Do I need a bigger volumizer: 8kW Daikin Altherma R32 LT split

Hello all,

I have an 8kW Daikin Altherma R32 LT split and I'm having a problem whereby basically the system is (or appears to be) over-specified for the house. At minimum fan rpm, minimum heat output, it still generates more heat than the house wants to take to maintain an even temperature. I have tried everything - different emitter types, different temperature ranges, different weather compensation curves, different pump settings, you name it, I've tried it. We have a recently renovated/extended 1960s double-walled bungalow, now a two-storey house with the original bungalow section cladded and south-facing, and the new back area built with standard building regs cavity walling. Reasonable insulation in the roof (30+cm of itchy stuff). Calculations showed that the system needs to provide 5.5kW, so an 8kW system was specified (which seems reasonable). I have an 18 litre volumizer in the heat pump loop, feeding the radiators via a low-loss header. Pump is a fairly standard Grundfos pump with various operating modes available. Heating system is an Honeywell Evohome set-up. Most rooms have Honeywell TRVs, plus three on standard TRVs set to about 20C, and two heated towel rails which are left open to provide minimum flow capacity at all times.

The most efficient set-up I've found at the moment is this:

- Evohome sets target temperature of radiators, all about 20-21.5C during the day, about 19C overnight.

- ASHP is set to be in underfloor heating mode, 8C temperature difference at max 38C, no weather compensation, triggering via temperature comparison of out vs return flows.

- Grundfos pump is set to auto-pressure mode, so it sets the speed according to how open the TRVs are.

With this, I get around a SCOP of 2-2.5 for external temperatures around 8-12C. When it's colder, the SCOP goes UP to about 3.

The last few days, we were away on the Saturday so the system was turned off from 9am and the house cooled slowly. From midnight to 9am we had a SCOP of about 2.

It was turned on again on Sunday morning at about 9am and the house had cooled to 15-18C. By the time we got home at about 5pm, everything was back up to temperature... with a SCOP of 4!

General consensus from Daikin (who spent a lot of time trying to figure this out last year) and the experienced installers is that the system is simply over-specified and is working correctly when it's not having to cycle in and out, which tallies with our experience in the last few days.

So... after all that... I have a simple question - would a larger volumizer help? Basically we need the ASHP to be on for longer at a time (not just the pump, actually doing work to heat something, so min operation time doesn't help), so if we fitted a larger volumizer, would this ensure that the ASHP is working for longer, then off for longer?

Any other suggestions are welcome but believe me, we've tried everything, including the oft-suggested route of setting all of the TRVs wide open and controlling heat output via the lock nut valves. This doesn't work for us because the heat requirement in the rooms varies massively depending on whether it's sunny or not, as we're south-facing on the side of a hill with a patio in front of the house which reflects even more sun back to the house! In any case it doesn't solve the problem of the ASHP cycling, as fundamentally the heat needed by the house is less than the heat provided by the ASHP at minimum operating conditions.

Thanks in advance!

Can you provide some more info?

What leads you to believe its oversized. If its cycling, how often, at what oat?

Roughly what's the system volume (how much water in it)

Have you got any other buffer tank, plate heat exchanger or anything else in the system we need to know about. What's the llh for or is this the same as the volumiser

So far as I can tell from the specs Daikin only make one or two different variants of hardware in any given range and just rate them down in the firmware, thus 'lower power' models may not modulate down as much as one might expect. If your calcs said 5.5kW it's an evens bet the real demand is <4 and with an 8kW device that may well be a downrated larger one I think your conclusion is almost certainly correct, it would just be better to have more info before trying to speculate on answers.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

@jamespa Thanks. Apologies, I've no idea what "oat" is. Assuming it's something to do with temperature, I have it set to target 38C, and it's aiming for 8C differential (i.e. 30C coming back), though I'm not sure if that setting applies to underfloor heating in the same way. No idea what the system volume is, I'm afraid - we have 16 radiators of average size 500x800, I'd say, plus two towel rails.

There's no buffer tank, there's a heat exchanger inside the inside unit to take heat out of the circuit to the outside unit. No idea what llh is, I'm afraid. Sorry for not being au fait with the tradesman's terms!

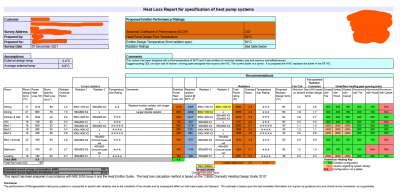

I've just looked back at the calculation spreadsheet, and it seems to be calculated as 6.8kW (I misremembered) with a target radiator temperature of 50C, which seems really high. Have I just gone down completely the wrong route for configuration...? The calculations are shown below...

Posted by: @rgledhill@jamespa Thanks. Apologies, I've no idea what "oat" is. Assuming it's something to do with temperature, I have it set to target 38C, and it's aiming for 8C differential (i.e. 30C coming back), though I'm not sure if that setting applies to underfloor heating in the same way. No idea what the system volume is, I'm afraid - we have 16 radiators of average size 500x800, I'd say, plus two towel rails.

There's no buffer tank, there's a heat exchanger inside the inside unit to take heat out of the circuit to the outside unit. No idea what llh is, I'm afraid. Sorry for not being au fait with the tradesman's terms!

I've just looked back at the calculation spreadsheet, and it seems to be calculated as 6.8kW (I misremembered) with a target radiator temperature of 50C, which seems really high. Have I just gone down completely the wrong route for configuration...? The calculations are shown below...

-- Attachment is not available --

Sorry, im not a tradesman but have spent far to much time on heat pumps so have become blasé about the TLAs (three letter acronymns)

oat = outside air temperature, llh = low loss header which you mention.

Rad temp depends on site of rads in relation to room loss. System size is independent of rad temp and is basically your whole house loss.

If you could answer the remaining questions now I explained the jargon, I'll take a look at some of the data.

Spreadsheet shows both ufh and rads, can you clarify what you actually have. It's a bit confusing to say the least. Do you have any system diagram?

Is weather compensation enabled?

Also you say you are operating at 38 yet the rads were apparently sized for 50. Is 38 sufficient when it's really cold outside, or only in milder temps.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

Thanks James, TLAs are the way of the world these days! It's cycling a lot at outside air temperatures of between 8 and 15C, less so at 7C or less. Do you have any suggestions as to how I might estimate the system volume? It's an average 3-bedroom house with the configuration of radiators and towel rails above.

I guess the spreadsheet calculates things for both types of systems, but we have radiators. I just happen to have ended up with it configured in UFH mode as this gives more continuous operation, ignoring the external pump activity and monitoring the leaving vs return temperature to see if it needs to run.

I've had weather compensation enabled but it actually made things worse, since it reduced the flow temperature even further and causing even more cycling around the house's set points. Turning weather compensation off and fixing it to 38C means that the system doesn't continuously run at low duty cycle.

I realised I'd actually posted initially about this back in 2022: https://renewableheatinghub.co.uk/forums/renewable-heating-air-source-heap-pumps-ashps/daikin-altherma-lt-r32-poor-scop-and-breaking-heat-exchangers

Sadly my final post was somewhat premature as it happened to be that it spent the first full day getting the house back up to temperature, resulting in a nice high COP. Once the house was sitting at the desired temperatures, we went back to cycling again.

The house will actually stay perfectly warm at 32C at 10C or higher, and 38C even at -5C.

I think the estimated energy usage is way off. The calculations show 19,000kWh/yr but even with two EVs doing nearly 20,000 miles between them, we only use 15,500kWh in total for the house! I'd estimate our annual heating usage (CHW only) is probably around 6-7,000kWh/yr, which further confirms my suspicion that it's grossly overspecified.

OK

I think you have two problems, excess cycling, and poor cop at moderate oat (outside air temperature). The first may explain the second, but more likely its just one of at least two contributing factors and not the dominant one.

Your system volume is probably about 100l based on your rads. But I strongly suspect it rarely reaches this because most of the time several, possibly the majority, of the rads are shut off. So much of the time it's probably very small.

It's likely that fitting a larger volumiser will lead to longer cycles however much less likely (but not impossible) it will fix your cop problem (cycling is not ideal, but the extent to which it is not ideal appears to be unquantifiable and its unlikely to be a factor of 2). I am suspicious of the llh, these are just very small, 4 port buffer tanks and afaik have no place in an efficient heat pump setup.

Personally I wouldn't buy more hardware before working out what's likely to be happening. To do that you need a system diagram and some data on the cycling, and quite possibly some temperature measurements across some of the components.

If you would be able to post a system diagram I and others might be able to make some informed suggestions, without its largely guesswork. Without that its pure guesswork and given how long you have been trying and the apparent scale of the problem the chances of mak8ng the right guess are quite small.

I realise this is not what you want to hear but I think that the duration and number of the attempts to fix to date point to a more root and branch review.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

Thanks James. I'd come to the same conclusion about the effective system volume as the radiators are likely to be largely closed when the house is sitting at its set point, which is what led me to ponder the idea of having a larger volumiser which would (I think?) have a similar effect to having the radiators with the valves fully opened.

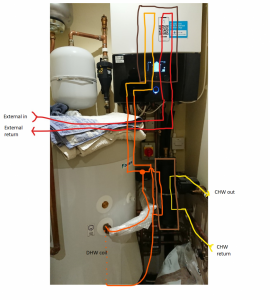

I'll try and put together a system diagram - what's missing from the overlaid photo I put in the other thread? I can then find out the information you need and add it in.

What information do you need on the cycling and temperature measurements? I will do what I can to measure things, if you can point me in the right direction.

Many thanks for the help and thoughts.

Ok first questions

What's the box in brown (llh or heat exchanger)

When it cycles how long off how long on

Where is the 17l volumiser and llh you mention

Hom many water pumps are there and are they wired to the heat pump controller

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

Adding a larger volumiser is not the same as having all the radiator valves fully open, because once it is up to temperature the heat loss on the volumiser should be quite small, which should not be the case with the heat emitters.

All heat pumps will start to cycling once the OAT gets above a temperature of probably 6C to 10C, dependent upon the size and make of heat pump and the relevant heat loss.

Ideally you should aim to have all the TRV's fully open, individual room temperatures achieved by balancing of the lockshield valves, and operate the heat pump at the lowest Leaving Water Temperature (LWT) on Weather Compensation (WC).

To try to prevent room temperatures rising too high, but also reduce cycling frequency, set your room thermostats 1C above the desired level, ideally with a 1C deadband between switching the heat pump off and switching it back on. You should hopefully find that your heat pump runs for a longer period at higher efficiency, until the room temperatures are raised to say 22C, at which point the heat pump should shutdown for an extended period while the room temperatures fall from 22C to 21C, at which point the heat pump should restart. Try to keep doors open to allow for circulation of the air to help balance out room temperatures.

Then adjust the WC curve settings to provide the desired room temperatures when OAT is low enough that cycling does not normally occur.

If you try this method then please post back on the result.

@jamespa External box in brown is the LLH (heat exchanger is inside the main Altherma internal unit above, the upper brown box); cycles on/off time - very difficult to tell, as the pump continues to run even though the outside unit compressor is off, not sure how I can measure or quantify this; 18l volumiser is the white vessel directly above the DHW cylinder; there's one water pump inside the Altherma internal unit which does the loop to the external unit (red line) and another that goes through the volumiser and the LLH (orange / light orange loop). There's the Grundfos pump which is the other side of the LLH and is the standard CHW pump, controlled by the EvoHome system. I can either control the yellow/orange loop pump directly in line with the external (Grundfos) control, or I can control it based on leaving/return temperature of the orange lines.

@derek-m Agreed and understood. Unfortunately (as explained above) the idealistic approach of having TRVs fully open and controlling flow rate using the lockshield valves isn't appropriate for our system, due to massively differing heat requirements on half of the house depending on whether the sun is shining or not. I spent many, many days trying to get this to balance and it proved completely impossible. That said, I guess I could try it again, but I did spend considerable time on that approach as I realise it's often touted as best practice where possible.

Also (sorry to keep coming back to this) - the house simply needs less heat to maintain 21C than the ASHP generates at minimum operation, so cycling is 100% inevitable. All I can do is make the cycling as infrequent as possible, hence the idea of using a larger volumiser to slur the cycling - at least, that was my theory.

Posted by: @rgledhillAlso (sorry to keep coming back to this) - the house simply needs less heat to maintain 21C than the ASHP generates at minimum operation, so cycling is 100% inevitable. All I can do is make the cycling as infrequent as possible, hence the idea of using a larger volumiser to slur the cycling - at least, that was my theory.

As I say above, whilst the cycling is likely to be degrading performance its unlikely that it accounts entirely, or even in the majority, for the poor cop you tell us you are seeing. So you can fit a larger volumiser and it will increase the cycle time, but it probably won't fix the cop (although it will probably help).

Basically I agree with @derek-m but also think you are likely to have other problems. That llh (if that is what it is) has got to go as its more or less certainly causing you significant inefficiency. Is it inside the insulated thermal envelope of the house?

Fundamentally imho you need a review of the system design, which needs a system diagram, then to set it up properly, starting with @derek-m s advice (there is a possible compromise where you have say half of the trvs fully open and properly balanced) and then review again to work out what tweaks need to be made but this time starting from a sensible place. If you attempt to tweak from where you are you may improve things a bit, but more likely than not you will be finding another 'local better' not the significant improvement you seek.

As a caution all of my comments are based on the limited info about the system I have so ay yet be proven wrong.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

-

Daikin 6kw setup with Dixell controller

2 weeks ago

-

Daikin Octopus installation update - I saw my first defrost. 😍😂

4 months ago

-

Daikin Error Code 7H05

1 year ago

-

British Gas versus Octopus: Two possible heat pump routes - how to evaluate them?

1 year ago

-

Daikin COP / energy used measurement from MMI

2 years ago

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 272 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

I'd be happy with what you have (so would millions of o...

By Deltona , 13 minutes ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@benson I see, I misunderstood obviously. So you set LW...

By Tasos , 31 minutes ago

-

This is absolutely standard for any sealed pressurised ...

By JamesPa , 10 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 10 hours ago

-

RE: What determines the SOC of a battery?

@batpred Your BMS parameters will be the same as m...

By Bash , 11 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 12 hours ago

-

RE: Setback savings - fact or fiction?

I also need to correct something I said by mistake earl...

By cathodeRay , 12 hours ago

-

RE: Electricity price predictions

@judith Thanks for sharing, and nice to see how the ...

By Batpred , 12 hours ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 15 hours ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 15 hours ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 15 hours ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 17 hours ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 17 hours ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 19 hours ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 20 hours ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 20 hours ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 1 day ago

-

RE: DIY solar upgrade - Considering adding more panels

I know this is a bit old, but it made me wonder what co...

By Batpred , 2 days ago

-

RE: New Vaillant aroTherm Plus in black - When will it come to the UK?

@majordennisbloodnok Daikin, take note! (In fact, I hav...

By Toodles , 2 days ago

-

RE: Midea ASHP – how to set weather compensation

@mk4 — good work! First, I agree, no evidence of cycl...

By cathodeRay , 2 days ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

I don't know about Solis inverters. It isn't a featur...

By Transparent , 2 days ago

-

Daikin Altherma 3 H HT - Freeze Prevention Threshold

Hi. We have an Altherma 3 HT (18kW I think) which, now ...

By RICHARDF5033 , 2 days ago

-

RE: Passiv Smart Thermostat - Help & Forum Support

@petch We are not yet compatible with the R290 from Gra...

By Will H , 2 days ago