Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

Hi - I’m new here so please forgive any repetition of what might be deemed “dumb questions”….

So back story…. 5 yeas ago I decided to “go electric” and installed solar, battery, Eddi and a Zappi for my EV. I then decided I’d like to get off gas and took advantage of the green homes grant and found a local installer (now ceased trading) who installed a heat pump taking advantage of the then £5k grant and installed the system including a new DHW cylinder. At the time the grant could only make up 2/3 of the total cost and so he manged to come in at £7.5k so my grant was the maximum and cost was the minimum at £2.5k. However, this meant no upgrades to rads or pipework and an oversized heatpump. The house is a 1994 3 bed semi of about 90 sq metres with 22mm simple copper backbone running front to back with 10mm copper flow and return tails. The downstairs rads obviously have longer tails running in the cavity. The heat loss survey conducted at the time gave a figure of 3.2kWh which is all I have to go on and I assume it’s based on sound data?? As part of the installation they removed my old gravity system water in the loft but brought the 22mm plastic flow and return pipes up the outside not the house into the loft and through a large what I assume is a volumiser tank (don’t know how big this is) and then down into the old airing cupboard where the new 200l cylinder is located. I don’t believe there are any pumps. In terms of the heat pump the initial design specified a 6kW Grant Aerona3 but at the last minute he offered me an “upgrade” to a 10.5kW condenser - and being ill informed and stupid I thought “bigger must be better” and accepted.

So bottom line is that I’ve now got an oversized heat pump heating my house on undersized radiators through 10mm microbore. To make matters worse due to the Grant controller being not user friendly at all, I have no idea what the COP or flow temperatures/rates are - I even rang Grant yesterday to see if they would advise as to possible augmentations - but I got an unhelpful “ It was designed that way leave as is” he predicted that my flow temperature would be set at 55 degrees at minus 4 but didn’t offer to help me find out what the config actually was, probably thinking I would just tinker and muck things up!

In terms of performance and running costs, it hasn’t been too bad I’ve tried most strategies over the years from on/off to a 24/7 which is where I am now and over last couple of days have proved I can just about get the ambient temp to 19-20 with open loop but at a cost of about 1.5kWh per hour 30+ kWh/day that’s at about 4-5 degree outside daytime temp. I can get this down to nearer 20kWh by reducing temp to 18 degrees. Of course the larger unit will be cycling quite a bit which isn’t great!

So to my question… I am now conducting a whole home renovation and have the option of upgrading/downgrading elements of the system - however, I’m now retired and so funds are tight and so I need to be smart as to where I put my efforts (both mental and physical), time and of course money. I would love to start again but have to be realistic as to what’s doable. By the way I’ve tried engaging local heat pump installers but it’s a bit of a nightmare getting anyone to come out to look especially when there are so many variables and their busy with new installations - hence my thinking that I need more knowledge and skills and might well do some of the work myself only going to plumbers when it’s beyond my skill set!

My thoughts are that I look to remove the 10mm copper tails upstairs and upgrade radiators where needed and if funds allow install underfloor heating downstairs. I remove the pipe run through the loft altogether and run the primaries up to the first floor where the tank is located. In so doing I take out the volumiser and a load of unnecessary pipework and run a simple open loop system with no buffers or pumps. I would like to be able to monitor performance of the system and so I need some better monitoring kit and was thinking of installing open energy monitoring system? I guess that leaves the issue of an oversized heat pump - I’d welcome thoughts as to the consequences of running a larger heat pump assuming the other suggested changes are made? I’d ideally like to avoid cost of downgrading to a smaller heatpump but am prepared to contemplate this at some point. Also I’d welcome advice on the replacement of the 10mm tails - if I put in 15mm plastic with inserts will that be much better than 10mm copper or would I be better off with 22mm plastic or even maybe I should rip up the whole floor and install 15mm copper?

Sorry I know it’s a long post and I’m not expecting anyone to provide all the answers but thoughts on viability or specific points of what I’m thinking of doing would be helpful. My objective is to balance cost/effort vs long term gain (a tricky one I know) at 67 years old I maybe have 10-20 years ahead of me where I’d like a system that does what it’s meant to do (heat house/water) at a reasonable cost. The fact that I’ve got solar and a home battery means I can load shift and so costs can be managed and therefore it doesn’t have to be perfect. One option is just to leave “as is” with some new larger rads and maybe some work on insulation? Not a terrible idea maybe??

Thanks again for talking the time to read this very long post.

Firstly welcome to the forums and thank you for all the details. You are asking the right questions.

Lets start with the 10mm tails. With such a low loss its not at all impossible that 10mm tails are OK and its highly disruptive to change them. Two questions can help ferret this out

1. Are you warm enough?

2. What is the DT across the radiators (ie difference between flow to rads and return from rads, ideally measured at a selection of rads)?

if the answer to (1) is yes and the answer to (2) is 5C or less, then your tails are not causing a restriction. Even if DT is as much as 8C I wouldn't necessarily conclude that changing the tails is your most cost effective way to go. Larger pipework wont automatically reduce running costs, once DT is down to about 5C it really makes negligible difference, provided you are getting enough heat through).

Now we come to radiator sizing and heat pump capacity

Increasing the size of the radiators will mean you can operate at a lower flow temperature, which will reduce running costs, roughly by 3% for each degree you reduce it. You might easily get the FT down to 45C or even 40, which will make a big difference. Increasing rad size is also simple and involves relatively little disruption. Even I can do 2 in a day single-handedly and Im not a plumber!

Larger rads dont imply larger pipework BTW.

Swapping to a more modern, lower capacity heat pump will also probably reduce running costs, but its difficult to quantify.

Now system configuration

Firstly check if its a buffer with (usually 4 ports) or a volumiser with only 2 ports, either in the flow or return. A buffer will also have at least one water pump external to the heat pump which is another 'give away.

If its a volumiser its doing no harm and may well be necessary.

If its a buffer then it is probably increasing running costs by 10-15% or more

Note that some Grant heat pumps come with low loss headers, a sort of mini buffer.

Hope that gives you enough to do a bit more discovery on what you have. Without answers to the questions about the 10mm tails its difficult to be more prescriptive.

Now the main issue in my mind.

With such a low loss the savings to be made by upgrades (particularly if they also involve lots of disruption) may need to be carefully considered, as they may not pay back. Your biggest bang for the buck by far would be to stop running at a fixed 55C flow temperature (which is an absolutely terrible idea), and instead use weather compensation correctly adjusted for open loop running. This will also, almost certainly, improve comfort. Whatever Grant say there is a controller and it is supposed to be used. I would strongly recommend you get hold of a copy of the manual and also post here the exact model, as there are plenty of others who know Grant machines well. Anything you learn from tweaking now will help you with any future upgrade, whether or not you change the heat pump.

My personal approach, faced with this opportunity, would be:

1) Get to grips with the control of the Grant unit

and in parallel

2) Do the measurements/calcs on the rad tails

Depending on the answer to (2) I would then look, in decreasing order of priority at

3) rad upgrades

4) repiping buffer as volumiser

5) changing the unit

or

some or all of the above plus a more major (but still possibly selective) repiping if the answer to (2) was unfavourable

I hope that gives you something to start with and points you in the direction of a little more discovery. Please feel free to ask for more explanation and also more specific suggestions once the question about tails has been answered..

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

@jamespa thank you so much for such a wonderful thoughtful and articulate reply - I think I’ll need to read it several times to get my head around it!

One immediate question is - how do I measure flow and return either for the system or at a radiator level? What I did do yesterday, is put a wireless probe in the top of the main radiator in my living room to get an idea of flow rate - it’s showing c45 degrees which indicates a flow rate (right now) at outside temp of c4 degrees of maybe 50 or 55?

You also picked up on my ignorance around volumizers, buffer tanks, low loss headers - I have no idea what I have but I’ve just gone up into the loft and had a look and I think it’s in fact a two port Grant low loss header. I’ve attached a picture. Also a couple of others of loft pipework and tank install.

in terms of comfort, I can confirm that with my Hive TRV’s all set to 20 degrees (even with some undersized rads I am comfortable with indoor between 19-20 at outside between 0-4 degrees. As a data point on efficiency, to get that comfort my home today (since midnight) has used c20kWh in last 10 hours about 17 of that has I estimate been used by the heat pump. I would normally set to 18 with a corresponding lower electric usage. I do feel the heat pump is working too hard and as such is inefficient at 20 degrees.

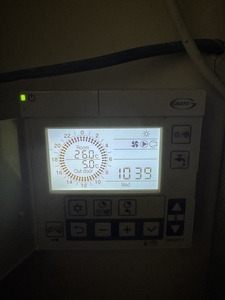

By the way I don’t know whether I have weather compensation on - I actually suspect I do as rad temps do seem to vary a lot but I’d need to know how to interrogate my Grant Controller CMR 2613?

Very good advice and I’ll certainly work through your suggestions and take stock.

Posted by: @uknickOne immediate question is - how do I measure flow and return either for the system or at a radiator level? What I did do yesterday, is put a wireless probe in the top of the main radiator in my living room to get an idea of flow rate - it’s showing c45 degrees which indicates a flow rate (right now) at outside temp of c4 degrees of maybe 50 or 55

Hi, this is just a quick reply to the above quote, I will look at pictures later today.

It's not the flow rate you need to measure its the difference between the flow and return temperatures (pipe coming into the radiator and pipe going out respectively). If you have a temperature sensor (many multimeters come with one) strap it to the pipe so it's in good contact, put some insulation over. Now, when it's cold outside, is a good time to do it.

As an alternative, not quite as good, tell us the sizes (width and height) and types 11, 21, 22? of your largest radiators, or better still all of them.

This helps assess whether going to all the hassle of upgrading the 10mm tails is necessary.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

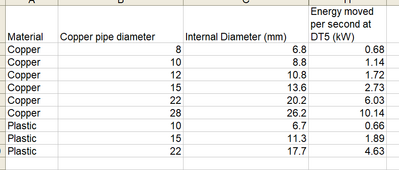

It gives the maximum power that can be put through different pipework. As you can see 15mm plastic is significantly higher than 10mm copper if needed. The other advantage of using plastic is that often bends can be eliminated with sweeping curves. The plastic inserts do narrow the pipe significantly so I use the Hep2O steel inserts instead.

House-2 bed partial stone bungalow, 5kW Samsung Gen 6 ASHP (Self install)

6.9 kWp of PV

5kWh DC coupled battery

Blog: https://thegreeningofrosecottage.weebly.com/

Heatpump Stats: http://heatpumpmonitor.org/system/view?id=60

@bontwoody that’s great thanks for that. Are the HEP20 inserts less restrictive therefore give better flow? I think plastic is feasible whereas copper would be a pain but if I don’t have to then I’ll probably leave as is! What would be really helpful is to understand flow rates and temps. I did remove an old bathroom towel rail recently and it did have quite a bit of black fluid and some metal residue which I assume comes from the inside of the pipes or rads?

@jamespa thanks again for the reply I’ll have a go at measuring the flow/return and difference. What would be good is to be able to install something onto each rad that measures temperature and maybe even flow - does such a thing exist?

also separate question is it better on heat pump system to have individual stats such as my Hive TRV’s or just to open all rads and rely on a single centrally located thermostat?

@uknick yes. The steel inserts are much thinner. Its usual to find black gunk in pipework thats been used for some time. I believe its mostly oxidation products.

I bolted my system onto existing 22mm copper combi boiler pipework and use 15mm plastic tails down to my radiators. As long as the pipework diameter exceeds the power output of the radiators at your flow temperature you should be fine.

Something I did to save money was change the biggest radiator that needed upgrading and then moved the old one down to the next room etc.

I take it your flow rate at the moment is fine for your size of heat pump?

House-2 bed partial stone bungalow, 5kW Samsung Gen 6 ASHP (Self install)

6.9 kWp of PV

5kWh DC coupled battery

Blog: https://thegreeningofrosecottage.weebly.com/

Heatpump Stats: http://heatpumpmonitor.org/system/view?id=60

- @bontwoody thanks for the reply - unfortunately I have no idea what my flow rates are?? My Grant system doesn’t allow me to see that? I’m considering installing an open energy monitoring system to allow visibility of power usage, flow rates and temps… how do you see your flow rates/temps?

Posted by: @uknick@jamespa thanks again for the reply I’ll have a go at measuring the flow/return and difference. What would be good is to be able to install something onto each rad that measures temperature and maybe even flow - does such a thing exist?

Not that you can buy economically. You can buy temperature sensors with displays for very little, but measuring flow is invasive so more complex.

Posted by: @uknickalso separate question is it better on heat pump system to have individual stats such as my Hive TRV’s or just to open all rads and rely on a single centrally located thermostat?

Its better to open all the rads and not have a thermostat at all!

Seriously, the best way to run a heat pump is to open all the individual stats, turn the the central thermostat to max, so it has no effect, then adjust the weather compensation curve until the house is at the right temperature, if necessary balancing the radiators by adjusting the LSVs (the valves opposite the TRVs) until rooms settle at the same temperature or with the desired temperature difference.

You can tweak this slightly by having a very small proportion of rooms on individual stats, but only do this if there is a good reason not just because you want the room at a different temperature, this adjustment is best made on the LSV.

You can also set stats in rooms that 'suffer' from solar gain a couple of of degrees above the target so they come into action when solar gain is high. You can do the same with the main stat if the house as a whole gets very variable solar gain, but its almost always better to use the temperature sensor in the heat pump controller itself.

Basically minimal or no external controls is the way to go.

Its probably worth saying at this point is that there is only really two rules for running a heat pump which are

a) get the flow temperature as low as possible, the most important one - everything else derives from this - running 24x7, keeping DT across radiators low, large radiators, eliminating buffers, running 24x7, and weather compensation, not using external controls are all ways to keep the flow temperature down.

b) The other which by comparison is really only a half rule is run for as long as possible (long cycles not short ones if the heat pump does cycle). This minimises waste heat, which in turn translates to keeping the flow temperature down (for the same energy delivered to the house) which is why I call it a half rule!

There are cases where these rules have to be bent a little (eg ToU tarrifs and grossly oversized pumps in houses with a high thermal mass due usually to UFH), but starting from those, particularly the first, is always a good place to start.

Ive now had a look at the pictures, the big tank is the DHW tank, the small tank is a 2 port volumiser, I cant see a LLH anywhere not can I see a secondary water pump (perhaps you could check if there is on anywhere). If so then you got lucky, its rare for older Grant installations not to have a buffer or LLH. It really would be worth checking around to be certain its not hiding anywhere.

Im assuming this is the R32 pump which is actually made by Chofu, not the later R290. Perhaps you could confirm so we can find out what monitoring capabilities it has. Pretty certain it will know flow rate, the question is likely to be how do you get it to display the value. Its highly unlikely its not there somewhere!

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

@uknick unless you are having issues with low flow rate errors then things are likely fine. I use OEM and its great but a bit of an investment.

What James says is spot on but some monitoting will definitely help set things up well

House-2 bed partial stone bungalow, 5kW Samsung Gen 6 ASHP (Self install)

6.9 kWp of PV

5kWh DC coupled battery

Blog: https://thegreeningofrosecottage.weebly.com/

Heatpump Stats: http://heatpumpmonitor.org/system/view?id=60

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 912 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

Actually, it’s better for wooden furniture – or at leas...

By Majordennisbloodnok , 6 hours ago

-

This is absolutely standard for any sealed pressurised ...

By JamesPa , 8 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 8 hours ago

-

RE: What determines the SOC of a battery?

@batpred Your BMS parameters will be the same as m...

By Bash , 9 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 10 hours ago

-

RE: Setback savings - fact or fiction?

I also need to correct something I said by mistake earl...

By cathodeRay , 10 hours ago

-

RE: Electricity price predictions

@judith Thanks for sharing, and nice to see how the ...

By Batpred , 10 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@tasos the OAT is incorporated into the control logic. ...

By benson , 11 hours ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 13 hours ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 13 hours ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 13 hours ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 15 hours ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 15 hours ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 17 hours ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 18 hours ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 18 hours ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 1 day ago

-

RE: DIY solar upgrade - Considering adding more panels

I know this is a bit old, but it made me wonder what co...

By Batpred , 1 day ago

-

RE: New Vaillant aroTherm Plus in black - When will it come to the UK?

@majordennisbloodnok Daikin, take note! (In fact, I hav...

By Toodles , 2 days ago

-

RE: Midea ASHP – how to set weather compensation

@mk4 — good work! First, I agree, no evidence of cycl...

By cathodeRay , 2 days ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

I don't know about Solis inverters. It isn't a featur...

By Transparent , 2 days ago

-

Daikin Altherma 3 H HT - Freeze Prevention Threshold

Hi. We have an Altherma 3 HT (18kW I think) which, now ...

By RICHARDF5033 , 2 days ago

-

RE: Passiv Smart Thermostat - Help & Forum Support

@petch We are not yet compatible with the R290 from Gra...

By Will H , 2 days ago