Method note (only of interest if you are interested in the code): I have sorted out the split regression line in the polynomial plot, using sort (sic). Without sort the values are returned, err, unsorted, GOKY (God Only Knows Why). Go figure... [edit: which I did, it's because the data is a datetime series, sorted by datetime rather than by the columns of interest] Earlier posts (plots and code) edited to include this change. I have also changed from predict() to fitted to get the values as it is more 'correct' (though for lm() models they should be the same).

Midea 14kW (for now...) ASHP heating both building and DHW

Posted by: @sunandairIs this topic causing so much debate because there has always been a problem with heat pumps operating at varying set temperatures? And has someone in the industry just decided it’s easier to just say there is no gain in operating setbacks so don’t bother?

It is obvious to me that Weather Compensation alone is not sufficiently sophisticated enough to handle quick recovery to 21c after a setback of say 17c. And most heat pumps appear to rely on weather compensation.

If the weather compensation curve is correctly set up - in other words, at its most efficient output - it should only maintain a constant temperature and only gently rise and fall as the outside temperature changes. Whereas when it’s put into the situation of having to raise the room temperature 4 degrees in 3 hours the curve would need to be set at roughly 5c higher flow temperature and so, at an inefficient higher operating output leading to inefficient cycling as it hits the over-temp threshold stops-cools-and reheats etc.

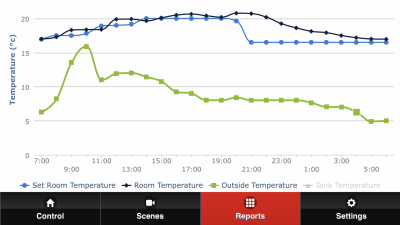

here is a 24hour graph of our WC Curve attempting to reheat without any adjustment to the flow temperature.

-- Attachment is not available --

So enter the arena Auto adapt which constantly operates at least 5c above the WC curve even after a learning period. I believe it’s the clumsy controls which haven’t been refined at this moment in time which make setbacks challenging.

I believe there are savings to be had but it requires quite a bit of intervention because the preset schedules and flow temp variation controls are not sophisticated enough.

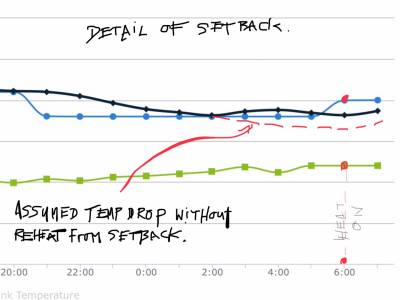

there are ways to make thing so more efficient as shown below. Such as using a “rebound Setback” I’ve called it that because it uses the setback temp to trigger a reheat to bounce the temperature back up at say 3am so that when the heating comes on the temperature is already raised. We have found the temp can be raised by 2c from one rebound reheat which means the targeting room temperature is that much closer.

The second adjustment is to action a +3c alteration to the WCcurve for 3 hours at the start of he reheat. Neither of these things can be programmed into the schedules.

-- Attachment is not available --

These should be within the scope of the heat pump controls but I haven to found a way to schedule it yet.

I think most, if not all, of this is spot on. Both the saving and the comfort are functions of the control strategy during recovery, and most heat pumps simply don't have a controller with the required functionality. It is certainly the case that there are savings to be made in many circumstances (as well as improved comfort if, like many, one prefers a slightly cooler environment when sleeping). The right type of control could switch in setback when there are savings to be made, and not when there aren't.

One of my 'concerns' all along has been that if the system, put into setback mode, doesn't recover fast enough with whatever controller is present (which it shouldn't in at least some circumstances if the WC curve is well tuned), the most likely human reaction is to jack up the WC curve, rather than turn off setback. This almost certainly more than negates the saving. So preaching setback to those who don't care to get obsessed with heat pumps (ie the vast majority) could be a dangerous thing giving the controllers we have and human nature.

I'm far from convinced that a saving of 10% or thereabouts (which is the order it will be, I'm 90% certain based on the various models/experiments/theory) is sufficient to persuade heat pump manufacturers to develop highly sophisticated controllers, certainly not before they have run out of steam on optimising the hardware. It really is a pity that heat pump controls are so inextricably linked to heat pump hardware, but I'm also doubtful that will change in the mass market, despite the efforts of Homely. We have, after all, lived for decades with gas condensing boilers that don't condense (and thus aren't running efficiently) because they are incorrectly set up, and looking at the flues I pass we still are doing that.

So we are left with either imperfect and crude algorithms, or a hobby project if we want to do it anything approaching properly.

In any case ToU tariffs may come to dominate cost optimisation, making it cheaper to operate at night than during the peak period or possibly even than during the day.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

@jamespa thanks for your rounded comments. It may create more room for further discussion.

Hopefully future controls will will be more intelligent. In the mean time there may be small setting tactics which may result in little wins.

I guess the Idea of targeting ToU tariffs brings its own juggling challenges and it’s one we are looking into. And one of the simplest little wins is to start the setback at 9pm rather than 11pm since the latent heat even in our low mass home should give 1 or 2 hours of comfort before the temperature will drop below 20c. The chart below shows the temperature overrunning.

Sorry if you think that I did not comment sufficiently on your previous post.

You appear to be operating your system in a manner I suggested probably well over a year ago, as part of the 'low and slow' method.

As you have discovered, ASHP controllers would appear to lack a 'ramp' capability, whereby a change in setpoint does not happen immediately, but is performed gradually over a period of time. So to increase the IAT from say 18C to 20C, your present choice would appear to be an immediate setting change from 18C to 20C, or an immediate change from 18C to 19C, with a later change from 19C to 20C.

You are using the latter of the two methods with what you have termed a 'rebound setback', with which you are actually ending the setback period at 03:00 with the increase in the setpoint.

The primary function of a controller is to keep the controlled variable as close as possible to the desired setpoint. So when the controller is presented with a setpoint change from say 18C to 20C, it has a mild panic, because all of a sudden, the variable that it is controlling would now appear to be 2C below its correct value. The controller therefore calculates how much it needs to increase the output, in this case the LWT, to get the IAT back to the desired value within a reasonable timescale.

If the controller calculates that to maintain a constant IAT of 20C requires 4kW of thermal energy, to raise the IAT from 18C to 20C may require the actual thermal energy output to be increased to 5kW, whereas if the ramped method is used going from 18C to 19C, then 19C to 20C, the required thermal energy output may be calculated at 4.5kW.

Your method is therefore what I would recommend as far as producing the greatest possible energy saving, but of course by replacing the thermal energy lost at a slower rate, the time taken to get IAT back to the desired value will be longer.

At the end of the day it is down to individuals to decide how they wish to operate their system, but what works for them quite probably may not work for others.

Posted by: @jamespaPosted by: @sunandairIs this topic causing so much debate because there has always been a problem with heat pumps operating at varying set temperatures? And has someone in the industry just decided it’s easier to just say there is no gain in operating setbacks so don’t bother?

It is obvious to me that Weather Compensation alone is not sufficiently sophisticated enough to handle quick recovery to 21c after a setback of say 17c. And most heat pumps appear to rely on weather compensation.

If the weather compensation curve is correctly set up - in other words, at its most efficient output - it should only maintain a constant temperature and only gently rise and fall as the outside temperature changes. Whereas when it’s put into the situation of having to raise the room temperature 4 degrees in 3 hours the curve would need to be set at roughly 5c higher flow temperature and so, at an inefficient higher operating output leading to inefficient cycling as it hits the over-temp threshold stops-cools-and reheats etc.

here is a 24hour graph of our WC Curve attempting to reheat without any adjustment to the flow temperature.

-- Attachment is not available --

So enter the arena Auto adapt which constantly operates at least 5c above the WC curve even after a learning period. I believe it’s the clumsy controls which haven’t been refined at this moment in time which make setbacks challenging.

I believe there are savings to be had but it requires quite a bit of intervention because the preset schedules and flow temp variation controls are not sophisticated enough.

there are ways to make thing so more efficient as shown below. Such as using a “rebound Setback” I’ve called it that because it uses the setback temp to trigger a reheat to bounce the temperature back up at say 3am so that when the heating comes on the temperature is already raised. We have found the temp can be raised by 2c from one rebound reheat which means the targeting room temperature is that much closer.

The second adjustment is to action a +3c alteration to the WCcurve for 3 hours at the start of he reheat. Neither of these things can be programmed into the schedules.

-- Attachment is not available --

These should be within the scope of the heat pump controls but I haven to found a way to schedule it yet.

I think most, if not all, of this is spot on. Both the saving and the comfort are functions of the control strategy during recovery, and most heat pumps simply don't have a controller with the required functionality. It is certainly the case that there are savings to be made in many circumstances (as well as improved comfort if, like many, one prefers a slightly cooler environment when sleeping). The right type of control could switch in setback when there are savings to be made, and not when there aren't.

One of my 'concerns' all along has been that if the system, put into setback mode, doesn't recover fast enough with whatever controller is present (which it shouldn't in at least some circumstances if the WC curve is well tuned), the most likely human reaction is to jack up the WC curve, rather than turn off setback. This almost certainly more than negates the saving. So preaching setback to those who don't care to get obsessed with heat pumps (ie the vast majority) could be a dangerous thing giving the controllers we have and human nature.

I'm far from convinced that a saving of 10% or thereabouts (which is the order it will be, I'm 90% certain based on the various models/experiments/theory) is sufficient to persuade heat pump manufacturers to develop highly sophisticated controllers, certainly not before they have run out of steam on optimising the hardware. It really is a pity that heat pump controls are so inextricably linked to heat pump hardware, but I'm also doubtful that will change in the mass market, despite the efforts of Homely. We have, after all, lived for decades with gas condensing boilers that don't condense (and thus aren't running efficiently) because they are incorrectly set up, and looking at the flues I pass we still are doing that.

So we are left with either imperfect and crude algorithms, or a hobby project if we want to do it anything approaching properly.

In any case ToU tariffs may come to dominate cost optimisation, making it cheaper to operate at night than during the peak period or possibly even than during the day.

Industrial type controller algorithms are already available that could be used to overcome the control issues of heat pump controllers.

The problem is that many of the heat pump installers cannot setup the present controllers to operate efficiently, so would have little or no chance of fine tuning industrial type control algorithms.

The other problem is the expectation of the homeowners, who no doubt wish their heat pump to provide the response of a gas boiler, which to an extent it can, but at the same time maintain the much higher efficiency of a heat pump, which of course it can't.

One thing that could quite easily be added to a heat pump controller, that I think would help greatly with the above problems, is a 'ramp' capability. By 'ramping' the desired IAT setpoint up or down in a slow, but controlled, manner, would help the heat pump to continue to operate in the 'low and slow' regime, but at the same time allow homeowners, who wish to do so, to lower overnight room temperatures.

Below is some information that all you budding statisticians may find of use.

The table shows a comparison of the 1.18 correction factor against OAT.

I will leave it up to individuals to decide upon both the accuracy and usefulness of using a correct factor in the manner in which it is being used.

I would respectfully suggest that rather than the V x I x Correction Factor, a more suitable equation would be:-

Input Power = V x I + Auxiliary Power.

Where Auxiliary Power is the sum of the power used by the other equipment which is powered through the heat pump dedicated Power Meter.

Posted by: @derek-mThe problem is that many of the heat pump installers cannot setup the present controllers to operate efficiently, so would have little or no chance of fine tuning industrial type control algorithms.

The other problem is the expectation of the homeowners, who no doubt wish their heat pump to provide the response of a gas boiler, which to an extent it can, but at the same time maintain the much higher efficiency of a heat pump, which of course it can't.

One thing that could quite easily be added to a heat pump controller, that I think would help greatly with the above problems, is a 'ramp' capability. By 'ramping' the desired IAT setpoint up or down in a slow, but controlled, manner, would help the heat pump to continue to operate in the 'low and slow' regime, but at the same time allow homeowners, who wish to do so, to lower overnight room temperatures.

I think a lot of people expect gas boilers to heat instantly, witness the prevelance of whacking the thermostat to max because they think this will somehow heat more quickly.

A ramp function, as you say, would be a simple and good addition, perhaps enabled by default for any change in programmed temp greater than 1C.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

Posted by: @derek-mSorry if you think that I did not comment sufficiently on your previous post.

You appear to be operating your system in a manner I suggested probably well over a year ago, as part of the 'low and slow' method.

As you have discovered, ASHP controllers would appear to lack a 'ramp' capability, whereby a change in setpoint does not happen immediately, but is performed gradually over a period of time. So to increase the IAT from say 18C to 20C, your present choice would appear to be an immediate setting change from 18C to 20C, or an immediate change from 18C to 19C, with a later change from 19C to 20C.

You are using the latter of the two methods with what you have termed a 'rebound setback', with which you are actually ending the setback period at 03:00 with the increase in the setpoint.

The primary function of a controller is to keep the controlled variable as close as possible to the desired setpoint. So when the controller is presented with a setpoint change from say 18C to 20C, it has a mild panic, because all of a sudden, the variable that it is controlling would now appear to be 2C below its correct value. The controller therefore calculates how much it needs to increase the output, in this case the LWT, to get the IAT back to the desired value within a reasonable timescale.

If the controller calculates that to maintain a constant IAT of 20C requires 4kW of thermal energy, to raise the IAT from 18C to 20C may require the actual thermal energy output to be increased to 5kW, whereas if the ramped method is used going from 18C to 19C, then 19C to 20C, the required thermal energy output may be calculated at 4.5kW.

Your method is therefore what I would recommend as far as producing the greatest possible energy saving, but of course by replacing the thermal energy lost at a slower rate, the time taken to get IAT back to the desired value will be longer.

At the end of the day it is down to individuals to decide how they wish to operate their system, but what works for them quite probably may not work for others.

no apology needed Derek. It was more important to me that you at least understood what my post was driving at.

And as you noticed the chart did indeed start heating at 3am however the key point of note was that only WCCURVE was being used with a plus 3c adjustment for 3 hour period to create a slightly faster recovery. The second key point was the slope of the recovery curve within the first 3 hours. And lastly the plateaued room temperature after the recovery following removal of the +3c and reverting only to the weather compensation setting. This graph was not driven by a targeted set temperature in other words it was not the Auto Adaptive control during this trial.

the graph and comments that went with it is shown below.

“However the chart below shows today’s 24 hour chart of room temperatures showing wc with a +3 start period for the first 3 hours. Which is more efficient than Auto Adapt which seems to add 5c to the WCcurve setting and often keeps a higher flow temperature all day.”

however I have to agree that this doesn’t show the rebound to great effect since the rebound didn’t happen until 3am.

However todays chart does show a rebound at 2am and the graph then shows the WCcurve and schedule coming on at 4am. Note: see how the scheduled-reheat springboards off the rebound-reheat making what I believe is an efficient gain in room temperature before the reheat has even started.

You will also see the +3c add on was stopped a little earlier this morning so the targeted comfort temperature of 19.5c isn’t reached until later in the morning… it is Sunday after all.

So what I’m trying to illustrate here is that even with a simple plus-3c or +4 with variable period selection and an accurate WCcurve reheats are achievable for different house types. But it would be far better if it were an automated control.

The current targeted room temp, ie Auto Adaptive control sometimes does appear to get into a bit of a panic.

The reheat at 2am occurred because the OAT was lower last night, so the IAT fell at a faster rate and reached the set room temperature at 2am. This caused the heat pump to operate before the scheduled restart.

Posted by: @derek-mThe reheat at 2am occurred because the OAT was lower last night, so the IAT fell at a faster rate and reached the set room temperature at 2am. This caused the heat pump to operate before the scheduled restart.

Hi,

your first question the lowering of the room set temperatures was done by simply removing the +3 on the WCcurve. So it’s just operating from the WCcurve.

The reheat isn’t being deliberately created by setting the setback high enough so that the setback triggers a reheat. And yes this will vary depending on OAT but it still boost some the room temperature by 1.5 to 2 degrees which raises the start temperature of the reheat.

the principle isnt overly complicated but doesn’t speed up the reheat time

The above chart shows a sketched on cooling period if there wasn’t a setback bounce.

Its obviously even better if it happens right at the phased moment of the normal reheat but this might be more possible through intelligent controls.

- 27 Forums

- 2,520 Topics

- 58.6 K Posts

- 650 Online

- 6,800 Members

Join Us!

Worth Watching

Latest Posts

-

@petch Same with me, I had to insist and taking a le...

By MK4 , 1 hour ago

-

RE: Tell us about your Solar (PV) setup

Since you seem to quite thoroughly investigate every st...

By MK4 , 2 hours ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

Well I've had an interesting few days and would like to...

By giganto , 14 hours ago

-

RE: Peak Energy Products V therm 16kW unit heat pump not reaching flow temperature

Yes, here's mine. From the service manual parts numbers...

By bobflux , 18 hours ago

-

RE: Underfloor Heating Installation Issues with Heat Pump

Thanks for sharing your observations, both of you. From...

By Jonatan , 18 hours ago

-

Had to learn the hard way 🤣 now I'm sharing T...

By bobflux , 18 hours ago

-

RE: Issue with a Grant Air Source Heat Pump & Tado Smart Thermostat

Im assuming from your original post that hysterisis ref...

By JamesPa , 19 hours ago

-

RE: Heat Pump vs New Gas Boiler for Inherited House - Worth the Extra Cost?

Hi @fretless6 Mike, I have experience with Taggas (Re...

By Old_Scientist , 21 hours ago

-

RE: Daikin Altherma 3 LT compressor longevity question

@bobflux With my limited HA skills I can't ad...

By Ubert767 , 22 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

Now seems a good time to summarise the costs and effici...

By benson , 1 day ago

-

RE: Connecting Growatt SPH5000 over wired ethernet rather than wireless

The simplest wired option is usually the Growatt Ethern...

By Jonatan , 1 day ago

-

RE: Electricity price predictions

@jamespa And it seems some of the nasty public cloud...

By Batpred , 2 days ago

-

RE: Jokes and fun posts about heat pumps and renewables

Technology is rapidly advancing. BBC News reported th...

By Transparent , 2 days ago

-

RE: Do Fridges and Freezers have COP ratings?

@editor Thank you all for your replies and submitted in...

By Toodles , 2 days ago

-

I know and yes. The secondary deltaT wont necessaril...

By JamesPa , 2 days ago

-

RE: Designing heating system with air to water heat pump in France, near Lyon

Just love the way you put it! 🤣

By Batpred , 3 days ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thank you for sharing. So it seems that your Schneid...

By Batpred , 3 days ago

-

RE: Forum updates, announcements & issues

@upnorthandpersonal thanks for the thoughtful, consider...

By Mars , 3 days ago

-

RE: Solar Power Output – Let’s Compare Generation Figures

@mk4 All 21 panels have their own Enphase IQ7a microinv...

By Toodles , 3 days ago

-

RE: Setback savings - fact or fiction?

Great, so you have proven that MELCloud is consistently...

By RobS , 4 days ago

-

RE: Mitsu PUHZ120Y 'Outdoor Temp 'error?

Thanks David & James It almos...

By DavidAlgarve , 4 days ago

-

RE: Surge protection devices SPDs

@trebor12345 - your original Topic about the right type...

By Transparent , 4 days ago

-

RE: Help needed with Samsung AE120RXYDEG

@tomf I’ve been sent this from a service engineer at Sa...

By Mars , 4 days ago