Simulation of ASHP with Gas boiler as part of decision process

@cathoderay On a general note, I wonder what ball-park figure one might apply to the accuracy tolerance of the data supplied by default measuring equipment rather than by instruments installed for the purpose. My system readings are provided by the default (Daikin) equipment and the stats look very respectable; might I expect to allow perhaps + or - 10% on any given reading perhaps? Regards, Toodles.

Toodles, heats his home with cold draughts and cooks food with magnets.

Posted by: @toodlesI wonder what ball-park figure one might apply to the accuracy tolerance of the data supplied by default measuring equipment rather than by instruments installed for the purpose

I don't think, for my system, it is too bad, because I have some basic independent monitoring tools, and they broadly agree with the Midea data collected over modbus. For example, I calculate energy out from:

(1) Midea reported flow rate, which I can verify with an analogue flow meter installed in the circuit

(2) LWT/RWT delta t, which I can verify using an IR thermometer/camera

(3) specific heat of the circulating fluid, which is fixed for a given fluid mix

The problem is verification for (1) and (2) is based on spot readings, whereas the modbus/Midea data is continuously recorded at minute intervals. Nonetheless, a short while ago the Midea controller said the flow rate was 1.23 m^3/h (20.5l/min), while the analogue meter showed 20l/min, a ~2.5% difference, but the analogue meter has a very crude scale, maybe it was actually showing 20.5l/min. A few moments later, the delta t on both the Midea controller and the IR measurements was zero (because the heat pump is cycling, and it was in an off phase). A few minutes later, with the on phase underway, the delta t was 4 on both. Since the Midea numbers are integers, they may be a bit out, but not hugely so, and I should add that absolute values for the temps are not the same, the Midea numbers are about 3 degrees below the IR measured values eg Midea number is 38, IR number is 41, but it is not the absolute values we need, rather the difference (delta) value, which is the same. These readings (and others done in the past) are enough to satisfy me that the Midea data based calculated energy out is tolerably close to the real value, say within 5%. At least, that is what I think is the case...

Midea 14kW (for now...) ASHP heating both building and DHW

@cathoderay We are back to the person with one watch always knowing the correct time whilst the person with two watches never being quite sure.😉 Toodles.

Toodles, heats his home with cold draughts and cooks food with magnets.

@toodles - we are, but back to basic principles: if two independent data sources agree, or are close, then that does generally suggest that both are at least about right for what they purport to measure. There is always the possibility you have stuck the two independent sensors into the wrong orifice, and are not in fact measuring what you think you are measuring, but usually such things can be checked, though I have heard of a doctor who somehow managed to get two anatomically clearly defined orifices mixed up, until the patient, who told me the tale, mentioned to the doctor they might be barking up the wrong tree.

The other thing with the temperature measurements is they don't have to be accurate, as long as they are consistent, because it is the delta t we are after. The real temps might be 40 and 35, the measured ones 37 and 32, but in each case the delta t is the same, 5 degrees. Because I am using the same instrument to take the readings for each source (IR for the independent, whatever Midea use for the Midea data), the chances are each instrument is reasonably consistent, and so it is not unreasonable to assume it gets the delta t right, even if the absolute number is out.

Another thought: I measure the primary flow and return temps as the primary circuit enters and leaves the plate heat exchanger, mainly because it is the least awkward place to take the measurement. But strictly speaking, it they are not the LWT/RWT, which should be (and are, but the Midea sensors) measured at the heat pump. But which is more valid? It's a bit like HP at the flywheel vs HP at the road wheels on a car. Assuming losses in the flow and return pipe, the heat pump may put out X at the heat pump, but only some of X ends up delivered to the house.

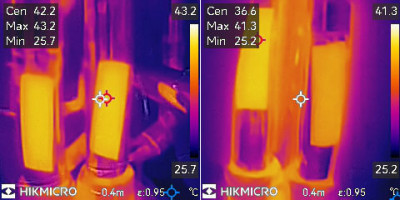

I've just taken another set of temp recordings, this time capturing the IR images while noting the Midea values. The latter were LWT 38, RWT 35, and here are the IR images:

The pipes here are copper, with black insulating tape applied (the warm bars you can see) to get the emissivity at a reasonable level, primary inlet to the plate heat exchanger (and outlet from the secondary circuit) in the left hand image, primary outlet (and secondary inlet) in the right hand image. In each image, the red cross hair is on the hottest point in the image (in both cases the primary pipework), and as you can see, the primary in was 43.2 degrees, the primary out 41.3 (this red cross hair is partially obscured by the readout panel).

This time the Midea delta t was 3 (with the integer reading caveat) , the IR delta t 1.9. They may or may not be correct, but they are at least credible. This time there was a difference between the Midea and IR data, with the former being (as may perhaps be expected, see above) having the higher delta t.

The eagle eyed will also spot something else: on the left hand image, the centre cross hair (white) is very close to the max cross hair (red), yet there is a degree centigrade difference in temperature. I can't account for this, unless, and I am just thinking aloud here, it is an angular effect caused by the curve of the pipework, some of the heat misses the camera. The two red dots you can see are both on the centre of the pipe, ie perpendicular to the tangent of the pipe at that point, the point at which it 'points' most directly towards the camera.

By the way, this IR camera has already paid for itself. Not only is it very useful for heat assessments and loss detection, it is also useful among other things for monitoring things like engines and drive trains. It can probably even tell you when your bun in the oven is ready to come out, but there are probably simpler ways to do that.

Midea 14kW (for now...) ASHP heating both building and DHW

@cathoderay Your wife or the mid-wife will probably have the best idea!😳 (Sorry) Toodles.

Toodles, heats his home with cold draughts and cooks food with magnets.

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

1 day ago

-

Rodents! A word of warning for heat pump owners

3 weeks ago

-

Ecodan Pump Issues… Circulation pump turns off when heat pump compressor turns off

1 month ago

-

Running my new Nibe ASHP efficiently

1 month ago

-

Weather compensation- why you should use it

1 month ago

Currently viewing this topic 2 guests.

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 303 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Electricity price predictions

I am always impressed with how you keep abreast of so m...

By Batpred , 59 seconds ago

-

RE: Setback savings - fact or fiction?

I fully understand your reasoning, same steady inputs s...

By cathodeRay , 10 minutes ago

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

@majordennisbloodnok I’m glad I posted this. There see...

By AndrewJ , 32 minutes ago

-

RE: What determines the SOC of a battery?

@batpred I didn't write the Seplos BMS software, I a...

By Bash , 2 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@tasos and @cathoderay thanks. I have some history grap...

By benson , 2 hours ago

-

I am having my existing heat pump changed to a Vaillant...

By trebor12345 , 3 hours ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 3 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

Just to wrap this up here for future readers: The S...

By Batpred , 6 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 6 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 8 hours ago

-

@painter26 — as @jamespa says, it's for filling and re-...

By cathodeRay , 11 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 22 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 24 hours ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 1 day ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 1 day ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 1 day ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago

-

RE: DIY solar upgrade - Considering adding more panels

I know this is a bit old, but it made me wonder what co...

By Batpred , 2 days ago