No spare parts for Vaillant Ground Source Heat Pumps in the UK & major corrosion issue is another problem for GSHP

We've been without any heat since 28 December, as our 7-year-old Vaillant Geotherm 17kW ground source heat pump gave out due to internal corrosion. This corrosion can cause major internal damage - possibly to the condenser (£3000+), as well as to the backup heater and several sensors. The GSHP and all UFH pipes fill with black crud and particles, as though they were choked with ash. To avoid this corrosion, which comes from several sources that are part and parcel of heating systems (e.g. UFH pipes, mains water, etc.), we are forced to install an expensive (>£1000) filtration system, as well as pay for repair of all damages.

We also discovered that Vaillant does NOT ensure the supply of spare parts in the UK in anything like a timely fashion. Vaillant sells spares through distributors and, for most spare parts, distributors must order the spares - all say that delivery takes 7-10 working days. However, we learned that these distributors actually order from Vaillant UK, which turns around and orders these from Vaillant Germany. The spares we ordered on 28 December from Direct Heating Supplies online were NOT delivered in 7-10 days - instead, Direct Heating told us after the parts hadn't arrived that the supplier didn't have the spares and that they had to re-order, which would take another 7-10 days. I then called Vaillant's Heat Pump Division, who told me that the only way I could get the spares needed was if they had them in stock AND their own engineers performed the repairs. We were thus forced to use Vaillant engineers, which cost at least twice as much as our local GSHP service team - parts also cost more when purchased direcly through Vaillant. When the Vaillant engineer arrived six days later, he didn't have two of the spares that are needed - and couldn't say when these would be available, as Vaillant has to order them from Germany.

This situation is reprehensible.

LESSON 1: Installing a Vaillant GSHP requires an act of faith that may leave you confronting a real emergency that cannot be addressed because the manufacturer is unwilling to provide the critical spare parts required. Not only are two families living with 12C internal temperatures - and using an electric boiler for hot water and space heaters to keep minimally warm - hoping that the temperatures don't drop further; we are not insured for GSHP emergencies (NFU excludes these) and will only be insured in the case that our pipes freeze and burst, causing major property damage.

LESSON 2: You must consider installing a magnetic filtration system anytime you install a GSHP - you are very likely not being advised that this may be essential if you want to avoid major damage to your GSHP within a few years after installation. Be prepared to add a further £1000-£1500 to your overall installation costs - if you download the Elyasator SorBox manual on this website you can read all about the causes and solutions: https://www.elysator.co.uk/products/sorbox

If you have similar experiences please post them here.

Hi @phowardstutterheim and thanks for posting here. You raise a number of points which I'd like to pursue.

1: There are other routes through which you can obtain spare parts for Vaillant heat pumps, such as Heating Spare Parts online. Enter the details of your model to see parts diagrams and choose what you're looking for.

2: Most magnetic filters don't have to cost anything like the type that you refer to from Elysator. The black crud you refer to does indeed sound like iron oxide to me. So the additional features within the Sorbox may be unnecessary.

BES stocks a score of models under £200.

3: Iron oxide requires oxygen in the water to create it. So I'm also wondering how that amount of damage could occur. The original installer should've ensured that there was a System Inhibitor chemical present at a minimum concentration of 1%. That's not a Vaillant fault per-se.

4: If your home insurer doesn't provide cover for heat pumps, then there's nothing to prevent you taking out insurance or a maintenance contract with a 3rd party like IsoEnergy or Heat Collector. However, there are other topics on this Forum which cast doubt on whether such contracts are worthwhile. The best level of service seems to be experienced by those who use a local heating company who survive by their reputation.

Save energy... recycle electrons!

@transparent Thanks much for your response to my post, the discussion is really appreciated!

1: We went to all of the online distributors that Vaillant uses/recommended for the parts we required - I did this while on the phone with Vaillant's Ground Source Heat Pump Division! None of them had any of the parts we needed in stock - all reported a 7-10 working day delivery time, or longer. We have the parts diagramme and know what parts we need - our installer gave these to us and they couldn't get the parts any faster. I've done extensive research since that time directly with Vaillant - they don't stock the parts themselves, other than some that they supply via their direct repair services. We are currently waiting for parts that they will order themselves from Germany. I was told by an insider that all of these distributors - e.g. Heating Spare Parts online - order parts from Vaillant UK, which then orders them from Vaillant Germany. Thus the very long downtime to get parts.

2: I'm not sure why you think the magnetic filters will do the job. There are several functions of the Sorbox in addition to magnetic filtration of particles, including dealing with oxygen, limescale, salt, pH, and anode protection: you can read why these cause corrosion in the Sorbox manual, which you can find in the link that I provided.

3: Oxygen enters into the water via permeable UFH pipes, valves, fittings, circulation pumps, control units, air vent valves, and faulty expansion vessels. Again, see the manual, which also discusses the disadvantages of chemical system inhibitors. I'm not saying this is a Vaillant problem per se - I am saying that buyers and people who have GSHPs should be aware of these problems and take measures to avoid them. We were NOT, we were not advised about these problems by our installers or by various companies that have maintained our system - until too late.

4: Thanks for the advice about the insurers. We have local heating companies that have been installing / maintaining GSHP systems for years that are certified - but this is still a young industry and lessons are being learned all of the time. For instance, we installed using a borehole as our water source, which was considered to be a good idea a decade ago - but now, quality issues with the groundwater are causing perpetual problems with maintenance, and it is no longer recommended to use boreholes as a source in our region (on clay soils).

Well this going to be an interesting discussion.... we're starting from a position where our experiences differ!

1: What about bypassing Vaillant UK and instead ordering from a German-based parts distributor? Enter Vaillant Ersatzteile für Erdwärmepumpen into a search engine and you'll get a list of companies with a .de at the end of their website address.

They could provide next-day delivery using FedEx.

3a: I have UFH in my house, albeit supplied from a thermal store rather than a heat-pump system. The three types of pipes are all PEX (cross-linked polyethylene) which prevents oxygen migrating into the circulating water from the air. So where is oxygen getting into your sealed system?

3b: My UFH manifolds are brass, as are all the manual valves and connections. The only iron-based component which I can think of is the cast-iron body of the circulation pumps made by Gründfoss. But they have an internal lacquer coating. I don't need to use a magnetic filter because there's naff-all iron available to form black iron oxide.

Where is your system finding iron to corrode?

2: Apart from the evidence of iron-oxide in your heating system, what symptoms are you seeing which cause you to consider that other parts of the Sorbox approach would be relevant at your site?

Does the acidity vary significantly away from the usual pH7.5?

How are limescale deposits being formed since there's no replenishment of water once it's within the sealed system?

There's no new source of calcium salts available once the system is filled and pressurised.

What metal(s) in the electro-chemical series are you expecting to protect against by using a sacrificial anode?

Where are those metals found in component parts of your system that are in contact with the circulating water?

You would need to have metals and salts available in significant quantity to be a factor in forming corrosion by your circulating water, assuming that it does indeed have a system inhibitor in it.

I have over 300-litres of circulating water, and have made a deliberate decision to double the quantity of inhibitor I use to 2%.

4: I have no mains water. My heating system is filled from our well water which is mildly acidic. I use a cylinder with a pH regulator chemical to bring it close to pH7.5 which is typical of a mains supply.

The well is blasted out of bedrock known as Kate Brook Slate, which is common in West Devon and East Cornwall. This comprises thin plates of slate, held together with a fine layer of clay.

But clay is inert, and only a small quantity of the very smallest particles could remain suspended in our water (less than 10 microns). There's certainly not enough to create any sort of maintenance problem, and I wouldn't hesitate to install a GSHP based on my knowledge of the water available here... even if we used a borehole as the mechanism to transfer heat to the ground-loop water/glycol mix.

There's no mixing of water in the borehole with that in the ground loop; so where are you seeing a problem?

Save energy... recycle electrons!

@phowardstutterheim, how old is your system?

To answer your poll question, our heat pump is made in the UK so parts should be readily available. I don’t think Vaillant is alone on low supplies of spares… most of the manufacturers are struggling to maintain stock levels for some odd reason.

Get a copy of The Ultimate Guide to Heat Pumps

Subscribe and follow our YouTube channel!

There sounds like there are some tall stories being told by Valiant, or others. The supply side of the heat pump consists of a pump, a stainless steel plate heat exchanger joined together with some copper pipe. In reality, there is nowhere where irreparable corrosion can take place. Any good plumber can re-pipe it, the pumps can be bought off the shelf from any good pump supplier, and it is very unlikely, anything in the system will corrode stainless steel, but if it does, and it has failed, it is an easy task to get a comparable replacement from another supplier/manufacturer. The pumps are cast iron, so may rust.

I presume this installation is a retrofit and possibly not cleaned properly before the heat pump was installed. If it was, then it was not dosed properly with inhibitor, there is a leak and the system is continually being topped up, or it is a vented system and the vent pipe has not been extended down in to the water to prevent aeration. When black sludge is formed, there is usually a simple explanation. We have many installations with old cast iron radiators with no problems whatsoever with crystal clear water after many years of operation. There is definitely something that is not right.

I suspect that the plate heat exchanger has blocked with the black sludge. This is relatively simple to clean by connecting a high pressure pump, circulating a corrosive acidic solution (patio cleaner) which will remove any rust or black sludge and leave it like new. We have done this many times, very successfully.

I have never seen a heat pump's distribution circuit corroded so badly that it needs replacing. I would be interested to see exactly what does need replacing. Some more details would be helpful.

Hi Brendon,

Thanks for your very comprehensive response. FYI - we do not have a retrofit. We installed a spanking new Vaillant Geotherm 17kw in 2015. The installer was an MCS certified company that has both a GSH and a plumbing and heating division. The design was done independently by a top heating engineer who previously worked for Danfos to correct all of the faulty installations performed by Danfos prior to 2014. No inhibitor was used to my knowledge - either in the GSHP or in the 2 UFH systems that it supplies. It is connected to these UFH systems via Uponor 4-core pipework laid underground. NuHeat designed and supplied the UFH system. In other words, the system installed was new and top-class in 2015.

I am not an expert in corrosion. My MCS-certified installer/service company reports that the Elysator SorBox is now being recommended for all GSHP installations because corrosion problems are being encountered fairly frequently. Our UFH system has pipework that apparently is permeable to oxygen. Vaillant's repair department told me that only a few cases of corrosion have been reported to them. I cannot verify any of this, of course - I mentioned Vaillant only because they do not supply spare parts in the UK on a timely basis.

I am rather surprised that you say that any good plumber can carry out repairs to the Vailliant GSHP using equipment that is not from the manufacturer. This I have not heard before. Is this indeed what you are saying - that non-Vaillant equipment can be retrofitted into Vaillant Heat Pumps and will perform well?

Another question for you - we still don't know whether the GSHP condenser is going to work satisfactorily - it may have been filled partly with corroded particles. The Vaillant engineer who came to site yesterday said that, because the internal construction of the condenser is very tight, it is quite difficult to flush. If it contains many particles and can't be flushed out completely, it may have to be replaced - at a cost of some £3000 plus. What do you think about the challenges of flushing out a GSHP condenser - and, would you recommend acid?

My husband regularly flushes the external components of our GSH system (heat exchanger, pump) as clay particles enter these and foul them - he also uses acid in this process.

Thanks again,

Patricia

Brendon,

I forgot. Two temperature sensors and the backup heater have had to be replaced so far - the question of the condenser is still to be assessed. The system is finally heating again, but we don't know for how long. Vaillant has had to order the backup heater and some other bits related with the sensors from Germany.

Posted by: @phowardstutterheimThe installer was an MCS certified company that has both a GSH and a plumbing and heating division.

I don't regard that as a particularly reassuring observation.

Two years ago, I was able to dialogue online with a group of 250 households who were part of a heat-pump survey entirely funded by BEIS (ie using public funds). They were very forthcoming in publishing photographs and data of their installations, which enabled us all to see what was happening.

The major problem was definitely the quality of the installations, which were compromised due to there being too little knowledge and understanding by the MCS-accredited (BEIS-approved) installers. ASHP manufacturers were being forced to attend on-site to evaluate what was going wrong, which resulted in a number of sites having most of the new equipment removed and the site then re-installed. The largest installer was 'removed' from the scheme, despite having very high credentials on paper.

Mistakes included

- incorrect pipe insulation (external insulation without UV protection from sunlight)

- absence of buffer-tanks (or too small a tank), resulting in water which was too hot being returned to the heat-pump

- missing air-release valves at highest point in pipework

- thermostats connected, but sited within a cupboard

- system controls and displays where they couldn't easily be reached, such as the far end of the attic

Having MCS accreditation makes no assumptions about the installing possessing common-sense!

Posted by: @phowardstutterheimNo inhibitor was used to my knowledge - either in the GSHP or in the 2 UFH systems that it supplies.

1: When chemicals are added to circulatory/closed water systems, it is usual practice to

- write this on the relevant page of the main manual, which usually serves as a check-list, and assures the customer of the installation being guaranteed

- leave a label from the container, with a date, stuck to the relevant part of the heating system

Have you looked for such 'evidence'?

2: The chemicals required for the ufh system and the GSHP ground-loop are different.

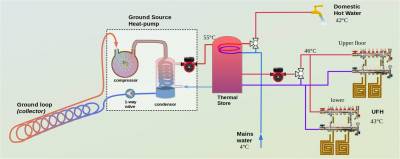

May I offer the following generic diagram to show the composition of the three categories of water in a typical GSHP system:

The ground-loop contains a mixture of water and glycol to prevent it freezing.

The body of water in the thermal store, and that being pumped to the UFH manifolds, contains a system inhibitor. That prevents oxidisation of metals and formation of sludge.

The mains water, which picks up heat to supply the domestic hot water (DHW) contains no additives.

No mixing occurs between these three bodies of water.

Save energy... recycle electrons!

Quick question please - if chemicals were not added (ever) would this constitute negligence?

Posted by: @editormost of the manufacturers are struggling to maintain stock levels for some odd reason

The lingering knock-ons of the health crisis and the recently-erected trade barriers don't seem that odd to me.

I would certainly call it negligence @phowardstutterheim - for both bodies of circulating water.

I'm not sufficiently certain of the legal definition to know if 'negligence' can be used within a claim.

Even so, it would seem that there is a possible claim under the Consumer Rights Act 2015, which replaced the Sale of Goods Act. The CRA extended the earlier Act by including aspects of inadequate service, rather than just the goods themselves being faulty.

The downside is that there are time limits on what is defined as faulty goods/services - usually 12 months. But if the absence of chemical additives could itself only be detected after a prolonged period of use, then that limit might yet be overridden. The Citizens Advice Service are the arbiters for Consumer Rights, and you should ask them.

Remember that the presence or absence of chemicals can be detected by performing a laboratory test. You would probably want the samples taken by a suitably-qualified heating engineer, along with dated photographic evidence of the sampling occurring.

Save energy... recycle electrons!

- 26 Forums

- 2,372 Topics

- 53.8 K Posts

- 187 Online

- 6,053 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Solar Power Output – Let’s Compare Generation Figures

@papahuhu Indeed! One could put sheds all round one’s p...

By Toodles , 18 minutes ago

-

RE: Radiator sizing sanity check

@jamespa thanks, yes it seemed mad to me. An exert f...

By Papahuhu , 25 minutes ago

-

RE: Optimum new build house design for Heat Pump

From first principles I would say: Definitel...

By JamesPa , 2 hours ago

-

RE: Cascade 2x Grant Areona 10kw ASHP - Ongoing setup issues

This is actually normal, or at least its more or less w...

By JamesPa , 2 hours ago

-

RE: Weather compensation- why you should use it

As good a place as any to drop this video:/p>

By Mars , 5 hours ago

-

RE: Forum updates, announcements & issues

@transparent D'Oh - I did look before I posted but I mi...

By dr_dongle , 6 hours ago

-

Compatibility with Samsung AE080RXYDEH

I am new to all this. We have a SamsungAE080RXYDEH that...

By John999 , 6 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@benson is using an esphome controller which integrates...

By Mosibi , 6 hours ago

-

RE: New Fogstar 15.5kWh upright solution

@batpred Maybe you should buy your additional batter...

By Bash , 8 hours ago

-

RE: Data Accuracy Problem: Daikin 8kW Heat Pump's Onecta App vs MMI Power Consumption

@nursethescreens Yes, comfort and happiness of the fami...

By Toodles , 9 hours ago

-

RE: Connecting Growatt SPH5000 over wired ethernet rather than wireless

Thanks folks. I had tried googling an ethernet lab adap...

By z8lccda , 23 hours ago

-

RE: Changing from 4-port buffer to volumizer

@toodles I'm not concerned that the behaviour is not no...

By Andy1618 , 24 hours ago

-

-

RE: Setback savings - fact or fiction?

I agree, and I think there are two things in play here....

By cathodeRay , 1 day ago

-

RE: Water Hammer After Heat Pump Install

That's really helpful. Yor last sentence confirms it'...

By JamesPa , 1 day ago

-

RE: Help needed with Grant Aerona 3 issues

First time posting so bear with me. Some bits that have...

By Adamp , 2 days ago

-

RE: Mitsu PUHZ-SW120YHA + EHSC-VM20Uk - Performance

All understood. Obviously its a bit house de...

By JamesPa , 2 days ago

-

RE: Who's your electricity provider and what's your tariff?

@majordennisbloodnok This may be a better thread to ...

By Batpred , 3 days ago

-

RE: Best Heat Pump Brand in the UK

Last Call to Vote & Win! Haven't voted for your Hea...

By Mars , 3 days ago