Posted by: @cathoderayThere is also a question of whether a full heat meter set up would actually be more useful on the secondary circuit (I have a plate heat exchanger) as that is what actually goes round the house, but that then means I can't measure the DHW heating as it is on the primary circuit.

I am finding this thread somewhat confusing as my brain 🧠 overloads when data takes priority over basics. I feel this seems to be what’s happening here and for quite some time now. Please forgive my do-it-and-see methodology.

the above statement confuses me- do you have a secondary circuit that does your DHW via the plate HE or does the secondary circuit go around the house? If the latter that must mean you should have at least 3 pumps?

so if you have a secondary circuit I can only presume you have a LLH or some other hydronic separation device?

I think, from earlier convo’ your property has a huge amount of thermal mass. So when it cools it takes a huge amount of time to reheat?

Midea I think, have an internal primary pump? So you may only be able to see 2 pumps. Midea also have a variable speed primary pump which means you may be having massive mixing between flow and return? Especially during high flow cycles!

Plate heat exchangers are very efficient at exchanging heat as in - very quick, rather than very efficient. They were developed to put hot water straight into the top of the tank with both sides requiring a pump do speed up the H transfer process but they need high temp delivery to do this. This compromises the low and slow strength of HPs.

Don’t know if this helps the number crunching

First, quiescent use: taking readings from the external dedicated kWh meter, which reads to one decimal place, the heat pump used 0.2kWh over the 12 hours between 2000 last night and 0800 this morning. That's 200W, or 16.7W per hour, less than a normal incandescent bulb. During that period, there was no evidence of any heating activity in the modbus minute data: zero amps for every minute, and zero flow rate apart from 2 x 2mins, 0141-0142 and 0744-0745 when the flow rate was ~1.03m^3/h (not 1.3, the normal rate when heating).

Worth noting that during normal heating, the heat pump might well use on average 2kWh per hour overnight, or 24kWh over the same 12 hour period. That's two orders of magnitude more than the quiescent use.

Second, I have got myself confused again on the heat delivered equation while looking at the minute data charts, which have everything on them needed to calculate energy in and energy out in your head. Energy in is amps (from the chart) divided by four (kWh = amps x (240/1000). which is near enough divide by four) and energy out (flow rate x specific heat x delta t) boils down to delta t x 1.5, because in my case both the flow rate (0.361lires/sec) and specific heat (4.0) are constant and evaluate to 1.444 or lets say 1.5. But therein lies my confusion: the only determinant of energy delivered (in this case) is delta t, which is a relative measurement that takes no account of absolute temperature. That means if my system runs one one occasion with a LWT/RWT of 25/20 degrees and on another with a LWT/RWT of 50/45, it still delivers exactly the same amount of energy. This is, at least for me, counter-intuitive, as in the second case, they system is running twice as hot. Maybe the answer lies somewhere around that is true in a steady state (same energy delivered), where the difference appears is in the period getting to the steady state. I see this as pertinent because my system spends a lot of time not in a steady state.

Posted by: @jamespaA 3 bed house may be quite a lot smaller than the designers of a 14kW unit were thinking. I have a distinct suspicion that your house is 8-10kW not 14.

I still think it is about 12kW. When I did the original full U value air change etc pencil and paper calculations in the mid 1980s for a solid fuel hopper fed boiler, I got a figure of just over 10kW. I then had an extension, upstairs bathroom plus third bedroom, in the late 1980s (just before the house was listed) and then redid the heat loss before putting in the oil boiler on the early 1990s and got a figure of 12kW. Although some comedy installers came up with comedy figures, the more reputable quotes I had from installers using the Freedom and MCS based heat loss calculators got the same figure, 12.3kW. A LOT of heat goes through the walls, which are a delightful mellow old sandstone, but they are not particularly thick (typically 400mmm, and no, I am not going to ruin the outside with external insulation nor got to the expense and disruption of losing valuable internal space to internal insulation). Since a so called 14kW unit is only that in the Midea/Freedom sales person's eye, and in reality delivers nearer 11.3kW when it's cold outside, a 14kW unit is in fact marginal. There is also the empirical evidence to back this up: down to about zero or just under, my heat pump can meet the demand (room temps remain at design temp), below zero it can't keep up, and room temps fall.

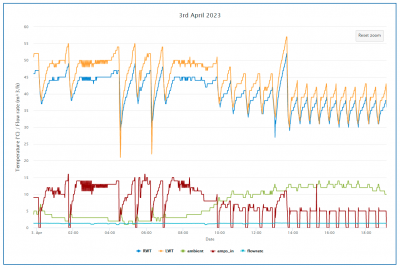

And then another fly lands in the thick brown Windsor soup that is heat pump performance: my heat pump appears to get nowhere near 11.3kW even when it is approaching zero outside. Consider the night of the 3rd of April. There was an error in my modbus script at the time that failed to take into account the ambient temp is a signed integer (it treated it as unsigned integer) and so an OAT of -2 almost certainly got recorded as +2. Based on local Met office data, it got down to -2 that night, and here is the performance data:

Even in the two relatively steady state periods 0200-0400 and 0700-0900, the delta t was around 5, which gives a power output (not a typo, I am using power not energy calculation because the data points are in effect instantaneous readings) output (using the above multiply by 1.5 ready reckoner) of 7.5kW at or approaching or just below zero outside, which is nowhere near the supposed 11kW or so it should be producing in those conditions. Using the power in ready reckoner (divide amps by 4) we get 3kW in, and so incidentally a COP of about 2.5.

Arrrgghhh!

@kev-m - I think the above chart may also show the true cycling (not the defrost cycles or the DHW spike at 1300) when it does happen doesn't lead to a big energy in/out and so efficiency hit. Compare the eye-balled average delta t and amps in between 0000 and 0200 (some cycling) and 0200-0400 (more steady state, and they look pretty similar.

To answer other questions/comments as best I can:

Posted by: @jamespaWhat controls the pump speed in the secondary circuit?

I think it was on (it is now off of course) a basic internally controlled proportional flow curve. It is a very basic Grundfos UPM3 Auto pump with no external control option.

Posted by: @derek-mCR was advised to consider removing the PHE quite some time ago. I think that Batalto followed the advice and achieved quite considerable improvement in the performance of his system.

I certainly haven't ruled out removing it, and I also recall @batalto's findings when he removed his (or was it a LLH in his case?). I'm not sure off the top of my head whether the improvement was 'quite considerable, or just a few percent. The reason for my inertia is that removing it will involve quite a lot of disruption, both circuits drained down, awkward plumbing in tight spaces, I lose the hydraulic separation and end up with far more glycol in my system. I suppose what I am saying is that I need to be persuaded the material gains in efficiency will be sufficient to make the disruption worth while. The same applies to a volumiser.

Posted by: @roblExactly what controls do you have? I understand you have a manufacturers weather compensation system, and TRVs (on full so not used). Is there somewhere a simple thermostat kicking in and out ?

Weather comp and open TRVs correct, one simple (room) thermostat, which is only used as the on/off switch: set to 26 degrees in winter (so always on) and 9 or 12 degrees in summer (so always off).

More generally, I am increasingly coming to the idea the major cause of the increased heat use with the heat pump is down to the timing. It is an unfortunate fact that current heat pumps are intended to be run 24/7 (because all said and done they are rather feeble compared to fossil fuel boilers) because it obliges us to run them at times when they aren't really needed eg overnight. This is aggravated by the fact that certainly Midea and likely most but not all (Mitsubishi being perhaps an exception) other heat pumps have what I have called dumb weather curves, they only take into account outside temp, not inside temp, and so have no way of recovering in a reasonable time from an overnight setback if one is applied (see previous posts for evidence for this). I think this amounts to a general flaw in mainstream heat pump thinking: the general requirement to have them on 24/7, chiefly because they are incapable of recovery from a setback. A householder who previously used a fossil fuel system on a timer (as I did) is going to get a bit of a shock when he or she sees how how much extra heat an heat pump needs to keep the house warm.

This has been discussed before, almost to death and beyond, but I am still inclined to think setback plus boost will always use less total heat than always on. The problem is heat pumps as delivered can't do this, a rather stark design omission. It may be possible to achieve this adaptive type of control via modbus but really householders should not have to write computer programs to control their heat pumps!

Back to solving the paradox: in very simple terms, if I ran the oil boiler 12 hours a day, and the heat pump 24 hours a day, then it seems entirely plausible the heat pump will need to deliver twice the amount of energy. If perchance I ran the oil boiler for say 8 hours a day (four hours in the morning, four hours in the evening) then by the same logic the 24 hour heat pump will need to deliver three times the amount of energy. Under the oil regime, I may perceive much the same warmth levels, because the house is at the right temp when it needs to be (courtesy of the oil boiler's ability to deliver a lot of heat in a hurry). At other times, the temp falls, but I don't notice, because I am either asleep under my duvet, or up and active, or even out. During the day, especially in autumn and spring, the house also benefits from solar gain (it's real, I can see it on the thermometer in the kitchen, sometime 2 degrees or more). The relatively high thermal mass for size also evens out things under the oil regime.

There is one bit of observational evidence that I think is very relevant to this, because it gives a handle on what happened to overnight temps under the oil regime. In the past, using oil, the house tended to have a LOT of condensation on the windows in the mornings. With the heat pump there is none. I rather put this down to the secondary glazing, but the fact of the matter is the windows that aren't yet secondary glazed (and used to have a lot of condensation) now don't have any condensation. I think this implies that overnight temps were significantly lower with oil, and are now significantly higher with a heat pump. Less condensation is of course a significant benefit, but it comes at a cost of heating the house when I don't need to for comfort reasons.

This thread is about what we need to know before installing a heat pump. I think the lesson I have learned, and would have been glad to know before installing, is that the change from timed heating (if that is what you had) to 24 hour heating (because the heat pump is comparatively feeble) will mean you use more energy, perhaps (as in my case) a LOT more energy. A heat pumps higher efficiency will mitigate this greater energy use, with a very roughly estimated break even point where the COP meets the ratio of heating to non heating intervals: eg moving from 8 hours heating to 24 heating, an increase of 3, will be offset by a COP of 3, and by and large your energy in will remain the same. This, give or take, is I now think the main explanation of the paradox, which I now rather grandiosely declare is, at least for me, no longer a paradox.

Put at its simplest, a heat pump may well be three or more times more efficient than a fossil fuel boiler, but you may well find that any potential savings are wiped out by the fact that, because of the way heat pumps are designed to be run, you have to change the pattern (timing) of your heating. The more you used to rely on timed heating with a fossil fuel boiler, the more this will apply to a heat pump system.

I have deliberately used disparaging words about heat pumps (incapable, feeble, can't recover etc) because that is the reality when they are compared to fossil fuel boilers. Prospective heat pumps owners may well want to be aware of theses realities, and more importantly, the fact that they have consequences.

But I still have a heat pump. So they can't be all bad, can they?

PS I have just checked for new posts while writing this and see there are some, will reply to them separately. Going to post this now, before it gets even longer (and even more boring!).

Midea 14kW (for now...) ASHP heating both building and DHW

[quote data-userid="5190" data-postid="19305"

A volumiser in the primary, together with a good insulation of the PHX to reduce delta T to around 1C maybe, might well help, but its a sticking plaster. The real question is - why bother with the PHX at all? Its introducing uncertainty, a loss in flow temperature, and reducing the volume directly available to the HP which has got to be a bad thing. What value is it adding?

The phx allows glycol to be used outside, water inside, thus reducing the quantities needed. Of course there are other solutions to this issue. Insulating it won’t make much difference - a larger phx would reduce the Tglycol-in to Twater-out.

Apols for badgering on this topic about other controls, but do you really have just have weather compensation only running ? As I understand it, WC is purely open loop. If you chose even slightly wrong, your house would be too hot or too cold. I’m surprised there’s no target temperature anywhere?! If there is, the WC just makes your heatpump operate at reduced power as it warms up outside, and clicks in/out with a software thermostat somewhere. Apols again for sounding like a broken record. Test it - if you use a higher WC curve, does your house get warmer ? If not, there’s a thermostat somewhere.

Posted by: @sunandairI am finding this thread somewhat confusing as my brain

overloads when data takes priority over basics.

I know the feeling! I have been known to say you only need one meter for a heating system, and it is inside you. If you are warm and comfy, then the system is working. More formally, instead of looking at structure (how many rads etc do I have?) and process (how do I heat them?), focus instead on outcome (am I warm and comfy?).

My set up is one primary circuit with a diverter valve that puts the primary flow either through the plate heat exchanger or through the DHW tank. The plate heat exchanger then heats a secondary circuit that goes round the house ie to the rads. Each circuit has one pump. The primary one appears to run at a remarkably constant rate (see charts), so the implication is that it isn't used to control output, even if it potentially has the ability to be externally controlled (see other posts elsewhere). The secondary circuit has a basic pump that is effectively always on when the heating is on. There is no LLH, just the PHE, which does of course mean there is hydraulic separation.

I do believe the relatively high thermal mass in a small building is relevant to how my house reacts to periods of heating and non-heating, notably in evening out temperature fluctuations when running a timed system. But there is also a negative consequence, by switching to a relatively feeble heat pump (roughly half the max power output of my old oil boiler), I can only get very slow recovery from setbacks. This is the main reason why my heating needs to be on 24/7.

Posted by: @jamespaReading the above I think there is a large measure of agreement that

- the difference in operating conditions vs the oil boiler, and

- the adverse effects of the PHE,

are major contributors.

I agree, especially on the former. And I also think the cycling may well be important. It is certainly worth trying to reduce it, if only to reduce wear and tear.

Posted by: @jamespaAt high OATs cycling is inevitable, my concern is that this may be happening at lower OATs. Your most recent plot doesn't really give us enough to go on to tell whether this is occurring or not (it suggests it might, but its not conclusive). However I don't think we can yet rule it out.

I think the 3rd April data I posted earlier shows periods of cycling during low OATs, eg 0000 to 0200 and either side of the defrost cycles. What is completely opaque is why some of the time it runs at a reasonably steady state, at others it cycles. It is also rather disappointing that at around 7 degrees and above OAT, cycling is virtually constant.

Posted by: @jamespaIt really would help to know what controls the secondary pump and how the primary and secondary flow rates are related,

See earlier reply (secondary pump is very basic, internally controlled). So far as I can see, the primary and secondary flow rates are totally independent of each other, neither has the slightest clue what the other is doing. Furthermore, it looks as though the primary pump, although it can be externally controlled isn't, or if it is, it is controlled to have a constant flow rate (as seen on the charts).

I am becoming persuaded removing the PHE is worth the hassle. Doing so will automatically significantly increase the circulating volume in the primary (and once the PHE is removed, only circuit), and may perhaps even be enough to in effect add a volumiser, if that makes sense. Headroom Heat Pumps used to make a big fuss about not fitting or heaven forbid removing PHEs (pop goes your warranty) but they have relaxed somewhat and @batalto got clarification from them that removing his PHE (or LLH, whichever it was) would not void his warranty. If I do remove it, it means I will have more glycol in the system (at the moment it is only in the primary circuit), should we perhaps consider whether this will have any meaningful detrimental impact on performance?

Posted by: @jamespaIm not sure further staring at the data (with the exception of the specific data mentioned above) is going to help a lot more. It needs some experiment, if you are brave enough to do it of course. Otherwise I think you are going to have to live with a SCOP of perhaps 1.5-2 most likely due, it would appear, to a system the configuration of which is, sadly, sub-optimal.

I agree about staring at the data. Lack of courage and unwillingness to experiment is not normally something I am known for, after all I put a heat pump in a building many said would fail, and by and large it hasn't been a failure. I've also been happy to experiment with the modbus connections and data collection, which meant sticking wires and screwdrivers inside the wired controller (what could possibly go wrong?). But I don't agree about the low SCOP. I think mine is about 3 (which I can live with) but it gets swallowed up by/disappears because of the need to heat the house for much longer periods: very crudely, it runs at a COP of 3, but for three times as long, and so the COP 'efficiency' appears to disappear (but it is still there, in that the building is warmer for longer).

Posted by: @roblApols for badgering on this topic about other controls, but do you really have just have weather compensation only running ? As I understand it, WC is purely open loop. If you chose even slightly wrong, your house would be too hot or too cold. I’m surprised there’s no target temperature anywhere?! If there is, the WC just makes your heatpump operate at reduced power as it warms up outside, and clicks in/out with a software thermostat somewhere. Apols again for sounding like a broken record. Test it - if you use a higher WC curve, does your house get warmer ? If not, there’s a thermostat somewhere.

Yes, as far as I know, I only have weather compensation as the control: the simple straight line between the upper and lower ambient temps, and the respective LWTs. There is I believe a thermostat in the wired controller, but that only comes into play if you turn weather comp off, and I definitely have weather comp turned on, you can see it altering output (changes in LWT) in many of the charts I have posted as ambient outdoor temp changes. There are also times when I have changed the curve settings, and yes, a higher curve does increase the temperature. The only active thermostat in the system is the room stat in the kitchen, and that is effectively neutralised by setting it either very high or very low, ie it becomes the on all the time/off all the time switch for the heating.

I think it's normal not to have a target temp set anywhere in the system in a weather comp set up. Instead, the owner has a target temp 'in mind' (literally) and then tweaks the curve until he or she gets pretty much gets the room temp to match the 'in mind' target temp. This is exactly what I did, and I now have a curve (58 @ -4 / 35 @ 15) that pretty much does what I want on average days. Worth noting that, at least on Midea systems, the 'curve' flat lines either side of the ambient set points, which is why I have moved my lower ambient from 55 @ -2 to 58 @ -4 (so it gets a fraction more umph when it is -4 compared to -2 outside). I also needed to up the LWT at the other end from 30 to 35, but that may have been a fraction too high recently, as solar gain became more common.

Midea 14kW (for now...) ASHP heating both building and DHW

Can confirm, they (Freedom) said I could take out the LLH with no impact as long as it was done by someone they work with.

No negative impacts at all from what I've seen and the data suggests a significant benefit at lower outside temperatures. When the weather is warmer it has a limited benefit, but i use much less power anyway?

Posted by: @bataltoCan confirm, they (Freedom) said I could take out the LLH with no impact as long as it was done by someone they work with.

No negative impacts at all from what I've seen and the data suggests a significant benefit at lower outside temperatures. When the weather is warmer it has a limited benefit, but i use much less power anyway?

Thanks for confirming, much appreciated.

Midea 14kW (for now...) ASHP heating both building and DHW

It is not that heat pumps are badly designed, in fact it is probably the opposite, it is that heat pumps are not designed to be operated in the same way as a gas or oil boiler.

With a gas or oil boiler it is possible to obtain a large amount of thermal energy over a relatively short time period, and this can be done without adversely affecting the overall efficiency. You could have installed two 16kW heat pumps at your home, which could output approximately the same amount of thermal energy as your old oil boiler, and if you ran the heat pumps to produce a LWT of 60C or even 65C, they could have been operated in the same manner as your oil boiler, with slightly better efficiency than the oil boiler.

The sizing of a heat pump, to a home, is a compromise, since it needs to be large enough to meet the maximum anticipated heat demand, but also small enough to be able to achieve the maximum turndown during milder weather conditions. I am surprised that no manufacturer has yet developed a heat pump unit containing two compressors, one to do say 67% duty and the smaller one to do the remaining 33% duty.

To have a system that could perform in a similar manner to your oil boiler, an A2A ASHP would probably have been a better solution. Our small A2A unit can raise the indoor temperature by approximately 1C within a 30 minute period, since it heats the air directly, rather than via a number of heat exchangers and heat emitters. You could consider having A2A units installed in the normally used roomsould , to provide quick heat up during the morning period, which would provide plenty of time during the day for your Midea unit to heat up your home for the evening period. Such a system could provide a number of benefits:-

The whole system could be shutdown overnight.

The A2A system could heat up the required rooms fairly quickly with minimum energy usage and cost.

The A2W system could gradually heat up your home during the daytime period when the heat pump will likely be operating more efficiently. If the required temperature has not been achieved, the A2A system can provide additional heating fairly quickly.

Whilst there appear to be fundamental design issues with your present system, you could, as stated, consider removing the PHE, but instead of refilling the system with a glycol mixture, fit automatic drain valves to protect against freezing.

To try to reduce the frequency of cycling, I would suggest that you try the following:-

Set the warm end of the WC curve to 40C.

Lower the setting of your kitchen thermostat to 1C above desired temperature.

If the thermostat has an adjustable deadband then set it at 1C. i.e. switches heat pump on at 19C, then switches heat pump off at 20C.

Posted by: @derek-mWhilst there appear to be fundamental design issues with your present system

It is a bog standard Freedom installation, my installer had their installation manual in his hands as he did it, as far as the heat pump piping is concerned. It does seem remarkable that major suppliers like Freedom don't seem to know whether the LLH/PHE is necessary or not. Not so long ago Freedom said you had to have one, otherwise your warranty was void. Currently I think they recommend them. As @batalto has confirmed, they are also happy for them to be removed. Such clarity!

In any event, I am going to talk to my installer (who is someone Freedom work with) and see if we can remove it. I will also weigh up the pros and cons of AF valves, in particular what happens if (a) you are away (b) while you are away, there is a power cut during a cold spell, and pop go the valves, and then (c) the power comes back on, also while you are away. Does the pump run dry, or does it sense no fluid and not come on, leaving the main house pipework vulnerable? By and large, with something like this, I prefer fail-safe systems.

I do know heat pumps are designed to be run differently to fossil fuel boilers, I've always assumed the drive towards high COPs means low LWTs and that in turn limits outputs. If it's not the design is bad, which I concede, insofar as they do what they are designed to do, then the concept has a flaw, a sort of can't have your cake and eat it flaw: you can't have a high COP and high output. That said, I think there is a solution, the adaptive weather compensation curve. There are reports from Ecodan owners that their heat pumps do adapt to more than just the ambient temp, and I have previously described how it might be possible to do something similar over modbus. Although it is not entirely clear what Homely does, it may also use an adaptive curve. It is notable the only brands it currently works with with are modbus enabled brands.

Posted by: @derek-mTo try to reduce the frequency of cycling, I would suggest that you try the following:-

Set the warm end of the WC curve to 40C.

Lower the setting of your kitchen thermostat to 1C above desired temperature.

Can I clarify this? By warm end, I take it you mean the warm ambient end (right hand end), not the warm LWT end (left hand end). At the moment, mine is currently 35 @ 15, and in the recent milder weather plus some solar gain the house was getting above design temps eg 21 for an 18 degree design temp. If you mean the warm LWT end, 40 degrees won't cut it, it needs to be in the 50s, or perhaps these settings only apply in milder weather say early autumn and late spring, in effect manually applying the sort of logic I am hoping to use modbus to achieve automatically.

If I lower the kitchen stat to design + 1 (ie 19) won't it just cause cycling?

As I am now no longer running the central heating, these tests will have to wait until a cold snap makes me put it on again, or next autumn, but it would be useful to have answers now, so the questions are neatly tied up before we enter the glorious days of summer.

Midea 14kW (for now...) ASHP heating both building and DHW

Posted by: @cathoderayBut therein lies my confusion: the only determinant of energy delivered (in this case) is delta t, which is a relative measurement that takes no account of absolute temperature. That means if my system runs one one occasion with a LWT/RWT of 25/20 degrees and on another with a LWT/RWT of 50/45, it still delivers exactly the same amount of energy. This is, at least for me, counter-intuitive, as in the second case, they system is running twice as hot.

You are mixing up cause and effect. The heat delivered by the heat pump to the system absolutely is equal to (mass) flow rate * specific heat capacity of the medium x deltaT. Thats just basic physics and its not dependent on steady state.

However this is a result of heat lost at the emitters which is dependent on the temperature difference between the emitter and the room (in the case of the radiator, raised to the power 1.3). The HP adjusts the amount of heat it delivers to the water to match the heat lost by the radiators and maintain the delta T it targets.

If you bypass/remove the PHE you should see better performance and defrost and probably (but only probably) less cycling. Like @derek-m Id consider antifreeze valves instead of glycol (ie water in the system), or alternatively you might fill it with water initially then add glycol once the change is permanent. Once this is done you can look at further tweaks and deal with any remaining material cycling.

Many heat pump controllers do provide for set back, from what you say Midea does not. However you can get Homely which attaches to Midea and does a whole range of useful things including set back, if you don't care to program

Heat pumps are like any other technology, they have good points and not so good points. Fossil fuels require either that you pipe an explosive gas into your home or that you have an ugly tank in the garden. They can deliver lots of instant heat but are pretty inefficient if you want constant or near constant heat. They contribute massively to global warming.

Heat pumps, on the other hand, are very efficient if you want constant heat and a bit less so if you don't. They deliver a high level of comfort for less energy use and there is no need for explosive gasses or ugly tanks. They contribute to global warming only about one quarter as much as fossil fuel boilers, and that will steadily reduce over the next couple of decades.

The problem is that salesmen only tell you the advantages, leading to inevitable disappointment (again true in many technologies), and this is compounded by the fact that the relative running costs are driven by both global and local politics, so are unstable and unpredictable.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

Sorry, I should have clarified, it is the high ambient end of the curve, so changing the present 35C to 40C. It will indeed cause cycling, but hopefully at a much slower rate than at present, since it would be heating up over a longer period, and then shutting down for an extended period whilst the indoor temperature falls. The problem with home heating systems is the range over which they are required to operate, from no heating at all, to maximum output on some occasions, trying to deal with that is a control systems nightmare.

Whilst adaptive control may help keep the indoor temperature more constant, there are situations when it may use more energy. If the heating system reduces output or even shuts down during the warmer part of the day, when the heat pump would operate more efficiently, it may then have to work harder at nighttime to maintain the desired indoor temperature. There is no bog standard control philosophy that meets all requirements throughout the whole year.

Posted by: @jamespaIf you bypass/remove the PHE you should see better performance and defrost and probably (but only probably) less cycling. Like @derek-m Id consider antifreeze valves instead of glycol (ie water in the system), or alternatively you might fill it with water initially then add glycol once the change is permanent.

I guess one advantage of a PHE over a LLH is that there won’t be any mixing between Flow and Return. However is there a quantifiable energy loss through the plates of the PHE?

I think I read somewhere that not all PHE’s are equal in that some are made of plastic plates and some are brazed copper plate construction giving much higher heat transfer efficiency?

The added material/energy demand would, like any hydronic separation, be the cost of installing a second pump and the energy to operate that pump annually.

is it fair to say that the industry stated these were required particularly for the retrofit business as some sort of guarantee that the system would work EVEN WITH bad or unknown existing pipework?

Perhaps installation expedience within the industry has overtaken efficiency goals?

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 335 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Electricity price predictions

I am always impressed with how you keep abreast of so m...

By Batpred , 8 minutes ago

-

RE: Setback savings - fact or fiction?

I fully understand your reasoning, same steady inputs s...

By cathodeRay , 17 minutes ago

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

@majordennisbloodnok I’m glad I posted this. There see...

By AndrewJ , 39 minutes ago

-

RE: What determines the SOC of a battery?

@batpred I didn't write the Seplos BMS software, I a...

By Bash , 2 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@tasos and @cathoderay thanks. I have some history grap...

By benson , 2 hours ago

-

I am having my existing heat pump changed to a Vaillant...

By trebor12345 , 3 hours ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 3 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

Just to wrap this up here for future readers: The S...

By Batpred , 6 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 6 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 8 hours ago

-

@painter26 — as @jamespa says, it's for filling and re-...

By cathodeRay , 11 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 22 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 1 day ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 1 day ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 1 day ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 1 day ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago

-

RE: DIY solar upgrade - Considering adding more panels

I know this is a bit old, but it made me wonder what co...

By Batpred , 2 days ago