Midea ASHP – how to set weather compensation

@pash44pump what we did to resolve a not too dissimilar issue with our installers was to simply provide them some screenshots of our graphs showing IAT, OAT, and flow temp over a 24 hour period or so- as Cathoderay says the proof is in actually whether it works, rather than heat loss estimations. For us this clearly evidenced that a max flow temp of 45 (which they specified would be required to meet design temp at -2) was not enough to keep the house warm enough, when it was between 0 and -2 outside.

Hope you get it all sorted.

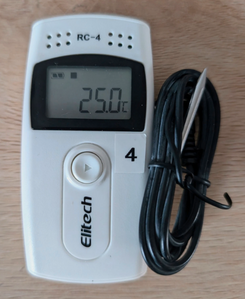

@pash44pump - to collect the IAT/OAT data, can I suggest you get a couple (more if you want) of these RC-4 data loggers:

Ebay listing here, these are used but look OK to me, under a tenner each. New ones are also available for about £20, see also on Amazon. They run for ages off a button cell, logging the air temperature at whatever interval you specify (I use an hour). You can then download the data over USB in spreadsheet format using a rather clunky software interface and produce whatever charts take your fancy.

I haven't done it (because I get the data via the wired controller), but it may also be possible to record at least an approximation to the flow temp, by taping and then insulating the supplied external probe onto the primary flow pipe. For air temps, you don't need the external probe.

I can go into more detail later if necessary, but there is one potential difficulty: the time stamps in the two (or more) data sets are different eg one data logger records the temp at nine minutes past the hour, the other at ten minutes past the hour, ie the data is out of sync, which can make for awkward plotting, but there are ways round this eg just remove the minutes (datetime stamp becomes yyyy-mm-dd-hh, but you do have to be careful, spreadsheets can be very annoying in the way they handle date/time) .

Midea 14kW (for now...) ASHP heating both building and DHW

@benson thanks. @cathoderay suggests using data loggers to collect the data. How did you do it? Same method or different?

@pash44pump at the time I was using the homely installer dashboard, as this is what I had initially installed as the controls. This provided plots of all of the different running parameters on an easy to read graph, if you registered as an installer and got access via the backdoor to speak (homely don't really want customers seeing the data for some unfathomable reason). You can see in this screenshot with the max flow temp set at 46, that the IAT would struggle to reach 20 when outdoors it was around zero degrees C, and this is what I used to evidence our particular case.

screencapture-dashboard-homelyenergy-charts-d4-d4-da-14-58-88-2025-01-04-21_37_04.pdf

I now use home assistant and a svenar heat pump controller (which basically allows integration of the controls and measurement parameters from the heat pump in HA and connects via modbus) due to a few issues with homely, and this essentially provides the same thing. I have a tp link temp sensor again all integrated within HA, which measures the indoor hallway temp. The below is a screenshot where I have just isolated the outlet temp and the hallway temp sensor. Obviously the outlet flow temp at the moment is just for hot water.

I don't know if you use HA. I'd probably class myself as a beginner, but it is quite easy to set up. Others might be able to advise on a simpler or indeed cheaper solution but this is what I have done. I can also adjust the WC parameters vi HA as well. I went for the ready made home assistant green which was even easier to get all up and running. Likewise the svenar controller is an out of the box solution made by a chap called Sven who lives in the netherlands....clearly a small business/DIY type setup but I really like it thus far.

I think cathoderay would have been recommending those devices as the cheapest starting point to logging data. CR is far more knowledgeable than I when it comes to this sort of thing so may be able to provide further advice.

Posted by: @bensonI don't know if you use HA. I'd probably class myself as a beginner, but it is quite easy to set up. Others might be able to advise on a simpler or indeed cheaper solution but this is what I have done.

HA does work for some, but I found it over-complicated, a bit like using a sledge hammer to crack a nut. I do in fact still have it installed, but my primary monitoring is done over modbus (Midea and Midea clone heat pumps make this relatively easy) using python scripts (which is what HA does under the hood). The raw data ends up in csv files, not a temperamental database setup (HA uses sqlite which is OK until HA corrupts the main database file) and can be plotted either in any spreadsheet or using something a bit more chart focused like plotly in python (see the chart I posted recently for an example). The other advantage of this approach is you can do DIY 'smart' controls' eg my auto-adapt script which tweaks the weather curve and thereby the LWT in response to the IAT being too low or too high.

The weak points in Midea based monitoring are the IAT and OAT. The former uses a sensor in the wired controller, nut much use if the wired controller is in a non-living space (mine is in the airing cupboard), and the OAT sensor is in the heat pump, believed to be near the air intake, meaning it is in fact the air intake temp, close to but not the same as the OAT. The IAT I now monitor with a separate modbus temp sensor place centrally in the living space.

@pash44pump - it all depends how much time and money you want to invest. Some time ago I wrote a guide on how to do it the way I did it, see here, so far complete apart from the code details which I have for my sins never got round to posting. But it will give you an idea of what is involved if you do go down this route. The reward is very robust and detailed monitoring.

Midea 14kW (for now...) ASHP heating both building and DHW

@cathoderay is one possible slight advantage with the HA setup the ability to integrate a wireless smart temp sensor?

I've also got an auto adapt of sorts via an automation to lower the curve if the IAT rises. Yet to be tested though.

Posted by: @bensonis one possible slight advantage with the HA setup the ability to integrate a wireless smart temp sensor?

I think the setup I have could use wireless sensors, the mini-pc has a wireless card, but being paranoid about some joker dialing my DHW temp up to 90 degrees I chose to go down the wired route. It's also simpler, two wires, no networking hardware or configuration to set up.

Posted by: @bensonI've also got an auto adapt of sorts via an automation to lower the curve if the IAT rises. Yet to be tested though.

I am sure that is possible, and once you test it, plus or minus a few tweaks, it will work. But I think, being HA, the code will be less human readable. One thing to watch out for if you haven't, make sure you don't have anything that can do a runaway continuous positive feedback thing. You don't want your heat pump to do this:

Midea 14kW (for now...) ASHP heating both building and DHW

@pash44pump My opinion on data collection is the following:

Regarding OAT, I would use the pump's sensor, since it is this value that the system uses to control outflow water temperature.

Regarding, IAT, I would use the wired controller's value, if it is correctly positioned, i.e. in a "representative" location, away from heating or cooling sources.

These 2 values, together with water temperature can be initially monitored manually for a period of 16 hours (that is 24 minus sleep).

Your installer can also record these values I think, by connecting remotely to the wired controller.

I assume these would be enough to decide what is wrong with the installation.

My feeling is, the system will be adequate for the UFH of the ground floor, but not for the whole house.

Midea MHCV10WD2N7 R290, 4.8kW peak energy community solar power.

Posted by: @tasosThese 2 values, together with water temperature can be initially monitored manually for a period of 16 hours (that is 24 minus sleep).

Your installer can also record these values I think, by connecting remotely to the wired controller.

I don’t get how you’d do this effectively without something collecting the data and plotting it on a graph, over time. Snapshot data manually read from the control panel every now and again is surely of limited use?

@benson I believe, noting the data in 16 hourly intervals should be more than enough for the purpose we are discussing (after the system has been working for some days). That is if the user is willing to do it. Otherwise, of course he may invest in the other things that have been suggested.

Midea MHCV10WD2N7 R290, 4.8kW peak energy community solar power.

Posted by: @tasosRegarding OAT, I would use the pump's sensor, since it is this value that the system uses to control outflow water temperature.

Regarding, IAT, I would use the wired controller's value, if it is correctly positioned, i.e. in a "representative" location, away from heating or cooling sources.

On the OAT, what you say is true, it is the value the system uses to set the leaving water temperature via the weather compensation curve, which I thought made sense, but @jamespa has done some work based on the fact the building, which is what loses heat, is sitting in another slightly different temperature. See again my recent plot with the OAT spikes (especially pronounced because they are associated with defrost cycles).

One the IAT, yes, fine if the wired controller is in a representative location, but what if it is not (mine isn't, it is in the airing cupboard, along with the DHW tank). An RC-4 data logger (like the one I linked to before) is the obvious simple inexpensive solution if the owner doesn't want to go down the full monitoring route. In fact, two RC-4s can take of both the IAT and the OAT.

There is really only one definitive test @pash44pump needs to do, record the IAT in one or more locations for a few hours minimum, preferably (much) longer, at a time when the OAT is at or very close to the design OAT. RC-4s can do that. Then plot the two on a chart and you have your answer.

Midea 14kW (for now...) ASHP heating both building and DHW

@cathoderay OK let's wait and see, it sounds an interesting exercise.

Midea MHCV10WD2N7 R290, 4.8kW peak energy community solar power.

Recently viewed by users: Judith 13 minutes ago, benson 23 minutes ago, pash44pump 28 minutes ago, JamesPa 31 minutes ago, Transparent 11 seconds ago.

- 26 Forums

- 2,158 Topics

- 47.4 K Posts

- 31 Online

- 5,736 Members

Join Us!

Podcast Picks

Latest Posts

-

Vaillant aroTherm Plus 10kW thoughts?

Hi, Any thoughts on this (larger) heat pump?...

By realevil , 4 seconds ago

-

RE: Midea ASHP – how to set weather compensation

@cathoderay OK let's wait and see, it sounds an interes...

By Tasos , 2 hours ago

-

RE: What is the Heat Geek Guarantee?

@judith, I’m with you on Heat Geek, but there really do...

By Mars , 3 hours ago

-

RE: Failing heat pump system - seeking thoughts on a rebuild

I couldn't agree more. This is a case where you buy as...

By JamesPa , 12 hours ago

-

RE: Electricity price predictions

Community energy installations are a great idea, but th...

By Scalextrix , 1 day ago

-

Inventor (Midea) Heat Pump short cycling advice

Hello, I have a Inventor (Midea) 8kW with a 800meters Φ...

By immunity , 1 day ago

-

RE: Can you help with our research: solar panels, EV chargers, home batteries, heat pumps?

I have signed up as well. @belsnugg could you outline ...

By JamesPa , 1 day ago

-

RE: New Vaillant aroTherm Plus in black - When will it come to the UK?

Ooh, heat pumps in neon blue wrap 🤣 🤣 &...

By Old_Scientist , 1 day ago

-

@profzarkov Good to know in case it ever happens to me...

By bontwoody , 2 days ago

-

RE: Are Octopuses Slowing Consumer Adoption of Heat Pumps?

I mean, is this surprising? The local installers in my ...

By Alex , 2 days ago

-

@old_scientist sorry, I should have made it clear that ...

By GrahamF , 2 days ago

-

RE: Mitsubishi Ecodan 11kw Defrosting Issue.

@thundermink can you provide photos to illustrate your ...

By Morgan , 2 days ago

-

RE: Boiling Mad: Exposing Radiatorgate

Hi @Rob, I’d be more than happy to contribute. I have ...

By DREI , 2 days ago

-

RE: Solar Power Output – Let’s Compare Generation Figures

@andris a great year - very happy with our system

By Profzarkov , 2 days ago

-

RE: A Customer's Lessons Learnt from a Heat Pump Installation in a Large House

After our rather lengthy meander off piste, I thought I...

By GrahamF , 2 days ago

-

RE: Ecodan software update. Real or scam?

@vinz86 Contact Mitsubishi and an engineer attends and ...

By ASHP-BOBBA , 3 days ago

-

@drei When I was in local government we were of cours...

By JamesPa , 3 days ago

-

RE: Heat Pump SCOPs – The Truth Might Not Be What You Think

Sufficient system volume is also essential for ensuring...

By Old_Scientist , 3 days ago