@Crimson, I hesitate to state it, but it seems like your plumbers are clueless. You need a fresh pair of eyes on the job as there's something seriously wrong with your primary flow assuming the flow indication is correct. There's nothing to go wrong with a LLH, it has no internal parts. It's not a necessary component in simple systems, but if correctly balanced with equal flow on primary and secondary side, it not a deal breaker. You lose some efficiency as there is heat conduction transfer in the fluid between flow and return, and the sudden volumetric expansion and contraction as flow enters and leaves the LLH adds some circuit resistance [pump head]. Neither are massive however.

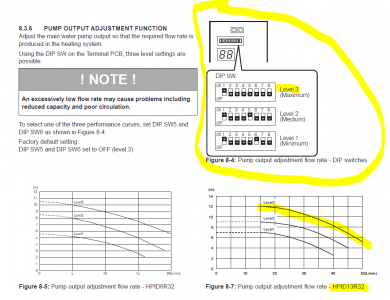

The Grant ASHP circuit board has dip switches to set the primary pump flow. There is no flow sensing in the Grant Aerona, the controller displays pump speed but that's a rather meaningless value as it never changes from what the dip switch selection is. The dip switch settings are easily checked and changed by popping the small cable entry cover plate off and looking at the PCB. Refer Grant Aerona installer manual. Grant say to commission starting at pump speed 1, but the unit comes defaulted to pump speed 3, and I would wager most installers leave it at 3 and just close off the flow setting valve, which is the most inefficient way to run the pump. Here's the switch settings and the flow/head curve for the 13kW Aerona at various speeds:

There's no need for a Y strainer on the system, nor do Grant specify one. If there is one, check it's clean. Hopefully someone has had the sense to fit full bore 1/4 turn isolation ball valves each side of any strainer to service it? OK, that was wishful thinking! I hope your plumbers have also checked the Mag One filter is clean while they have been head scratching and tyre kicking while on hold to Grant UK!

@iancalderbank, I think the Grant Mag One pressure loss flow curve in the data sheet is complete bollox. 3bar pressure loss is 30.6m head. That can't be right, the pump for the 13kW Aerona can only supply 12m head max (1.2bar). I have the same Mag one filter in the 10kW Aerona, and it has no issue with flow rate at 22l/min and that's on pump speed 1 (about 3.5m head) on the internal ASHP setting! I think Grant has stated bar instead of m head, as their values seem a factor of 10 out from what would be expected. Grant make quite a lot of mistakes in their literature... If you compare with Adey Magnaclean, or other commercial magnetic filters, pressure loss in correctly sized magnetic filters isn't that high.

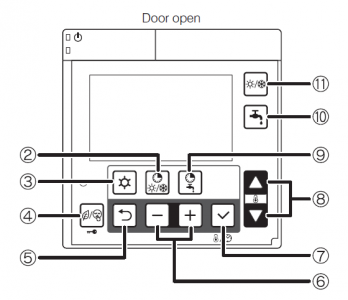

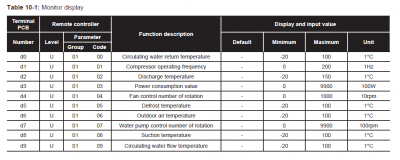

@Crimson, the Grant controller can display these parameters at 'user level', press and hold the back button [5] for 3s to enter these parameters, and use the up and down arrows [8] to select 0-9 then press 'tick'/enter [7] to display. Press and hold back button again for 3s to return to home screen:

Isha killed my internet so out of loop a bit on this one, but has the auto bypass valve been checked? It should be set to almost never operate as your heat emitters should always be asking for heat. That's another thing usually left at default for gas boiler flow rates, not heat pumps. Could be causing a short loop of flow on secondary side.

Grant Aerona 3 10kW

Thanks @allyfish, will get back here tonight with results from the codes. Plumber did try I believe 3 speeds on the pump. To no avail, I couldn’t see any difference each time checked in on him.

fully aware these guys could be dead clueless. The mistakes across the job have been a bit much to take. Everyone else involved, builders, carpenters, decorators, electricians etc have been fantastic. These guys have been a real sore point. I really didn’t appreciate having to jump on and research radiator calculations to get sizing as seemed to take them an eternity holding up the work considerably. At one point suggesting monolithic rads with 2 tall plus 2x 2m wide rads in rooms. Turned out they hadn’t inputted any u values that took into account all the material changes happening to the property. So heavily suspect anything with the ASHP they haven’t a clue with either.

Posted by: @mikeflIsha killed my internet so out of loop a bit on this one, but has the auto bypass valve been checked? It should be set to almost never operate as your heat emitters should always be asking for heat. That's another thing usually left at default for gas boiler flow rates, not heat pumps. Could be causing a short loop of flow on secondary side.

I can ask them to check this Friday/Monday - or is that something I could look at?

Posted by: @allyfish@Crimson, I hesitate to state it, but it seems like your plumbers are clueless. You need a fresh pair of eyes on the job as there's something seriously wrong with your primary flow assuming the flow indication is correct. There's nothing to go wrong with a LLH, it has no internal parts. It's not a necessary component in simple systems, but if correctly balanced with equal flow on primary and secondary side, it not a deal breaker. You lose some efficiency as there is heat conduction transfer in the fluid between flow and return, and the sudden volumetric expansion and contraction as flow enters and leaves the LLH adds some circuit resistance [pump head]. Neither are massive however.

The Grant ASHP circuit board has dip switches to set the primary pump flow. There is no flow sensing in the Grant Aerona, the controller displays pump speed but that's a rather meaningless value as it never changes from what the dip switch selection is. The dip switch settings are easily checked and changed by popping the small cable entry cover plate off and looking at the PCB. Refer Grant Aerona installer manual. Grant say to commission starting at pump speed 1, but the unit comes defaulted to pump speed 3, and I would wager most installers leave it at 3 and just close off the flow setting valve, which is the most inefficient way to run the pump. Here's the switch settings and the flow/head curve for the 13kW Aerona at various speeds:

-- Attachment is not available --

There's no need for a Y strainer on the system, nor do Grant specify one. If there is one, check it's clean. Hopefully someone has had the sense to fit full bore 1/4 turn isolation ball valves each side of any strainer to service it? OK, that was wishful thinking! I hope your plumbers have also checked the Mag One filter is clean while they have been head scratching and tyre kicking while on hold to Grant UK!

@iancalderbank, I think the Grant Mag One pressure loss flow curve in the data sheet is complete bollox. 3bar pressure loss is 30.6m head. That can't be right, the pump for the 13kW Aerona can only supply 12m head max (1.2bar). I have the same Mag one filter in the 10kW Aerona, and it has no issue with flow rate at 22l/min and that's on pump speed 1 (about 3.5m head) on the internal ASHP setting! I think Grant has stated bar instead of m head, as their values seem a factor of 10 out from what would be expected. Grant make quite a lot of mistakes in their literature... If you compare with Adey Magnaclean, or other commercial magnetic filters, pressure loss in correctly sized magnetic filters isn't that high.

@Crimson, the Grant controller can display these parameters at 'user level', press and hold the back button [5] for 3s to enter these parameters, and use the up and down arrows [8] to select 0-9 then press 'tick'/enter [7] to display. Press and hold back button again for 3s to return to home screen:

-- Attachment is not available --

-- Attachment is not available --

here are th me results of the codes, and another photo of the probes by LLH for context (it’s heating at this point not hot water cycle)

00 - 38c

01 - 47c

02 - 66c

03 - 1300

04 - 560

05 - 2c

06 - 9c

07 - 4400

08 - 11c

09 - 45c

@crimson great stuff. The delta T between flow and return is high, especially when your ASHP is on low load, 1300W power consumption, that's about 1/3 of what you can expect a 13kW Aerona to consume at high load. The high delta T is symptomatic of your low primary flow. At 9 l/min your are producing about (9/60) x 4.2 x (45-38) = 4.4kW. That's very approximate as Grant displays temperature to the nearest 1degC. A COP in the order of 3.4 = 'modest'. I can see that to get much more duty out of the ASHP the flow rate is going to need to be much higher, because the optimum delta T between flow and return is around 5 or 6deg. On part load like today, a delta T or 3 or 4 deg is probably more typical.

PS: I have exactly the same temperature indicators on my LLH, I would clag some pipe insulation of the sensors if you can. They're not that accurate, but they do show up things that are not right, like your very high primary side delta T compared to your secondary side delta T, When the flows are balanced, the delta T should be the same on both sides, or a little higher on the secondary side. The primary side should never be higher regardless of what your heat load is - space heating, hot water, etc.

@allyfish thanks for this.

could you explain the figures in the calculation here:

(9/60) x 4.2 x (45-38)

are those from the panel results? (9 and 60 I’m not seeing)

apologies if a dumb question, learning when I can

ignore seeing 9 in the results. Need to get my iPad out lol instead of trying to read this on an iPhone

Hi @crimson, sure. The formula is the sensible heat equation, to work out how much heat energy in kJ/s is being added.

9 is your flow rate as indicated in your flow setter valve photo in litres/min. Divide by 60 to get litres/second. For pure water this converts directly to a mass flow in kg/s.

The value of 4.2 is approximately the specific heat of pure water in kJ/kG per deg C.

45-38 is the difference [delta] in flow and return temperatures in degC

Multiply it all together: kg/s x KJ/kg degC x degC and you end up with kJ/s or kW heat output.

Posted by: @allyfishI think the Grant Mag One pressure loss flow curve in the data sheet is complete bollox. 3bar pressure loss is 30.6m head. That can't be right, the pump for the 13kW Aerona can only supply 12m head max (1.2bar). I have the same Mag one filter in the 10kW Aerona, and it has no issue with flow rate at 22l/min and that's on pump speed 1 (about 3.5m head) on the internal ASHP setting! I think Grant has stated bar instead of m head, as their values seem a factor of 10 out from what would be expected. Grant make quite a lot of mistakes in their literature... If you compare with Adey Magnaclean, or other commercial magnetic filters, pressure loss in correctly sized magnetic filters isn't that high.

yes 3 bar is 30m but we're not up that high (Fortunately!)

13kw at DT5 = 37l/min. 2200 kh/g (annoying grant units). Mag one graphs, about 0.8 bar = 8m head.

22l/min = 1320 kg/h. Mag One needs about 0.3 bar, 3m head for that. you pump probably ok with that if the rest of the pipework is clean.

10kw at DT5 needs 28l/min so I guess you must be running about DT6.5? 28l/min would take about 4m of head with this filter. So if there is a big pump dedicated driving only the primary through an LLH you probably get away with it.

My 1 1/4" spirotech spirotrap filter needs 1kpa which is 0.1m of head. Basically negligible to the pump. It is an order of magnitude better than the grant one. Trust me, there are significant differences between brands if you check their details. I don't think Adey is particularly good either. Caleffi was the other good one, remembering back to when I did the research. This is part of what I went through hours learning from all heacols work in building my own single loop system. If you're going to include a filter in a single loop those it has to be super low resistance.

TLDR I still think @crimson 's mag-one is an issue.

My octopus signup link https://share.octopus.energy/ebony-deer-230

210m2 house, Samsung 16kw Gen6 ASHP Self installed: Single circulation loop , PWM modulating pump.

My public ASHP stats: https://heatpumpmonitor.org/system/view?id=45

11.9kWp of PV

41kWh of Battery storage (3x Powerwall 2)

2x BEVs

Posted by: @allyfish45-38 is the difference [delta] in flow and return temperatures in degC

if what you have told us about the pipework is correct, then the high number (code 9) should match the temperature on the pipe coming from the heat pump (top right) and the low number (code 0) match the temperature on the pipe going to the heat pump (bottom right). A little bit out is ok as they are cheapo thermometers - but these are more than 5C out, particularly concerning is that the return LLH pipe is HIGHER than the HP return. Thats a possible red flag.

Given those numbers don't match the temperatures in your LLH pictures, can you check both at the same time please?

as per previous mention and allyfish, please go to screwfix or similar and buy 1x length of 28mm pipe insulation , cut lengths with a stanley knife and fit over the temperature sensors, just adds a bit more accuracy.

My octopus signup link https://share.octopus.energy/ebony-deer-230

210m2 house, Samsung 16kw Gen6 ASHP Self installed: Single circulation loop , PWM modulating pump.

My public ASHP stats: https://heatpumpmonitor.org/system/view?id=45

11.9kWp of PV

41kWh of Battery storage (3x Powerwall 2)

2x BEVs

great stuff. The delta T between flow and return is high. The high delta T is symptomatic of your low primary flow.Posted by: @allyfish

except its not, according to the LLH temp probes. Something very odd is going on here.

My octopus signup link https://share.octopus.energy/ebony-deer-230

210m2 house, Samsung 16kw Gen6 ASHP Self installed: Single circulation loop , PWM modulating pump.

My public ASHP stats: https://heatpumpmonitor.org/system/view?id=45

11.9kWp of PV

41kWh of Battery storage (3x Powerwall 2)

2x BEVs

Thanks I’ll get some pipe insulation.

just rechecked - 00 - 38, probe 35. 09 - 45, probe 39.3.

if plumber comes tomorrow and replaces LLH I’ll report back on findings. Will ask to temp remove Mag one and tacosetter too to see if any changes.

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 1,181 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

That’s my pleasure, @andrewj. The only challenge now is...

By Majordennisbloodnok , 8 hours ago

-

RE: Electricity price predictions

@toodles @skd Then there is not going to be much from t...

By ChandyKris , 9 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

@batpred I reckon Andy might know a thing or 2 about...

By Bash , 9 hours ago

-

RE: What determines the SOC of a battery?

@batpred Ironically you didn't have anything good to...

By Bash , 10 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

Here’s a current graph showing a bit more info. The set...

By benson , 10 hours ago

-

RE: Setback savings - fact or fiction?

True there is a variation but importantly it's understa...

By RobS , 10 hours ago

-

Below is a better quality image. Does that contain all ...

By trebor12345 , 11 hours ago

-

Sorry to bounce your thread. To put to bed some concern...

By L8Again , 11 hours ago

-

@painter26 — they (the analogue gauges) are subtly diff...

By cathodeRay , 11 hours ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 15 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 18 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 20 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 1 day ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 1 day ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 2 days ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 2 days ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 2 days ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 2 days ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 2 days ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 2 days ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 2 days ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 2 days ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago