cylinder / post a photo. there might be a 2nd probe pocket hidden underneath a boiler stat.

My octopus signup link https://share.octopus.energy/ebony-deer-230

210m2 house, Samsung 16kw Gen6 ASHP Self installed: Single circulation loop , PWM modulating pump.

My public ASHP stats: https://heatpumpmonitor.org/system/view?id=45

11.9kWp of PV

41kWh of Battery storage (3x Powerwall 2)

2x BEVs

ok so nothing obvious in terms of additional temperature pockets. might be one at the top, can't tell.but there's lots of pipework that you can insulate for an easy gain. and putting an anticonvection U into the upper horizontal exit wouldn't be hard either.

I can't see any spec for that exact cylinder so you might want to look up what its insulation level is and rated daily wattage for loss. If its a bit low, you've plenty of room to DIY an external jacket round it.

once thing you'll find once done is , you'll have more hot water, but the temperature in the cupboard will drop..... so the washing hanger (I see you have one too) won't dry the clothes as quickly (not a joke, mrs grumbles at me about this).

My octopus signup link https://share.octopus.energy/ebony-deer-230

210m2 house, Samsung 16kw Gen6 ASHP Self installed: Single circulation loop , PWM modulating pump.

My public ASHP stats: https://heatpumpmonitor.org/system/view?id=45

11.9kWp of PV

41kWh of Battery storage (3x Powerwall 2)

2x BEVs

Posted by: @catapultIs it just a case of "suck it up buttercup, it's cold outside", and there'll be big improvements when it gets warmer?

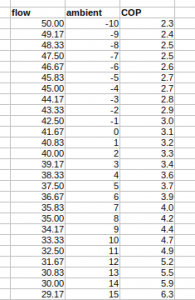

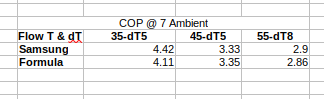

While I don't have a lot of experience installing heat pumps - I have only installed one (mine). There are some basic principles I think you can work with on efficiency. So in an ideal case with a modern heat pump, with your weather compensation settings as you mentioned I worked out that the following should be achievable with a good install. (it will be a bit less than this with defrosts and pumps).

If you are way off the numbers below, then your specific setup in terms of plumbing and emitters is likely dragging your COP down, I can't really help you fixing that, but many others on this site likely can provide useful direction. I added a comparison between the numbers using the formula and those published in the Samsung documentation, for comparison.

[I removed the bottom of the table, the numbers started to get quite high from a COP perspective]

On one of the other heat pump forums, a chap has taken all the COP data from a 11.2kW Ecodan, and the degree days data from where he lives and modelled different compensation curves against fixed flows degrees for SCOP. The headline was that WC makes about 25% difference at 55C, 20 at 50C, 15 at 45C, 10 at 40C and 5 at 35C.

I've asked the chap in question if I can publish the model here as it could easily be tweaked to different Ecodans and a little less easily to different ASHPs.

Posted by: @kev-mOn one of the other heat pump forums, a chap has taken all the COP data from a 11.2kW Ecodan, and the degree days data from where he lives and modelled different compensation curves against fixed flows degrees for SCOP. The headline was that WC makes about 25% difference at 55C, 20 at 50C, 15 at 45C, 10 at 40C and 5 at 35C.

I've asked the chap in question if I can publish the model here as it could easily be tweaked to different Ecodans and a little less easily to different ASHPs.

Oh that's interesting. I was kinda hoping it'd be a lot more of a difference! But those numbers seem to be similar to what I'm seeing.

@iancalderbank @derek-m I got some thermometers onto the pipes to/from the buffer. At flow temp of 37 degrees

from ASHP to buffer 36.7

from buffer to rads 34.8

from rads to buffer 33.4

from buffer to ASHP 33.8

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 644 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Electricity price predictions

@toodles @skd Then there is not going to be much from t...

By ChandyKris , 17 minutes ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

@batpred I reckon Andy might know a thing or 2 about...

By Bash , 45 minutes ago

-

RE: What determines the SOC of a battery?

@batpred Ironically you didn't have anything good to...

By Bash , 2 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

Here’s a current graph showing a bit more info. The set...

By benson , 2 hours ago

-

RE: Setback savings - fact or fiction?

True there is a variation but importantly it's understa...

By RobS , 2 hours ago

-

Below is a better quality image. Does that contain all ...

By trebor12345 , 2 hours ago

-

Sorry to bounce your thread. To put to bed some concern...

By L8Again , 2 hours ago

-

@painter26 — they (the analogue gauges) are subtly diff...

By cathodeRay , 3 hours ago

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

@majordennisbloodnok I’m glad I posted this. There see...

By AndrewJ , 4 hours ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 7 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 10 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 11 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 1 day ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 1 day ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 1 day ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 1 day ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 1 day ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago