@markc Great news, it appears that my claims are being verified, however, you must remember that you are still compromising without removing un-needed controllers, valves. actuators, pumps etc. Once set up properly, there will be significantly more savings and bettor comfort levels.

Most of our customers run their systems between 19 and 20 Deg, (some as low as 17), this is comfortable and you will have significantly more savings.

Good morning Mark,

As can be seen clearly from the excellent data you have provided, a lower water flow temperature gives better operation of your ASHP, with much improved efficiency. How consistent was the indoor temperature over the test periods? Did you find much variation between the different type of control employed? Did you notice any large temperature differences between rooms?

So, with a few simple changes to the way that your system was set to operate, you have improved the overall efficiency by almost 50% and reduced your energy consumption by almost 33%.

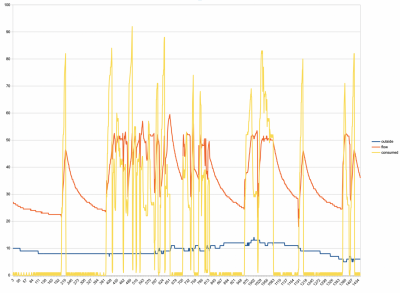

Looking at the graphs, it can be clearly seen that in the first one, whilst boosting the water flow temperature to 50C means that your ASHP operates less frequently, when it does operate it uses much more electrical energy to produce the same amount of heat energy.

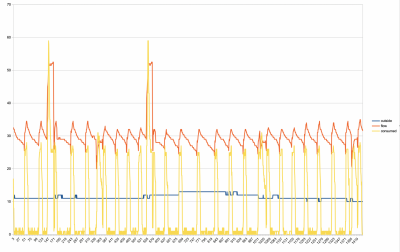

The second graph shows that your heat pump is now operating in a more consistent and predictable manner, and that the slight variations in water flow temperature, equate to the variations in ambient air temperature. In fact, the water flow temperature trace is almost identical to the radiator temperature trace on my data logger at home. When your ASHP and water pump initially start to operate, the water flow temperature reading actually falls, because colder water from the pipework is being drawn in and sensed before the heat pump has started to produce heat. As your heat pump starts to produce heat, the water flow temperature increases quite rapidly, until the desired temperature is reached and the compressor is stopped. The water flow temperature continues to increase for a period of time, and then starts to fall at a rate determined by the present heat loss. As you can see, this process continues and helps maintain a reasonably constant indoor temperature.

You are no doubt quite happy with the improvements you have so far made, but as with many things in life, there is often room for further improvement. This is where comfort and economics come into the equation.

Based on calculations I have made, energy consumption could potentially be reduced by up to 10%, merely by lowering the desired indoor temperature by 1C. Obviously, it is your decision to make, but you could try lowering the weather compensation curve by 1C, by reducing the large number on your controller by 1. You could try this for the full day, or just for the overnight period.

Whilst the actual water flow temperature is set by the weather compensation curve, the required water flow temperature is set by the heat loss. So improved insulation and draft proofing would reduce heat loss, and hence reduce required water flow temperature. Calculations would indicate that a 20% reduction in heat loss, would give up to a 25% reduction in energy consumption.

Installing larger, or more efficient heat emitters, is also a way in which the required water flow temperature can be reduced, with subsequent reduction in energy consumption.

At the end of the day it is down to each individual to decide what works best for them.

Mark, please continue to provide the data whenever possible, which I feel certain is not only appreciated by myself, but also many of the forum members.

Does anyone know how the energy delivered is calculated by the Ecodan and other ASHPs that work out COP? To do it accurately, don't you need flow volume and temp difference? I know the Ecodan monitors the temps, but without MMSP, there is no flow meter? Does it maybe use the ambient and flow temps and use its own internal 'tables' to look up the COP?

Other than curiosity, I'm asking because my Ecodan has stopped recording energy produced and I'm wondering why (supplier has been called)

Hi Kev,

I do remember reading somewhere that the approximate heat energy output can be calculated from temperature measurements and power consumption. As i'm certain you know, if you have two of the three parameters in an equation, it is quite easy to calculate the third.

I suggest that you check your system for any fault alarms that may indicate a faulty sensor. Did you loose this indication after you got your MMSP to be providing more meaningful information? Is the MMSP connected to your FTC6 controller? If so, try swapping the MMSP sensors over again, and see if the energy delivered reading returns.

No, I lost it when they installed MMSP in early October! Flow and return temps are available without MMSP and I can still see them in Melcloud. I assume they are from different sensors to the ones on the MMSP energy meter. The meter part of the energy meter is connected to the FTC6.

@kev-m I am not 100% sure you for you. But as long as you know the flow rate and the temperature you know the heat in KW. It takes 1W to heat 1cm3 of water 1degree. So 1kw will heat 1m3 of water 1°. If I am moving 1m3 per hour and I've raised the temperature from 11° to 13° and then back to 11° I've delivered 2kw of heat.

Posted by: @batalto@kev-m I am not 100% sure you for you. But as long as you know the flow rate and the temperature you know the heat in KW. It takes 1W to heat 1cm3 of water 1degree. So 1kw will heat 1m3 of water 1°. If I am moving 1m3 per hour and I've raised the temperature from 11° to 13° and then back to 11° I've delivered 2kw of heat.

@batalo, yes you are right but how is the flow rate measured by the ASHP? When you get MMSP you get this

I don't know how it measures flow rate without this?

Posted by: @kev-mNo, I lost it when they installed MMSP in early October! Flow and return temps are available without MMSP and I can still see them in Melcloud. I assume they are from different sensors to the ones on the MMSP energy meter. The meter part of the energy meter is connected to the FTC6.

Hi Kev,

Your answer is probably in the first line of your statement, 'I lost it when they installed MMSP'.

If you look at section 4.5 of the FTC6 controller manual, there is a table detailing the signal connections. IN8, IN9 and IN10 relate to the connection of the MMSP equipment.

What has probably happened, is that the FTC6 controller is now expecting a heat energy produced signal from the heat meter, rather than an internally calculated value. Because your heat meter is not fully functional, the controller may be ignoring the signal from the heat meter because it is not within anticipated parameters.

If, when your installer returns, you initially get them to disconnect the MMSP wiring from the FTC6, you should find that the energy produced value returns. Get your MMSP equipment fully functional, and then record the energy produced value without MMSP connected. Then get the MMSP equipment connected and see if the value produced is close to the value without MMSP.

If the two values are vastly different or you once more lose the energy produced indication, then it would indicate that the MMSP equipment is not correctly configured. If you and your installer then require further assistance then please get in touch.

Posted by: @kev-mNo, I lost it when they installed MMSP in early October! Flow and return temps are available without MMSP and I can still see them in Melcloud. I assume they are from different sensors to the ones on the MMSP energy meter. The meter part of the energy meter is connected to the FTC6.

Hi Kev,

I have just noticed under section '5.1 DIP Switch Functions' of the FTC6 manual, that there are some DIP switches that need to be changed when MMSP is installed. It would appear that SW3-4 and SW3-8 need to be changed from off to on.

@kev-m mine is measured in the unit. I can see exactly what it's current flow rate is on the controller and the unit measures heat delivered in its app - or it gives a pretty good estimate

-

Struggling to get CoP above 3 with 6 kw Ecodan ASHP

54 minutes ago

-

Running my new Nibe ASHP efficiently

1 month ago

-

Have Consumers Been Lied to About the Efficiency of Heat Pumps Made in China?

7 months ago

-

Ecodan consuming 100kwh per day in new build!!!

7 months ago

-

Help with understanding my Mitsubishi Ecodan air source heat pump

10 months ago

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 213 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Electricity price predictions

@transparent Triggered by the various commen...

By JamesPa , 18 minutes ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

Just to wrap this up here for future readers: The S...

By Batpred , 48 minutes ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 54 minutes ago

-

RE: What determines the SOC of a battery?

I agree. Fogstar confirmed that the Seplos BMS does ...

By Batpred , 1 hour ago

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

I've found that generally the humidity in the house is ...

By IRMartini , 2 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 2 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@benson — as @tasos suggests, plotting multiple variabl...

By cathodeRay , 5 hours ago

-

@painter26 — as @jamespa says, it's for filling and re-...

By cathodeRay , 6 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 17 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 19 hours ago

-

RE: Setback savings - fact or fiction?

I also need to correct something I said by mistake earl...

By cathodeRay , 19 hours ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 22 hours ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 22 hours ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 22 hours ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 24 hours ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago

-

RE: DIY solar upgrade - Considering adding more panels

I know this is a bit old, but it made me wonder what co...

By Batpred , 2 days ago

-

RE: New Vaillant aroTherm Plus in black - When will it come to the UK?

@majordennisbloodnok Daikin, take note! (In fact, I hav...

By Toodles , 2 days ago

-

RE: Midea ASHP – how to set weather compensation

@mk4 — good work! First, I agree, no evidence of cycl...

By cathodeRay , 2 days ago