In the Bleak Midwinter... Midea heat pump performance, poor COP and windchill in action

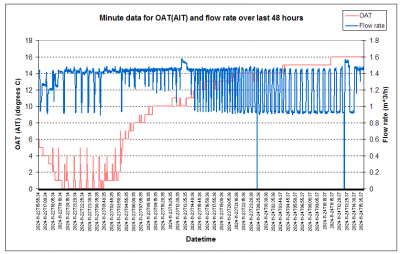

@jamespa - here's a not very pretty plot of OAT and flow rate for the last 48 hours. The right hand end is not typical, as the OAT exceptionally high. There is more variation in the flow rate that I thought, but it still spends most of it time at 1.4 or thereabouts. It does not appear to be affected by the OAT which varied considerably during the period in view, except perhaps on the RHA side where it is very mild, with OATs above the WCC right hand set point of 15 degrees:

Doing your heat transfer calculation the other way round, ie solving for power available, and using a specific heat that allows for glycol which I have, at a LWT/RWT of 4 (probably closer to my average), I get:

power available = 4 x 4.05 x (1.4/3.6) = 6.3kW (or 6.3kWh over one hour), which is close to what I get.

I am currently manually (via a script) upping the set LWT every hour (after the auto-adapt resets it) and it seems to be doing the trick. I will post a chart later of what has happened.

Midea 14kW (for now...) ASHP heating both building and DHW

Its not pretty but its pretty clear, pump speed is constant.

However the manual seems to say it isnt!

Something odd!

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

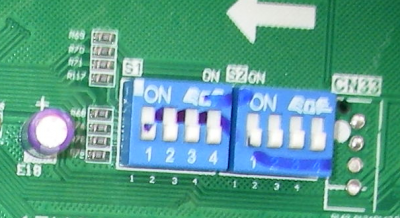

@jamespa - some more info such as it is (photos taken a while back):

(1) I appear to have a Grundfos primary pump (this is the inside of the outdoor unit):

(2) Dip switch 2 appears to be all off:

(3) from the Dip switch table you posted recently, this suggests I have "00=variable speed pump (Max head:8.5m,Grundfos)"

(4) there appear to be two wires going to the pump (had to tweak the image RGB curve rather dramatically to make them visible) which makes it at least possible one of them is the PWM control lead (the other being power):

BTB, I think this may have been discussed in the past.

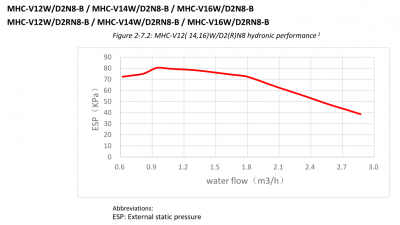

(5) In the Engineering Data you posted, it says "The pump is controlled via a digital low-voltage pulse-width modulation signal which means that the speed of rotation depends on the input signal. The speed changes as a function of the input profile. The relationship between external static pressure and water flow rate is described in Part 2, 7 “Hydronic Performance”. This is on page 59:

But as I said before, to my eyes this has the axes the wrong way round. Or maybe it is just descriptive, as flow rate goes up, pressure goes down.

Whatever it means, the charts shows a wide range of flow rates. The quote above includes "The speed changes as a function of the input profile" but no where can I find any other references to "input profiles", or even just profiles. Nor are PWM and its variants to be found elsewhere.

Manuals can be at best most confusing, at worst full of gaps and or misinformation. Here is one of my favourites, part of the service manual for a small marine diesel engine. It is a simple screenshot, not altered in any way by me. The item shown is the gearbox:

Midea 14kW (for now...) ASHP heating both building and DHW

Two wires doesn't seem enough - this isn't a boat with return via the chassis (I presume) so I would have expected three! That said I thought that PWM pumps default to max speed if no pwm signal present. Worth investigating but surely wiring is something done at manufacturing not an installer thing? if you can find the model number its likely the Grundfos website has a wiring diagram.

I think the pump graph is simply depicting that at higher flow rates less head is available to overcome resistance in the external circuit, which of course is a double whammy because the head required for the external circuit will go up as throughput increases, but thats pumps!

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

Posted by: @jamespaTwo wires doesn't seem enough - this isn't a boat with return via the chassis (I presume) so I would have expected three!

I'm pretty sure the two wires visible are multi-core. The secondary pump for example has only one wire (cable) going to it, but it must have more than one core, because it certainly doesn't use the chassis (pipework) as the return! Boats by the way invariably have separate returns, they don't have a chassis as such, and if they did there is salt water everywhere, not a good mix!

I don't think my installer or even Freedom touched the wiring at all, this is how it left the factory. I'm not sure I can get to see the model number, but if I can find that previous thread that had a discussion on the pump, it may be that someone else managed to identify it by appearance.

But we are still completely in the dark about how Midea control its speed, if indeed they do.

Midea 14kW (for now...) ASHP heating both building and DHW

Posted by: @cathoderayI'm pretty sure the two wires visible are multi-core. The secondary pump for example has only one wire (cable) going to it, but it must have more than one core, because it certainly doesn't use the chassis (pipework) as the return! Boats by the way invariably have separate returns, they don't have a chassis as such, and if they did there is salt water everywhere, not a good mix!

I think you are right about multi-core, I just saw it in the manual. One of the cables appears to be the pwm cable.

Im thinking narrowboats, which being metal sometimes do use the hull for the return just like a car.

Posted by: @cathoderayBut we are still completely in the dark about how Midea control its speed, if indeed they do.

One possible way is to maintain a constant deltaT. But there are others and its a moot point whether pump speed constol is necessary other than for the convenience of installers.

You could try pulling the PWM cable and see what happens, it may complain, blow the thing up or cause the pump to run at max speed. The first or last are the most likely, but the middle could I suppose happen.

Really there are, so far as I can see, only two broad possibilities (a) for some reason the Midea isnt sending the right PWM signal to the pump or the pump isnt responding or (b) even though it is there is too much resistance in the primary circuit for it to run at max design speed.

If you can somehow persuade the pump to operate at max speed then you can distinguish between these two, unless of course you have an oscilloscope you can put on the PWM pin (actually you can probably test with a multimeter, the PWM pin will have an average voltage which is somewhere between zero and the reference voltage (probably 5 or 12 volts), which should be on the other two pins of the PWM connector).

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

Posted by: @jamespaIm thinking narrowboats, which being metal sometimes do use the hull for the return just like a car.

Sorry, I should have said non-metal (ie wood, GRP) seagoing boats! Even on non-metal boats, galvanic corrosion is a major problem, and stray currents can be potential boat sinkers.

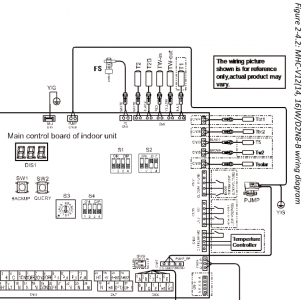

I presume this is the place where you found the pump wiring in the manual:

I don't have an oscilloscope but I can usually use a volt meter without blowing things up. I think CN17 is the PWM control wire, I found this in the Installation Manual "CN17 Port for variable speed pump communication" (CN28 is "Port for variable speed pump power input"). Assuming I can find exposed metal to get a probe on (I am not going to disconnect it and risk blowing the thing up!), what should I be looking for?

Primary circuit resistance shouldn't be that high, the runs are short, and no small bore rad tails. But the pipe is 28mm plastic which has a narrower bore than 28mm copper, and the PHE must also have some resistance.

I've found the thread with the past mentions of the pump, see here. The primary pump is a Grundfos UPMM, with documentation available here (thanks to @iancalderbank).

Midea 14kW (for now...) ASHP heating both building and DHW

@jamespa - thanks. I'll wait for better weather before opening the cabinet!

Posted by: @jamespaThat said it may be time to consider getting a midea engineer in.

It might be worth seeing if other Midea owners here on the forum have anything to add. The current flow rate can be seen on the wired controller under Operation Parameters, doesn't need modbus just to get the current value. Anyone out there with a Midea heat pump care to have a look? It's called 'Water Flow' and is on page 3 of the Operation Parameters menu. Just a few spot readings would be very helpful!

Midea 14kW (for now...) ASHP heating both building and DHW

The water pump manual tells us there are 3 pins, control, feedback and voltage reference ( presumably the return is via the case, ie ground) or if the cable has a shield the cable shield). It also says that if no pwm cable is fitted it runs at max. A voltmeter on the control will record the average voltage, which will be zero for max speed and the voltage reference level for min.

In the heat pump manual there is something about a pump test mide. Might be worth exploring that first

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

@jamespa - I've done some more research...

(1) it looks like the pump test mode is very basic. It is accessed via the 'For Serviceman' menu. When run, it just detects insufficient flow (not defined) and displays Error E8, and then E0 is E8 happens three times. It doesn't give the actual flow. But I'm pretty sure the E8/E0 checks are always on, because they are the errors that appear when for example a filter gets clogged. Putting it the other way round, the fact my unit doesn't show these these codes (and never has done) means the unit thinks the flow is sufficient. If the bar for 'sufficient' is low (as it may well be) then the unit passes, even though the flow is insufficient for higher levels of heat transfer.

[Note on nomenclature: P_o/P_O/PUMPO seems to be the outside (radiator circuit) pump, O is letter o not zero, and P_i/P_I/PUMPI is the inside (internal) to the unit pump, letter i not digit 1, it is this latter pump that we are interested in]

(2) I found this in the Installation and Owners Manual and it is rather interesting:

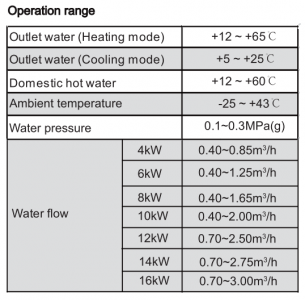

I think we have discovered how Midea use the same hardware to get three different models, the 12, 14 and 16kW models, they just limit the max flow rate for the 12 and 14kW models. I haven't done the sums, but I suspect 2.5, 2.75 and 3m^3/h correspond to the flow rates needed to deliver 12, 14 and 16kW. The other thing this table tells us is that my heat pump (14kW) should be capable of going up to 2.75m^3/h, but it doesn't.

This page from the same manual also suggests the same thing (and seems to confirm PWM is/should be used):

It may of course be the sensor is faulty, but I think this is unlikely, because we have an indirect test, whether the building is heated adequately at low OATs. It isn't which means (provided all the rest is OK eg emitters are of adequate size which they are etc) either the LWT/RWT delta t is too low, the specific heat of the circulating fluid is too low, or the flow rate is too low. From the monitoring I have, we can see that the LWT/RWT delta t is sometimes lowish, but mostly adequate, the specific heat of the fluid is fixed, and that only leaves one thing, the flow rate. Both the direct test of flow rate (the sensor) and the indirect functional test (is enough heat transferred) give the same answer: the flow rate is too low.

[Note on flow sensors: I think there are two, one is a binary flow is OK/not OK sensor which triggers the E8/E0 error codes when it is not OK, the other supplies the flow rate we see on the wired controller/via modbus, and it is in fact an indirect measure, there is no physical sensor. From the same manual: "The flow rates parameters are calculated according to the pump running parameters,the deviation is different at different flow rates,the maximum of deviation is 15%. The flow parameters are calculated according to the electrical parameters of the pump operation." Even after applying the 15% 'deviation' my flow rate is still far too low at low OATs.]

I think I have enough substance here to take it up with my installer. As you know, there are no Midea engineers in the UK, only Freedom Heat Pump engineers, and as you may also recall, they have a long and distinguished career in being as unhelpful as possible to end users. They will however hopefully engage with my installer. We shall see. The Midea/Freedom warranty is also somewhat opaque, both in what it covers, and for how long it lasts, but thanks to the monitoring I have done, I can demonstrate the flow rate has been compromised since at least March 2023, which is only just over a year after installation, and thereby well within any reasonable warranty period express or implied.

Midea 14kW (for now...) ASHP heating both building and DHW

Posted by: @cathoderayI think I have enough substance here to take it up with my installer. As you know, there are no Midea engineers in the UK, only Freedom Heat Pump engineers, and as you may also recall, they have a long and distinguished career in being as unhelpful as possible to end users. They will however hopefully engage with my installer. We shall see. The Midea/Freedom warranty is also somewhat opaque, both in what it covers, and for how long it lasts, but thanks to the monitoring I have done, I can demonstrate the flow rate has been compromised since at least March 2023, which is only just over a year after installation, and thereby well within any reasonable warranty period express or implied

I agree with your conclusions and I agree with the above. If they try to argue its your system, you have a heat exchanger which they presumably installed, so you should be able to defeat that one.

Good luck

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 403 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

Without knowing it, @andrewj, you've laid down the gaun...

By Majordennisbloodnok , 2 minutes ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@tasos and @cathoderay thanks. I have some history grap...

By benson , 6 minutes ago

-

I am having my existing heat pump changed to a Vaillant...

By trebor12345 , 39 minutes ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 1 hour ago

-

RE: Setback savings - fact or fiction?

@cathoderay The input power is largely determined by...

By RobS , 2 hours ago

-

RE: Electricity price predictions

@transparent Im impressed by all your work on this. ...

By JamesPa , 3 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

Just to wrap this up here for future readers: The S...

By Batpred , 4 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 4 hours ago

-

RE: What determines the SOC of a battery?

I agree. Fogstar confirmed that the Seplos BMS does ...

By Batpred , 4 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 5 hours ago

-

@painter26 — as @jamespa says, it's for filling and re-...

By cathodeRay , 9 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 20 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 22 hours ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 1 day ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 1 day ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 1 day ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago

-

RE: DIY solar upgrade - Considering adding more panels

I know this is a bit old, but it made me wonder what co...

By Batpred , 2 days ago