Posted by: @iancalderbankI am now able (via modbus , from HA) to control the target LWT directly

As I think you know, I am planning to do something similar (control via modbus, using python plus minimalmodbus) with my Midea heat pump. Just a thought: I was going to directly set the LWT as well, but it then occurred to me the internal Midea controls may constantly over-ride my set LWT, perhaps better, if you can, to set the weather compensation curve end points, just as if you had done it manually, then the heat pump internals will just operate as if you had set it manually, and set an appropriate LWT.

Midea 14kW (for now...) ASHP heating both building and DHW

@cathoderay yeah good idea, but samsung doesn't have modbus registers for the WC points (yes I know derek will say "ah thats just because they are undocumented") but... I have no idea what they would be if they did exist!

also, I've noticed that with my physical setup the HP's OAT sensor is very sensitive to whether the HP is on or not. It seems to picks up a bit of draught no matter which way I align it. so I lose up to 1C of "OAT as viewed by the HP" when the HP is running. which of course you'd expect to alter the WC temp calculated by the HP itself. So I may calculate an average OAT over the last X mins using an external sensor or three rather than relying wholly on the samsung outdoor unit's OAT.

FYI I will probably start writing my (shoddy, because I'm not a s/w engineer) attempt at a control system in NodeRed. HA's native automation scripts, I freely admit, are not the easiest to work with.

My octopus signup link https://share.octopus.energy/ebony-deer-230

210m2 house, Samsung 16kw Gen6 ASHP Self installed: Single circulation loop , PWM modulating pump.

My public ASHP stats: https://heatpumpmonitor.org/system/view?id=45

11.9kWp of PV

41kWh of Battery storage (3x Powerwall 2)

2x BEVs

Posted by: @iancalderbanksamsung doesn't have modbus registers for the WC points

That's a pity. Luckily the Midea manual does document the registers to set (and get) the weather comp curve endpoints (complete with typos), and a quick test earlier in the year confirmed modbus could be used to set them. @derek-m may have a point (when he does chip in and say it is there but undocumented on the Samsung because Homely can be used to control a Samsung, and I suspect it will do it by changing the WCC set points). You could also try to find the addresses empirically, if you know what the WCC is set to from the Samsung controller, then look for an address that contains that value, change it manually and check again. A quick and dirty python loop could do the 'gets' (for a in 0 to 100 get address(a) sort of thing).

Posted by: @iancalderbankHP's OAT sensor is very sensitive to whether the HP is on or not.

Isn't this a general effect, the ambient air around a heat pump is cooler when it is running? I'm considering, but haven't yet implemented, and third party OAT sensor placed away from the heat pump for just the same reason.

Posted by: @iancalderbankHA's native automation scripts, I freely admit, are not the easiest to work with.

Maybe time to watch out for a knock on the door from the HA Inquisition. They don't suffer heretics gladly, as I know only too well...

Midea 14kW (for now...) ASHP heating both building and DHW

Posted by: @iancalderbank@cathoderay yeah good idea, but samsung doesn't have modbus registers for the WC points (yes I know derek will say "ah thats just because they are undocumented") but... I have no idea what they would be if they did exist!

also, I've noticed that with my physical setup the HP's OAT sensor is very sensitive to whether the HP is on or not. It seems to picks up a bit of draught no matter which way I align it. so I lose up to 1C of "OAT as viewed by the HP" when the HP is running. which of course you'd expect to alter the WC temp calculated by the HP itself. So I may calculate an average OAT over the last X mins using an external sensor or three rather than relying wholly on the samsung outdoor unit's OAT.

FYI I will probably start writing my (shoddy, because I'm not a s/w engineer) attempt at a control system in NodeRed. HA's native automation scripts, I freely admit, are not the easiest to work with.

Well done Ian.

If you can actually write to the Target LWT register, and it retains the setting, then this would probably be easier than modifying the WC curve settings.

What is the resolution of the register, does it only accept integers or can you set a decimal place or two?

If you need any help in developing suitable control equations I may be able to assist.

Posted by: @derek-mand it retains the setting

I think that is going to be the problem - won't the internal Samsung control circuits constantly set the LWT to what it thinks it should be, and so over-ride any other externally set setting? In practice, it should be easy enough to see whether this happens, set the LWT over modbus yo something different enough to be obvious, and see whether it stays the same, or changes.

Midea 14kW (for now...) ASHP heating both building and DHW

Posted by: @cathoderayPosted by: @derek-mand it retains the setting

I think that is going to be the problem - won't the internal Samsung control circuits constantly set the LWT to what it thinks it should be, and so over-ride any other externally set setting? In practice, it should be easy enough to see whether this happens, set the LWT over modbus yo something different enough to be obvious, and see whether it stays the same, or changes.

Also try the same test with the controller in fixed LWT mode.

@cathoderay @derek-m thats exactly what I did already - that is in fact the only way this works. you change the configuration of the HP so that it is in fixed LWT mode - i.e. turn off WC, then it retains the LWT setting that you write by modbus. the target LWT is exactly what I tell it to be. tested this afternoon. not sure about the resolution yet.

My octopus signup link https://share.octopus.energy/ebony-deer-230

210m2 house, Samsung 16kw Gen6 ASHP Self installed: Single circulation loop , PWM modulating pump.

My public ASHP stats: https://heatpumpmonitor.org/system/view?id=45

11.9kWp of PV

41kWh of Battery storage (3x Powerwall 2)

2x BEVs

Posted by: @iancalderbankit is in fixed LWT mode - i.e. turn off WC, then it retains the LWT setting that you write by modbus. the target LWT is exactly what I tell it to be

That makes sense, and then you set up your own adaptive WCC. It will be very interesting to have feedback on how you get on.

Midea 14kW (for now...) ASHP heating both building and DHW

I'm expecting adding simple WCC to this to be mathematically trivial - its should just a case of calculate the value of a point on a straight line, then send that value to the target LWT. The "adaptive" part will be the interesting bit!

the first thing I am tempted to have a go at is an anti-short(ish)-cycling control. having just put the heating on last week, I now have several runs with low LWT (33C) in mild weather (12C), its clear that the system cycles because the min output of the HP (about 3kw) is higher than the emitter output at this LWT (2 - 2.5 kw), so the actual LWT inevitably goes higher than the target LWT, and so the compressor switches off, waits long enough for the actual LWT to cool down, then comes on again. I'm seeing cycles with an 8-10 min periodicity.

my thought was to do this

- when the compressor OFF period starts (detected by electrical load drops to the standby level) decrease the target LWT by N degrees C (intended effect is that the OFF period lasts longer because it waits longer - for an additional N degrees of cooldown - to come back on)

-after the initial 2 mins of the compressor ON period (that seems to be how long the compressor startup electrical load takes to drop off), increase the target LWT by N degrees C (intended effect is that the ON period lasts longer)

with the objective being to make the more efficient behaviour seen in the first 40 minutes , be present in the subsequent cycles. N is unknown at this point of course, that'll be the experiment. note that during all this period heat demand = ON as measured by target vs actual IAT, we're not going to be using that as a means to control cycling as its changing very slowly.

The other thing I want to try is a "slow run up" at DHW. when the system goes into the factory DHW mode it sets the target LWT immediately very high and runs the compressor flat out with high electrical power, as we all know. I want to try 1) move the 3 way valve to DHW but not put the system in DHW mode , still in CH mode but the flow is going to the DHW 2) increase target LWT from the low level (32C say) slowly, perhaps 1C every minute , until after 25 mins we're at 55C ish target LWT - and see what the difference is

thoughts?

My octopus signup link https://share.octopus.energy/ebony-deer-230

210m2 house, Samsung 16kw Gen6 ASHP Self installed: Single circulation loop , PWM modulating pump.

My public ASHP stats: https://heatpumpmonitor.org/system/view?id=45

11.9kWp of PV

41kWh of Battery storage (3x Powerwall 2)

2x BEVs

You are indeed correct, calculating the required LWT from the OAT reading is a simple mathematical formula. I would suggest that you incorporate the WCC settings as individual variables within operating program, so that it will be an easy process to vary the underlying curve.

I would recommend using a Proportional Action (P) and Integral Action (I) solution for adaptive control, details of which I have posted previously, but can do so again if required.

Your idea to reduce cycling frequency sounds similar to my suggestion of using a basic thermostat to start and stop the heat pump. Rather than using a thermostat, you should be able to use the IAT reading from your sensor and set operating limits around the desired indoor temperature setting. Something along the lines of:-

If the IAT is 0.5C below the desired temperature setting, set the required LWT at the value required to run the heat pump at constant minimum output.

If the IAT is 0.5C above the desired temperature setting, set the required LWT at a value that will ensure the compressor does not run.

Obviously it will be necessary to try different values of LWT to obtain the optimum running parameters.

Posted by: @iancalderbankThe other thing I want to try is a "slow run up" at DHW. when the system goes into the factory DHW mode it sets the target LWT immediately very high and runs the compressor flat out with high electrical power, as we all know. I want to try 1) move the 3 way valve to DHW but not put the system in DHW mode , still in CH mode but the flow is going to the DHW 2) increase target LWT from the low level (32C say) slowly, perhaps 1C every minute , until after 25 mins we're at 55C ish target LWT - and see what the difference is

Are you on a variable rate electricity tarrif? I have 3 hours of cheap overnight electricity (2am -5am) and during this period I want to:

- Heat the underfloor area of my home to a higher than normal temperature (22-23°C)

- Heat the DHW to a higher than normal temperature (55°C)

I have set the heat pump to run a DHW cycle for maximum of 60 minutes which leaves 2 hours for underfloor (and during very cold periods, downstairs radiators).

In my situation, I think the optimised DHW heating cycle would be useful during the day, but during the cheap window, I would possibly still want the DHW cycle to run flat out, especially when it is cold outside.

@redzer_irl yes on Intelligent Octopus. so 6 hrs cheap. I run the DHW during this period in the winter. I'm just interested to see how the DHW cycle behaves if the target LWT is slowly wound up rather than set to max from the go i.e. to answer the questions is the cop better or worse? overall energy use? reheat time?

My octopus signup link https://share.octopus.energy/ebony-deer-230

210m2 house, Samsung 16kw Gen6 ASHP Self installed: Single circulation loop , PWM modulating pump.

My public ASHP stats: https://heatpumpmonitor.org/system/view?id=45

11.9kWp of PV

41kWh of Battery storage (3x Powerwall 2)

2x BEVs

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 852 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

That’s my pleasure, @andrewj. The only challenge now is...

By Majordennisbloodnok , 6 hours ago

-

RE: Electricity price predictions

@toodles @skd Then there is not going to be much from t...

By ChandyKris , 7 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

@batpred I reckon Andy might know a thing or 2 about...

By Bash , 7 hours ago

-

RE: What determines the SOC of a battery?

@batpred Ironically you didn't have anything good to...

By Bash , 8 hours ago

-

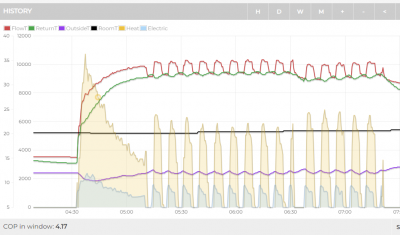

RE: Testing new controls/monitoring for Midea Clone ASHP

Here’s a current graph showing a bit more info. The set...

By benson , 8 hours ago

-

RE: Setback savings - fact or fiction?

True there is a variation but importantly it's understa...

By RobS , 8 hours ago

-

Below is a better quality image. Does that contain all ...

By trebor12345 , 9 hours ago

-

Sorry to bounce your thread. To put to bed some concern...

By L8Again , 9 hours ago

-

@painter26 — they (the analogue gauges) are subtly diff...

By cathodeRay , 9 hours ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 13 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 16 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 18 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 1 day ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 1 day ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 2 days ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 2 days ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 2 days ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 2 days ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 2 days ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 2 days ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 2 days ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 2 days ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago