Help me understand my Mitsubishi Ecodan system

Hi everyone

With my new house came a nice and shiny Mitsubishi Ecodan air-to-water HP system with it's UFH (and ceiling) loops, buffer tank, valve actuators, zone controllers, circulation pumps and all bells and whistles. The only problem is: it's not very efficient + it short cycles like crazy. I'd like to get things in to improve it as much as I can but there are few conflicting information that I don't quite understand yet.

First, by monitoring the flow and return temps it seems to me that the heat pump doesn't really care about the buffer tank at all just provides a more or less constant flow temperature around the setpoint until it reaches about setpoint+2 C°, at which point the compressor stops and then starts again after few minutes starting from setpoint again. Strangely (or maybe not) it doesn't even have sensors past the box, so all it sees are the primary flow and return temperatures. I've read from multiple sources that the buffer tank should help avoid short cycling by storing some of the heat but I don't really see it happening here with this 2 C° delta.

But anyway, let's go further. It's not a good idea anyway to use the buffer tank for storing heat, right? So I read that it'd be more efficient to match flow rates in and out of the buffer to avoid distortion and disturbance of the water inside for optimal efficiency. I can kind of see that by putting in some effort I might be able to match that 25L/min flow that I can read from the heat pump. What it would cost is having a constant pressure, constant rate setup and losing all dynamic control. BUT it would be doable... for the winter. For summer however, when cooling kicks in I don't see how this would be viable at all: there's excessive solar gain on one side of the property in the morning and on another side in the afternoon, which means I need dynamic control. There's also the dew point to take into account for cooling so the mixing valve after the tank is absolutely necessary, which will decrease the flow from the tank, worsening the balance.

So to summarize: I can't really see myself going the balanced/open-loop route but maybe I could, I'm just overcomplicating it (?). On the other hand currently the heat pump doesn't seem to store any usable amount of heat in that buffer tank and it short-cycles a lot, so that's also not great.

I've talked to the installer who recommended a device that disables the heat demand signal if it detects overly frequent compressor starts but to me that seems like we are only treating the symptom.

Do you think everything is in order and I'm just chasing shadows or is there something I could do to improve the situation?

Welcome to the forums. Everything you’ve described points to a system that’s not set up to play to the Ecodan’s strengths. These units can perform really well, but they’re sensitive to poor system design, especially when it comes to flow rates and buffer implementation.

What’s happening in your system sounds like classic short cycling due to the heat pump “seeing” only the primary circuit and not the wider dynamics of your emitter side. If there are no sensors beyond the buffer, the heat pump has no idea what’s happening on the other side and just runs until its own internal return temp says “enough.” The 2C delta you’ve described is a dead giveaway… it’s trying to hit flow targets without any real feedback on what’s actually being used.

In theory, a buffer tank should absorb enough heat to smooth out these cycles, but in practice, it only works if your system flow rates and draw-off volumes are large enough to make a dent in the thermal mass. This is why buffer tanks and heat pumps are not usually good companions. If the load side isn’t pulling enough energy out quickly enough, or if flow imbalance is causing temperature distortion inside the buffer, then the heat pump’s just bouncing on and off unnecessarily.

I’d agree with your instincts that simply adding a device to block demand when the compressor starts too often is just papering over the cracks. It might reduce wear on the compressor in the short term, but it’s not fixing the underlying design flaw that’s causing the short cycling.

If you’re able to post the full flow schematic and any sensor data you’ve got, I’m sure a few people here would be happy to help you pick it apart and see where the improvements can be made.

Get a copy of The Ultimate Guide to Heat Pumps

Subscribe and follow our YouTube channel!

Fundamentally I agree with @mars and yes please post the full system schematic for detailed suggestions.

Seriously heat pumps work best when operated without zone valves, without buffer tanks, without mixing valves and certainly without bells and whistles. Ideally you would remove almost all of these and leave only the absolute minimum of controls needed to deal with the imbalance caused by solar gain. For summer cooling you would have the water emerging from the heat pump at a temperature just above dew point (some heat pumps natively support this - I don't know if Mitsubishi does or not).

I guess warranty issues may prevent you from actually removing controls/zone valves, but disabling them and adjusting flow rates so that the buffer does nothing is the next best thing.

if you post schematics as @mars says you will get plenty of suggestions.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

@gergoh Hello and welcome. I will try to help answer some questions respectively:

The less the HP cycles the better, imagine you have around 100-120,000 cycles on your compressor then its starts to be warn. you want to see if the system can cycle less than 40 times per day to get 15 years out of the system at least, some systems cycle as low as 12 which would give you a lot more years on the compressor. Its not a hard rule but a good guide. Most manufacturers say 3 time per Hr is fine.

A buffer is for mixed flows, most of the time you simply do not need them on a system as small as a house unless you need a hydraulic break, they have been around a long time in the heating industry. They often get designed in as manufacturers / installers are very unlikely to get warranty issues or calls for flow rates as the HP will be happy in a small circle heating the buffer not limiting flow, its also often used as its a ways to design and set the ASHP up to act like a normal boiler with TRV's for example, when the TRVs all close they only short out / stop the house circuit and do not stall the ASHP primary circuits avoiding flow issues, this is bad design, expensive to run and will cause more ware on your system over a long period but likely past the warranty cover stage. 2DT is bad, the system is just not commissioned correctly or is short cycling around the buffer, this would need rectifying if you want the system to cycle less and ware out less. Most ASHP are programmed to target 5 DT.

Buffer tanks are not for storing heat they hold no reasonable stored value and if anything reduce the efficiency of systems, they separate flow acting as a hydraulic break, you do not need this but the system will need to be balanced and commissioned to work properly after it is removed.

Unless all of your pipework is vapour sealed for condensation you will not be able to run this system in cooling for any meaningful value without causing rain in your house, water running off the pipes and so on.

Part open loop (in my opinion) is often a very good solution but most important is to have the system balanced so the ASHP runs at the correct 5/6 Deg DT across the whole system without a buffer. The key is to allow the system to flow unrestricted (like if it was through a buffer) but with heat exchange (which is what you do not get with a buffer, the buffer will only exchange its heat into the forward house circuit and if these are closed by valves stats and restrictors it does not exchange or transfer its heat, leading to cycling) The reason for part open loop is so you have what we like to call an over heat protection often needed in rooms south facing that may get solar gain, these rooms can have TRV's 2 deg above desired temp.

If you are able to justify the cost, it is probably worth asking a good ASHP company to look at this for you, modify the system and help improve it operation as it is very likely this will give you more years on the systems lifetime saving you money and potentially reduce your running cost over a long period saving you money.

I hope the above helps

AAC Group Ltd covering the Kent Area for design, supply and installation of ASHP systems, service and maintenance, diagnostics and repairs.

Professional installer. Book a one-to-one consultation for pre- and post-installation advice, troubleshooting and system optimisation.

Thank you so much for the input so far. I kind of thought that buffer tank is supposed to heat up/cool down cyclically to stretch the ON times of the compressor to avoid short cycling but I guess I was wrong and they are more complex than that.

@ashp-bobba Thanks for suggesting the part open loop solution, it would be the best of both worlds. I will get a good company if I can find one, perhaps even get rid of the buffer tank if I'm able to. First I'd like to understand what's going on before buying snake oil.

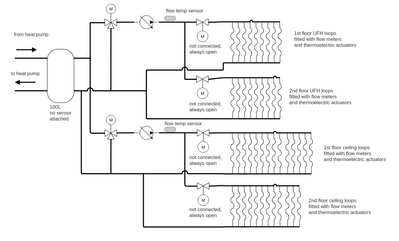

@jamespa @mars I did my best in collecting some info and drawing a diagram of the system.

This is the system as it is. I didn't include the lots of ball valves, balancing valves and air release valves as they are not active parts of the system. Also there's a DHW system that I didn't include here.

Every sensor and actuator is connected to a controller (called NGBS) that is only attached on the IN1 thermostat port of the heat pump, so it only gives an ON/OFF signal, nothing else.

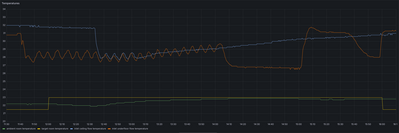

Here are some measurements during a period of heating: there was 2 rooms having demand, a small one about 12 m2 and a living room, that's about 35m2. That's 4 UFH loops in total, each being about 100m in length, set to between 2-3 l/min flow rate.

At a certain point ceiling also was enabled for the small room (it kicks in when there a larger delta between target and ambient temperatures), that's about 2x2 l/min flow rate.

It's important to note here that during this time the mixing valve was overriden to 100% open towards the buffer tank in order for the heat pump to be able to weather compensation correctly.

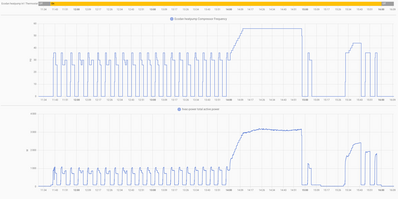

Heat pump operating mode, flow temperatures (primary circuit, sensors inside the indoor unit) and output power as reported by the unit:

IN1 thermostat input (heating demand), compressor frequency, input power (measured with a Shelly):

Ceiling and UFH circulation pump enablement signals:

Flow temperatures measured by the sensors next to the circulation pumps + ambient and target for the small room.

I hope it's not too much information. I was really trying to give you guys the right info but please tell me if something is missing or incorrect.

Thanks. Just a few more questions to get a handle on sizing

- What was the date of the plot and what was the approx OAT then?

- Which model ASHP do you have?

- What is the assessed heat loss of the house, whats the floor area and construction.

- If the zone valves are not connected, how come only some zones have demand?

- the motorized valves seem to be able to short circuit the system, is this correct? (or are they mixing)

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

@ashp-bobba I am watching this post with interest… I too have Ecodan, DT of 2degrees, and lots of short cycling (especially now the weather is warmer).

I can’t seem to find a way to stop the ASHP heating cycle when the outside temp is above 18 degrees - which seems really daft? (Unless I go to the controller and manually switch off the heating! - can’t even do that from the MELCloud app!)

- What was the date of the plot and what was the approx OAT then? Date was 19th April, OAT howered between 18C and 20C in this period.

- Which model ASHP do you have? It's a PUHZ-SHW112YAA + ERSC-VM2C combination, 11kW nominal capacity.

- What is the assessed heat loss of the house, whats the floor area and construction. The heat loss in total is ~0.225 W/m^3*K, total volume being 527.6 m^3, so 118.71 W/K is the calculated loss. Floor area is roughly 200 m^2 in total. Outer walls are 30 cm Porotherm clay bricks with 20 cm EPS foam insulation.

- If the zone valves are not connected, how come only some zones have demand? Sorry, I'm mixing up terminology here a little. The are 12 "virtual" zones throughout the house, each has a thermostat and a number of loops (both UFH and ceiling). Most zones are only one room, but there are some that are shared between multiple neighbouring rooms. The loops for each zone are switched together via the thermoelectric valves on the manifold. The zone valves on the schematic are partitioned entirely differently and honestly I don't know what use they have in the current system but they might actually be useful in a semi-open-loop scenario.

- the motorized valves seem to be able to short circuit the system, is this correct? (or are they mixing) They are mixing water from the buffer tank with the return flow in order to regulate flow temperature towards the loops using the input from the flow sensor and a simple PID logic. Afaik they have a role in reducing temperature to below the dew point calculated from the room temperature and humidity coming from the room thermostats + they are trying to do a weather compensation during heating (which I've overridden since it didn't seem to make sense to me to run the heat pump at a fixed flow temp and then mix it to a lower temp, this probably worsened the short cycling though)

I hope I was able to give clear answers. Please tell me if I missed something important.

Hi

Just to confirm my understanding. You have an 11kW heat pump and an assessed loss of roughly 2.5kW (118W/K * 20). Is this a correct interpretation?

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

@jamespa

Your understanding is entirely correct. It is massively oversized. And the compressor can't seem to be able to modulate to under ~3kW or so, which means balancing demand is quite the challenge. This setup is what came with the property so now I'm trying to cook from what I have. 🙂 I guess I need a way to store heat? Either in the thermal mass of the home or in a tank?

OR perhaps add another heat source for shoulder seasons?

@gergoh You cannot have the system so far oversized it just will not work unfortunately. This seems to be a very common mistake. if your heat loss is 2.5kw you need to have one of the much smaller systems.

Perhaps you can get a swap out.

AAC Group Ltd covering the Kent Area for design, supply and installation of ASHP systems, service and maintenance, diagnostics and repairs.

Professional installer. Book a one-to-one consultation for pre- and post-installation advice, troubleshooting and system optimisation.

I'm not a heating engineer, but with a heat loss of 2.5kw at minus whatever, is there any heat pump that can modulated low enough at the more typical british temps. Maybe just light a few candles?

- 27 Forums

- 2,475 Topics

- 56.9 K Posts

- 262 Online

- 6,165 Members

Join Us!

Worth Watching

Latest Posts

-

RE: If a heat pump can only heat DHW to 50C then what? Issue with 18KW Heliotherm heat pump

Hi, Nothing yet. I've asked customer to measure flow...

By errmm , 5 hours ago

-

RE: High Temp Heat Pumps for fast warm-up of house

I don't know exactly how long it takes to heat up (and ...

By JamesPa , 6 hours ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

OK. What Im seeing looks fairly normal TBH: 1 start ...

By JamesPa , 7 hours ago

-

RE: Vaillant Tech Support Flagged Low DT: UFH Return Cold, Suspected Zero Flow

@editor thanks for the tips which I will try before cal...

By DavidB , 8 hours ago

-

RE: Daikin 6kw setup with Dixell controller

@jamespa Many thanks for your reply, a very detailed an...

By CraigH , 8 hours ago

-

RE: Exploring the role of alternative clean heating solutions - Government Consultation

Despite reservations, I found some time to respond to t...

By Rusty , 9 hours ago

-

RE: New Vaillant aroTherm Plus in black - When will it come to the UK?

@crankplus, nope, still not, and I've followed up with ...

By Mars , 9 hours ago

-

RE: Octopus Cosy Heat Pump Owners & Discussion Thread

@agentgeorge Probably, but temperature change at -10 ha...

By AndrewJ , 10 hours ago

-

RE: External wall insulation - your experience

To be clear, my experience was very positive. The journ...

By Batpred , 12 hours ago

-

@foxesfan Re: ‘Servicing’ as @editor has covered in his...

By Toodles , 12 hours ago

-

RE: A Smarter Smart Controller from Homely?

@benson No idea why mine doesn’t work, all I see on ...

By Papahuhu , 12 hours ago

-

RE: Battery sizing - How low can you go!

It seems I am seeing something similar to what you do, ...

By Batpred , 13 hours ago

-

RE: Gaslighting in the heat pump industry – has anyone else experienced this?

Don’t know if this is relevant to this thread, but my A...

By Gruff2001 , 14 hours ago

-

RE: Bosch CS5800i 5kW - Experience So Far

@majordennisbloodnok While getting Home Assistant runni...

By Steelbadger , 1 day ago

-

RE: MCS - BS EN 12831-1:2017 – Heat Loss Survey

Since May 2025 it no longer a requirement in England to...

By JamesPa , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handel @jancold Manufacturer: Daikin Model: E...

By Jancold , 1 day ago

-

RE: Octopus Cosy 12 Heat Pump Regret: Incredibly Loud, Poor Heating & Constant Hum - Help!

@harriworld it was roughly 3am for an hour as that’s ...

By L2jad , 1 day ago

-

RE: Hoped for improvements not being realised on my Mitsubishi heat pump

I have been wondering that myself. The fact is that, ...

By JamesPa , 1 day ago

-

RE: Filtering Tap Water – Share Your Setup for Cleaner, Better-Tasting Water

I remember when I was in my early 20s I was introduced ...

By Majordennisbloodnok , 1 day ago

-

RE: Setback savings - fact or fiction?

But if it is recorded an an integer, which it seems it ...

By cathodeRay , 2 days ago