@sliderule no worries at all. One black segment is quietest/min power. Three black segments is normal/full power (see photo)👍

Mitsubishi Ecodan 11.2kW R32 ASHP; Ecodan DHW cylinder; UFH+rads

20x430W Jinko TOPCON Tiger Neo solar; Luxpower 6+4kW hybrid inverter; 20kWh Hanchu ESS LFP battery storage

PHEV; Zappi charger

1997 stone detached house with updated insulation. 140sqm, maintained at 20-22degC 24/7

that's on mine which is a 2021/22 FTC6 btwPosted by: @skd@sliderule no worries at all. One black triangle is quietest/min power. Three black triangles is normal/full power 👍

Mitsubishi Ecodan 11.2kW R32 ASHP; Ecodan DHW cylinder; UFH+rads

20x430W Jinko TOPCON Tiger Neo solar; Luxpower 6+4kW hybrid inverter; 20kWh Hanchu ESS LFP battery storage

PHEV; Zappi charger

1997 stone detached house with updated insulation. 140sqm, maintained at 20-22degC 24/7

Posted by: @sunandair...it’s flow rate recommendation is around 11 LPM...I have found it’s important to keep Farley close to the recommended flow rate for your model of HP.

To pick up on this (flow rate) comment... I've a Grundfos primary pump which the FTC6 reports as producing 8lpm on constant speed 1, and 12 or 13 (it flip-flops every few seconds) on constant speed 2 - a) I assume the FTC pump speed setting has no effect whether it's 1 or 5, and b) with UFH and rads, what's the guidance on whether I should be at 8 or 12/13; is it just 'nearest the book flow' (e.g. nearest to 10.8lpm) or, with the UFH likely using/being on more, the nearest slower setting?

Unlikely, but c) is there any known way I adjust the Grundfos to get near half way in-between, e.g. ~10.5lpm?!

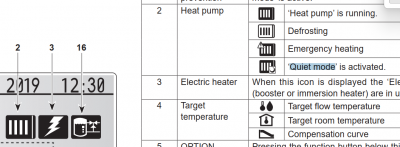

Posted by: @skdOne black segment is quietest/min power. Three black segments is normal/full power (see photo)

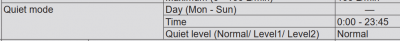

Can I just check this is correct - having read the FTC6 installation manual, the three bar settings are described as Normal / Level1 / Level2; does anyone know what Level1 and Level2 mean, precisely? (I can't find anything on google) Do we not think that 'Normal' is 'Normal quiet mode' (i.e. reduced noise) and not 'normal noise mode', given it's under the Quiet mode settings/schedule?

Posted by: @rhh2348Posted by: @skdOne black segment is quietest/min power. Three black segments is normal/full power (see photo)

Can I just check this is correct - having read the FTC6 installation manual, the three bar settings are described as Normal / Level1 / Level2; does anyone know what Level1 and Level2 mean, precisely? (I can't find anything on google) Do we not think that 'Normal' is 'Normal quiet mode' (i.e. reduced noise) and not 'normal noise mode', given it's under the Quiet mode settings/schedule?

This is what I worked out after speaking to Mitsubishi Tech Support, and experimenting myself. You're right, it's poorly described in their literature.

3 black bars is Normal mode, and refers to standard power / loudest compressor setting.

2 black bars is slightly reduced power, and a bit quieter than Normal. This is Level 1 Quiet Mode.

1 black bar is the greatest available reduction in compressor power. Level 2 Quiet Mode.

Hope this is some help.

Mitsubishi Ecodan 11.2kW R32 ASHP; Ecodan DHW cylinder; UFH+rads

20x430W Jinko TOPCON Tiger Neo solar; Luxpower 6+4kW hybrid inverter; 20kWh Hanchu ESS LFP battery storage

PHEV; Zappi charger

1997 stone detached house with updated insulation. 140sqm, maintained at 20-22degC 24/7

Posted by: @skdYou're right, it's poorly described in their literature.

3 black bars is Normal mode, and refers to standard power / loudest compressor setting.

2 black bars is slightly reduced power, and a bit quieter than Normal. This is Level 1 Quiet Mode.

1 black bar is the greatest available reduction in compressor power. Level 2 Quiet Mode.

Hope this is some help.

That's an understatement - the manual states the three levels as text (e.g. 'Normal / Level1 / Level2') rather than the number of 'bars'/squares the FTC6 actually displays, and then reverses the order (e.g. rather than 1 bar = Normal, 2 bars = Level1, 3 bars = Level3)! Extremely odd, thus:

However, further down it also states that if quiet mode is enabled, the heat pump icon changes to one with a crescent moon bottom-right, thus:

It'd be nice to know exactly what the two alternative levels adjust, if anyone's got/can find that info?

Will test with quiet mode settings once the W/C is roughly there. Thanks again for now, though.

@rhh2348 yes, the compressor symbol on the main screen will include a moon icon whenever either of the Quiet Mode settings is selected.

I know what you mean - I wish Mitsubishi would provide a written description on the workings of this mode.

Mitsubishi Tech Support verbally told me that each Quiet Mode setting simply places an electronic restruction on maximum compressor speed, nothing more than that.

Mitsubishi Ecodan 11.2kW R32 ASHP; Ecodan DHW cylinder; UFH+rads

20x430W Jinko TOPCON Tiger Neo solar; Luxpower 6+4kW hybrid inverter; 20kWh Hanchu ESS LFP battery storage

PHEV; Zappi charger

1997 stone detached house with updated insulation. 140sqm, maintained at 20-22degC 24/7

Posted by: @rhh2348Posted by: @sunandair...it’s flow rate recommendation is around 11 LPM...I have found it’s important to keep Farley close to the recommended flow rate for your model of HP.

To pick up on this (flow rate) comment... I've a Grundfos primary pump which the FTC6 reports as producing 8lpm on constant speed 1, and 12 or 13 (it flip-flops every few seconds) on constant speed 2 - a) I assume the FTC pump speed setting has no effect whether it's 1 or 5, and b) with UFH and rads, what's the guidance on whether I should be at 8 or 12/13; is it just 'nearest the book flow' (e.g. nearest to 10.8lpm) or, with the UFH likely using/being on more, the nearest slower setting?

Unlikely, but c) is there any known way I adjust the Grundfos to get near half way in-between, e.g. ~10.5lpm?!

Where is your circulator pump located in the circuit? Is it positioned on the Primary Flow or the Primary Return? Do you have a Mitsubishi pre plumbed cylinder with a plate heat exchanger? And do you know where your flow sensor I see located- as it should be on the return pipework going back to the heat pump? Do you have a Low Loss Header fitted? Regarding c) there is a device called a flow setter valve which simply restricts flow but might not be necessary. One litre faster than optimum shouldn’t be a problem.

dont understand a) what are you assuming. What isn’t happening?

A bit of a late response to this reply, however thank you for doing so, @sunandair.

I've done some more reading around this since my previous post, and thought it'd be useful to cover off some of the points:

- it's not a Mitsubishi (pre-plumbed) cylinder / the flow sensor is on the return pipework, yes / there is a LLH.

- question (a) was to understand if this [the FTC pump speed setting] affected anything other than purely what speed a Mitsubishi pump [for their pre-plumbed cylinder] runs at - e.g. if set to 1 or 5 does that affect something else, like compressor speed, or is otherwise included in any of their algorithms?

- Previously, I'd mangled primary flow rate with UFH zone flow rate, the latter of which is handled by an additional pump on my system - plus, I believe my assumption (that UFH pumps should run slower to provide an optimal reduced flow rate) is incorrect, and that typically one aims for UFH pumps to provide three times the flow of a rad zone! 😳

Posted by: @rhh2348A bit of a late response to this reply, however thank you for doing so, @sunandair.

I've done some more reading around this since my previous post, and thought it'd be useful to cover off some of the points:

- it's not a Mitsubishi (pre-plumbed) cylinder / the flow sensor is on the return pipework, yes / there is a LLH.

- question (a) was to understand if this [the FTC pump speed setting] affected anything other than purely what speed a Mitsubishi pump [for their pre-plumbed cylinder] runs at - e.g. if set to 1 or 5 does that affect something else, like compressor speed, or is otherwise included in any of their algorithms?

- Previously, I'd mangled primary flow rate with UFH zone flow rate, the latter of which is handled by an additional pump on my system - plus, I believe my assumption (that UFH pumps should run slower to provide an optimal reduced flow rate) is incorrect, and that typically one aims for UFH pumps to provide three times the flow of a rad zone! 😳

I believe that the FTC controller can only vary the water pump speed if the actual water pump is capable of having its speed varied. An easy way to check is change the speed setting from 1 to 5 and listen for a change in pump speed.

The actual water pump speed, and subsequent variation in flow rate, is one of the factors which determines how much thermal energy is being transported from the heat pump to the heat emitters.

If the flow rate is say 10 lpm and the DT is 5C, then a certain quantity of thermal energy will be transported. If the flow rate is now increased to 20 lpm then to transport the same quantity of thermal energy the DT must reduce to 2.5C.

As the heating demand increases, the options from a control point of view is to run the water pump at constant speed and allow the DT at the heat pump to vary, or vary the water pump speed to maintain a reasonably constant DT.

If you can vary the water pump speed between 1 and 5 by means of the FTC, then it may be possible to identify the setting that produces a DT of approximately 5C when the heating demand is at a maximum.

With regard to the required flow rate through UFH as against radiators, I suspect it will depend upon the heating capacity of the UFH and radiators. If you pass 3kW of thermal energy into both radiators and UFH, and both are capable of emitting 3kW of thermal energy, then the required flow rate and subsequent DT should be approximately the same.

-

Struggling to get CoP above 3 with 6 kw Ecodan ASHP

32 minutes ago

-

Ecodan Zone 2 Mitshibishi thermostat Auto Adapt

3 weeks ago

-

Ecodan Pump Issues… Circulation pump turns off when heat pump compressor turns off

1 month ago

-

New Mitsubishi Ecodan 11.2kW installation - L9 errors and maybe more

1 month ago

-

Ecodan with FTC7 - True Weather Compensation

1 month ago

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 262 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

Just to wrap this up here for future readers: The S...

By Batpred , 26 minutes ago

-

RE: Electricity price predictions

I get the scientific argument however I would ask what ...

By JamesPa , 31 minutes ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 32 minutes ago

-

RE: What determines the SOC of a battery?

I agree. Fogstar confirmed that the Seplos BMS does ...

By Batpred , 51 minutes ago

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

I've found that generally the humidity in the house is ...

By IRMartini , 1 hour ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 2 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@benson — as @tasos suggests, plotting multiple variabl...

By cathodeRay , 4 hours ago

-

@painter26 — as @jamespa says, it's for filling and re-...

By cathodeRay , 6 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 17 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 18 hours ago

-

RE: Setback savings - fact or fiction?

I also need to correct something I said by mistake earl...

By cathodeRay , 18 hours ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 21 hours ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 22 hours ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 22 hours ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 24 hours ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago

-

RE: DIY solar upgrade - Considering adding more panels

I know this is a bit old, but it made me wonder what co...

By Batpred , 2 days ago

-

RE: New Vaillant aroTherm Plus in black - When will it come to the UK?

@majordennisbloodnok Daikin, take note! (In fact, I hav...

By Toodles , 2 days ago

-

RE: Midea ASHP – how to set weather compensation

@mk4 — good work! First, I agree, no evidence of cycl...

By cathodeRay , 2 days ago