@derek-m It is very east to install, plug it in, flick a switch on the board, and it works.

Heacol,

I know, though it may be better if you referred to the equipment as a Wireless Remote Controller and Wireless Receiver, rather than a thermostat which may be confusing.

So.....................me looking at those drawings is a bit like me trying to translate Greek to English 😆

But in basic terms I need to ask why the installer has gone with his preference, insist he install via the preference outlined above or go with his install and change it myself after install. When I say 'myself' I of course mean 'somebody' given that even the drawings are beyond my comprehension.

Really appreciate the help guys. I suspect others will benefit from this conversation too.

Retrofitted 11.2kw Mitsubishi Ecodan to new radiators commissioned November 2021.

14 x 500w Monocrystalline solar panels.

2 ESS Smile G3 10.1 batteries.

ESS Smile G3 5kw inverter.

Hi Morgan,

That's okay. You don't need to understand the drawings, that's what you pay your installer to do.

Being an old cynic, I suspect that your installer has recommended a thermostat, because most people are familiar with thermostats, but people may start to panic if the word controller is mentioned. Also fitting a thermostat would probably require less configuring and commissioning of the system, so hence more profit. At the end of the day your installer wants to provide you with a system that works, but is not particularly interested in how efficiently it performs.

I would certainly be interested to hear why your installer decided upon a thermostat, rather than a controller. At the end of the day it is your decision as to whether to have a thermostat or a controller, but if you should need help in optimising it's operation, we can probably use skype or facetime to iron out any issues.

At the moment I am carrying out some calculations and number crunching on operational data provided by the manufacturer of Batalto's system. I am investigating how variations in ambient air temperature, and water flow temperature, affect the operating efficiency of an ASHP system, to find the 'sweet spot' which gives maximum efficiency.

@derek-m I await the details of the full tech survey carried out last Tuesday. When I have that I will ask the question re the thermostat v controller and go from there.

Retrofitted 11.2kw Mitsubishi Ecodan to new radiators commissioned November 2021.

14 x 500w Monocrystalline solar panels.

2 ESS Smile G3 10.1 batteries.

ESS Smile G3 5kw inverter.

@derek-m that's amazing. Thank you! As an FYI I already copied most of that COP and temperature data into Excel, if that helps?

Hi Batalto,

The manufacturer's data you supplied is highly useful. I have already copied the data for the 12kW ASHP into a spreadsheet and have been making some quite revealing calculations, the findings from which I will be posting in the near future.

If you have copied data for other sized units into a spreadsheet I would much appreciate a copy.

Many thanks.

Hi Everyone,

I have been analysing the detailed manufacture's data for a 12kW ASHP, kindly provided by Batalto, with the following preliminary findings. The first thing that I noticed is that although the data is for a nominal 12kW ASHP, the maximum capacity at -15C outdoor air temperature is only 8857W at a Leaving Water Temperature (LWT) of 30C, and this falls to only 5865W at an LWT of 60C. Conversely, at 15C outdoor air temperature the maximum capacity is 14361W and 12291W respectively. It is therefore necessary to specify an ASHP that is at least 1.5 times the required heat demand of a given property.

As expected, the data clearly shows a reduction of ASHP efficiency at lower outdoor air temperatures, indicating an estimated COP of 2.05 at -10C against a COP of 3.69 at 10C, when operating with a LWT of 45C. Both these values were with the ASHP operating at maximum capacity. (Just over 44% less efficient) Whilst not totally unexpected, I noticed with interest that the COP under both operating conditions was slightly higher 2.15 and 4.16 respectively when the ASHP was operating at minimum capacity. (Just over 48% less efficient). It therefore would appear that as the ASHP works harder, it's efficiency is reduced slightly.

Whilst the reduction in efficiency -10C to 10C is slightly greater (50% and 52%) at a water flow temperature of 30C, the actual COP values are vastly different. At an outdoor temperature of -10C, the COP value at 30C LWT, maximum capacity, is 2.74, at 45C LWT it is 2.05 (25% reduction) and at 60C LWT it is 1.3 (52.5% reduction). Whilst at an outdoor temperature of 10C, the COP value at 30C LWT, maximum capacity, is 5.49, at 45C LWT it is 3.69 (32.8% reduction) and at 60C LWT it is 2.65 (51.7% reduction).

To obtain the most efficient operation from an ASHP it is therefore necessary to run it consistently at the lowest possible LWT, along with the lowest acceptable capacity and during the highest outdoor air temperature.

Problem 1. We cannot easily change the outdoor air temperature, without additional equipment to capture and store heat energy for use when the outside air temperature is lowest. So it would undoubtedly be beneficial to use the ASHP to produce more energy when the outside air temperature is highest during the day. Warm your home a little extra (higher temp) during the daytime. Drop the desired temperature slightly at night.

Problem 2. Running your ASHP with a LWT of 30C may be possible from Spring through to Autumn, but I doubt it will be achievable during the Winter months. As heacol has suggested TRV's should be removed, or possibly a better option would be to just set them to a temperature 1C above the desired temperature. That way they will help limit any temperature rise due to solar gain or human activity. Wherever possible all heat emitters (Radiators, UFH) should be fully operational, to maximise their heat output and therefore allow the ASHP to be operated at the lowest LWT at all times. I have some further suggestions which I will explore in greater depth in another post.

A further method to reduce the LWT, would be to improve insulation.

I have attached an Excel Spreadsheet to which I have added some columns. The calculated values are shown in BOLD text or the cells are highlighted, as detailed below.

On line 1: Heat Demand and Indoor Temp. - These are values for the user to change, the Heat Demand being that calculated for an indoor temperature of 21C at an outside air temperature of -3.3C. Both can be varied by the user to see the effect changes have on the data in BOLD text.

Heat Demand column: This is the calculated heat demand at the specified outdoor air temperatures.

COP / PI column: The upper BOLD value is the estimated COP values under the different operating conditions. PI is the estimated Power Input values under the various operating conditions. These values are highlighted as follows:-

Red - Indicates that the ASHP has reached it's maximum operating capacity and cannot meet the heat demand.

Green - Indicates that the ASHP would operate continuously within it's normal operating range and would be able to meet the heat demand.

Yellow - Indicates that the heat demand is lower than the minimum operating capacity of the ASHP. The pump would therefore need to cycle to satisfy the heat demand.

I hope that the above makes sense, but please feel free to ask questions.

Retrofitted 11.2kw Mitsubishi Ecodan to new radiators commissioned November 2021.

14 x 500w Monocrystalline solar panels.

2 ESS Smile G3 10.1 batteries.

ESS Smile G3 5kw inverter.

@derek-m there is definitely some kind of issue with the file - wont open for me either

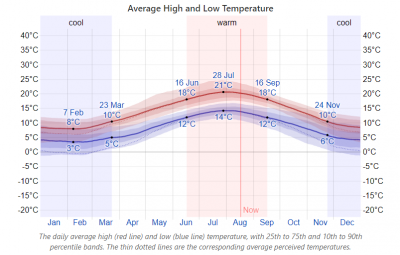

As an FYI this is the temperature range where I live - as you can see we are mild pretty much the whole year, with the odd cold day. The coldest points are always at night (as you would expect)

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 486 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

Below is a better quality image. Does that contain all ...

By trebor12345 , 26 minutes ago

-

Sorry to bounce your thread. To put to bed some concern...

By L8Again , 28 minutes ago

-

@painter26 — they (the analogue gauges) are subtly diff...

By cathodeRay , 1 hour ago

-

RE: What determines the SOC of a battery?

The answer from Fogstar was crisp. My hypothesis, su...

By Batpred , 1 hour ago

-

RE: Electricity price predictions

I am always impressed with how you keep abreast of so m...

By Batpred , 2 hours ago

-

RE: Setback savings - fact or fiction?

I fully understand your reasoning, same steady inputs s...

By cathodeRay , 2 hours ago

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

@majordennisbloodnok I’m glad I posted this. There see...

By AndrewJ , 2 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@tasos and @cathoderay thanks. I have some history grap...

By benson , 4 hours ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 5 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

Just to wrap this up here for future readers: The S...

By Batpred , 7 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 8 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 9 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 24 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 1 day ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 1 day ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 1 day ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 1 day ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago