Posted by: @editorPosted by: @toodles@prjohn Ooooh! Mars! Did you consider you might be opening a massive can of worms with this topic?! ;-)))

Always good to have discussions about topics like this.

And as i point out above, its easy to work out roughly how much its costing. Measure the flow to flow temperature drop across the llh and reckon on 2-3% loss in system efficiency per degree (if you want to be more precise, refer to the cop vs ft curves in the databook for youe machine). Add a few 10s of W for the second pump.

If you are happy with this leave the llh in place. If you are not then remove or bypass it.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

There are low loss headers, damned buffers, and then there are plate heat exchangers. The usual Freedom wording for Freedom based Midea (and Samsung?) systems/installations appears to consider these one and the same, the point being hydraulic separation, not how it is achieved (though how a two pipe buffer achieves this is beyond me unless they have to be four pipe buffers). This is from the Freedom Midea installation manual:

"Every system must have hydraulic separation between the primary (heat pump) and secondary (heating circuit) pipe work.

This can be via a buffer tank, low loss header or plate heat exchanger. If you install the unit without hydraulic separation, you will void the warranty."

I'm pretty sure GH wrote that. It is useful, insofar as it hints at why they are essential (at least as far as keeping your warranty): the system "must have hydraulic separation between the primary (heat pump) and secondary (heating circuit) pipe work". That just leaves the question: why must it have hydraulic separation?

Moving on, and this is I think what @toodles is getting at (as well as pointing out that changing the system by ripping bits out is disruptive), there is also a valid question as to whether in some way the the devices might also have benefits to the end user. Less glycol in my PHE setup is one possibility, no ex radiator crud flowing through the heat pump is another. There may be others.

That said, I am clear in my mind that my current PHE setup almost certainly throttles my system significantly when heat demand is high, though I do note @marzipan71's links to posts showing the removal of a LLH (not a PHE) appears to have made no difference.

I just want to be sure that removing my PHE won't (a) make no difference (as in @marzipan71's links, though in that case it was a LLH) and (b) cause unwanted effects.

Incidentally, no reply yet from Freedom to my email asking about the details of my PHE.

Midea 14kW (for now...) ASHP heating both building and DHW

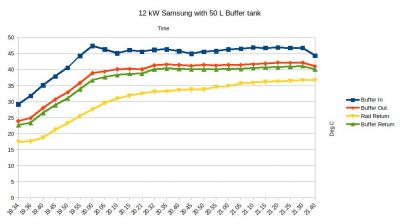

@editor Here is a graph of temperatures taken from my 4 pipe buffer tank ( before it was removed). You can see that Delta T between Buffer in (LWT) and Buffer return (RWT) is similar to the Delta T between Buffer out (to the radiators) and Radiator return (back to the buffer from the radiators). I take that to suggest that the flow rates in the primary and secondary circuits are similar. Nevertheless, there is a 4-5 degC difference between LWT from the Samsung and the temperature of the water going to the radiators. That in itself reduces efficiency and increases costs by around 12%.

Protons for breakfast found that removal of his LLH didn't make much difference, but I wonder if his LLH was tall and thin as opposed to my buffer tank which was short and stout. There is only a couple of inches between the pipes in my buffer tank, so mixing is inevitable.

Posted by: @prjohnAre all Low Loss Headers bad? Mine was fitted as per Samsung schematics. This I would imagine would remain part of the warranty agreement. The effect on my system seems to be negligible. I did discusses this at a resent service and the engineer comment was "if its not broken don't fix it". As my efficiency appears to be high, 2288kw/h energy use over a year as opposed to 1700litres (17000kw/h) of oil it seems my system is working OK. Another point is if by removing the LLH increases efficiency could it have an effect on the size of HP fitted? One other point, can a LLH act as a debris trap for older heating system thereby protecting the HP?

I've probably spent far too much time mulling over this topic. We've always had performance issues with the heat pump when temperatures drop. And it's got nothing to do with the heat pump. If it's set to deliver 45C water to the heating circuit, it does so without a problem. But this doesn't translate into a warm, cosy room because the radiators are not receiving the heat they ought to.

To address this issue, our installers have returned multiple times, fitting K3 radiators and installing more distribution pumps. Now we have four distribution pumps, yet the distribution of heat remains sporadic, which is nuts.

Then I came across @heacol who was harping on about buffer tanks and how awful they are. "Yada, yada, yada," I thought at the time. There's no way that buffers and LLHs can affect heating performance and I gave @heacol a hard time. So I went away and started to do more reading, and it's fascinating just much these additions do affect heat pump systems.

Buffer tanks did play a crucial role in the evolution of the heating industry. Their introduction was a response to the inherent drawbacks of traditional on-off fossil fuel boilers. These older boilers needed to run at elevated temperatures, often exceeding 80C, to avert heat exchanger corrosion. For the period's technology, operating at such high temperatures was deemed efficient, and utilising a buffer tank for temperature blending was beneficial. These earlier systems were also designed for lower flow rates, a stark contrast to the higher flow demands from multiple connected circuits. The introduction of buffer tanks helped manage these different needs more efficiently; but this belongs to an era that has since evolved, reflecting a different technological landscape than what we see today with heat pumps.

Because it's so entrenched in the industry, there's a common but incorrect belief that buffer tanks significantly assist heat pumps in balancing the load. The actual impact of a buffer tank on load management is quite limited. A buffer tank with a capacity of 100 litres (which is what we have at home) can only store around 1.17kW of energy when heated to a temperature 10C above the needed level. In a system requiring 10kW, this merely equates to a buffer duration of approximately 7 minutes, which is hardly noteworthy. Additionally, the extra effort to raise the temperature by that additional 10C could lead to an increase of as much as 25% in energy costs. And we have multiple distribution pumps trying to pump this water around the system, all of which have running costs too, for not that much effort.

This leads us to a critical point regarding the testing practices of heat pump manufacturers in the UK. While the performance and efficiency numbers they publish are derived from standardised testing conditions for consistency and reliability in comparing various models, the specifics of whether these tests include LLHs and buffer tanks are often not detailed in the general product literature.

According to information I've received from sources well-informed about the industry, most of these test setups do not incorporate LLHs or buffer tanks. Despite this, manufacturers frequently recommend their inclusion in actual installations. This discrepancy suggests that the performance results achieved in real-world settings may not align precisely with the published data, as the test conditions under which these figures are obtained do not fully mirror the recommended installation setups.

Get a copy of The Ultimate Guide to Heat Pumps

Subscribe and follow our YouTube channel!

@editor - interesting. If I may also borrow a quote and refer it to @derek-m:

Posted by: @editorThis leads us to a critical point regarding the testing practices of heat pump manufacturers in the UK. While the performance and efficiency numbers they publish are derived from standardised testing conditions for consistency and reliability in comparing various models, the specifics of whether these tests include LLHs and buffer tanks are often not detailed in the general product literature.

According to information I've received from sources well-informed about the industry, most of these test setups do not incorporate LLHs or buffer tanks. Despite this, manufacturers frequently recommend their inclusion in actual installations. This discrepancy suggests that the performance results achieved in real-world settings may not align precisely with the published data, as the test conditions under which these figures are obtained do not fully mirror the recommended installation setups.

I think this may be one of the problems encountered when modelling heat pump behaviour based on manufacturer data. The manufacturers quote efficacy (what can be achieved in ideal circs eg in a lab/RCT), whereas in the real world we get effectiveness (what can be achieved in practice, in the real world, where 'stuff happens'). In medicine, the two are often very different, and I think the same might apply to heat pumps: what the labs predict is not what you get. And that's before incorporating the PHE throttling effect (which is after all just another what you get in practice effect).

Midea 14kW (for now...) ASHP heating both building and DHW

Posted by: @toodlesThank you Mars, I accept that a LLH may affect the efficiency of the overall efficiency - but how can the average individual who has a system installed with a LLH know whether they would be better off without it? Ripping apart a system that has one such and a secondary pump is a little radical - and is ther any guarantee that the efficiency would improve without these components. Presumably, LLH was a concept with a purpose - is it just to protect the designer and installers? Regards, Toodles.

Your perspective on the matter is both practical and grounded. The decision to alter a heating system with a LLH and secondary pump hinges on a balance between current system performance and the potential for improved efficiency.

At a personal level, if your system is achieving a SCOP of 3 or more, maintaining a warm house without noticeable inefficiencies or discomfort, then the system can be considered effective. In such a case, the idea of overhauling the system might indeed seem unnecessary.

My own experience echoes a similar sentiment but also highlights the complexities involved. Our system, equipped with four distribution pumps, was designed to efficiently distribute heat throughout. However, in reality, it achieves a SCOP of 2.71, which indicates that it's not operating at optimal efficiency. This lower SCOP points towards potential inefficiencies, possibly exacerbated by the current configuration with the buffer and multiple pumps.

It's essential to recognise that LLHs are designed with specific purposes in mind – in theory, they help maintain consistent flow rates, prevent short-cycling of the heat pump and can contribute to system longevity. However, their impact on efficiency isn't universally beneficial and can vary based on the system's design and the property's heating requirements.

Get a copy of The Ultimate Guide to Heat Pumps

Subscribe and follow our YouTube channel!

@cathoderay, in addition to what you've mentioned above, the discrepancy between the performance and efficiency data cited by heat pump manufacturers (and by extension, the MCS) and the actual achievable outcomes in real-world installations is thought-provoking. This situation seems akin to the notable issue observed in the automotive industry, specifically the car emissions scandal, where the performance reported under test conditions did not accurately reflect real-world operation.

The heart of the issue lies in the testing environments and methodologies used by heat pump manufacturers. These tests are often conducted under idealised or controlled conditions that may not fully represent the typical installation scenarios or everyday usage patterns. Consequently, the efficiency and performance figures obtained in these test environments can be significantly higher than what a user might realistically experience.

Given the importance of time and resource efficiency in today's world, it would indeed be revealing and beneficial if manufacturers could provide more transparency about their testing environments. Understanding the specifics of these test setups, including the conditions and parameters used, could offer valuable insights into how these figures are derived and their applicability to real-world settings.

This level of disclosure would not only aid consumers in making more informed decisions but could also push the industry towards more realistic and practical performance benchmarks. Our heat pump's performance does not remotely match the numbers the heat pump is capable of according to the manufacturer. It would encourage a move away from idealised figures and towards data that better reflects the varied and sometimes challenging conditions of actual installations.

A call for greater transparency and realism in the performance data provided by heat pump manufacturers is not just about ensuring consumer trust; it's also about aligning industry practices with real-world applications and expectations. Just as the automotive industry had to confront and adapt to the revelations of the emissions scandal, the heat pump industry could benefit from a similar shift towards greater honesty and clarity in its performance reporting.

Get a copy of The Ultimate Guide to Heat Pumps

Subscribe and follow our YouTube channel!

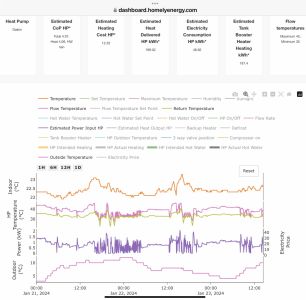

@editor Indeed, manufacturers of most devices have their own methods of measurement that do not always relate well to ‘real world’ situations; they provide a rough guide that should be taken with generous pinches of salt I think. OK, the last three days may not be typical of UK winter weather as it has been rather milder than of late. I attach a graph where I have just left in the (what I believe) salient pieces of data for the Daikin heat pump performance. The COP has just exceeded 4 whereas Daikin might have one believe that it might perform with a rather higher figure. There’s is an aspiration - mine was the achieved performance (with a LLH that they probably weren’t employing)! Regards, Toodles.

Toodles, heats his home with cold draughts and cooks food with magnets.

Posted by: @editor@cathoderay, in addition to what you've mentioned above, the discrepancy between the performance and efficiency data cited by heat pump manufacturers (and by extension, the MCS) and the actual achievable outcomes in real-world installations is thought-provoking. This situation seems akin to the notable issue observed in the automotive industry, specifically the car emissions scandal, where the performance reported under test conditions did not accurately reflect real-world operation.

The heart of the issue lies in the testing environments and methodologies used by heat pump manufacturers. These tests are often conducted under idealised or controlled conditions that may not fully represent the typical installation scenarios or everyday usage patterns. Consequently, the efficiency and performance figures obtained in these test environments can be significantly higher than what a user might realistically experience.

Given the importance of time and resource efficiency in today's world, it would indeed be revealing and beneficial if manufacturers could provide more transparency about their testing environments. Understanding the specifics of these test setups, including the conditions and parameters used, could offer valuable insights into how these figures are derived and their applicability to real-world settings.

This level of disclosure would not only aid consumers in making more informed decisions but could also push the industry towards more realistic and practical performance benchmarks. Our heat pump's performance does not remotely match the numbers the heat pump is capable of according to the manufacturer. It would encourage a move away from idealised figures and towards data that better reflects the varied and sometimes challenging conditions of actual installations.

A call for greater transparency and realism in the performance data provided by heat pump manufacturers is not just about ensuring consumer trust; it's also about aligning industry practices with real-world applications and expectations. Just as the automotive industry had to confront and adapt to the revelations of the emissions scandal, the heat pump industry could benefit from a similar shift towards greater honesty and clarity in its performance reporting.

In fairness to the manufacturers I think that most of the critical tests are done to BS/EU standards, and they generally quote the numbers. The standards themselves will specify the test method/environment. I cant see why they would include a buffer tank/llh unless its a mandatory part of the installation according to the manufacturer.

How many heat pump manufacturers actually insist on system separation in their installation manual. From my recollection of when I read most of the manuals (about a year ago so my recollection is now imperfect). Some show one in a diagram which also includes a backup boiler (so basically an all-options diagram), in this case its clear that some form of separation is required, but is it fair to infer that the same applies when there is no backup boiler. I think its been more the installation industry that has pushed this approach because it eliminates a potential source of call out.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

Posted by: @jamespaHow many heat pump manufacturers actually insist on system separation in their installation manual.

See my earlier quote (1:15pm) from the Freedom Midea Installation Manual (from 2022). The word used is 'must' (have hydraulic separation). I rather suspect if there is an equivalent Freedom Installation Manual for Samsung heat pumps, it may well say the same thing, or something very similar.

Midea 14kW (for now...) ASHP heating both building and DHW

Thats from Freedom, what does the OEM actually say

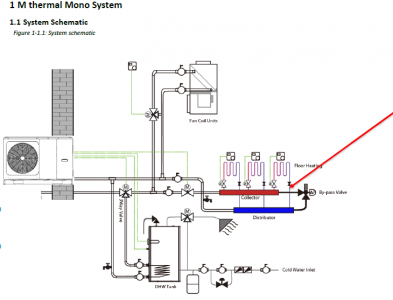

Here is the system diagram from page 4 of the Midea manual. No buffer tank, LLH or PHE in sight.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

-

British Gas Heat Pump Installation Complaint

4 months ago

-

Heating Turned Off but Radiators Still Warm

5 months ago

-

Samsung Heat pump with Yonos Pico circulating pump running all the time

5 months ago

-

Samsung 5kW R32 Monobloc Gen 6 ASHP

5 months ago

-

Ideal Logic 10kW Heat Pump Pipes Noisy and Very Expensive to Run

1 year ago

Currently viewing this topic 5 guests.

- 27 Forums

- 2,520 Topics

- 58.6 K Posts

- 641 Online

- 6,800 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Heat Pump vs New Gas Boiler for Inherited House - Worth the Extra Cost?

@fretless6, where are you based? I might be able to con...

By Mars , 25 minutes ago

-

RE: Underfloor Heating Installation Issues with Heat Pump

I'm going to install Thermacome ACOSI+ radiant ceiling....

By bobflux , 1 hour ago

-

Issue with a Grant Air Source Heat Pump & Tado Smart Thermostat

Hi all I'm having some trouble with a Grant ASHP and ...

By Renewables345 , 2 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

Now seems a good time to summarise the costs and effici...

By benson , 2 hours ago

-

RE: Tell us about your Solar (PV) setup

@mk4 Charge to 100%, discharge down to 10%.

By bobflux , 4 hours ago

-

RE: Daikin Altherma 3 LT compressor longevity question

This mess is intriguing: I wonder if this represent...

By bobflux , 5 hours ago

-

RE: Connecting Growatt SPH5000 over wired ethernet rather than wireless

The simplest wired option is usually the Growatt Ethern...

By Jonatan , 9 hours ago

-

RE: Peak Energy Products V therm 16kW unit heat pump not reaching flow temperature

ASHPs do have a minimum compressor speed. The minimum h...

By bobflux , 16 hours ago

-

RE: Electricity price predictions

@jamespa And it seems some of the nasty public cloud...

By Batpred , 16 hours ago

-

RE: Jokes and fun posts about heat pumps and renewables

Technology is rapidly advancing. BBC News reported th...

By Transparent , 20 hours ago

-

What matters for flow and pressure drop is internal dia...

By bobflux , 20 hours ago

-

RE: Do Fridges and Freezers have COP ratings?

@editor Thank you all for your replies and submitted in...

By Toodles , 23 hours ago

-

I know and yes. The secondary deltaT wont necessaril...

By JamesPa , 1 day ago

-

RE: Designing heating system with air to water heat pump in France, near Lyon

Just love the way you put it! 🤣

By Batpred , 2 days ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thank you for sharing. So it seems that your Schneid...

By Batpred , 2 days ago

-

RE: Forum updates, announcements & issues

@upnorthandpersonal thanks for the thoughtful, consider...

By Mars , 2 days ago

-

RE: Solar Power Output – Let’s Compare Generation Figures

@mk4 All 21 panels have their own Enphase IQ7a microinv...

By Toodles , 2 days ago

-

RE: Setback savings - fact or fiction?

Great, so you have proven that MELCloud is consistently...

By RobS , 3 days ago

-

RE: Mitsu PUHZ120Y 'Outdoor Temp 'error?

Thanks David & James It almos...

By DavidAlgarve , 3 days ago

-

RE: Surge protection devices SPDs

@trebor12345 - your original Topic about the right type...

By Transparent , 3 days ago

-

RE: Help needed with Samsung AE120RXYDEG

@tomf I’ve been sent this from a service engineer at Sa...

By Mars , 3 days ago

-

RE: Buying large amp bidirectional RCD and RCBO

Yes... I went through this particular headache and ende...

By bobflux , 4 days ago

-

O-oh! Let's take this as an opportunity to 'pass the ...

By Transparent , 4 days ago