Photo-2 shows no insulation on the copper pipes!

It's needed for heat retention, let alone the fact that it dampens sound.

What's the composition of the rear and right walls of that cupboard?

Solid brick/block, or timber-framed with plasterboard?

Photo-3: Pumps and valves only held in position by copper pipes...

... which will therefore carry all the vibration.

And the pipes themselves have inadequate clips/clamps.

Photo-4: I can't see if the pipes enter the house through a sleeved outer-pipe.

But it's certainly the case that the black insulation stops short at the brickwork.

It should continue, uninterrupted, right through the wall.

Those pipes should also be clipped (without crushing the insulation..

They mustn't hang from the right-angle elbow going through the wall.

... more comments to follow.

Save energy... recycle electrons!

Photo-5 looks like a position where a (gas?) boiler has been removed.

The un-insulated copper pipes are 'fixed' into the wall using expanding foam.

That might dampen some sound, but the pipes should not touch the fabric of the wall.

We can't see if that is the case, but we don't want a hot pipe rubbing against brick or concrete block as it expands/contracts.

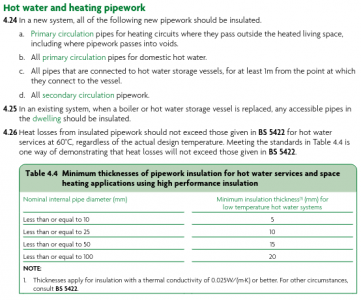

Pipe insulation for a newly-installed system in an existing dwelling is covered in Building Regulations, Part-L 4.24

This is not guidance... it is mandatory.

There are less clear rules (such as the Water Regulations) regarding the need to sleeve pipes passing through a wall.

Gas and foul-water (sewer) pipes must be sleeved; that bit is clear.

For other pipes, the points to note are:

- there is no exemption for the insulation of pipes as they pass through a wall

- any hole through which a pipe passes must not allow the spread of fire

- copper pipes must be protected against corrosion

- pipes passing through an external wall must retain the thermal characteristic of that wall

- pipes, sleeves and ducts passing through an external wall must slope down towards the outside to prevent rain/condensation entering the house

On a positive note, may I share this photo of a domestic heating pump being supported, rather than hanging from the copper pipework:

This pump is supported by using a galvanised steel strutt. These are readily available because they're used to 'tie' wall plates to the walls of the house.

The strutt isn't the thickest one available. It's deliberately selected so as to be able to flex.

This allows for pipe expansion, and prevents sound being transmitted to the floor.

There is a galvanised steel band (purple arrow) passing around the pump. It has 5mm holes and is fixed to the upright with M5 nuts and bolts.

There are 3mm thick pieces of neoprene rubber between the galvanised band and the body of the pump (yellow arrows).

This is very effective at dampening sound.

None of these bits are expensive, nor are they produced especially for this purpose.

Each installer will have their own way of supporting pumps and valves.

Experience and ingenuity are more important than 'training'!

Save energy... recycle electrons!

Thanks for all your advice, I'll mention all the above to the installer when he next visits. Looks like he's just insulated hot water pipes in the cupboard (old airing cupboard) which is wood framed and plaster board. Hopefully just an oversight, supporting the pumps looks like a good idea too.

Yes, picture 5 is where the old boiler was removed and they used the existing vent hole to run the pipes through then filled with expanding foam, I'll ask him to lag these pipes too.

To be honest, the sound isn't a vibrating pipe noise. We did get a bit of banging and vibration/ticking noise with the old system but luckily not with this one. It sounds more like when the old hot water tank used to fill or someones turned a tap on full.

**edit** had a closer look and the insulation appears to go into the morter and there are clips on the outside pipes so at least that bit seems OK.

, under the insulation

Posted by: @derek-mPosted by: @snuffyI think 2 pumps. No idea about how they're set though.

You should have been provided with the pump manual's by your installer, but if they did not then Google Make and Model to download any manuals.

I've got the manuals and tried to make sense of them, the heating one is basically a series of pictures, no explanations so I'll try and find a better manual online. On the controller, they are both set to 5 (max). What would happen if I turned them down to 3? Would this effect flow temp and heating efficiency?

Posted by: @snuffyPosted by: @derek-mPosted by: @snuffyI think 2 pumps. No idea about how they're set though.

You should have been provided with the pump manual's by your installer, but if they did not then Google Make and Model to download any manuals.

I've got the manuals and tried to make sense of them, the heating one is basically a series of pictures, no explanations so I'll try and find a better manual online. On the controller, they are both set to 5 (max). What would happen if I turned them down to 3? Would this effect flow temp and heating efficiency?

Because you have what looks like a buffer tank within your system, for maximum efficiency, it will be necessary to match the flow rate from the primary pump feeding into the buffer tank, with the flow rate drawn from the buffer tank by the secondary pump, whilst operating at the lowest LWT that meets the present heat demand.

Try lowering the speed of both pumps to position 3 and see how the system performs, and if it has any effect upon noise levels.

I have a circulation pump in the ASHP that is integral to the system and I have not touched the settings on this (Daikin) however, this pumps the water through the Low Loss Header and the secondary pump is also connected to the same LLH. I have that (Wilo Pico) pump set to approx 25% of max. speed. My installer explained to me that when using a LLH and a secondary pump in this way, the flow from the ASHP can be as high as required to ensure efficient heat dissipation. The Wilo runs far more slowly without adversely affecting the Delto T performance. Regards, Toodles.

Toodles, heats his home with cold draughts and cooks food with magnets.

Yes, I can see the clips on the external pipes

... but the insulation has been compromised and is no longer able to prevent the ingress of water.

Rain will run down between the pipe and the insulation, removing heat before falling to the ground.

The entire external insulation must be a continuous run, including the metal connections behind the heat-pump.

You also need to check if that external insulation is UV resistant.

If it's the same stuff as used inside, then I doubt it.

There might be a manufacturer's mark on it.

If so, tell us what it says.

I would expect it to be a closed-cell elastomeric nitrile rubber foam.

This allows it to have sheets of the same material wrapped around joins and glued in place.

The proper adhesive will allow the external insulation to last 20-years or more, even in full sun.

Once again, there are techniques to achieve this which are unlikely to be acquired simply by having the requisite training certificate!

Installers need to understand that we're not 'against them'.

We are ready to suggest strategies and materials.

The whole point here is to allow the spread of good techniques and skills.

Your installer can join in here on the Forum and ask for help on any tricky sites.

Commercial members are most welcome. The only 'rule' is that they can't advertise.

Save energy... recycle electrons!

@snuffy I agreed with transparent, that does not look like appropriate external insulation type (it looks like the standard grey interior stuff) or method (clips shouldn't break the insulation).

If your noise is air (common after a full system drain and refill) then bleeding is not the best answer. that only gets large lumps of air that have found their way to radiators. Small (micro) bubbles in the circulating water itself are very common in a newly filled system and they won't come out as big lumps via the radiators for a long time. you need an appropriately sized and installed one of these: https://www.spirotech.com/products/spirovent/

trivial to fit for a pro and they really work. I've had them on my system for years, I recently converted my house to self-installed ASHP, full drain and refill, the air noise was gone within a day.

its worth saying that the flow rate for the same house will be higher with an ASHP than a boiler (typically 4x higher) - thus the potential for flow noise is much higher (especially if pipework not significantly changed) and thus may well requires more effort to remove flow noise.

My octopus signup link https://share.octopus.energy/ebony-deer-230

210m2 house, Samsung 16kw Gen6 ASHP Self installed: Single circulation loop , PWM modulating pump.

My public ASHP stats: https://heatpumpmonitor.org/system/view?id=45

11.9kWp of PV

41kWh of Battery storage (3x Powerwall 2)

2x BEVs

Posted by: @snuffyOur installer had been very good and he's disabled the frost protection to stop it running at night soI can now sleep but I do worry what will happen in winter, not so much for house temp over night but for potential damage to the ASHP itself. As far as I'm aware, there is no antifreeze in the system as the manufacturer advises against it apparently.

The system is set to flow temp 46 degrees, we can't use the auto setting as the room thermometer is Honeywell so we've been advised to leave on flow temp setting.

you will need to have the frost protection re-enabled for the winter , with a no-glycol system, your ASHP has to be able to run at night to protect itself when below freezing outside (even if there is no heat demand) - so you need to get the noise issue addressed then re-enable this.

think of the noise in two areas:

- air noise - a recently filled system, will have loads of air in. look at the spirovent devices as I suggested.

- flow noise (the whooshing noise of water moving fast through a pipe, regardless of air or no air in the water). this is more likely to occur in an system converted from gas to ASHP as the flow rate is about 4x higher . once you are sure the air is out, if the noise is still there, ask your installer to look at the internal pipework (to the rads) from a sizing point of view - it maybe that some needs to be upsized or re-routed, as it may be carrying too much flow rate for the size of pipe.

fixed flow temp - your system will not be the most efficient like that. its acknowledged best practice to use a weather (outside temperature) compensated flow temp. colder outside => higher flow temp, warmer outside => flower flow temp. there will be others on this board who can advise how to get weather compensated flow temp working with your particular heat pump, I can't.

My octopus signup link https://share.octopus.energy/ebony-deer-230

210m2 house, Samsung 16kw Gen6 ASHP Self installed: Single circulation loop , PWM modulating pump.

My public ASHP stats: https://heatpumpmonitor.org/system/view?id=45

11.9kWp of PV

41kWh of Battery storage (3x Powerwall 2)

2x BEVs

@transparent Thanks for the info. Looks like there is some printing on the insulation but I'll have a proper look in daylight. Not sure how to broach this with him but sure I'll find a way when he calls back later in week. Even less confident about mentioning he signs up to the forum for advice. Will see how it goes.

Thanks. I am worried about the fact its a retro fit but everyone I spoke to said it shouldn't be an issue and this installer was the only one who mentioned having to replace radiators at all.

I'm thinking if any are causing a problem, it's the one we have in the bedroom. It's a very different design to all the others, comprising a block of very fine fins inside a wooden cover. Great for gentle heat in a bedroom and avoiding having hot surfaces but I suspect the narrow bore of the pipes and fins will be causing a problem with flow.

I did ask about changing the control settings but was told the weather compensation wouldn't work well with the sensor the system uses being housed with the main controller so not accurate for room temp maintenance. I am going to check all this with him though as not had a proper hand over yet. Mainly getting everything third hand from my partner who has decided the whole thing is too complicated for him to listen properly...

Definitely need to bring up the frost protection with him too. If it is that the noise is due to current pipework being incompatible with flow pressure of the ASHP I'm not sure what can be done, certainly don't want to start having to replace it all but I don't think I'll be able to cope with the noise all night either. Think I'd sooner right it off as a loss and go back to a conventional boiler again.

Any way, thanks for all your advice. I have a long list of questions for the installer now.

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 702 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

That’s my pleasure, @andrewj. The only challenge now is...

By Majordennisbloodnok , 6 hours ago

-

RE: Electricity price predictions

@toodles @skd Then there is not going to be much from t...

By ChandyKris , 6 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

@batpred I reckon Andy might know a thing or 2 about...

By Bash , 7 hours ago

-

RE: What determines the SOC of a battery?

@batpred Ironically you didn't have anything good to...

By Bash , 8 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

Here’s a current graph showing a bit more info. The set...

By benson , 8 hours ago

-

RE: Setback savings - fact or fiction?

True there is a variation but importantly it's understa...

By RobS , 8 hours ago

-

Below is a better quality image. Does that contain all ...

By trebor12345 , 9 hours ago

-

Sorry to bounce your thread. To put to bed some concern...

By L8Again , 9 hours ago

-

@painter26 — they (the analogue gauges) are subtly diff...

By cathodeRay , 9 hours ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 13 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 16 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 17 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 1 day ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 1 day ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 2 days ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 2 days ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 2 days ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 2 days ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 2 days ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 2 days ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 2 days ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 2 days ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago