Which temperature sensor for a Steibel buffer and Ecodan?

My installer configured our Ecodan 14kW system with a 100 litre Steibel 4-port buffer (surprise) and I have recently had this converted into a volumiser in order for it to work better when in cooling mode (see other thread on rapid cycling when cooling with the old set-up).

Anyway, the buffer has "dry pocket" near the bottom for a temp sensor that uses a 14mm dia thread.

I would like to install a sensor and connect to the Ecodan controller so that it shows up on the temp graphs in iOS MELcloud app as "Mixing cylinder". This line on the graph is currently unused.

I asked Steibel tech support for recommendations but they just said that they didn't supply a sensor and the type needed would depend on the heat pump.

Two questions:

1 what sensor to use that will fit and have the correct wiring

2 where to connect it in the control box.

There are lots of temp sensors with 14mm diameter threads on Google but they mostly seem to be for car engines not heat pumps...

Mitsubishi Zubadan 14kW with Mixergy 210l DHW in 220m2 barn property. 24 solar panels = 9kWp with GivEnergy 5.0kW Hybrid inverter and 19kWh GivE batteries. Jaga Strada fan-assisted rads throughout. Landvac vacuum glazing/triple glazed windows.

@ashp-bobba might be able to help as an Ecodan expert.

Get a copy of The Ultimate Guide to Heat Pumps

Subscribe and follow our YouTube channel!

@downfield I have never added a buffer sensor as we never have used a buffer, I know on many brands you can add them as well as a flow sensor. I would need to look it up for you or you could speak to Mitsubishi and they would tell you which port would work for what you want.

1st we would need to know which FTC you have 5,6 or7?

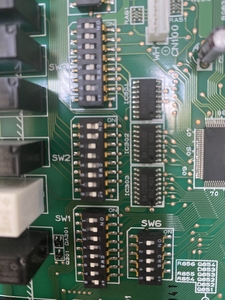

On the FTC6 it is most likely DIP switch SW2-6 is labelled “Mixing tank WITHOUT / Mixing tank WITH” indicating the controller has a feature for a mixing or buffer tank.

Mitsubishi typically uses 10 kΩ NTC thermistors at 25 °C with a specific resistance/temperature curve.

KR

AAC Group Ltd covering the Kent Area for design, supply and installation of ASHP systems, service and maintenance, diagnostics and repairs.

Professional installer. Book a one-to-one consultation for pre- and post-installation advice, troubleshooting and system optimisation.

@ashp-bobba many thanks for the information.

I have found the manual which has the numbers PAC-IF71B-E -IF2B-E and IF3B-E on the front - not sure what that means.

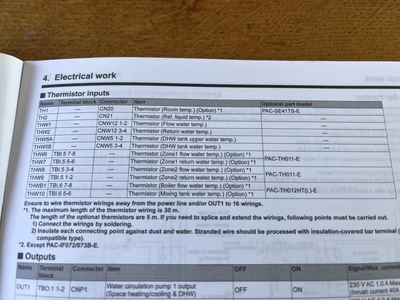

Anyway there is a table of thermistor inputs (attached) which mentions the Mixing tank on the last row and gives a part number PAC- TH012HT(L)-E for the thermistor.

So if I can get that will I be able to plug it in at the FTC end?

What do I need for the 14mm dry pocket at the volumiser end? will it just screw in?

thanks

Julian

Mitsubishi Zubadan 14kW with Mixergy 210l DHW in 220m2 barn property. 24 solar panels = 9kWp with GivEnergy 5.0kW Hybrid inverter and 19kWh GivE batteries. Jaga Strada fan-assisted rads throughout. Landvac vacuum glazing/triple glazed windows.

@downfield Hi, if it has a 14mm dry pocket you should just be able to insert heat transfer paste and push the probe into it to get a close reading, if you dont have paste or want to use it we recommend inserting the probe at the same time as some armaflex insulation to make sure the probe is tight up against the wall of the pocket. I think the probes for mitsi are around 8mm so it should fit.

All of this can be checked with Mitsi and its worth checking as there are often multiple choices, also you can ask them how to set up the reading and it is likely you will need to turn the power off, change a dip switch or 2 and power back on for it to read.

KR

AAC Group Ltd covering the Kent Area for design, supply and installation of ASHP systems, service and maintenance, diagnostics and repairs.

Professional installer. Book a one-to-one consultation for pre- and post-installation advice, troubleshooting and system optimisation.

@ashp-bobba Re:

"On the FTC6 it is most likely DIP switch SW2-6 is labelled “Mixing tank WITHOUT / Mixing tank WITH” indicating the controller has a feature for a mixing or buffer tank."

I wonder if you could expand on this point, please? I have recently had my buffer tank converted to volumiser, but with a contractor who had very little knowledge of Mitsu equipment and who could get even less support from them.

Are you saying that without a buffer SW2-6 should be Off i.e. "Mixing tank WITHOUT" ?

342sq m "Upside down" house in Algarve. Portugal

Mitsubishi PUHZ-120YUK 16kW ASHP

12 Solar Panels Growatt Inverter

2 x Growatt 7.5kW Batteries

Fronius EV Charger

Kia e- Niro 64kW

@davidalgarve As advised above, its worth speaking to Mitsi as I do not know having never used this function and not fitting buffers. I do not know what will happen with the control logic on the FTC5/6 if it can see an additional probe, it may be that is simply reads it only or that the reading feeds the info back and actually will make the machine try to run in a way that it takes this value into account, considering in most cases the last thing you want is a buffer or mixed load on your system its may not be desirable for the unit to read this probe.

Its just worth speaking to them, and TBH, in my experience they are helpful them techies.

AAC Group Ltd covering the Kent Area for design, supply and installation of ASHP systems, service and maintenance, diagnostics and repairs.

Professional installer. Book a one-to-one consultation for pre- and post-installation advice, troubleshooting and system optimisation.

- 26 Forums

- 2,396 Topics

- 54.3 K Posts

- 323 Online

- 6,077 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Recommended home battery inverters + regulatory matters - help requested

I do have some Manual Change switches within my off-gri...

By Transparent , 2 minutes ago

-

RE: Free Ecoheat Heat Pump Install

@deltona Yes older houses are problematic like that, bu...

By bontwoody , 2 hours ago

-

RE: Radiator sizing sanity check

As I mentioned early on the cost of supplying and fitti...

By JamesPa , 5 hours ago

-

RE: Advice for a novice on Mitsubishi Ecodan 6kW

I hadn't spotted that there were two pumps in the UFH (...

By JamesPa , 6 hours ago

-

RE: Setback savings - fact or fiction?

Never assume it makes an ass of u and me! You need the...

By JamesPa , 7 hours ago

-

RE: New Mitsubishi Ecodan 11.2kW installation - L9 errors and maybe more

Before I answer your specific questions just one more t...

By JamesPa , 7 hours ago

-

RE: Help me keep the faith with my air source heat pump installation

@agentgeorge Fortunately the one thing that you *won't*...

By dr_dongle , 7 hours ago

-

RE: ASHP Energy Consumption: Aira 12kW heat pump

@chandykris Thank you for your detailed response.It is ...

By Wally , 8 hours ago

-

RE: Electricity price predictions

Great point, one of the key ones in my chat with Octopu...

By Batpred , 17 hours ago

-

RE: Running from backup generaor in powercut?

Definitely and professionals sometimes miss it. I had...

By Batpred , 17 hours ago

-

RE: New Fogstar 15.5kWh upright solution

Let me point out that there are many Chinese suppliers ...

By Transparent , 22 hours ago

-

RE: Weather compensation- why you should use it

@majordennisbloodnok — The Two Ronnies Mastermind sketc...

By cathodeRay , 22 hours ago

-

Just realised that this image of the cylinder cupboard ...

By Sheriff Fatman , 1 day ago

-

RE: Rodents! A word of warning for heat pump owners

Two thoughts: 1: Let's ask @david-s if Primary Pro in...

By Transparent , 1 day ago

-

RE: Solis S6-EH1P8K-L-PLUS – Why I Chose It and What I’ve Learned So Far

In the diagram below, I describe my understanding of th...

By Batpred , 1 day ago

-

I need to have a look out for it. I know IBM feeds some...

By Batpred , 1 day ago

-

-

RE: Daikin Atherma ASHP Cycling 6 Times an Hour?

Thanks for your reply. Yes that's a good idea to try a...

By John Marshall , 1 day ago

-

RE: Hot water heating in parallel with space heating

An external heat exchanger would need a pump which woul...

By bontwoody , 1 day ago

-

RE: Gen 6 Samsung ASHP losing 20C of DHW in 60 min directly after generation

@ecobaker Thanks for this. I've had it in both slots. ...

By andbeck , 2 days ago