Avoid the Heat Pump Villain: Why Low-Loss Headers and Buffers Can Sabotage Your Heat Pump's Efficiency

@jamespa Fair point, its good to know better standards and designs are getting covered under the MCS schemes. Perhaps once it all starts to come together things will get better.

AAC Group Ltd covering the Kent Area for design, supply and installation of ASHP systems, service and maintenance, diagnostics and repairs.

Professional installer. Book a one-to-one consultation for pre- and post-installation advice, troubleshooting and system optimisation.

Questions for the Pro and anti-Buffer tank Zealots!!

Why NOT Design the Heat Pump, pipes and all, before you "try to adjust it with a hammer and a hack saw"!!

Does anyone know if "HeatPunk" Software design package, sold by Midsummer for heat pump systems is any good ??

Why not Fit your buffer tanks with valves to either use or Not use your buffer tanks.!!

These are all very good questions. Unfortunately most people are reliant on installers to do the 'design' and decide what valves are (or are not) put in, so don't have this option.

Those who, like me, had the fortune to 'lurk' here for a few months before getting their heat pump installed (not out of choice - it was serendipity) can do/did just this and are thus in a position to reject offers from installers that want to do silly things.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

HEATPUNK Design Software??

Does anyone have any experience with the HEATPUNK Design Software supplied by midsummer ??

Volumisers with Valves??

Volumising tanks can , sometimes, be easily fitted with valves.

Compare the performance of the System with or without the Volumising tank.

Heat Ex-changers ??

Heat Ex-changers allow the user to match the differing Water Flow rate requirements of the Heat Pump to the Radiator requirements.

For example, on my system, the Heat Pump flow rate cannot be reduced below 14 l/min while the Radiators require 7 l/min to provide an adequate Delta_T across the Radiators.

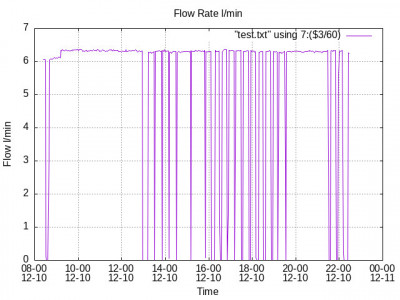

Flow rate Through the Radiator Circuit , as measured by a "Sharky" water Power/Flow meter is ~7 l/min.

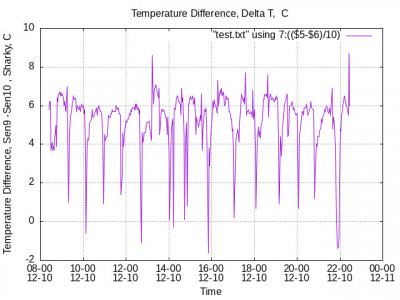

Delta_T across the Radiator Circuit, as measured by a "Sharky" water Power/Flow meter.

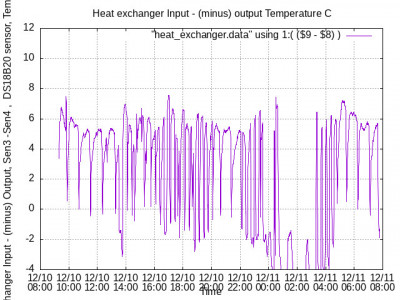

Delta_T across the primary ports of my Heat Exchanger, Measured by a pair of DS18B20 Sensors.

Notice the ~5 C Delta_T across the input ports of my Heat Exchanger.

The Heat Pump Water flow rate is 17 l/min .

The Flow rate cannot be reduced below 14 l/Min .

At 14 l/min the Heat Pump faults with inadequate flow rate.

Further observations

Short Cycling may NOT be caused by the Volumiser .

My Short Cycling was principally caused by my thermostat.

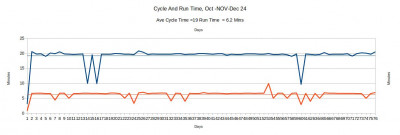

Setting my Thermostat for a 20 minute Cycle time solved SOME of my problems.

The Cycle time is now completely controlled at ~20 minutes.

My Heat Ex-changer has protected the Heat Pump from the Radiator water contamination.

I paid £600 to get this stuff Flushed from BOTH my Radiator circuit AND my Heat Pump , just in case!.

I paid a further ~£350 to replace the last of my old Radiators.

@iantelescope Heat-punk is good for seeing the effect of radiator size, flow temperature and general house heat loss. You put in all house dimensions and it calculates heat loss and hence what size heatpump you need and which rooms might need radiator changes.

It does nothing about pipe sizes since the pipe layout is not asked for, so no recommendations about valve sizes. It relies on the plumber sizing the pipes correctly. It has no knowledge of fluid dynamics at all, and is steady state.

I think your suggestion of a non-linear solver like the spice family is using a sledgehammer to crack a nut, ditto valves to add 2 or 4 port buffers. Who has the fault analysis technique to know what is needed from the system limits. Neither the homeowner nor the installer.

2kW + Growatt & 4kW +Sunnyboy PV on south-facing roof Solar thermal. 9.5kWh Givenergy battery with AC3. MVHR. Vaillant 7kW ASHP (very pleased with it) open system operating on WC

I am new to this forum. I am amazed at the breadth of discussion on this topic but have not absorbed everything. There are interesting snippets and some pretty wild theories. I am an electronic engineer, self-taught on heating systems, and I try to apply common sense to these things. So here is my take. IMO, there are a few critical factors that go into designing a heat pump (HP) system for UFH and radiators which will determine the use of buffers or not.

i) Calculate accurately the heat loss of the building to determine the design of heat emitters and the size of HP.

ii) From the model, determine UFH pipe spacing/layout and radiator oversizing, if any

iii) Decide on control philosophy to be implemented (no zones to multiple zones)

ii) Assess minimum water content of heat pump from specifications

iii) Determine minimum flow requirement of HP.

To calculate the heat loss and design, use the free British Research Establishment (BRE) tool available at https://www.ncm-pcdb.org.uk/sap/lowtemperatureheating. The design tool in Excel is available at the bottom of the page (BRE - Calculation tool for design of low temperature domestic heating systems - V1.2). This tool will do everything for you to determine pipe spacings and radiator oversizing. Unfortunately, it has errors and has not been updated since 2014. It over-estimates heat loss due to over-ventilation but it is not too serious. You have to ignore the floor temperature blending part which is a load of bollocks. Select an inverter heat pump with a power output a bit larger than the calculated heat loss for a margin, depending on your confidence in the data entered into the model. Heat pump should run on low temperature (as set by you in the model simulation) with weather compensation and HW tank switched via 3-way valve for best efficiency. Take care on room temperatures and regional design temperature, which can be obtained from ASHRAE site for different % occurrence.

Now the difficult part where buffers play a role or not – the control philosophy. Water content and flow critically affect system design. Arguably, the simplest and most HP efficient is to have a UFH only system with no on/off zone control on the manifold. The following numbers are hypothetical. 500m of 16mm pipe will contain 60l of water (0.12l per m) plus, say, another 5l in feeder pipes from HP (total 65l). If there are 6 zones with, say, average 3l/min flow, HP flow will be 18l/min. For switched HW part, content will be 5l feeder plus 7.5l in 1.5m2 copper coil (total 12.5l). Mitsubishi Ecodan 5kW requires minimum 7-12l content (>20C Return) plus 7-15l flow. So, at minimum, no buffer, but maybe volumizer for some head-room (however Samsung want minimum 50l content!). That’s the good news, but setting up, balancing and heat economising will be a nightmare. HP efficiency high, cost lower, but system efficiency/flexibility low due to no zone control.

Now the other end of the scale – all zones controlled with stats for maximum heat saving/timer control. The bathroom has 20m pipe with 2.4l water content and 2l/min flow. With only bath stat on, we now have 7.4l content and 2l/min flow. Flow error! Enter the humble buffer tank which can be located after the 3-way valve in Ecodan case, but with 2 pipe connection in parallel bypass, not series. LLH is a cheap alternative but dubious in my opinion as it is effectively in series. The buffer provides a parallel flow path but also an overrun route when all stats suddenly turn off. Also, when HW is on, the UFH pump can continue to operate pulling water from the buffer tank. This is where a thermal store like Xcel has great benefit also. It acts like a buffer for HW heating with indirect mains pressure HW, HW recirculation and hot towel rail supply plus attached gas/pellet boiler for peak electric periods (e.g. Octopus Cosy) and backup. Partial pellet use makes manual refuelling periods bearable also. UFH can also draw from thermal store during these peak periods. However, do not connect HP directly to it!

Configuring zone control without a buffer is possible if you take care of the basics – minimum water content and flow. HP efficiency for energy saving is not everything – overall system efficiency is, which means good control philosophy.

Private individual. No affiliation with commercial "Heat Geeks" of same coincidental name.

Welcome to the forums.

Posted by: @heatgeekI am amazed at the breadth of discussion on this topic but have not absorbed everything. There are interesting snippets and some pretty wild theories.

And this is precisely why the heat pump installation landscape is such a mess and we're getting such varied levels of installations of heat pumps, with and without buffers.

Get a copy of The Ultimate Guide to Heat Pumps

Subscribe and follow our YouTube channel!

Occams razor comes to mind here.

In any good system design every component has a purpose. If the purpose has little or no value then the same is true of the component. Furthermore, where there are alternative ways to achieve the same purpose (and that purpose has value), an analysis of the options should be done to work out which of the options is the best (however best is defined which of course is situation dependent). If introducing a component to solve a particular problem causes undesirable side effects, then the undesirability of these side effects needs to be assessed against the desirability of the purpose and an appropriate choice made.

Its also worth bearing in mind that most central heating systems are built by a branch of the construction industry and operated by normal human beings who have little or no interest in their inner workings. This means that the designer must assume that they may not be put together/commissioned in precisely the optimum way for the individual application, or even precisely as designed, and equally one must assume that they may be operated fairly crudely and with little or no understanding (or even interest in understanding).

Multiple zones (with all that implies), buffer tanks/low loss headers, volumisers (which should be distinguished from buffer tanks as they are totally different beasts) all add to system cost and complexity, both for the installer and the homeowner. All have potentially negative side effects in addition to the 'purpose' that they are intended to fulfil, and all have the potential to be mis-installed/misconfigured or operated in a way which largely or entirely defeats their purpose. That doesn't mean that they have no application at all, but it does mean that deploying them willy-nilly without thinking through the side effects and risks is a folly.

There is, of course, no one answer. A long, thin, 8 bedroom mansion with UFH is very different in nature to a 3 bed, essentially cubic, semi with radiators, both in its thermal dynamics and its use and it would not be surprising if these lead to different conclusions. That said there probably are only a relatively small number of classes of case such that, within any one class, 90% plus of properties will conform.

If we are to move this discussion much beyond 'be extremely wary of LLHs and buffers because they can sabotage your heat pumps efficiency', which is more or less undoubtedly excellent general advice, perhaps we need to talk of these classes and/or identify the exceptions where the general advice is at least reasonably unlikely to apply.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

@jamespa Invoking Occam’s razor in this context does not help. In engineering, there are right answers and wrong answers, not alternative facts. Nevertheless, I accept the spirit of the frustration regarding the plethora of confusing solutions and components. I will try and clear some of the fog as I see it.

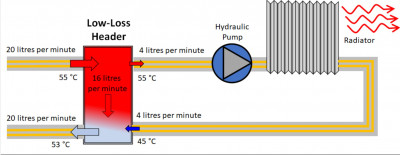

Regarding LLH, this is used when there is a mismatch of FLOW between primary and secondary water circuits. There is an interesting example from ProtonsForBreakfast early on in this discussion regarding his LLH. His figures and logic are all over the place, nevertheless it is a very good example.

He has a 5kW Vaillant HP. From his diagram, it is not possible for the HP to supply 20l/min, nor is it possible for 4l/min flow on the secondary for peak output to give 53C return. Ignoring these figures, let us assume that his 160 sqm house needs 5kW peak at design temperature. The following refers.

The secondary pump has a fixed flow and if a maximum of 5kW output is required with a 10C drop across radiators, then a pump flow of >7l/min must be set (numbers rounded). The valve restriction on rads will force the flow to 7l/min for 5kW. The HP however operates at 5C difference therefore will generate a flow of 14l/min for 5kW (math). Therefore half the flow goes to the rads with a 10C drop and the other half bypasses through the LLH to provide final 5C drop at HP due to the flow mismatch. If the outside temperature halves in value (i.e. half power required), the flow from HP will reduce to 7l/min to maintain 5C Dt for 2.5kW output and no flow will bypass through the LLH due to the 7l/min fixed flow of rads. Drop across the radiator is now 5C.

This is where the design stupidity is exposed. If you now remove the LLH and second pump, flow will still be 7l/min from the HP with 5C drop across the rads. If then outside temperature now doubles, HP flow will double to 14l/min and drop across rads will remain at 5C. This flow is perfectly compatible with the HP so the LLH is superfluous. This is why PFB saw no change in his performance. The designer was applying old fashion thinking of 10C drop necessary across radiators hence the mismatched flows.

Now for water content. Vaillant 5kW requires min. 40l in heating circuit for defrosting (if backup inactivated) which PFB presumably has due to the radiators. A problem arises when the heat requirement falls below the minimum flow requirement of the Vaillant i.e. 2.5kW. PFB requires 55C for his rads at peak output. If this output temperature is fixed on the HP, then cycling sets in when outside temperature dictates <2.5kW heat requirement. The way to overcome this is through Weather Compensation to increase the Dt linearly between the water flow temperature and room temperature to adjust to the lower heat loss to the outside and maintain 5C Dt.

This example suggests an answer to the 90% holy grail. If PFB replaced his downstairs radiators (half the area) with UFH he would need 400m of pipe @ 20mm spacing. This has a water content of 48l so defrost is satisfied, assuming upstairs rads do too. Multiple pipe loops in parallel will accommodate the flow needed. So he can have a directly connected 2 zone system. The downstairs heat loss and spacing would have to be meticulously planned to ensure uniformity. An average house of 120 sqm will require 300m of pipe downstairs with 36l plus the connecting pipe content, so also no problem with content. A house with no insulation would just have say 10kW and double water content so more zones possible.

The problem arises when fine control is wanted in a bigger house as pointed out in my previous post. There is not enough individual zone flow or water for defrost for a single connected zone like a bathroom. The answer is……you’ve guessed it. A BUFFER TANK! A 50l tank in parallel will supply sufficient content and flow in extremis.

So these components are not used “willy nilly”. They each have a purpose and do not cause efficiency problems. Only idiot installers abuse their use as seen above. For the average house of 120sqm, a 2 zone simple system with UFH downstairs and correctly rated rads above will suffice with a direct connected HP with Weather Compensation. The most important principle of all is to ensure that the heat loss design is carried out accurately to ensure uniformity of heating.

Water content and flow. That is my view, anyway and I am not an installer.

Private individual. No affiliation with commercial "Heat Geeks" of same coincidental name.

Posted by: @heatgeek@jamespa Invoking Occam’s razor in this context does not help. In engineering, there are right answers and wrong answers, not alternative facts.

I am referring to Occams razor in the sense of cutting out the unnecessary and I explain this in my post. If its unnecessary (in a particular application) then its unnecessary. Thats a fact, not alternative.

That said, in my personal experience of engineering, there are often a range of 'right' answers with different trade offs (as well as some wrong ones) and the trade offs you choose depend on the circumstances and customer. A 2CV and a Bentley are both valid solutions to the problem of creating a working car to get you from A to B, appealing to different markets.

In your first example I think you conclude that an LLH/buffer tank is not necessary but that the downstairs rads could be replaced with UFH to give adequate system volume for defrost/to meet the spec of the heat pump. The latter may well be true but it is rather disruptive and expensive unless the work is going to be undertaken for another reason. A much simpler and cheaper way to solve the problem is to add a volumiser (a 2 port buffer tank if you wish) which has minimal side effects because it is 2 port. You will note that, in my post, I draw a distinction between buffer tanks and volumisers for precisely this reason, a volumiser has few side effects. Of course it only solves one problem, system volume, but if that is the problem to be solved a volumiser is the right choice.

In the second (larger house) variation you suggest adding a 50l buffer tank in order to supply a bathroom as a zone to run on its own. I would question the wisdom (or utility) of designing a system to do this in the first place but agree that, if you must do this for some reason, its likely that a form of separation will be needed.

Finally you comment that

Posted by: @heatgeekSo these components are not used “willy nilly”. They each have a purpose and do not cause efficiency problems.

Unfortunately the evidence from this forum, over the two years plus that I have been following it, is that buffer tanks and LLHs are used willy nilly by some installers. Furthermore a badly designed buffer tank/buffer tank with badly designed controls certainly does cause efficiency problems, typically involving a sacrifice of 15% or thereabouts and/or poor heating capacity. Hence the title of this thread (not my title incidentally)- "Why Low-Loss Headers and Buffers Can Sabotage Your Heat Pump's Efficiency.". Many of the instances of poor performance on this forum can be traced to unnecessary buffer tanks /llhs. Its sad that this is the case, but that is the fact.

As a general reflection on your comments on 'control philosophy' it is pretty clear that the benefits (or not) of zoning and setbacks are both variable and themselves the subject of some discussion. Heat Geek (the website) gives a worked (and very plausible) example where physical zoning increases cost, because the reduced efficiency (due to smaller emitter area=higher flow temperature) outweighs the saving in heat loss. There are many variables, but I think its fair to say that its far from clear that zoning in a modestly sized, roughly cubic, house with little or no internal insulation may not save much or any money, and may even cost more. Setbacks are probably clearer, in many cases a modest setback will likely save money, however it is possible to come up with circumstances where this is not the case. Due care is thus necessary before assuming that trying to finesse which parts of a house are heated at which times is actually beneficial.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

@jamespa I am reposting this due to my revisions being gobbled up by this site. I have tried to remove the confusion and ambiguity caused by my previous post. I accept the spirit of the frustration regarding the plethora of confusing solutions and components. I will try to provide my own take on this.

Regarding LLH, this is used when there is a mismatch of FLOW between primary and secondary water circuits. There is an interesting example from ProtonsForBreakfast (through @toodles) early on in this thread regarding his LLH. He has done very detailed measurements on his HP system with LLH over 2 winters to evaluate his COP and 1 winter without LLH. He discovered that there was no difference in performance at all. Why, one might ask? His initial figures and logic in his diagram are all over the place, nevertheless it is a very good example to analyse.

He has a 5kW Vaillant HP. From his diagram, it is not possible for the HP to supply 20l/min, nor is it possible for 4l/min flow on the secondary for peak output to give 53C return. Ignoring these figures, let us assume that his 160 sqm house needs 5kW peak at design temperature. The following refers.

The secondary pump has a fixed flow and if a maximum of 5kW output is required with a 10C drop across radiators, then a pump flow of >7l/min must be set (numbers rounded). The valve restriction on rads will force the flow to 7l/min for 5kW. The HP however operates at 5C difference therefore will generate a flow of 14l/min for 5kW (math). Therefore half the flow goes to the rads with a 10C drop and the other half bypasses through the LLH to provide final 5C drop at HP due to the flow mismatch. If the outside temperature halves in value (i.e. half power required), the flow from HP will reduce to 7l/min to maintain 5C Dt for 2.5kW output and no flow will bypass through the LLH due to the 7l/min fixed flow of rads. Drop across the radiator is now 5C.

This is where the design stupidity is exposed. If you now remove the LLH and second pump, flow will still be 7l/min from the HP with 5C drop across the rads. If outside temperature now doubles, HP flow will double to 14l/min and drop across rads will remain at 5C. This flow is perfectly compatible with the HP so the LLH is superfluous. This is why PFB saw no change in his performance. The designer was applying old fashion thinking of 10C drop being necessary across radiators hence the mismatched flows.

Now for water content. Vaillant 5kW requires min. 40l in heating circuit for defrosting (if backup inactive) which PFB presumably has due to the radiators. A problem arises when the heat requirement falls below the minimum flow requirement of the Vaillant i.e. 2.5kW. PFB requires 55C for his rads at peak output. If this output temperature is fixed on the HP, then cycling sets in when outside temperature dictates <2.5kW heat requirement. The way to overcome this is through Weather Compensation to increase the Dt linearly between the mean water flow temperature and room temperature to adjust for the lower heat loss to the higher outside temperature and maintain 5C Dt.

This example suggests a possible answer to the holy grail of a generic use case which could satisfy 90% of average houses as posed by @jamespa. If PFB had implemented a UFH system downstairs (half the area of 160 sqms i.e. 80 sqms) he would need 400m of pipe @ 20mm spacing. This has a water content of 48l so defrost is satisfied, assuming upstairs rads do too. Multiple pipe loops in parallel will accommodate the flow needed. So he can have a directly connected HP with a 2 zone system. The downstairs heat loss and spacing would have to be meticulously planned to ensure uniformity. An average house of 120 sqm will require 300m of pipe downstairs with 36l plus the connecting pipe content, so also no problem with content. A house with no insulation would just have say 10kW and double water content so more zones possible

.The problem arises when fine control is wanted in a bigger house as pointed out in my previous post. There is not enough individual zone flow or water for defrost for a single connected zone like a bathroom or bedroom. The answer is……you’ve guessed it. A BUFFER TANK! A 50l tank in parallel will supply sufficient content AND flow in extremis.So these components are not to be used “willy nilly”. They each have a purpose and do not cause efficiency problems in my view. Only idiot installers abuse their use as seen above. In summary, for an average house of 120sqm, a 2 zone simple system with UFH downstairs and correctly rated rads above will suffice with a direct connected HP with Weather Compensation WITHOUT LLH or Buffer Tank. Some argue that LLH is required even if there is full flow-through without diversion due to the need for an HP overrun bypass. Not idiotic, but it is infinitely more expensive than a cheap automatic bypass valve across the flow lines. Therefore in my view there is absolutely no need for a LLH unless there is flow mismatch. The most important principle of all is to ensure that the heat loss design is carried out accurately to ensure uniformity of heating.

Finally, a volumizer provides increased water content for defrost but it is in series with flow so a large one will cause hysteresis and will not provide a water bypass flow path. A buffer tank is better for both content and bypass flow if connected 2 pole across the flow pipes where needed as per my previous post. The push and pull of the pumps will cause flow to largely bypass the tank without mixing. A buffer should only be needed exceptionally.

Water content and flow are paramount. That is my view, anyway, and I am not an installer.

Private individual. No affiliation with commercial "Heat Geeks" of same coincidental name.

Posted by: @heatgeektherefore in my view there is absolutely no need for a LLH unless there is flow mismatch.

Agree, and if there is a flow mismatch the question is 'why' and can it be eliminated using something without undesirable side effects. In most cases the answer will be yes (or that the flow mismatch arises only because of the LLH).

Posted by: @heatgeekFinally, a volumizer provides increased water content for defrost but it is in series with flow so a large one will cause hysteresis and will not provide a water bypass flow path.

A correctly sized volumiser will bring the system volume up to the figure required to satisfy the defrost requirement, and thus will have no more hysterisis than is necessary for that purpose. Obviously if its oversized it will have more, but if your installer cant properly size a volumiser then they surely cant properly design and fit a buffer in a way that does not cause significant degradation of performance. A buffer connected from flow to return has the potential to short circuit the heating system altogether, and indeed we have seen this in posts on this forum. A volumiser fitted either in the flow or in the return is fool proof which is an important feature in practice, it seems. A pressure activated release valve can be fitted if deemed necessary (I have yet to hear a convincing argument for this which does not simply mask a problem, but I grant it does depend on the details of both the heat pump and the system.)

Posted by: @heatgeekA buffer should only be needed exceptionally.

Agreed, hence the whole thrust of this thread. Unfortunately buffers, it seems, are fitted more often than 'exceptionally'.

Posted by: @heatgeekSo these components are not to be used “willy nilly”.

Absolutely agreed that they are not to be, unfortunately the evidence is that they are!

My personal view is that we are 'in transition'. There has been an unfortunate history of fitting buffers/LLHs principally to avoid the risk of call outs due to low flow (which is masking the problem not solving it) and the need to do so has become to an extent embedded. There was a point where fitting a buffer was more or less the default for many installers, and there are probably some where it still is.

More recently the problems they cause have been recognised and so the previous practices are being called out and some who used to advocate them admitting the reasons and changing their position. Its going to take a while before we get to the point where buffers etc are not 'fitted willy-nilly' and for that period the public need to be warned, to the extent that this is possible.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

-

British Gas Heat Pump Installation Complaint

2 months ago

-

Heating Turned Off but Radiators Still Warm

3 months ago

-

Samsung Heat pump with Yonos Pico circulating pump running all the time

3 months ago

-

Samsung 5kW R32 Monobloc Gen 6 ASHP

3 months ago

-

Ideal Logic 10kW Heat Pump Pipes Noisy and Very Expensive to Run

11 months ago

- 26 Forums

- 2,396 Topics

- 54.3 K Posts

- 257 Online

- 6,077 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Recommended home battery inverters + regulatory matters - help requested

The diagram below is a simplified view of the internals...

By Batpred , 21 minutes ago

-

RE: Heat pump not reaching flow temperature

@davec Ive had a look at the screenshots. Lots of th...

By JamesPa , 38 minutes ago

-

RE: Vaillant aroTherm not heating with many faults

When I had a series of apparently unrelated faults my i...

By JamesPa , 55 minutes ago

-

RE: Considering MLCP (Multi-Layer Composite Pipe) for ASHP

OK, TBH I dont know enough about MLCP to comment with a...

By JamesPa , 4 hours ago

-

RE: Predicted Heat Loss from MCS calcs vs EPC vs actual

My gut feeling is that the heat pump is right sized. ...

By Tim441 , 4 hours ago

-

RE: Power outages and storms: A surprisingly good DNO experience

Agreed, which is no more nor less than a customer shoul...

By Majordennisbloodnok , 6 hours ago

-

RE: Running from backup generaor in powercut?

@batpred In our case, 3 times each day when the Octopus...

By Toodles , 6 hours ago

-

RE: Advice for a novice on Mitsubishi Ecodan 6kW

Hi @sheriff-fatman Cycling at 5C and below is usuall...

By RobS , 6 hours ago

-

RE: New Fogstar 15.5kWh upright solution

@batpred Here's the latest Fogstar ready built pack....

By Bash , 8 hours ago

-

RE: RDSAP10 effect on existing heat pump EPC rating?

@mike-patrick yes, even though the current system is ru...

By Tim441 , 8 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

Solis confirmed that the S6 works with a single battery...

By Batpred , 9 hours ago

-

RE: Who has a V2G EV installation

I am wondering if in any V2X, would the car battery eve...

By Batpred , 9 hours ago

-

RE: Setback savings - fact or fiction?

Yes, by calculating it manually from the minute data, w...

By cathodeRay , 11 hours ago

-

Fan unit Making terrible noise HELP!!

One of a pair of fan units on an Earth Save Classic II ...

By GutoFfowc , 11 hours ago

-

RE: New Mitsubishi Ecodan 11.2kW installation - L9 errors and maybe more

OK. I think your system, which seems well designed, is...

By JamesPa , 13 hours ago

-

RE: Heatpunk Floor plan issues

It's usually the complete opposite... seldom that Safar...

By Mars , 1 day ago

-

RE: Fan is clipping ice build up from the front of unit.

@majordennisbloodnok I’ll not go there thanks! Toodles.

By Toodles , 1 day ago

-

RE: Running my new Nibe ASHP efficiently

I'm new to the forum. Did you get a reply to this last ...

By Mike @ Camelot , 1 day ago

-

RE: ASHP Energy Consumption: Aira 12kW heat pump

@grantmethestrength MCS requirements for DHW capacity h...

By Toodles , 1 day ago