How to Understand Wiring Up a Heat Pump

Hi everyone,

I’m looking to get a better understanding of heat pump wiring and would really appreciate some advice. I’m 18 and have some experience in solar and EV's, but wiring for heat pumps seems a bit more involved, especially when it comes to controls, sensors, and integration with cylinders or multiple zones.

Could anyone point me in the right direction for learning resources? I’m particularly interested in:

- Wiring Layouts

- Good training courses (online or in-person, ideally UK-based)

- Videos or books that break down common setups and troubleshooting

If you’ve learned from experience, what helped you most when starting out? And are there any common pitfalls or mistakes to avoid?

Thanks in advance for any pointers - I'm really keen to build up my knowledge properly.

Firstly welcome to the forums, I hope you will find us friendly and helpful. And congratulations for being interested in renewables.

Heat pump control systems are certainly more complex than EVs or Solar panels, fundamentally due to the complexity of the (seemingly simple) problem of heating a house to a comfortable temperature and doing so whatever the outside does and indeed whatever the design of house is.

Posted by: @renewables345controls, sensors, and integration with cylinders or multiple zones.

The simple rule (with the caveat that every rule has some exceptions) is DONT use any external controls which are not specifically designed for heat pumps, of which there are currently only 3 to the best of my knowledge namely Homely, Adia, Havenwise. Almost all other external controls will conflict, in a bad way, with the heat pumps own controller. You wont necessarily know it but you (or rather the customer) will pay for it in running costs.

Heat pumps should generally have the minimum controls possible other than those provided by the manufacturer, basically operated on weather compensation with possible a little room influence but generally not much. Mostly single zone too, not multiple zones unless the house is very unusual.

If any 'Smart' control manufacturer (other than the three above) tells you that their controls are suitable for heat pumps (a) doubt the statement and (b) ask how it integrates with the heat pump bus/weather compensation curve. If you get a blank stare or BS, walk away. Plenty will try to give a swish sales pitch, but generally its not worth the paper its written on.

Thats the starting point, if you want to understand controls for heat pumps, as opposed to simply following diagrams drawn by others (often generic designed to apply to all possible cases and thus include lots of extraneous stuff), you need to get your mind round this and also why its the sensible thing to do.

Sensors, other than those in the ODU itself, are generally limited to a thermistor for the DHW temperature and maybe an OAT sensor to be placed on a wall out of direct sun.

Beyond that you need to learn about the controls in the plumbing as well as electronic controls, because these are part of the overall control strategy and cannot possibly be separated from the electronic controls when thinking about the system. The only necessary one is a diverter valve (DHW or space heating) but there are often TRVs or UFH mixers. Both of the latter can be bad news and should be avoided, or set above the desired temperature, to act as limiters not controllers. Ideally you shouldn't need a UFH mixer.

Static adjustments by LSVs or the UFH equivalent are an important part of the overall picture. These are set once and forget (albeit via an iterative process in most cases), but vital to getting the system operating comfortably. In addition to the above there are some safety mechanisms associated with the pressurised parts of the system, not really controls.

Posted by: @renewables345Could anyone point me in the right direction for learning resources? I’m particularly interested in:

Wiring Layouts

Good training courses (online or in-person, ideally UK-based)

Videos or books that break down common setups and troubleshooting

If you’ve learned from experience, what helped you most when starting out? And are there any common pitfalls or mistakes to avoid?

Most if not all heat pumps have a wiring centre either in the ODU or separate, to which all sensors/controls should connect (and if they dont they probably shouldnt be used, but sadly often are). These are manufacturer specific but of course there are common themes. Download a few installation manuals and you will see what I mean.

In addition all heat pumps have an installation menu in which a whole host of control parameters can be set up. This is a vital part of the commissioning process. Unfortunately its not always obvious what any particular setting does and, while the concepts are similar, the implementation differs from manufacturer to manufacturer.

For more general instruction you could do worse than look at some of the heat geek videos. They cover much more than controls but in order to understand the controls fo9r a system you need to understand the system! Other than that I cant suggest anything particular, others may be able to

I would sound a strong warning that there is a lot of poor material around evidenced by the number of poor installations seen. Thus view anything with a pinch of salt and try to get to the bottom of whats really happening, whats really necessary (and what is just an unnecessary and frequently destructive sales gimmick), and why its sensible for a heat pump. Heating control manufacturers have brainwashed us into thinking that micro-zoning in time and space is a good idea. It certainly isnt for heat pumps (and very likely not for many boiler installations) There are good reasons why this is the case, look at some of the Heat Geek videos on zoning.

Finally heat pumps need generally either a 16A, a 32A single phase, or a three phase feed for the higher capacity ones. Best practice is RCD protection (I think generally Type B), and some heat pump manuals specify or encourage this; the IET regs require only MCB protection for external fixed plant unless the electrician assess that the risk is sufficiently high to merit RCD. This is a point of occasional consternation.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

I would recommend youtube videos by Glyn Hudson of open energy monitor if you are contemplating installing one yourself. 😀

House-2 bed partial stone bungalow, 5kW Samsung Gen 6 ASHP (Self install)

6.9 kWp of PV

5kWh DC coupled battery

Blog: https://thegreeningofrosecottage.weebly.com/

Heatpump Stats: http://heatpumpmonitor.org/system/view?id=60

I’m watched @pirate-rich rewire our wiring centre last week, which was MASTERFUL! It was calm, methodical and meticulous.

I have no technical ability in this area, but I’ll share what I saw as general guidance to steer you in the right direction. It’s quite complicated, but for people that are technically astute and can follow technical diagrams, it’s something that should come naturally with the right training.

Maybe Richard can recommend a course and/or reading materials.

Get a copy of The Ultimate Guide to Heat Pumps

Subscribe and follow our YouTube channel!

Posted by: @renewables345If you’ve learned from experience, what helped you most when starting out?

And are there any common pitfalls or mistakes to avoid?

I've learned from experience rather than received any formal training.

I had access to a rudimentary electronics workshop during my last couple of years at school.

That enabled me to learn about categories of wire and connectors in a safe environment whilst using ULV.

Ultra-low voltage is usually defined as "below 75v".

You can still damage equipment by making incorrect connections, but you're not going to die!

My first professional work which required a combination of power and signal wiring was when I joined a team working on remote-controlled marine robotics.

That was a huge step into the unknown.

The people who are likely to have the most helpful experiences to share with you are to be found in a model railway club!

Typically they're run by retired gentlemen from a technical/engineering background who are desperately keen to share their knowledge!

You can also ask for help here on the forum of course.

If you post a photo of a circuit-board or a diagram from a manual, we can use our combined skills to help solve a problem.

Whatever you pick up from formal training will never teach you all that you need to know.

Learning about new techniques and equipment is a life-long quest.

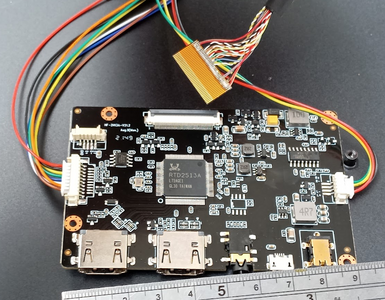

At this moment in time I have a circuit board beside me from a monitor screen.

It can accept power input from either 5v or 12v...

... but not 12v fed into the 5v connector - which is why it's now dead!

Google image-search enables me to find some possible alternative boards which I can order directly from China.

I can also search for the board number HF-2H13A-v21.2 or the chip number RTD2513A which can often turn up a circuit schematic.

I'm now busy checking the connectors to find a board which can be a plug-in replacement.

In this case I note that the white connectors to the right and left are made by JST (a Japanese company)

and that there is a convention amongst monitor manufacturers as to what each of these do.

Central heating systems have been using 'standard' wiring centres for pumps, thermostats and motorised valves for decades.

But the connections for boilers and heat pumps are unique to each manufacturer.

Moreover, those manufacturers will inevitably make one control board which they then use in a number of different models.

The board will offer a wide range of functions, many of which won't be used in your particular configuration.

It takes years of experience before you build up a 'feel' for what these control boards should be doing.

Ask for help from as many people you can find who are willing to assist you.

Save energy... recycle electrons!

Posted by: @editorI’m watched @pirate-rich rewire our wiring centre last week, which was MASTERFUL! It was calm, methodical and meticulous.

I have no technical ability in this area, but I’ll share what I saw as general guidance to steer you in the right direction. It’s quite complicated, but for people that are technically astute and can follow technical diagrams, it’s something that should come naturally with the right training.

Maybe Richard can recommend a course and/or reading materials.

Richard, Rich, Dick, Captain or Pirate... I answer to them all in any sequence! 🏴☠️☠️👍

See my heat pump running live here... 👉 HeatPumpMonitor.org 👈

Buying from 🏴☠️ PirateHeatingSupplies.com 🏴☠️ means you support my family owned, independant business! 🙏❤️👍

I completely agree with @transparent and @pirate-rich that there is absolutely no way you can 'learn' what decades of experience teaches you.

However everyone has to start somewhere, so if you are serious what you can do is learn to understand how heat pump based heating systems and their controls work. Why is sensor A connected to point B and what is the controller doing with the information? Is it a zero volt contact, a low DC logic level or 240V AC (yes, 240 V AC logic exists in heating systems, in fact it is almost the default in older boiler based systems). Why does the heat pump connect to/control the water pump, what does it do with the connection and why? Why is weather compensation so important especially for heat pumps and why is it a very sensible thing to do (as opposed to a control loop based on measuring room temperature alone). Why do we sometimes use mixing valves in UFH systems?

If you understand systems then the wiring up becomes relatively straightforward. That does not mean that you don't have to look at wiring diagrams provided by the manufacturers, you do because they have different connection points sometimes with different functions. But knowing what to expect (and, equally, what is suspect) is half the battle, particularly when faced with an instruction manual written in chinglish (and indeed a fair few where the author had english as a first language, but not english as we know it!). This is particularly true of heating systems which are often put together with components from several manufacturers, on the fly without a wiring diagram, and thus need a bit of 'reverse engineering'.

In my book at least developing an understanding is not optional. Failure to understand is, I have little doubt, the reason for many of the f-ups that certain elements of the industry delivers. With understanding you can still make mistakes, without it you are reduced to blindly following what someone else has set down, or some rules you have been given, probably a long while ago and/or for completely different circumstances. With retrofits its particularly important because the new parts and the old parts of the system have to work together and no manual can tell you how to do that for every circumstance. This, incidentally, is nothing to do with heat pumps, it applies to all systems!

So my advice is to understand a bit about heating systems in general, a bit about the specifics of heat pumps, and a bit about the types of control available and then study some wiring diagrams (and plumbing) and see if you can work out why they are as they are.

Hope that helps.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

@renewables345 you say you are 18 and I’m assuming you might be considering this a a future professional direction. I suggest you look at the local further education colleges for TEC courses in electrical and plumbing subjects. Without the basics you will always be over dependent on wiring diagrams from manufacturers and getting it wrong is all too easy as customers here can tell you. YouTube and the internet are no substitute for for a thorough understanding

2kW + Growatt & 4kW +Sunnyboy PV on south-facing roof Solar thermal. 9.5kWh Givenergy battery with AC3. MVHR. Vaillant 7kW ASHP (very pleased with SCOP 4.7) open system operating on WC

Morning, On top of what everyone else I would deffo look into an apprenticeship. My boy failed all his exams at school and was pretty despondent but managed to get onto an apprenticeship. His dyslexia really knocked his confidence but with good tutors and mentors he worked his way through electronics, soldering, welding, PAT testing all while earning a wage working full time. He now installs and maintains massive CNC and 3D printing machines (for the same company) in industries like automotive, petrochemicals, Defence.

Books and courses can only get you so far but a good, experienced mentor is worth their weight in gold.

Good luck to you on your journey of learning, never be afraid to ask!

Kind Regards

Si

——————————————————————————

Grant Aerona3 13kW

13 x 435w + 13x 480w Solar Panels

Sigenergy 10kW Inverter

16kW Sigenstor battery

-

Aira Heat Pump: Stylish Scandinavian Heating

2 weeks ago

-

Heat Pump Paradox: The Industry's Adoption Divide

2 years ago

-

Not So Hot: Too Many Subpar Heat Pump Installations in the UK

2 years ago

-

The Most Popular Heat Pump in the UK: Is It In Your Home?

2 years ago

-

Heat Pumps - An Expensive Folly?

3 years ago

- 27 Forums

- 2,475 Topics

- 56.9 K Posts

- 249 Online

- 6,165 Members

Join Us!

Worth Watching

Latest Posts

-

RE: If a heat pump can only heat DHW to 50C then what? Issue with 18KW Heliotherm heat pump

Hi, Nothing yet. I've asked customer to measure flow...

By errmm , 5 hours ago

-

RE: High Temp Heat Pumps for fast warm-up of house

I don't know exactly how long it takes to heat up (and ...

By JamesPa , 6 hours ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

OK. What Im seeing looks fairly normal TBH: 1 start ...

By JamesPa , 7 hours ago

-

RE: Vaillant Tech Support Flagged Low DT: UFH Return Cold, Suspected Zero Flow

@editor thanks for the tips which I will try before cal...

By DavidB , 8 hours ago

-

RE: Daikin 6kw setup with Dixell controller

@jamespa Many thanks for your reply, a very detailed an...

By CraigH , 8 hours ago

-

RE: Exploring the role of alternative clean heating solutions - Government Consultation

Despite reservations, I found some time to respond to t...

By Rusty , 8 hours ago

-

RE: New Vaillant aroTherm Plus in black - When will it come to the UK?

@crankplus, nope, still not, and I've followed up with ...

By Mars , 8 hours ago

-

RE: Octopus Cosy Heat Pump Owners & Discussion Thread

@agentgeorge Probably, but temperature change at -10 ha...

By AndrewJ , 9 hours ago

-

RE: External wall insulation - your experience

To be clear, my experience was very positive. The journ...

By Batpred , 11 hours ago

-

@foxesfan Re: ‘Servicing’ as @editor has covered in his...

By Toodles , 11 hours ago

-

RE: A Smarter Smart Controller from Homely?

@benson No idea why mine doesn’t work, all I see on ...

By Papahuhu , 12 hours ago

-

RE: Battery sizing - How low can you go!

It seems I am seeing something similar to what you do, ...

By Batpred , 13 hours ago

-

RE: Gaslighting in the heat pump industry – has anyone else experienced this?

Don’t know if this is relevant to this thread, but my A...

By Gruff2001 , 14 hours ago

-

RE: Bosch CS5800i 5kW - Experience So Far

@majordennisbloodnok While getting Home Assistant runni...

By Steelbadger , 1 day ago

-

RE: MCS - BS EN 12831-1:2017 – Heat Loss Survey

Since May 2025 it no longer a requirement in England to...

By JamesPa , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handel @jancold Manufacturer: Daikin Model: E...

By Jancold , 1 day ago

-

RE: Octopus Cosy 12 Heat Pump Regret: Incredibly Loud, Poor Heating & Constant Hum - Help!

@harriworld it was roughly 3am for an hour as that’s ...

By L2jad , 1 day ago

-

RE: Hoped for improvements not being realised on my Mitsubishi heat pump

I have been wondering that myself. The fact is that, ...

By JamesPa , 1 day ago

-

RE: Filtering Tap Water – Share Your Setup for Cleaner, Better-Tasting Water

I remember when I was in my early 20s I was introduced ...

By Majordennisbloodnok , 1 day ago

-

RE: Setback savings - fact or fiction?

But if it is recorded an an integer, which it seems it ...

By cathodeRay , 2 days ago