Ecodan - optimal external installation?

Hello all,

First time post, been a lurker for a while.

Looking to understand best (Mitsubishi-approved) installation practices to minimise noise (heard both externally, and currently internally!) and maximise efficiency/performance of a year-old Ecodan PUZ-WM60VAA in a modern house. Have had a search around the site and can't find anything similar; if there is, please signpost me to it and I'll delete this post.

Our external unit sits c. 300mm in front of a house wall with the flow and return pipes snaking to a length of c. 450mm behind it before entering the building.

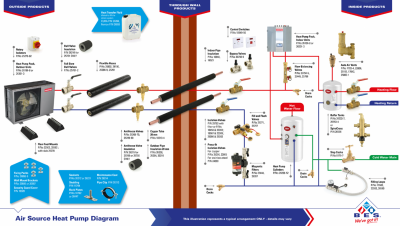

With the attached diagram in mind (found from clicking the 'Air Source Heat Pump Diagram' button on https://www.bes.co.uk/primary-pro-ashp-insulation-28-x-19mm-x-1m-26208/)...

...from the wall there is the foam-like (I think it's called Class O) insulation over the copper pipes to the isolator levers maybe 60mm along, then more Class O secured by cable ties over copper piping that bends down at 90deg then again to create a square 'U' before the second half of the pipework is copper pipe with a different shiny cover insulation that then goes over (not attached to) the flexible hoses to the back of the unit. I can't see any anti-freeze valves or full bore ball valves.

The unit is mounted on 600mm rubber feet that sit on a concrete base. I don't know if they are bolted to the base or not (there seems some movement when the top edge is pushed). Rain collects to one side on the top so I assume it isn't level.

My initial challenge points are around

- the length/configuration of the pipework between the wall and unit - I've read shorter runs create vibrations that can also travel along the internal pipework

- the unit should be level/straight in all directions - for balance / to ensure the blades turn optimally / minimise noise

- downwards from the feet - Mitsubishi's installation manual says to bolt the feet to concrete with a maximum of 30mm exposed out of the concrete. I note they do list the feet as an accessory (as 'anti-vibration mounts', and separately 'anti-vibration fix-it-foot' optionally with a slab), along with Anti-freeze!

I'm considering replacing the pipework between the isolators and flexihoses so it is longer and straighter (and probably secured by wall-mounted rubber brackets). Is there an optimised run/length?

This means I'd create a new (level) base alongside existing - whether a slab or two concrete plinths, with the rubber feet possibly bolted to it/them.

Also wondered if there is an optimal unit height, relative to the pipework runs from the house?

Grateful for people's critique / thoughts / suggestions on my thinking, anything I've missed, and other possible optimisations.

Thanks in advance.

So, you're looking to maximise efficiency eh.... Step 1 - remove all extra pumps. Step 2 - remove all unnecessary hydraulic separation. Step 3 - ensure optimum flow rate at all times by removing mag filter, fill-flush-flowsetters and the like. Step 4 - disable all external thermostats and dial in your weather comp curve.

Off grid on the isle of purbeck

2.4kW solar, 15kWh Seplos Mason, Outback power systems 3kW inverter/charger, solid fuel heating with air/air for shoulder months, 10 acres of heathland/woods.

My wife’s house: 1946 3 bed end of terrace in Somerset, ASHP with rads + UFH, triple glazed, retrofit IWI in troublesome rooms, small rear extension.

Silly question, perhaps, but do you have a problem with the noise of the unit? If so, are you able to quantify it? Not necessarily in terms of decibels but some kind of description that can allow us to understand the scale.

I have an Ecodan (a PUZ-WM85VAA) that is installed about that distance from a side wall of our house and the pipework runs straight to the wall, up the wall and then into the loft (all well insulated, I might add). Directly the other side of the wall is the head board to my and my wife's bed, so we would certainly know if the Ecodan was being noisy, but it's quiet as a mouse, to the extent that our neighbours have commented on how much quieter it is than they expected. In short, there's no reason why an Ecodan can't be installed to run quietly.

All this adds up to the suggestion that any noise issues you may be having could be related to the rest of the system, not the ASHP. As @hughf suggests, taking a look at pumps, flow rates and so on may well be a good start.

105 m2 bungalow in South East England

Mitsubishi Ecodan 8.5 kW air source heat pump

18 x 360W solar panels

1 x 6 kW GroWatt battery and SPH5000 inverter

1 x Myenergi Zappi

1 x VW ID3

Raised beds for home-grown veg and chickens for eggs

"Semper in excretia; sumus solum profundum variat"

Thanks @majordennisbloodnok and @hughf ffor your replies.

Reflecting on my post, I wanted validation that the external parts of my install were optimal, and if not, what would be optimal. The 'trigger' for the post was, yes, probably majority due to the noise, though also to ensure performance (and, likely ultimately, reliability/failure) and efficiency (not spending more money than required by the unit overworking e.g. due to reduced flow rates, poor insulation, etc).

HughF's suggestions are welcomed and I will look at the elements inside the house once I know outside is as good as I can get it.

Posted by: @majordennisbloodnokSilly question, perhaps, but do you have a problem with the noise of the unit? [snip]

Yes, there is humming/vibration throughout the house and can hear the unit ramp up + down indoors at the opposite side to the pump!

I have an Ecodan (a PUZ-WM85VAA) that is installed about that distance from a side wall of our house and the pipework runs straight to the wall, up the wall and then into the loft (all well insulated, I might add).

It sounds like you have a nice straight run from the flexihoses up to an elbow straight into the house - this takes me back to the question of optimal (minimum) pipe run and whether bends (at the short run we have) negatively impact, which I'd like opinions/facts on.

(How) is your pipework secured to the brickwork / how does your external install compare with that noted from para 2 in https://renewableheatinghub.co.uk/forums/renewable-heating-air-source-heap-pumps-ashps/ashp-flow-through-pipes-is-noisy-and-preventing-us-from-using-at-night-looking-for-help/paged/2#post-25615 (which I'm working through at present, though it feels the pipework-through-brick elements may be at least part of the issue)?

@iancalderbank, noting the above and your comments in the post I linked to in which you touch on some of the elements in my OP, may I please ask - is there a 'definitive minimum' install standard that one could refer to when speaking with installers? You mentioned MCS inspection - do you know if Mitsubishi would insist on installs passing this, or another/equivalent (and if so, which), certification before they would consider servicing/supporting it? For example, *must* primary pipes going through brickwork have the insulation type you mention or is it just 'best practice'? Any related info gratefully received.

(Also, happy to remove and repost this in the other thread if more-appropriate)

@rhh2348 not that I've been ever involved but from what others have said, getting MCS to actually rectify is a waste of time. So its more about best practice, and if you can improve it yourself, do so.

post some photos?

is your efficiency issue due actually insulation or something else? more normally when people have efficiency issues its a system design thing. have you thought about flow temps, weather comp, do you have low loss headers / buffer tank, all that stuff. plenty of threads on this, several focused on ecodan.

My octopus signup link https://share.octopus.energy/ebony-deer-230

210m2 house, Samsung 16kw Gen6 ASHP Self installed: Single circulation loop , PWM modulating pump.

My public ASHP stats: https://heatpumpmonitor.org/system/view?id=45

11.9kWp of PV

41kWh of Battery storage (3x Powerwall 2)

2x BEVs

(I can't seem to edit my original post so commenting here).

The post was intended to discuss optimising efficiency, performance, and quietness of all the *external* parts of the system, so I could work backwards / move onto the internal elements from there. @iancalderbank covered off some of the elements around primary pipework routing and insulation in the post I linked to (thanks again Ian).

I've now split out creating an optimal base into a separate topic but am still keen to hear opinions around the other elements of an external install to achieve an optimal, Mitsubishi-approved setup if people would be generous enough to offer their thoughts.

@rhh2348 ok get it, you want to focus on the external. I do think it would help if you post some photos. picture paints a thousand words and all that.

My octopus signup link https://share.octopus.energy/ebony-deer-230

210m2 house, Samsung 16kw Gen6 ASHP Self installed: Single circulation loop , PWM modulating pump.

My public ASHP stats: https://heatpumpmonitor.org/system/view?id=45

11.9kWp of PV

41kWh of Battery storage (3x Powerwall 2)

2x BEVs

Hi - as Ian said it really would be a great help if you could post some photos of your installation.

In the meantime, noisewise, somehing you maybe could have a look at is whether your 6kW Ecodan has enough spare capacity to operate comfortably in one of the Quiet Mode settings. If your controller is FTC6 the option should be available under Heat Pump Settings in the Service menu.

I run our Ecodan in Quiet Mode all year, except during continuous periods at sub zero ambient when I switch over to Normal mode.

Quiet Mode limits maximum compressor speed. On our 11.2kW it is considerably quieter.

Just for comparison, ours is freestanding on the antivibration pads, standing on stone paving. This means it can be lifted (shuffled) out on the flexible connections sufficiently for rear cleaning if needed. Your 6kW should be considerably lighter.

Mitsubishi Ecodan 11.2kW R32 ASHP; Ecodan DHW cylinder; UFH+rads

20x430W Jinko TOPCON Tiger Neo solar; Luxpower 6+4kW hybrid inverter; 20kWh LFP battery storage

PHEV; Zappi charger

Posted by: @skdIn the meantime, noisewise, somehing you maybe could have a look at is whether your 6kW Ecodan has enough spare capacity to operate comfortably in one of the Quiet Mode settings. If your controller is FTC6 the option should be available under Heat Pump Settings in the Service menu.

Yes, I did try that a few weeks ago and it did seem to make a difference, though that might have been placebo effect if I misunderstood the Quiet Level setting (see another of your posts and my follow-up)!

What differences, if any, did you notice between the three settings / which one are you on now?

Also, I started tweaking my W/C curve yesterday - it was mild last night however the unit was barely audible with my first W/C attempt, which is promising (as HughF alluded to).

Just for comparison, ours is freestanding on the antivibration pads, standing on stone paving.

Thank you - do you have a link to the pads you used / are you happy with that setup/would you do it again?

1 black bar (Level 2 Quiet Mode) is the quietest setting, and that is the one we use all the time, except when it is forecast to remain below zero all day. Then we switch back to 3 black bars / Normal power, as the heat output can fall a bit short otherwise.Posted by: @rhh2348Posted by: @skdIn the meantime, noisewise, somehing you maybe could have a look at is whether your 6kW Ecodan has enough spare capacity to operate comfortably in one of the Quiet Mode settings. If your controller is FTC6 the option should be available under Heat Pump Settings in the Service menu.

Yes, I did try that a few weeks ago and it did seem to make a difference, though that might have been placebo effect if I misunderstood the Quiet Level setting (see another of your posts and my follow-up)!

What differences, if any, did you notice between the three settings / which one are you on now?

Also, I started tweaking my W/C curve yesterday - it was mild last night however the unit was barely audible with my first W/C attempt, which is promising (as HughF alluded to).

Just for comparison, ours is freestanding on the antivibration pads, standing on stone paving.

Thank you - do you have a link to the pads you used / are you happy with that setup/would you do it again?

2 black bars (Level 1 QM) also reduces noise, but to a lesser degree.

The pads were ordered by the installer, and are described as Mitsubishi anti vibration feet 600mm. They seem well made, durable and effective, so I wouldn't hesitate to use them again.

Ours is the 11.2kW R32 Ecodan. Dimensionally the enclosure appears to be the same as the 6kW version.

Mitsubishi Ecodan 11.2kW R32 ASHP; Ecodan DHW cylinder; UFH+rads

20x430W Jinko TOPCON Tiger Neo solar; Luxpower 6+4kW hybrid inverter; 20kWh LFP battery storage

PHEV; Zappi charger

The most important thing to remember with external insulation is that it’s UV stable. So that’s either primary pro, or aluminum covered rockwool.

standard insulation isn’t UV stable and will degrade over time.

I have primary pro through the wall, where I then transfer over to regular climaflex grey stuff. Flow and return are lagged all the way to the cylinder.

Off grid on the isle of purbeck

2.4kW solar, 15kWh Seplos Mason, Outback power systems 3kW inverter/charger, solid fuel heating with air/air for shoulder months, 10 acres of heathland/woods.

My wife’s house: 1946 3 bed end of terrace in Somerset, ASHP with rads + UFH, triple glazed, retrofit IWI in troublesome rooms, small rear extension.

-

New Mitsubishi Ecodan 11.2kW installation - L9 errors and maybe more

21 hours ago

-

Ecodan with FTC7 - True Weather Compensation

3 days ago

-

Ecodan unable to hit legionella target temp - what's the consensus?

2 weeks ago

-

Mitsubishi Ecodan 11kw Defrosting Issue.

4 weeks ago

-

Rate the quality of your heat pump design and installation

1 month ago

- 26 Forums

- 2,396 Topics

- 54.3 K Posts

- 211 Online

- 6,077 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Help me keep the faith with my air source heat pump installation

@simonf I’ll ask the installers to get them out. What k...

By AdamK , 6 hours ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

Thanks for all the help/comments. I completely agree w...

By JamesPa , 9 hours ago

-

RE: ASHP Energy Consumption: Aira 12kW heat pump

I doubt that matters, ToU tariffs are for the benefit o...

By JamesPa , 14 hours ago

-

RE: Free Ecoheat Heat Pump Install

@deltona Yes older houses are problematic like that, bu...

By bontwoody , 17 hours ago

-

RE: Radiator sizing sanity check

As I mentioned early on the cost of supplying and fitti...

By JamesPa , 19 hours ago

-

RE: Advice for a novice on Mitsubishi Ecodan 6kW

I hadn't spotted that there were two pumps in the UFH (...

By JamesPa , 21 hours ago

-

RE: Setback savings - fact or fiction?

Never assume it makes an ass of u and me! You need the...

By JamesPa , 21 hours ago

-

RE: New Mitsubishi Ecodan 11.2kW installation - L9 errors and maybe more

Before I answer your specific questions just one more t...

By JamesPa , 21 hours ago

-

RE: Electricity price predictions

Great point, one of the key ones in my chat with Octopu...

By Batpred , 1 day ago

-

RE: Running from backup generaor in powercut?

Definitely and professionals sometimes miss it. I had...

By Batpred , 1 day ago

-

RE: New Fogstar 15.5kWh upright solution

Let me point out that there are many Chinese suppliers ...

By Transparent , 2 days ago

-

RE: Weather compensation- why you should use it

@majordennisbloodnok — The Two Ronnies Mastermind sketc...

By cathodeRay , 2 days ago

-

Just realised that this image of the cylinder cupboard ...

By Sheriff Fatman , 2 days ago

-

RE: Rodents! A word of warning for heat pump owners

Two thoughts: 1: Let's ask @david-s if Primary Pro in...

By Transparent , 2 days ago

-

RE: Solis S6-EH1P8K-L-PLUS – Why I Chose It and What I’ve Learned So Far

In the diagram below, I describe my understanding of th...

By Batpred , 2 days ago

-

I need to have a look out for it. I know IBM feeds some...

By Batpred , 2 days ago

-

-

RE: Daikin Atherma ASHP Cycling 6 Times an Hour?

Thanks for your reply. Yes that's a good idea to try a...

By John Marshall , 2 days ago

-

RE: Hot water heating in parallel with space heating

An external heat exchanger would need a pump which woul...

By bontwoody , 2 days ago

-

RE: Gen 6 Samsung ASHP losing 20C of DHW in 60 min directly after generation

@ecobaker Thanks for this. I've had it in both slots. ...

By andbeck , 2 days ago