Bosch CS5800i 5kW - Experience So Far

Around two years ago, my partner and I moved into a new-build ground-floor flat in Edinburgh. This flat was claimed to be energy efficient and cheap to run, with a heat pump supplying both the underfloor heating and hot water. It was not until after we'd agreed to the purchase, and I started doing some research that I started to get worried. However, it wasn't until we moved in and I was able to get a proper handle on it that the flaws gradually revealed themselves.

The Old System

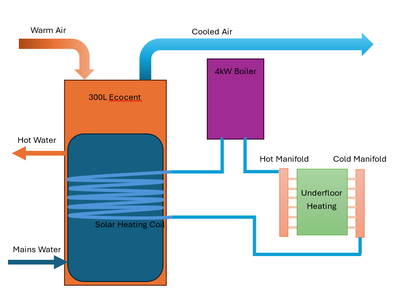

The system that came with the flat was composed of underfloor heating throughout, with an Earth Save Products 300L Ecocent Exhaust Air heat pump which draws air from the kitchen and bathrooms, extracts the heat and moisture from it in its small heat pump unit, then vents it outside. The heating was supplied through a reverse use of a secondary solar heating coil within the Ecocent:

This had numerous issues. First, the Ecocent itself is fairly loud while running the compressor, and it is in a utility cupboard in the middle of the flat. In winter it would run constantly, and while we got used to the drone, it was far from ideal. Then there was the way drawing heat out through the solar heating coil impacted our hot water. If the heating was running for any significant length of time, the tank temperature in most of the volume would drop substantially, but the top of the tank would remain hot. This generally gave us about 50-75L of hot water, and then a sudden drop to water in the region of 30C, unless the electric boiler was running. However, as the electric boiler was on the hot side of the manifold, it typically wasn't able to actually heat the water in the tank if that temperature dropped. Finally, with the Ecocent set to store at 50-55C, this meant the underfloor heating flow temperature could be as high as 55C. The manifold did have a thermostatic mixing valve on it, but that introduced its own slew of issues. Set fully open, as it was when we moved in, it would permit 55C water into the underfloor manifold, potentially damaging the floor coverings. But set to a more reasonable flow temperature of 40C, it would then start passing 32-35C water back to the Ecocent after going through the floor, and it would become impossible for the boiler to heat the hot water at all.

That's to say nothing of the fact that the Ecocent was only able to achieve a delta T between its air inlet and outlet of about 15C, which meant that our overall energy balance would become negative when the outdoor temperature was below 7C:

21C Air is drawn in, cooled to 6C, then vented outside. Outside air would be drawn in to replace the lost air, if it was freezing outside, that meant the heating would now need to heat the same volume of air from 0C to 21C. All that shortfall could only come from the boiler.

During the colder months, I had to constantly watch and manage our heating and hot water in order to get reasonable comfort at a minimum (but still very high) cost. It was exhausting.

Looking for Something Better

After a full year of attempting to work with the system we had, and after more complaints to the builder than I can could, we finally had to accept that it wasn't going to get much better. While I was able to work around the hot water issue by turning the heating off for a few hours overnight, it still left the flat cold and uncomfortable. My attempts to get the existing system working had led me to Heat Geek videos and Urban Plumbers, and I'd already done a heat loss calculation both by hand and in Heat Punk, so I had some ideas for where to start. Depending on air change assumptions, we were probably looking at a heat loss between 2.5 and 3kW at a design temperature of -4C.

The big question was funding availability. As expensive as our system was, my spreadsheets suggested we only stood to save between £400 and £600 per year by switching to a heat pump, and we don't expect to remain in this flat for the 30 years necessary to pay off an 'average' heat pump install. The good news was that we shouldn't be an average install; we already had a plant room, a hot water tank, and underfloor heating throughout. Really all we needed to do was find somewhere to put the pump, and connect it to the underfloor manifold.

The less good news was that our existing EPC certificate already claimed that our heating was by 'heat pump' so it was possible that we'd be turned down point blank when it came time to apply for the Home Energy Scotland grant. It took a few weeks of back-and-forth, and an in person assessment from a HES advisor, but eventually they were able to give us a detailed report which recommended a heat pump, and the EST accepted it.

At the same time, I was also trying to negotiate the mess of permitted development and planning permission.

As a flat, we don't seem to need to comply with the 1m rule, which in theory meant we could get the unit installed under permitted development. However, the best location for the unit was in our front garden, which then removed the possibility again. In addition, we needed to seek permission from the factors for our block of flats, and through them all of our neighbours, too.

However, while all this took weeks or back and forth, it was eventually decided that this was something we could do, provided we met the necessary noise requirements.

Enter the Bosch

As a flat, we obviously have neighbours on all sides, and the windows closest to all of our possible heat pump sites were living and bedrooms. The furthest we could possibly get away from a neighbour's window was probably about 2m, and the best site was only about 1.5m away. This placed some very tough limitations on the noise level from the unit. Many of the installers we arranged to visit for a quote didn't really seem to understand this, and they kept on giving me the same line about how quiet they are, and how I could come to one of their other installs to hear how quiet it is.

I had to keep repeating that I'm not worried about the actual noise. I was purely worried about making sure we passed the MCS test.

While I'd been playing around in Heat Punk, I'd noticed the strange sound level of the Bosch CS5800i unit, which was reported at just 42dB, a whole 10dB less than the next quietest heat pump. I became intrigued by it, as at 42dB I could effectively place it anywhere without needing to worry about noise. All I needed to worry about was the minimum safety clearances due to its use of R290. The Bosch is available in 4, 5 and 7kW versions. I originally planned to go with the 4kW version, but upon reading the specs it looks like the minimum modulation on the 4 and 5kW is the same, so that's what we got in the end.

Finding someone to actually specify the Bosch, however, was easier said than done. We had multiple quotes for Vaillant, Riello, and Nibe units, but only a single installer was willing to go with the Bosch. Fortunately, it was one of the more reasonable quotes at £10,100 before grants.

The Install

After getting our grant promise, permission from the neighbours and factor, and planning permission, we finally began the install around 9 months after I decided to start the process of pursuing a new heat pump. I spoke to the engineer about the plans, and was very happy to hear that we were in agreement about what was needed. We'd remove the boiler and all the existing room thermostats, moving to an open loop system. We'd run the pipework from the heat pump through the ceiling void to the utility room. We'd connect the wall hung indoor unit to both the heating and the Ecocent to provide a quicker hot water heat-up time, but not in series this time. There would be no buffers, low loss headers, or volumisers on the new system as it was all open-loop underfloor with plenty of thermal mass.

It wasn't all sunshine and roses, however.

The installing engineer had never installed a Bosch heat pump before, although he had a high opinion of Bosch from working with their boilers for years before he'd switched to heat pumps. He did however have a lot of experience with Vaillant units and figured it would mostly be the same. The manuals held a few errors and pitfalls which delayed things by a few days due to incorrect wiring diagrams. The biggest woopsie was probably when I noticed that there was no expansion vessel on the heat pump's circuit. The guy who hung the wall unit assumed the plumber was fitting one, and the plumber assumed it was in the wall unit. The two commissioning Bosch engineers missed it too, as they thought the hot water expansion vessel was on the heating circuit. But that issue was fixed almost as quickly as it was noticed.

The sensors for the hot water tank also presented an issue, as different configurations of sensors require different resistance profiles from those sensors, and we ended up with the wrong sensor 3 different times, which might be a record.

Finally, it took nearly an entire day to bleed air from the system due to the design of the wall-hung unit, and even now it will occasionally complain about pockets of air, but fortunately I'm plenty savvy enough to bleed the few pockets that remain.

The End Result

So far, although we're not yet fully into the heating season, we're happy with the unit and the install. It looks sleek and is whisper-quiet. We'll have to see how it is while running a defrost cycle, but at the moment even when running flat out it is basically inaudible beyond a couple of meters from the unit. In the low-noise operation mode it is even quieter, and I basically need to stuff my head down the back of the unit to hear anything more than air movement.

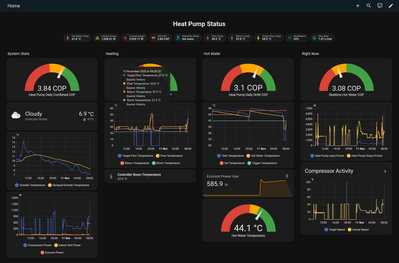

Currently, we're heating our hot water each morning at a COP of about 3.6 (45C store temperature, heat pump assisting up to 42C, then Ecocent alone up to 45C. The combined COP of the two together is similar or even a little higher but it's hard to judge as we can't measure the heat output of the Ecocent) and what little heating we've done has been at a COP of around 4.5 but the weather is still fairly mild. It's fully open loop and controlled only by weather compensation. The maximum flow temperature is 36C at -6C and the design dT is 4.5K. The actual COP since we installed the unit is only around 2.8, however, as the unit has a standby draw of about 25W on average. That actually adds up when we're doing so little else.

All we still have left to do is to paint the outside insulation to match the brickwork.

Total cost was around £10,600, including the cost of arranging for planning permission and for a new EPC.

We were able to claim both the £7500 HES grant, and the £2000 Barclays Greener Home Reward. Finally, our installer was also able to claim £500 from the Bosch Clean Heat Cashback scheme.

Good to hear of peoples experience with both your type of systems. Exhaust air work better in warmer climates or situations, over here we often don't have enough waste heat to reuse. Earlier Bosch heat pumps were not made by them and were not up to the standard expected, which is why you struggled to find an installer. They are now made in the UK I believe, time will tell how good. Your COP of 3.6 and under isn't good, we've had a very warm Autumn so far. An update from November would be appreciated.. Hope all goes well, at least you don't have a drone anymore!

We do like the exhaust air heat pump as a centralised MEV system. It means we get good extraction from the bathrooms without the accompanying noise of an extractor fan. New builds often have always-on extractors in bathrooms and en-suites (as we did in our last flat), which are noisy enough that they are typically turned off at the isolator switch a lot of the time. That often contributes to the damp problems in many new builds, and I can say after two years that we do not have any damp problems at all in this flat.

Trying to use it as the primary source of heating is just a bit of a bridge too far, however.

As far as the current efficiency of the new system goes, we're still right on the edge of needing heating. I'm not completely clear on exactly how its weather compensation system operates, but it may be something similar to Vaillant's energy integral as it has so far only come on sporadically and while it obeys the compensation curve when on, it is frequently off when you might expect it to be on. The temperature has stayed rock solid on 21-22C, however, so for now I have no complaints. We'll see how it goes as we get deeper into the heating season. Today it came on briefly and, for the hour or so it was operating, it was running a COP of 5 so I'm not too worried yet.

Also, while the numbers nerd in me wants to push it to the best possible efficiency, there is the fact that we were replacing an electric boiler anyway, so even a lousy COP is likely to save us some real money in the long run.

I'll definitely report back when I have some better data, although I think my biggest gripe at the moment is with the energy monitoring in the app. It only reports numbers rounded to the nearest 0.1kWh, despite measuring to a precision of 0.01. It only uses the high precision numbers for drawing its graphs, and doesn't even include them in the output CSV files. Also, it only retains hourly data for the last 3 days, which makes tracking its use a little annoying. I may have to invest in a proper energy monitor.

Excellent posts, thank you for sharing! Rare to see one of these units in the field, let alone detailed so comprehensively...

I had a chat with the Bosch team about the 5800i at Installer Show this year; they confirmed that the control mechanism is based on hysteresis, not 'energy integral'.

Please do keep this thread updated with winter performance if you can.

Fully agree. First Bosch on the forums, so it'll be good to see how it performs.

Get a copy of The Ultimate Guide to Heat Pumps

Subscribe and follow our YouTube channel!

Posted by: @ectoplasmosisExcellent posts, thank you for sharing! Rare to see one of these units in the field, let alone detailed so comprehensively...

I had a chat with the Bosch team about the 5800i at Installer Show this year; they confirmed that the control mechanism is based on hysteresis, not 'energy integral'.

Please do keep this thread updated with winter performance if you can.

Yes, over the last few days I've been keeping a very close eye on it as it didn't seem to be performing as I'd come to expect. As you say, after watching it closely, it's clear that it's using a hysteresis system to manage cycling.

At this point, I've confirmed my suspicions and can say with some certainty that there has been another (blessedly easy to fix, I think) shortcoming in the installation.

As I think I said before, we have the system installed without volumiser, buffer, or low-loss header, and it is feeding a fully open loop in-screed underfloor system. What I noticed was not only that the heating was, as @dgclimatecontrol suggested, somewhat less efficient than it should be, but it also wasn't 'always on' as it should be. My understanding is that the water in the underfloor loops should be continually circulating, even if the compressor has cycled off and in our case it is not.

What has been happening is that the heating was coming on, then eventually overshooting its target flow temperature. The compressor then cycles off, but this also turns off the pump housed in the wall-hung unit, leaving the water in the pipes stagnant. With the lagging, this means that the temperature in the flow pipe (where the flow sensor is) drops very slowly. Only once that section of pipe eventually air-cools does the compressor get triggered to come on again, at which point it starts circulating and the much colder underfloor (or outdoor) water cools the pipe further, resulting in the controller ramping up the heat output to compensate. This means we were seeing shorter bursts of relatively high power and low efficiency heat at long intervals. Additionally, heating the hot water tends to introduce a small 'slug' of hotter water to the heating circuit, which effectively blocks the heating from coming on for 8 hours or more after going into hot water mode.

I think our installer assumed the pump in the wall-hung unit would continue to run while the compressor was off, but the heating mode was active. To be fair, there's nothing in the manuals which suggests that this is impossible, but then the manuals also presuppose a buffer in all cases with the flow temp sensor installed in the buffer itself. This is despite the commissioning process allowing for a no-buffer system.

Fortunately, we opted to keep the old circulation pump on the manifold; it was simply powered off. I have turned it back on, and things are already looking a lot more like I would expect. All that needs to happen is for that pump to be rewired to the control board of the wall-hung unit so that it can be automatically turned off when the unit goes into 'summer' mode. This is something I can probably do myself, but I'll give the installer a chance to inspect/fix it first to avoid impacting service agreements and the like.

I have also contacted Bosch regarding the limitations of their energy monitoring and asked if they have any plans to allow me to interact with the unit through Home Assistant (or other smart home setup).

It's early days, but turning on the underfloor circulation pump has brought the heating COP from between 3 and 4 to over 5 (in not at all cold weather, of course).

When we get into some colder weather, I'll update with our experiences.

What a difference a pump makes.

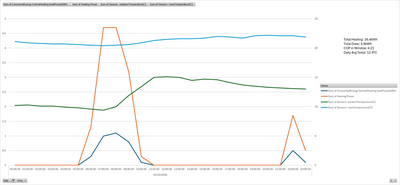

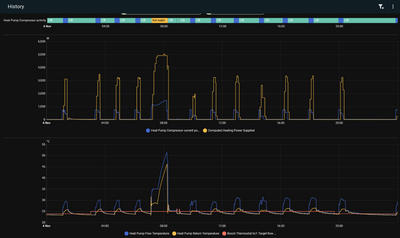

We don't have OpenEnergyMonitor installed, and the resolution of the data provided by the Bosch app is limited, but I've been doing what I can with it. Here's a graph of our purely heating energy use for the day before I switched on the circulation pump:

A spike of higher-power use, then nothing for the rest of the day (admittedly, the flat barely needs to be heated at these temperatures, but as it's on purely weather compensation, that shouldn't really matter until I can dial in the curve). At first glance, the COP for the day was 4.21 for just heating (lower when hot water is included, but I'm optimising that separately), which isn't terrible, but it could be better. The pump didn't really modulate below the 50% upper bound imposed by the low-noise mode. Additionally, the data resolution is making things look better than they are, as it rounds the hourly idle use of the unit to zero when it's actually pulling an average of 25W constantly. Not much, but when not much heating is happening, that extra 0.5kWh of missing draw drags the true heating COP down to 3.75. For a mild 12°C day, that's not as good as I was hoping for.

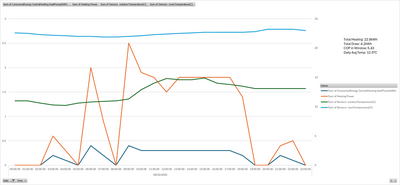

After turning on the pump, yesterday was a very similar day in terms of temperatures:

Clearly, I need to adjust my heating curve down more, as the room temperature got up to 23°C, but the behaviour of the pump looks much better. It modulated down to its minimum compressor power of 18% and sat there for much of the day, achieving a true heating COP of 5.1 for the day (including the missing idle draw). The end result is we used 4.4kWh for heating on the 5th, and 4.5kWh for heating on the 8th, but got 6.3kWh more actual heating out of it.

It is heating we didn't really need, though. I suppose the next step is to keep turning the curve down until the temperature equalises. I may also want to turn on room influence, but I want to get the curve to roughly the right area before I do that.

At the risk of looking like I'm talking to myself, I wanted to record some of my more recent findings regarding this unit. There's not much easily found online about this unit, but recently I have discovered that the install base in Germany seems to be much larger, and better established. I've been reading through some German-language blogs and forums to improve my understanding of the unit and how it works. From what I can see, the Bosch unit is functionally the same as a Buderus Logatherm WLW186i AR.

Getting Good Data

Firstly, by purchasing an EMS Bus Wi-fi Gateway, I've been able to increase my logging capabilities by a huge amount. I'm no longer limited to the information Bosch have provided in the app as the EMS bus gives energy consumption and heat production figures to 2 decimal places, broken down into hot water, heating, and cooling, as well as totals. Based on chatter on the German language forum Haus Technik Dialog, where people have compared the numbers provided by the EMS against third-party metering devices, the accuracy seems fairly high. It even tracks the energy lost during a defrost by ticking the counter backwards.

I have been able to send this information into Home Assistant, which gives me the ability to track a large number of data points:

Using the Data

I am also able to send commands to the heatpump, which I have tried to minimise for now; however, I do have an automation which alters the silent mode setting for hot water vs heating. I have also set up an automation which minimises the use of the underfloor circulation pump. Now, rather than operating 100% of the time, it is off while the compressor is running (as the included pump is able to handle circulating the heating easily), but when the compressor goes off (and the included pump goes off), I now have the circulation pump pulse on for 4 minutes every 12 minutes to make sure the flow/return temperature readings are reasonable. This seems to work well.

Looking at the graphs also allowed me to identify some issues with my weather compensation curve. Our flat is very well insulated and has a heat loss of around 2.8-3.5kW at -4C (depending on how many window vents are open and wind direction, etc) which means that the unit will need to cycle at basically any temperature above about 8C:

I wanted to improve this cycling behaviour a bit, however and after watching the system for a while, it became clear that it can't sustain a flow temperature of less than 27 at all, and it is only able to maintain 27 for a while before it overshoots. The lowest flow temperature it seems to be able to manage for an extended period of time is 28C. With this in mind, I've implemented a minimum flow temperature of 28 in the weather curve, alongside a reasonably large room influence so that when it overshoots the target room temperature by a degree or more, the whole system will stop trying to heat until the flat's temperature has dropped sufficiently. In colder weather, it will also tail-off the heating power delivered above the target temperature. It's still early days on this control strategy, but I'm hopeful.

Investigation and reading on the German-language forums has also made a few other things clear.

Quirks and Features

- Compressor on/off is managed through flow-temperature hysteresis. The flow temperature is allowed to overshoot the target by up to 4K before the unit turns off. It will then wait until the measured flow temperature is 2K below the target flow temperature before kicking on again.

- The expected installation has a small 2-port buffer, and the installer should ensure that the heating system dT matches the heat pump's target dT or you'll end up with mixing and distortion. Some owners have used flow/return temperature sensors and Home Assistant to intelligently manage the system's dT, and have seen good results. The instructions do not really talk about this (they just give a flat 4.5K for underfloor and 7.5K for radiators).

- The unit has two (or three, kinda) different defrosting modes. 'Smart Soft Defrost' is used if the air temperature is over 5C and involves running the fan at a higher speed while still employing the compressor. This allows it to defrost while still providing heat. If the unit is in silent mode, it will instead turn off the compressor and keep the fan running, for a similar effect, but without the continuous heating. Once the ambient temperature drops below 5C the unit does a proper defrost by reversing the flow and drawing heat from the heating/hot water systems.

- There may be a bug in the ECO+ hot water mode which forces it to go to maximum power immediately, rather than ramping up through the heating cycle. This is a behaviour I've seen, but I can't be sure if this is because the bug isn't fixed, or if it's due to the peculiarities of our EAHP, which has a coil capable of sucking up a lot of heat.

Posted by: @steelbadgerAt the risk of looking like I'm talking to myself

…

Have you ever heard of Warnock’s Dilemma? My guess is that it applies here because you’ve said all that needs to be said. A good job comprehensively chronicled.

Well done.

105 m2 bungalow in South East England

Mitsubishi Ecodan 8.5 kW air source heat pump

18 x 360W solar panels

1 x 6 kW GroWatt battery and SPH5000 inverter

1 x Myenergi Zappi

1 x VW ID3

Raised beds for home-grown veg and chickens for eggs

"Semper in excretia; sumus solum profundum variat"

I’ve been reading to find out about the Bosch and you’re learning fast. Just for info our Vaillant is giving a cop of 5-6 in this mild weather. Our design is for 42C at -2C, but I can’t see the present flow temp easily but cop for Nov is 6.1 (suspiciously high on just the Vaillant readings)

Good luck with the investigation and improvements!

2kW + Growatt & 4kW +Sunnyboy PV on south-facing roof Solar thermal. 9.5kWh Givenergy battery with AC3. MVHR. Vaillant 7kW ASHP (very pleased with SCOP 4.7) open system operating on WC

Posted by: @majordennisbloodnokHave you ever heard of Warnock’s Dilemma? My guess is that it applies here because you’ve said all that needs to be said. A good job comprehensively chronicled.

Well done.

I'm not all that worried about the talking to myself thing, but I know some forums frown on bumping your own posts repeatedly. In this case, though, I'm hopefully documenting something useful for any future (english-speaking!) Bosch customers.

Posted by: @judithI’ve been reading to find out about the Bosch and you’re learning fast. Just for info our Vaillant is giving a cop of 5-6 in this mild weather. Our design is for 42C at -2C, but I can’t see the present flow temp easily but cop for Nov is 6.1 (suspiciously high on just the Vaillant readings)

Good luck with the investigation and improvements!

This is certainly the target. I've largely let it run without too much interference over the last few weeks to get a feel for how it's working. The upshot is that once we're below about 8C ambient temperature, the unit performs fairly well, but it can be a bit unruly and annoyingly inefficient when it falls below its minimum part load. Most of what I've been doing over the last few days has been aimed at curbing that unruliness. I think setting a minimum flow temperature has been a good start. If I put today side-by-side with a reasonably comparable day from earlier in the month, I see much less cycling, and a heating COP of close to 6, which is a big improvement over the cycle-per-hour of the comparison day, which had a heating COP of just 3.75.

The flat is still warmer than it should be, however, so there's still some work to do to find a way to turn it down further without impacting the newly-found performance.

Thank you for your continuous research, and posts. As you’ve mentioned, there’s very little in the way of English-language info about this model out there.

Interesting about the Bosch unit being identical to the Buderus; is the Bosch a white-label version engineered by Buderus, or the other way round? The older Bosch units were indeed outsourced…

-

My Octopus Cosy 6 Heat Pump Journey: From Quote to Completion

3 months ago

-

Yes, the "zoning with ASHP" topic again...

9 months ago

-

Installations in Flats

1 year ago

-

My British Gas – Heat Force ASHP Installation: A Frustrating Experience

1 year ago

-

Low shower pressure after ASHP retrofit

1 year ago

Currently viewing this topic 1 guest.

- 27 Forums

- 2,475 Topics

- 56.9 K Posts

- 776 Online

- 6,165 Members

Join Us!

Worth Watching

Latest Posts

-

RE: If a heat pump can only heat DHW to 50C then what? Issue with 18KW Heliotherm heat pump

Hi, Nothing yet. I've asked customer to measure flow...

By errmm , 3 hours ago

-

RE: High Temp Heat Pumps for fast warm-up of house

I don't know exactly how long it takes to heat up (and ...

By JamesPa , 4 hours ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

OK. What Im seeing looks fairly normal TBH: 1 start ...

By JamesPa , 5 hours ago

-

RE: Vaillant Tech Support Flagged Low DT: UFH Return Cold, Suspected Zero Flow

@editor thanks for the tips which I will try before cal...

By DavidB , 7 hours ago

-

RE: Daikin 6kw setup with Dixell controller

@jamespa Many thanks for your reply, a very detailed an...

By CraigH , 7 hours ago

-

RE: Exploring the role of alternative clean heating solutions - Government Consultation

Despite reservations, I found some time to respond to t...

By Rusty , 7 hours ago

-

RE: New Vaillant aroTherm Plus in black - When will it come to the UK?

@crankplus, nope, still not, and I've followed up with ...

By Mars , 7 hours ago

-

RE: Octopus Cosy Heat Pump Owners & Discussion Thread

@agentgeorge Probably, but temperature change at -10 ha...

By AndrewJ , 8 hours ago

-

RE: External wall insulation - your experience

To be clear, my experience was very positive. The journ...

By Batpred , 10 hours ago

-

@foxesfan Re: ‘Servicing’ as @editor has covered in his...

By Toodles , 10 hours ago

-

RE: A Smarter Smart Controller from Homely?

@benson No idea why mine doesn’t work, all I see on ...

By Papahuhu , 11 hours ago

-

RE: Battery sizing - How low can you go!

It seems I am seeing something similar to what you do, ...

By Batpred , 12 hours ago

-

RE: Gaslighting in the heat pump industry – has anyone else experienced this?

Don’t know if this is relevant to this thread, but my A...

By Gruff2001 , 12 hours ago

-

RE: Bosch CS5800i 5kW - Experience So Far

@majordennisbloodnok While getting Home Assistant runni...

By Steelbadger , 1 day ago

-

RE: MCS - BS EN 12831-1:2017 – Heat Loss Survey

Since May 2025 it no longer a requirement in England to...

By JamesPa , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handel @jancold Manufacturer: Daikin Model: E...

By Jancold , 1 day ago

-

RE: Octopus Cosy 12 Heat Pump Regret: Incredibly Loud, Poor Heating & Constant Hum - Help!

@harriworld it was roughly 3am for an hour as that’s ...

By L2jad , 1 day ago

-

RE: Hoped for improvements not being realised on my Mitsubishi heat pump

I have been wondering that myself. The fact is that, ...

By JamesPa , 1 day ago

-

RE: Filtering Tap Water – Share Your Setup for Cleaner, Better-Tasting Water

I remember when I was in my early 20s I was introduced ...

By Majordennisbloodnok , 1 day ago

-

RE: Setback savings - fact or fiction?

But if it is recorded an an integer, which it seems it ...

By cathodeRay , 2 days ago