How To Balance Radiators & the Role of the Lockshield Valve: A Homeowner's Guide

@heacol I recall a considerable amount of discussion (relating to LLH’s mainly rather than buffer tanks as such though) some while back and one of the threads is:

There were other threads along similar lines and this is where I felt a ‘consensus’ was evident. If I am wrong, my apologies to all for leading you astray!

In my own case, I have a Daikin heat pump and I THINK that the primary pump adjusts automatically to maintain a set Delta T. Having an LLH in circuit, I have attempted to adjust the speed of the Wilo Pico pump (secondary pump) to minimise temperature difference between flow to LLH and flow out of LLH to the Wilo pump. Similarly, I have attempted a similar arrangement for the return to the LLH in and the out returning to the heat pump. I find that at times, the balance is within 0.3 degrees C but at other times, this may be as much as a degree of difference!! I think both pumps have a degree of dynamic control and that this is the reason for the apparent variation. Regards, Toodles.

Toodles, heats his home with cold draughts and cooks food with magnets.

@toodles I am totally against any form of system separation in a domestic environment and most commercial environments. I have installations with over 400 Kw in capacity and 9 heat pumps, all connected to a single flow and return, the separation/buffer arguments just do not stack up. Any form of separation makes things complicated and can cause significant performance losses. In my opinion, simplicity is always best.

Posted by: @heacol@toodles I am totally against any form of system separation in a domestic environment and most commercial environments. I have installations with over 400 Kw in capacity and 9 heat pumps, all connected to a single flow and return, the separation/buffer arguments just do not stack up. Any form of separation makes things complicated and can cause significant performance losses. In my opinion, simplicity is always best.

If only others took the same approach we would see far, far fewer posts on this forum (and others) complaining about poor performance, and indeed far fewer posts complaining about other problems, the origin of which it is difficult to diagnose due to the presence of system separation.

We would probably see an increase in posts about low flow errors which otherwise are masked by the buffer. But the underlying causes in many cases need to be fixed, so in many ways that's a good thing.

There is probably a business to be made from removing buffer tanks!

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

Maybe mine as well !As in Buffer remove.

New sensor in place and so to correct the flow indications between from HP to buffer /Tank there is a difference of 2.6 c. That is to say HP to tank and tank to emitters . Emitters return is 33.7 and Buffer/Tank to HP 36c

Too much or ?

Posted by: @alfapatMaybe mine as well !As in Buffer remove.

New sensor in place and so to correct the flow indications between from HP to buffer /Tank there is a difference of 2.6 c. That is to say HP to tank and tank to emitters . Emitters return is 33.7 and Buffer/Tank to HP 36c

Too much or ?

Sorry if Ihave written this somewhere , but it didnt save .

I have visited the sensors this morning and after previously turning the secondary pump down to reduce the turbulance , I have also turned down the circulation pump one notch and results are this :

Flow from HP:41.4c, flow out of LLH :35.3c , return to LLH:31.5c and return from LLH to HP: 36.0c

Still too much of a drop I guess

Not great, 5C = 10-15% efficiency loss (much more according to @heacol). TBH I cant understand whats going on in the buffer, its like there is no stratification at all and you have essentially a vessel sitting there at ~36C, with both outputs therefore at this temperature. Im beginning to wonder if its correctly plumbed but cant remember if we have already discussed this. Is it worth posting (or reminding us of) some pictures indicating flow/return to/from HP/rads. Also please can you remind me how the pumps either side are controlled and in particular can you get to a situation where one is on and the other off for a reasonable period of time (thus, inevitably, 'stirring' the tank)?

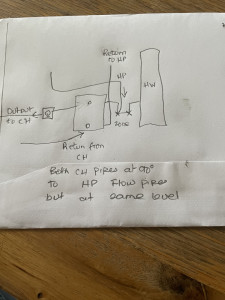

Here is the layout as much as I can.

Above left Ch pipes

Above zone valves.

Above right flow from HP.

Above showing Ch pump on white pipes.

If there is anything more specific I will take more.

no diagram!

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

Posted by: @jamespano diagram!

Ha should I have , sadly not, Only the one I have drawn.

What would you like to see , and I can give you some information

Sorry I didn't spot the pictures above.

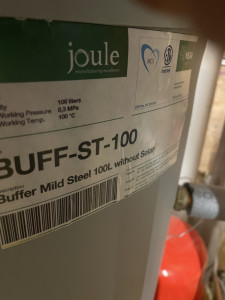

Buffer tank looks very squat (which would explain lots). How high is it and what is the vertical distance between the ports.

Also what capacity is your heat pump and what diameter the pipes to the buffer tank.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

@jamespa Will check James

Tank Capacity is 200l Pipes are 28mm Copper , not sure if you want the size of CH pipes I can check but definitely smaller of course either 24 or 21mm . Tank vertical distance is 65cm for HP pipes and 67 cm roughly for CH.

Thanks

Sadly with a 60cm high tank I think the chances of maintaining stratification (IE a temperature gradient from top to bottom, which is what you want) is negligible, which accounts for the almost complete mixing you observe with the temp sensors. Whilst the tank remains you are stuck with the 5C drop across it. I suspect that adjusting flow rates will make a marginal difference at best to this.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

@jamespa Thanks , looks like I should remove it then . Question I have , if the HP pipes are 28mm and they are directly connected to the smaller CH pipes , does that not cause a problem , except if you had control of the pump speeds ?

- 27 Forums

- 2,520 Topics

- 58.6 K Posts

- 451 Online

- 6,800 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Peak Energy Products V therm 16kW unit heat pump not reaching flow temperature

@davec At a wild guess a low external temperature ...

By JamesPa , 7 minutes ago

-

RE: Issue with a Grant Air Source Heat Pump & Tado Smart Thermostat

Im assuming from your original post that hysterisis ref...

By JamesPa , 18 minutes ago

-

I didn't appreciate that there was so much to a piece o...

By trebor12345 , 27 minutes ago

-

RE: Heat Pump vs New Gas Boiler for Inherited House - Worth the Extra Cost?

Hi @fretless6 Mike, I have experience with Taggas (Re...

By Old_Scientist , 3 hours ago

-

RE: Daikin Altherma 3 LT compressor longevity question

@bobflux With my limited HA skills I can't ad...

By Ubert767 , 4 hours ago

-

RE: Underfloor Heating Installation Issues with Heat Pump

I'm going to install Thermacome ACOSI+ radiant ceiling....

By bobflux , 6 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

Now seems a good time to summarise the costs and effici...

By benson , 7 hours ago

-

RE: Tell us about your Solar (PV) setup

@mk4 Charge to 100%, discharge down to 10%.

By bobflux , 8 hours ago

-

RE: Connecting Growatt SPH5000 over wired ethernet rather than wireless

The simplest wired option is usually the Growatt Ethern...

By Jonatan , 14 hours ago

-

RE: Electricity price predictions

@jamespa And it seems some of the nasty public cloud...

By Batpred , 21 hours ago

-

RE: Jokes and fun posts about heat pumps and renewables

Technology is rapidly advancing. BBC News reported th...

By Transparent , 1 day ago

-

RE: Do Fridges and Freezers have COP ratings?

@editor Thank you all for your replies and submitted in...

By Toodles , 1 day ago

-

I know and yes. The secondary deltaT wont necessaril...

By JamesPa , 1 day ago

-

RE: Designing heating system with air to water heat pump in France, near Lyon

Just love the way you put it! 🤣

By Batpred , 2 days ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thank you for sharing. So it seems that your Schneid...

By Batpred , 2 days ago

-

RE: Forum updates, announcements & issues

@upnorthandpersonal thanks for the thoughtful, consider...

By Mars , 2 days ago

-

RE: Solar Power Output – Let’s Compare Generation Figures

@mk4 All 21 panels have their own Enphase IQ7a microinv...

By Toodles , 2 days ago

-

RE: Setback savings - fact or fiction?

Great, so you have proven that MELCloud is consistently...

By RobS , 3 days ago

-

RE: Mitsu PUHZ120Y 'Outdoor Temp 'error?

Thanks David & James It almos...

By DavidAlgarve , 3 days ago

-

RE: Surge protection devices SPDs

@trebor12345 - your original Topic about the right type...

By Transparent , 3 days ago

-

RE: Help needed with Samsung AE120RXYDEG

@tomf I’ve been sent this from a service engineer at Sa...

By Mars , 3 days ago

-

RE: Buying large amp bidirectional RCD and RCBO

Yes... I went through this particular headache and ende...

By bobflux , 4 days ago

-

O-oh! Let's take this as an opportunity to 'pass the ...

By Transparent , 4 days ago