@crimson shouldn't need to flush if it's new piping throughout. I thought it was a retrofit and using existing pipework like mine was.

I have to say since the second install the house is warmer with the UFH just not operating as efficiently given the blocked Heat exchanger.

If you want a second opinion I would find a local heat geek to perform as assessment of the system

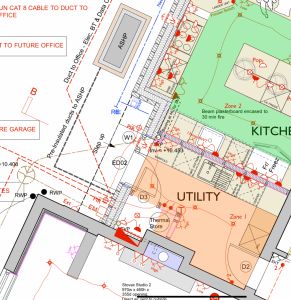

@crimson good morning. Lots of people here want this one fixed for you! What's the approximate length of buried pipework on the primary circuit under your utility? And what is it? It is some flexible piping, pipe material: copper, steel? What is it insulated with? Should be very well weather sealed outside to prevent moisture getting into what is a sump from which moisture can't drain out from. Buried primary pipes are usually best avoided where possible, when they are buried care needs to be taken with the materials and pipe sizing. I'm wondering if there's thermal bridging between the flow and return pipes, due to them being so close together in the pipe duct. If moisture gets in and saturates the insulation then you can lose a lot of primary heat from the flow pipe into the secondary return pipe. Are they separately lagged and clad pipes and then buried? They should be, but they look very close together on the photo in the plant room where they penetrate the floor.

Hi all, first thanks so much for everyone coming in to help!

Trying to catchup with everything here.

Some photos of temps around bypass valve. I also put one just before the 3 zones to see if much diff between that and top left of LLH

Context:

Top right node leads to bottom left of LLH - Flow out

Note I’m seeing a 1c diff between node reporting temp top left of LLH and Node just before 3 zones

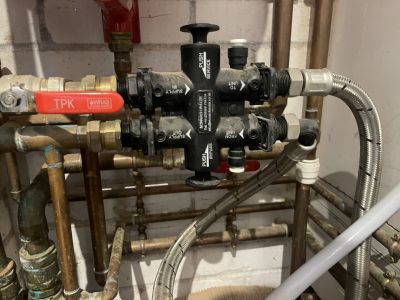

The 4 port black valve is this the one your referring to? Note pipes feel cold around this but can move temp probes to check.

Not 100% on length/type of the underground pipe work for that. I can ask plumber when attends. I’d estimate 3m-4m. I’ve attached a portion of the services diagram so have an idea of the layout of plant room to ASHP, it’s noted as a pre insulated duct.

Note saw insulation not fully around at points, photo showing pipes going into duct outside. Lost track who requested but photo showing area near blue valve exposed. Services diagram and picture of manifold across from plant room incase of use

@crimson, out of curiosity, have you raised any of this with Grant? Also, you refer to the installers as plumbers – are these the original installers or are you trying to get plumbers to sort out the zoning and piping issues. Just need a bit of clarity because I'll take this back to Grant and see what they say. Lastly, and apologies if you've already stated this in your replies earlier, but did someone from Grant come out to out sign off on the installation?

Get a copy of The Ultimate Guide to Heat Pumps

Subscribe and follow our YouTube channel!

@editor thanks for your reply.

Probably doing disservice to plumbers, essentially they’ve been contracted by builder to do the design and install of the heating system etc, so probably plumbers not correct term.

Grant have been contacted a few times by the plumbers (easiest term to use), I think after today/Monday - depending on new LLH delivery - intention is plumbers put in a warranty claim, they did register system last week to put that in motion.

Currently the system hasn’t been fully handed over to myself, I moved in ahead of project completion as things just kept getting delayed but this situation is effectively holding off handover as it’s not deemed to be running correctly.

I imagine the plumbers are trying to ensure it’s nothing install related (their end) before Grant come to avoid costs their end.

So far Grants suggestions have been to up values in WC and try different speeds at the ASHP end.

@crimson, OK, great. I'll raise this issue with Grant to see what they have to say.

Get a copy of The Ultimate Guide to Heat Pumps

Subscribe and follow our YouTube channel!

@crimson that 2 port bypass valve that you've identified for derek-m is another piece of stupidity in this install, but its not the first order problem. THAT is your low flow rate primary side. until we sort that, nothing else is worth working on.

I suspect the big black 4 port bypass unit is part of your water softening system, am I right? if yes, we can ignore it for the heating problem.

the uninsulated component outside is a Y strainer. If one is installed, it should be insulated but lets leave that for now. Most important: has anyone checked to see if its blocked? If it is, it will be killing the primary flow rate. That is absolutely part of troubleshooting primary flow rate. Your plumbers should absolutely know how to do this, if they don't , fire them on the spot.

My octopus signup link https://share.octopus.energy/ebony-deer-230

210m2 house, Samsung 16kw Gen6 ASHP Self installed: Single circulation loop , PWM modulating pump.

My public ASHP stats: https://heatpumpmonitor.org/system/view?id=45

11.9kWp of PV

41kWh of Battery storage (3x Powerwall 2)

2x BEVs

Thanks @crimson, buried primary piping looks a proper product, probably Isoflow or similar. Good.

Primary flow must be fixed #1 priority. Clean strainer as the first job, it may be a new system, but all sorts of solder crud, muck and debris can find its way inside the system during installation. MagOne wants cleaning out too for the same reason. Then some basic circuit checks between ASHP and LLH to rule out anything else that may cause such a low flow.

Outdoor insulation is indoor spec Armaflex type foam rubber sponge type, and no good. Once the big issues are resolved, snag that for complete replacement with more suitable external grade insulation - one with a moisture proof outer skin and all joints and seams bonded. Check the pipe clamps as well, they should be insulated type for external service, so heat is not conducted through them and lost. It all sounds very pedantic, but the devil is in the detail. You're paying the running costs and you want the absolute best in class installation practice and insulation product on any external pipework. Example: https://primary-pro.co.uk/

Thanks, I’ll ask about checking the y strainer. Chap here the other day said they had that in system as plastic pipes in the system which the Mag One wouldn’t filter?

4 port valve - connected to water softener yes.

I’ll press for focus on primary flow rate. Last I heard from them on the flow rate was they’re not sure that’s correct on that gauge/tacosetter - something about spring not right - and may replace that as didn’t think we’d get as much through as we are, but suspect this is a bit of blinded to checking all options and focusing on the LLH. Between the 2 that attended this week I get feeling 1 isn’t sure it could be the LLH itself and 1 is focussed on that.

if they come today, suspect not as that’s relying on a delivery coming decent time, after Monday if no change I’ll insist on Grant attending to get things moving

Posted by: @allyfishThanks @crimson, buried primary piping looks a proper product, probably Isoflow or similar. Good.

Primary flow must be fixed #1 priority. Clean strainer as the first job, it may be a new system, but all sorts of solder crud, muck and debris can find its way inside the system during installation. MagOne wants cleaning out too for the same reason. Then some basic circuit checks between ASHP and LLH to rule out anything else that may cause such a low flow.

Outdoor insulation is indoor spec Armaflex type foam rubber sponge type, and no good. Once the big issues are resolved, snag that for complete replacement with more suitable external grade insulation - one with a moisture proof outer skin and all joints and seams bonded. Check the pipe clamps as well, they should be insulated type for external service, so heat is not conducted through them and lost. It all sounds very pedantic, but the devil is in the detail. You're paying the running costs and you want the absolute best in class installation practice and insulation product on any external pipework. Example: https://primary-pro.co.uk/

thabks for this, will request that as part of snagging.

for inside the plant room, someone mentioned no insulation, I raised with plumber and he said 1m from cylinder? Does that add up?

Posted by: @crimsonfor inside the plant room, someone mentioned no insulation, I raised with plumber and he said 1m from cylinder? Does that add up?

All pipework on CH and DHW side in plant room that can get warm, flow and return, even expansion vessel connections, should be insulated. heat lost anywhere that not an emitter on the heating or point of use on the hot water is cost to you. This really is basic. As @iancalderbank mentioned, it may be time to ask your plumbers to step back and bring in a more competent contractor or individual to fix this.

Posted by: @crimsonThanks, I’ll ask about checking the y strainer. Chap here the other day said they had that in system as plastic pipes in the system which the Mag One wouldn’t filter?

if they'd fitted a proper quality unit instead of the Mag One, they wouldn't need both. Spirotech Spirotraps do non-magnetic dirt as well.

get one of these, put the mag one and the Y strainer in a skip.

My octopus signup link https://share.octopus.energy/ebony-deer-230

210m2 house, Samsung 16kw Gen6 ASHP Self installed: Single circulation loop , PWM modulating pump.

My public ASHP stats: https://heatpumpmonitor.org/system/view?id=45

11.9kWp of PV

41kWh of Battery storage (3x Powerwall 2)

2x BEVs

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 241 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Testing new controls/monitoring for Midea Clone ASHP

We have pretty much established by direct observation t...

By cathodeRay , 2 minutes ago

-

RE: What determines the SOC of a battery?

Fortuitously @bash got up early and did manage to check...

By Transparent , 51 minutes ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Thank you for the kind introduction! No, sadly not...

By GoodbyeGas , 1 hour ago

-

RE: Setback savings - fact or fiction?

This illustrates what I am getting at, even apparent st...

By cathodeRay , 2 hours ago

-

No you arent, because you dont need any, and furthermor...

By JamesPa , 2 hours ago

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

Can you link them to Home Assistant so they can be inte...

By JamesPa , 2 hours ago

-

RE: Electricity price predictions

I have often thought the same. In Italy (I am told) th...

By JamesPa , 2 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

As I mentioned earlier most radiators have a power outp...

By JamesPa , 3 hours ago

-

RE: Our Experience installing a heat pump into a Grade 2 Listed stone house

@travellingwave Looking forward to hearing the rest ...

By MK4 , 3 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

As a side note I observed the the charge/discharge time...

By Bash , 3 hours ago

-

Below is a better quality image. Does that contain all ...

By trebor12345 , 15 hours ago

-

@painter26 — they (the analogue gauges) are subtly diff...

By cathodeRay , 15 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 24 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 2 days ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 2 days ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 2 days ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 2 days ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 2 days ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 2 days ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 2 days ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 2 days ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 2 days ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 3 days ago