ASHP Pipe sizes

Hi

Im looking to future proof a building under construction for an ASHP, the walls are to be constructed out of concrete, so would appreciate your suggestions on what conduits I should leave in the wall before the concrete is poured.

thanks.

Graham

I'm just trying to imagine this construction approach @fingers

Is the concrete to be an 'internal' wall in which energy is stored as heat?

And you will therefore have an outer insulation layer?

How will the concrete be surface finished?

- plastered/tiled?

- plasterboard sheets on battens?

- directed painted?

Are we considering conduits which would be required to connect horizontally through the wall, solely for the ASHP's water and electrical connections?

Or should we (also) be thinking about vertical conduits to supply electrical outlets at the usual 400mm above Finished Floor Level (FFL)?

What about other services, such as hardwired CAT-6 network outlets?

They could connect back to a patch panel, enabling them to be deployed for computer data, phone, IP Cameras for security, as you wish at a later date.

I have extensive outlets throughout the house for stuff other than mains power.

I leave conduits in walls and below floors to allow additional wires to be installed at a later date.

They have nylon or polypropylene draw-strings left within them for that purpose.

Please feel free to take this discussion in any direction you wish.

Just because it's the Renewable Heating Hub forum doesn't mean we are limited to discussing heat-pumps.

If you want to comment on building regulations, construction materials, lighting or aspects of safety, then do so.

Save energy... recycle electrons!

Hi

Thanks for the reply, the walls are being constructed out of ICF blocks which are 280mm thick, 150mm concrete sandwiched with 65mm insulation either side. The finish both external and internal go on top of this whatever you choose. This give a U value of circa 0.18 W/m.k to 0.165 depending on any eadditional insulation. This also gives an easy route services to be channeled out behind the finishes.

what I’m after for now is the size of the pipework for the ASHP, I have the mains cable and water supply, soil pipe, Wi-Fi etc covered. I’m taking a punt on the position of the pipe through wall but if I put nothing in them I’m definitely into core drilling down the line which I’m trying to avoid.

Thanks

That's great @fingers ICF construction is known to me, although it's not used much in my area.

Let's look first at the conduit needed to carry the main flow & return pipes through the wall.

As it will have the mass of concrete bearing down on it during 'the pour', it needs to be rigid, and capable of withstanding that pressure until the set point.

It also needs to be much greater diameter than the pipes carrying the water itself, because the pipe-insulation must continue right through the wall.

Let's assume that the water pipework is 28mm diameter copper,

and that the outer insulation will have a 19mm wall thickness.

That means the conduit requires a minimum 66mm internal diameter.

I'd be looking at a 75mm (external) diameter plastic waste-pipe.

It will have a wall thickness of about 3.5mm, leaving an internal 68mm tube for the insulated pipework.

Let me stop there for the moment, and check that we're on the same wavelength.

Save energy... recycle electrons!

That sounds exactly what I’m after thanks, I’m hoping to have the ASHP directly outside of the plant room so 2 75mm pipes straight through the wall, any thoughts on spacing and height from the ground? I guess a small conduit for the electrics adjacent to these pipes.

Height above ground level matters only when you're considering the position at which you'll place the drain-valves.

They'll obviously need to be at the lowest point of the pipework.

The two conduits should slope downwards to the outside at an angle of around 5°.

Any condensation or ingress of rain will be directed to the exterior.

Save energy... recycle electrons!

Posted by: @fingersThat sounds exactly what I’m after thanks, I’m hoping to have the ASHP directly outside of the plant room so 2 75mm pipes straight through the wall, any thoughts on spacing and height from the ground? I guess a small conduit for the electrics adjacent to these pipes.

Yes, you'll need two conduits, for flow and return pipes, separated by a couple inches I would think.

Yes, you'll also need a conduit for electrical cabling capable of taking a chunky twin and earth of suitable rating (maybe 4mm or 6mm core), plus any additional control cabling as required.

Interesting you are using ICF. I built a home office at the end of our garden using interlocking polystyrene blocks with a poured concrete core. Depending on the system used, we have places where there is polystyrene interlinking across the concrete which means it's easy to pass small diameter items through the wall totally within the polystyrene, although from memory these would not have been large enough for such pipework, but were adequate to pass cabling through for things like outside lights and other electrical fittings etc.

This is the system we used: Beco Wallform

Samsung 12kW gen6 ASHP with 50L volumiser and all new large radiators. 7.2kWp solar (south facing), Tesla PW3 (13.5kW)

Solar generation completely offsets ASHP usage annually. We no longer burn ~1600L of kerosene annually.

I don't think the two conduits should be spaced horizontal to each other because they might block the flow of concrete when it's poured.

That could leave a void below them.

Equally, if they were vertically above each other, that would present a weak-zone, liable to fracture.

I'd be minded to displace them along an arbitary diagonal, leaving about 200mm + between them for concrete to pass through.

I'm also concerned that the holes in the polystyrene formwork would weaken it sufficiently that the wet concrete could burst out. 😯

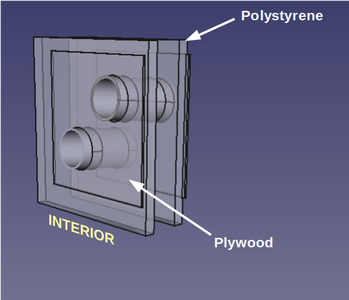

My solution would be to place a plywood rectangle on both the inner and outer surfaces, and hold these together using M6 threaded rod at each corner.

That would allow the plywood to add strength during the pour.

The ply would be removed once the concrete is set.

The protruding ends of threaded rod can then be cut off with an angle-grinder.

Save energy... recycle electrons!

- 27 Forums

- 2,523 Topics

- 58.7 K Posts

- 1,710 Online

- 6,802 Members

Join Us!

Worth Watching

Latest Posts

-

@petch Yes, if the flow and return pipes immediately sp...

By Old_Scientist , 18 minutes ago

-

RE: Home energy storage & battery register

Hanchu ESS - Home-ESS-LV9.4K (9.4kWh) Plus 1 for my ...

By Wino99999 , 54 minutes ago

-

RE: Noisy Grant Aerona 3 13kW ASHP question

Hmm. When they say the pipes are in the walls, is this ...

By Prunus , 1 hour ago

-

RE: Daikin Altherma 3 LT compressor longevity question

@ubert767 We recently had the 8kw Daikin installed a...

By Bash , 5 hours ago

-

RE: My misgivings about installing ASHP and solar panels via the ECO4 scheme...

It has been some time since I posted comments about Eco...

By Dwynwen , 6 hours ago

-

RE: Forum updates, announcements & issues

Something big is coming to Renewable Heating Hub! Ove...

By Mars , 8 hours ago

-

RE: A Single Voice for Heat Pumps, But Will It Finally Raise Industry Standards?

From what I’ve read, the Heat Pump Association UK is me...

By Jonatan , 11 hours ago

-

RE: Tell us about your Solar (PV) setup

Pylontech US5000 stores about 4.3 kWh accounting for in...

By bobflux , 12 hours ago

-

RE: Underfloor Heating Installation Issues with Heat Pump

Hi @martinhook_uk @bobflux The installer is making g...

By Maximumdo , 12 hours ago

-

RE: Octopus Cosy 12 Heat Pump Regret: Incredibly Loud, Poor Heating & Constant Hum - Help!

Hi all, Just an update on where we are with the "Consta...

By DEdwards , 12 hours ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

Well I've had an interesting few days and would like to...

By giganto , 1 day ago

-

RE: Peak Energy Products V therm 16kW unit heat pump not reaching flow temperature

Yes, here's mine. From the service manual parts numbers...

By bobflux , 1 day ago

-

Had to learn the hard way 🤣 now I'm sharing T...

By bobflux , 1 day ago

-

RE: Issue with a Grant Air Source Heat Pump & Tado Smart Thermostat

Im assuming from your original post that hysterisis ref...

By JamesPa , 1 day ago

-

RE: Heat Pump vs New Gas Boiler for Inherited House - Worth the Extra Cost?

Hi @fretless6 Mike, I have experience with Taggas (Re...

By Old_Scientist , 1 day ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

Now seems a good time to summarise the costs and effici...

By benson , 2 days ago

-

RE: Connecting Growatt SPH5000 over wired ethernet rather than wireless

The simplest wired option is usually the Growatt Ethern...

By Jonatan , 2 days ago

-

RE: Electricity price predictions

@jamespa And it seems some of the nasty public cloud...

By Batpred , 2 days ago

-

RE: Jokes and fun posts about heat pumps and renewables

Technology is rapidly advancing. BBC News reported th...

By Transparent , 2 days ago

-

RE: Do Fridges and Freezers have COP ratings?

@editor Thank you all for your replies and submitted in...

By Toodles , 2 days ago

-

I know and yes. The secondary deltaT wont necessaril...

By JamesPa , 3 days ago

-

RE: Designing heating system with air to water heat pump in France, near Lyon

Just love the way you put it! 🤣

By Batpred , 3 days ago