@jamespa Hello James and thanks again.

The rads are connected in parallel and there are two runs of 22mm running down the sides of the house, in the ceiling of the ground floor, with short 15mm branches running up or down to radiators. Recent pipework is composite and 25mm.

Upstairs is main living area with 3 bedrooms, but we converted ground floor for master bedroom and additional sitting room/ office.

I will see what I can get from MelPump, but we have not had really cold weather this year (just very wet) and I am not sure what MelPump can provide from last year

342sq m "Upside down" house in Algarve. Portugal

Mitsubishi PUHZ-120YUK 12kW ASHP

12 Solar Panels Growatt Inverter

2 x Growatt 7.5kW Batteries

Fronius EV Charger

Kia e- Niro 64kW

Posted by: @davidalgarveRecent pipework is composite and 25mm.

Woah - is that single run (flow and return) rather than two runs (2* flow and 2* return) in parallel and roughly how much of this is there please and where in the system?

Posted by: @davidalgarveThe rads are connected in parallel and there are two runs of 22mm running down the sides of the hous

Is that 2*2 (2* flow and 2* return) or 1*2 (flow and return?)

Depending on your answers pipework may well be a problem, workable of course once we have the data

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

@jamespa There are two 22mm flow and two 22mm returns shortly after rising from the heat pump where 25mm composite material pipework is used. I think this is the pipework coming out of the Ecodan.

I stress that this latter pipework was what was in place before the second pump was removed and when we were comfortable.

342sq m "Upside down" house in Algarve. Portugal

Mitsubishi PUHZ-120YUK 12kW ASHP

12 Solar Panels Growatt Inverter

2 x Growatt 7.5kW Batteries

Fronius EV Charger

Kia e- Niro 64kW

Posted by: @davidalgarve@jamespa There are two 22mm flow and two 22mm returns shortly after rising from the heat pump where 25mm composite material pipework is used. I think this is the pipework coming out of the Ecodan.

I stress that this latter pipework was what was in place before the second pump was removed and when we were comfortable.

OK, 2*22mm good, 1*25mm composite somewhere between pretty bad and unacceptable unless its very short with swept bends only.

Do you know roughly how long the 25mm run is, was this put in when the heat pump was fitted and what exactly does it connect at either end? Also does it have swept bends or elbows where it turns corners?

Posted by: @davidalgarveI stress that this latter pipework was what was in place before the second pump was removed and when we were comfortable.

Noted, I think the point is that your setup is marginal due TBC to the 25mm composite, so the buffer plus extra pump just got it to working, one pump alone the other side of the margin. Lets focus for now on the pipework and see where that takes us. My sense is we may be converging on an explanation for all or at least most of the observed phenomena. Once we have an explanation we can move to a fix!

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

@jamespa Hello James. I am a little "under the weather" literally and metaphorically, so delayed response.

1 - The approximately 2m of 25mm pipework was put in originally, but modified twice, the first when DHW was added and the second when the buffer tank was changed to a return line volumiser. I now see that the pipe between the Ecodan and the 3 way valve is 32mm 9not 25mm) and has two elbows. More on this later.

2 - I am much closer to the pipe restriction argument than I was, but I still find it strange that the flow rate(s) are much the same on house or DHW with vastly different pipework runs.

I have spent some time looking at the set up and thinking about it and I have come to the conclusion that neither the DHW pipework nor the radiator/ volumiser pipework is acceptable, irrespective of if a second pump is used.

I may be able to reduce the number of elbows (more so on DHW), but Plex pipework will have to be used and the only form of 90Deg fitting I have found so far, is a very sharp elbow, of which my installation has quite a few.

It is very difficult at any time to find a decent contractor here and it will be impossible to find one that will work to my instructions with e.g. straight Plex fittings combined with, perhaps, oversized elbows. Consequently, I may have to do this modification myself, but think I will have to wait until the heating season is over.

I cannot contemplate making any changes to the copper radiator pipework - I am an old man and one way or another, I will be moving on in the not too distant future!

In looking at a better pipework layout adjacent to the Ecodan, it occurs to me that the pipe run could, possibly, be better if the volumiser was to be in the flow rather than the return.

I will add a preliminary sketch and would appreciate your assessment on the relative merits of locating the tank in the flow or return.

I am quite undecided on making provision for a second pump in the repipe, but it would be expensive and sizing would be something of a guess.

As ever, your comments appreciated.

342sq m "Upside down" house in Algarve. Portugal

Mitsubishi PUHZ-120YUK 12kW ASHP

12 Solar Panels Growatt Inverter

2 x Growatt 7.5kW Batteries

Fronius EV Charger

Kia e- Niro 64kW

OK.

Im sorry to hear you are not feeling well and wish you a speedy recovery.

In a slightly perverse way I was hoping you were going to tell me that the 25mm pipework was much longer, as this would have explained everything. As it is Im not sure we yet have an explanation and until we have one I wouldn't be confident about a solution! However I think its worth fleshing out what the explanation would have been as it may yet turn out to have elements of truth.

So in summary you have a poor flow rate now, without a buffer. When you had a buffer you had a not great flow rate (ie << target) in the primary, we dont know about the secondary. Furthermore the flow rate for DHW is roughly the same as for space heating. The poor flow rate now is causing a high DT, which of course is reducing efficiency. Furthermore I suspect that there may be loops in the space heating where the flow rate is reasonable and the DT OK, and loops where it is very poor, causing cold areas. This could be significantly exacerbated by the change of buffer and more specifically the removal of the secondary pump.

Logical conclusion which would explain these would be that there is a major head loss/resistance in the common parts of the primary which, if you had told me that there was 10m of plastic pipe (20m in total out and back and bearing in mind that the ID of 20mm plastic is the same/less than the ID of 22mm copper) and a fair few elbows would have been correct. However you didn't, leaving still the question why is the flow rate low still a mystery. Something has to be throttling it! (An alternative explanation btw is that the pump is faulty)

There is a calculator here which calculates the head loss through plastic pipe which, in combination with the pump curve should allow one to calculate either throughput given head or head given throughput. Here is a screenshot. Putting in figures based on what you have said suggests 1m headloss max, whereas the pump is supposedly good for 7m (5m at 32l/min)

Nevertheless it does seem likely that the head loss in what was the primary must be significant. Perhaps there are other restrictions - eg a filter (other than the one in the heat pump) which is too small, more bends than allowed for, undersized shut off valves, that 3 way valve (what model?) etc. I do think this explanation is worth pursuing if only to rule it out, and an examination of what is actually there will flush this out.

As to the copper pipework 2*22mm should be sufficient assuming that the two halves are reasonably balanced in their demands, the runs aren't extremely long and it doesn't downsize to 15mm immediately it becomes invisible.

I would suggest that the next step is to take another look at what was the primary to assess if its possible that the head loss is quite a bit higher than the calculation based on 2*2m plus a couple of elbows would suggest.

In terms of solution, until we have worked out an explanation I hesitate to speculate but just swapping the volumiser between flow and return wont fix it unless it removes an obstruction. Finding the obstructions and removing them is the best solution,l alternatively I think it is a second pump. Im not sure it needs to be sized accurately as the current pump is adjustable, so in principle all you need is to 'lose' say 4m of head at 32l/h, which the pump you already have is perfectly sized to do. Id want to check with someone who is familiar with putting two pumps in series first, but cant see why this wont work

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

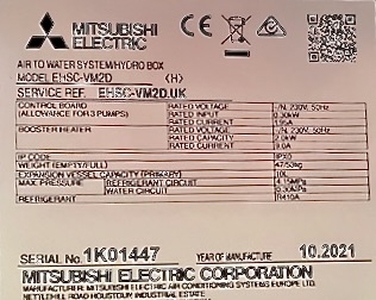

PS to above: This page from the R32 manual suggests a much less capable water pump might be fitted than the one you have quoted - something isnt stacking up, do you happen to have the model number of the Hydrobox?. It also suggests that 2 pumps may be necessary. The curves below may of course account for the head loss of the hydrobox itself.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

@jamespa Hello James. Thank you for the new comments.

Dealing with new questions first:

My Ecodan spec is an EHSC VM20.UK

I had previously obtained the pump curve as published by Mitsu for the EHSC, but once I gained access to the Grundfos pump I felt that this would be a much more reliable source for information on the specification. here:

Note that this model has neither on board control or local status indication and in this respect, resembles the one in the brochure referred to as UPM3 with two PWM profiles. Consequently I am reasonably confident that this is the data we can use.

I have also been wondering about the 3 way valve and whilst I think it is generally a reasonable choice, I do now wonder about the sizing at 20mm

See below:

However, the more I look at the pipework, the more I am dismayed at the number of severe elbows, e.g. this 3/4" one after the 3 way valve.

My suggestion of putting the volumiser in the flow rather than the return was more aimed at reducing the number of elbows rather than an inherent advantage in one or the other.

It may well be necessary to fit a second pump, but I don't want to go to the expense of a new pump before seeing what can be achieved with improved pipework. I don't favour installing the old pump because, although it is a PWM, I don't have the speed change control.

I continue to search for Pex pipe and fittings and so far I can only find straight couplings or severe elbows in 22mm and there is little available in 32mm.

Incidentally, I note that the current return from the volumiser is, in fact, 32mm, so I would aim to retain a longer length of this if I do re-pipe.

I am still trying to think of someone I could trust and that would be willing to do the re-piping, but I will almost certainly wait until the end of the heating season now.

342sq m "Upside down" house in Algarve. Portugal

Mitsubishi PUHZ-120YUK 12kW ASHP

12 Solar Panels Growatt Inverter

2 x Growatt 7.5kW Batteries

Fronius EV Charger

Kia e- Niro 64kW

Thaks for the response, either the pump is faulty or there must be restrictions somewhere so I think you are now on to it. Probably worth tracking down all the bends then thinking about a more sane route and how you can use swept bends. A 3/4" elbow is madness if you are trying to get 32l/min through! 32mm copper pipework is what you really need until it splits to 2*22; you might just get away with 28mm but its taking a big risk. 32mm pipework is rather clumsy so short lengths and few bends is rather desirable to say the least.

Posted by: @davidalgarveMy suggestion of putting the volumiser in the flow rather than the return was more aimed at reducing the number of elbows rather than an inherent advantage in one or the other.

Fair enough

Posted by: @davidalgarveI have also been wondering about the 3 way valve and whilst I think it is generally a reasonable choice, I do now wonder about the sizing at 20mm

Thats 1m head loss at 32l/min according to the data sheet. Based on the performance curve you need somehow to save about 3m of head loss; swapping this for a 32mm one wont be cheap, but will make a big contribution.

Posted by: @davidalgarveIt may well be necessary to fit a second pump, but I don't want to go to the expense of a new pump before seeing what can be achieved with improved pipework. I don't favour installing the old pump because, although it is a PWM, I don't have the speed change control.

I think thats sensible TBH if you are prepared to experiment. Its flow rate that matters and the heat pump measures that, so it doesn't have to be done in the heating season. A good plan for route and pipe sizing (as well as some approx calculations) is the key to making this work, and you perhaps consider some temporary 'experimental' links to diagnose head loss in each part as you go along so you know where to focus. I note that the rating plarte for the IDU says 'allowance for 3 pumps' so Im guessing that there are additional PWM connections available if you need them.

Im pretty confident that the problem is now identified, which is more than half the battle!

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

@jamespa Thank you James.

One of the most effective changes that I could make, is to reconnect the 3 way valve to the top left connection on the volumiser, (where it was originally in buffer tank configuration) and this would eliminate a number of reducers and elbows and a length of pipework.

The bottom connection on the same side of the tank would give the straightest, simplest route for onwards to the radiators.

Obviously, in the case of a buffer, it is essential to make connections across the tank, but is it just as desirable in a volumiser?

342sq m "Upside down" house in Algarve. Portugal

Mitsubishi PUHZ-120YUK 12kW ASHP

12 Solar Panels Growatt Inverter

2 x Growatt 7.5kW Batteries

Fronius EV Charger

Kia e- Niro 64kW

Posted by: @davidalgarveObviously, in the case of a buffer, it is essential to make connections across the tank, but is it just as desirable in a volumiser?

No, what you want in a volumiser is to ensure that the whole tank is 'engaged' ie you dont get dead spots or stratification, otherwise you are reducing its effective volume. So (at least as far as I can see applying 'first principles') in and out on the same side is fine so long as one is at the top and the other at the bottom (preferably in at the top and out at the bottom so the flow is in the opposite direction to any stratification which does occur).

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

@jamespa Thank you again.

In that case, that is the first thing I will try.

This tank is located in an attached pump room and insulated, but it will probably be worthwhile to box it in with additional insulation in view of the higher temperatures.

342sq m "Upside down" house in Algarve. Portugal

Mitsubishi PUHZ-120YUK 12kW ASHP

12 Solar Panels Growatt Inverter

2 x Growatt 7.5kW Batteries

Fronius EV Charger

Kia e- Niro 64kW

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 239 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@cathoderay yes that is it in a nutshell. I am keepin...

By benson , 40 seconds ago

-

@painter26 — as @jamespa says, it's for filling and re-...

By cathodeRay , 48 minutes ago

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

I'd be happy with what you have (so would millions of o...

By Deltona , 2 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 11 hours ago

-

RE: What determines the SOC of a battery?

@batpred Your BMS parameters will be the same as m...

By Bash , 12 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 13 hours ago

-

RE: Setback savings - fact or fiction?

I also need to correct something I said by mistake earl...

By cathodeRay , 13 hours ago

-

RE: Electricity price predictions

@judith Thanks for sharing, and nice to see how the ...

By Batpred , 14 hours ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 16 hours ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 17 hours ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 17 hours ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 19 hours ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 19 hours ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 20 hours ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 22 hours ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 22 hours ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago

-

RE: DIY solar upgrade - Considering adding more panels

I know this is a bit old, but it made me wonder what co...

By Batpred , 2 days ago

-

RE: New Vaillant aroTherm Plus in black - When will it come to the UK?

@majordennisbloodnok Daikin, take note! (In fact, I hav...

By Toodles , 2 days ago

-

RE: Midea ASHP – how to set weather compensation

@mk4 — good work! First, I agree, no evidence of cycl...

By cathodeRay , 2 days ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

I don't know about Solis inverters. It isn't a featur...

By Transparent , 2 days ago

-

Daikin Altherma 3 H HT - Freeze Prevention Threshold

Hi. We have an Altherma 3 HT (18kW I think) which, now ...

By RICHARDF5033 , 2 days ago

-

RE: Passiv Smart Thermostat - Help & Forum Support

@petch We are not yet compatible with the R290 from Gra...

By Will H , 2 days ago