Ecodan wont heat with mild outside temps

Hi everyone!

Since Ive been reading this forum religiously and it has helped me solve a few issues with my setup already, I'm at the point where I like to ask for advice with a problem i cant seem to solve. I'll try to be super specific since I have loads of data so apologies if its too much!

-----------------------------------------

My setup:

New build w/ 200mm loft insulation, insulated cavity walls, triple glazing, air-tightness tape on windows/door frames (i think thats what its called)

Ecodan R32 8.5kW

FTC6

2-zone valve on/off

No buffer or low loss header

2x Mitsubishi wireless controllers (set way higher than desired temp while testing, no interference wanted)

210m2 bungalow w/ UFH screed (i think 16mm OD pipes)

Compensation curve: -2° outside: 34° flow, 14° outside: 20° flow

Recorded COP: -2° outside: 3.27, 10° outside: 5.30, 12° outside: 3.10

-----------------------------------------

Basically, when it was installed 8 months ago there were a number of mistakes that the 'professional' installer made. I read this forum religiously and the Mitsi datasheets to teach myself and I resolved those things. However I think i might be at an impass now

A couple of weeks ago we had a cold snap with a low of -2°. I found the optimal flow was 34° for room temp of 20° so I set my comp curve as above. When it warmed to 10° outside, I found that 24° flow maintained my target temperature. Knowing that 20° is the coolest flow that the ecodan can do so I estimated that 20° would be roughly suitable for when it is 14° outside

When it started to fluctuate between 12-13° outside the unit went into standby and never came back on even after the temps dropped a bit. It still comes on when needed for DHW

I always noticed that my delta was very small (usually around 2° after the temps had stabilised and was just maintaining) but i have seen it fluctuate between 0.5 & 5° (thought that is usually around the time that the DHW kicks on/off)

Also, my low flow rate despite my pump speed set to max in the FTC6. My 2 manifolds with a combined 20 circuits would barely reach 1L/m. If i recall correctly, checking the actual flow rate on the controller said 21L/m. That adds up but what doesnt make sense to me is that with such a low flow rate, why is my delta also so low?..

-----------------------------------------

My working theory as to why it is going into standby and not coming back on might be one or a mixture of several of things:

1. The low delta, never getting much chance to increase due to the DHW coming on regularly

2. Low pump speed/flow rate, though having it faster would only serve to decrease the delta if im not misunderstood

3. The well insulated build not losing much heat (not even 1° per day while the heating wasnt coming on)

4. The installer speccing an 8.5kW unit where maybe a 5 or 6 would have done. I heard but couldnt verify that heat pumps can typically only modulate down to about 30% of their rated capacity. Maybe my house takes less than that to maintain?

Note 1: While it had been -2° outside and the 34° flow was nice and cosy, I had the FTC6 set to full-on quiet mode which apparently cuts the max compressor power to 25%. Heating that day used 26kW according to MelCloud with a COP of 3.27

Note 2: Just today, the rooms dipped to 18° and it still hadnt started heating. I set it fixed flow temp of 30° and boom, started right up

5. I read on this forum that UFH pipe should be 22mm so maybe mine are too small?

-----------------------------------------

If you read through all of that, thank you and im sorry!

I would love some pointers though as I went from zero knowledge to (maybe) a little more than the basic user but Im interested to keep learning, especially since the installer doesnt seem to care very much

Thanks in advance and Ill try to post pics shortly

Posted by: @sryan2525Hi everyone!

Since Ive been reading this forum religiously and it has helped me solve a few issues with my setup already, I'm at the point where I like to ask for advice with a problem i cant seem to solve. I'll try to be super specific since I have loads of data so apologies if its too much!

-----------------------------------------

My setup:

New build w/ 200mm loft insulation, insulated cavity walls, triple glazing, air-tightness tape on windows/door frames (i think thats what its called)

Ecodan R32 8.5kW

FTC6

2-zone valve on/off

No buffer or low loss header

2x Mitsubishi wireless controllers (set way higher than desired temp while testing, no interference wanted)

210m2 bungalow w/ UFH screed (i think 16mm OD pipes)

Compensation curve: -2° outside: 34° flow, 14° outside: 20° flow

Recorded COP: -2° outside: 3.27, 10° outside: 5.30, 12° outside: 3.10

-----------------------------------------

Basically, when it was installed 8 months ago there were a number of mistakes that the 'professional' installer made. I read this forum religiously and the Mitsi datasheets to teach myself and I resolved those things. However I think i might be at an impass now

A couple of weeks ago we had a cold snap with a low of -2°. I found the optimal flow was 34° for room temp of 20° so I set my comp curve as above. When it warmed to 10° outside, I found that 24° flow maintained my target temperature. Knowing that 20° is the coolest flow that the ecodan can do so I estimated that 20° would be roughly suitable for when it is 14° outside

When it started to fluctuate between 12-13° outside the unit went into standby and never came back on even after the temps dropped a bit. It still comes on when needed for DHW

I always noticed that my delta was very small (usually around 2° after the temps had stabilised and was just maintaining) but i have seen it fluctuate between 0.5 & 5° (thought that is usually around the time that the DHW kicks on/off)

Also, my low flow rate despite my pump speed set to max in the FTC6. My 2 manifolds with a combined 20 circuits would barely reach 1L/m. If i recall correctly, checking the actual flow rate on the controller said 21L/m. That adds up but what doesnt make sense to me is that with such a low flow rate, why is my delta also so low?..

-----------------------------------------

My working theory as to why it is going into standby and not coming back on might be one or a mixture of several of things:

1. The low delta, never getting much chance to increase due to the DHW coming on regularly

2. Low pump speed/flow rate, though having it faster would only serve to decrease the delta if im not misunderstood

3. The well insulated build not losing much heat (not even 1° per day while the heating wasnt coming on)

4. The installer speccing an 8.5kW unit where maybe a 5 or 6 would have done. I heard but couldnt verify that heat pumps can typically only modulate down to about 30% of their rated capacity. Maybe my house takes less than that to maintain?

Note 1: While it had been -2° outside and the 34° flow was nice and cosy, I had the FTC6 set to full-on quiet mode which apparently cuts the max compressor power to 25%. Heating that day used 26kW according to MelCloud with a COP of 3.27

Note 2: Just today, the rooms dipped to 18° and it still hadnt started heating. I set it fixed flow temp of 30° and boom, started right up

5. I read on this forum that UFH pipe should be 22mm so maybe mine are too small?

-----------------------------------------

If you read through all of that, thank you and im sorry!

I would love some pointers though as I went from zero knowledge to (maybe) a little more than the basic user but Im interested to keep learning, especially since the installer doesnt seem to care very much

Thanks in advance and Ill try to post pics shortly

I would suggest that you may need to increase the WC curve setting at the warmer Outside Air Temperature (OAT) end. Maybe try 25C LWT @ 15C OAT.

At mild temperatures, in a well insulated home, you should expect some degree of cycling, so to limit any increase in Indoor Air Temperature (IAT) you should probably set your room temperature controls to 1C above the desired temperature.

I don't think that a flowrate of 21 lpm is particularly low for a 8.5kW Ecodan, but check the specified minimum value as detailed in the manual. Lowering the flowrate should increase the DT, but having a specified DT I don't think is too critical, it is more important to transfer the correct quantity of thermal energy to the heat emitters.

Have you considered trying Auto Adaptation mode of operation?

Hey, thats great Ill try that now. I was hoping it would be able to manage running at 20C for the sake of efficiency but this is better than it not running at all

The installer had it in auto adapt and when i went to mitsi support about a separate issue i had they looked at my settings and description of the setup, said that its the wrong mode for me and that auto adaption tends to run better with radiators due to the algorithym expects quicker temp changes. I would like to go back and compare energy usage once i get the WC working though

Hi,

Your flow rate of 21L/min is fine, I would turn down the pump to 4 and recheck the flow rate, that will help with dT, you could probably drop it to 3 the Ecodan will complain if the minimum flow is too low.

Do you have all your circuits open at the same time with 20 circuits you need them all to be open to create enough water volume to avoid rapid cycling as you have no LLH or buffer to help with this.

Auto adapt is for radiators it doesn't work well with UFH as its too slow to react to temp changes you want WC.

As Derek said your flow temp is too low, I would expect the Ecodan isn't running as the water temp is set too low and regardless of the stats calling for heat if the water temp doesn't get below 20C its not going to turn on, it will just sit there in standby which is confirmed by your test in setting it to a fixed flow of 30C.

Let us know how you get on

What’s your UFH construction?

This is a suggestion based on what appears to be a restriction of heat transfer capacity of the UFH fabric, particularly at low flow temperature and at low HP output.

Do you have an insulated former, base layer carrying the pipework under the screed? How thick is the screed. Also plastic pipes are not most efficient at heat transfer. So if you also have insulation up against the pipes below the screed this will further compromise heat transfer esp at low flow rates.

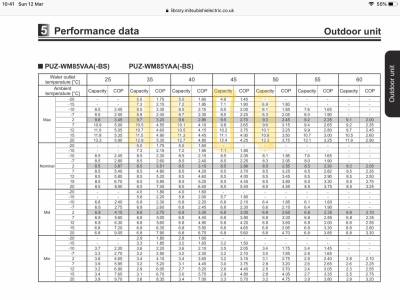

if you’re operating at 20c flow the data sheet on minimum output doesn’t even go down that low. I think you’ll find the ecodan8.5 will need minimum output of around 3.6 kWh to prevent shutting down.

see Minimum Operating Output at 25c. This is the lowest column of outputs available. So 20c is somewhat unknown but is also variable up and down depending on ambient temperature and possibly needs a higher minimum output.

possibly try different flow temperatures?

if you are able to get it to operate at higher flow temperature but not able at 20c then it would suggest the higher flow is allowing a manageable heat transfer into the screed slab to allow the HP to continue operating.

did you say your flow rate through the UFH was quite low? Not sure, but is this adjustable in any way?

your primary flow rate at 21lpm is ok if that is being measured in the correct place.

hope this helps

If desired room tmp is 20, i doubt 20degflow would achieve that, surley some losses on transfer and to get up through the slab.

Per your guys' suggestions Ive since had the WC curve set at 25C minimum, turned the pump speed down from 5 to 3 and it seems to be staying on with a more reasonable delta 🍻

Posted by: @newhouse87If desired room tmp is 20, i doubt 20degflow would achieve that,

I had thought that too, like surely theres no way it could be that efficient. Everyone i know with similar setups have to run way higher in the 35-45 range so I had little to compare against but might as well push it to see what it can do

Posted by: @garyDo you have all your circuits open at the same time with 20 circuits

I have all but one open as that room gets pretty spicy compared to others

Posted by: @sunandairDo you have an insulated former, base layer carrying the pipework under the screed? How thick is the screed.

If i recall correctly I was told its 50mm screed but Im not actually confident that there is any insulation under the pipework or any many other aspects of it. I know someone here has a picture before the screed went down I should really check that

I never came across that chart in my searching either, that explains a lot actually

Posted by: @derek-mAt mild temperatures, in a well insulated home, you should expect some degree of cycling

I meant to ask about cycling too, Ive had some tell me little to no cycling is best and others say you want it cycling 2 to 3 times an hour..

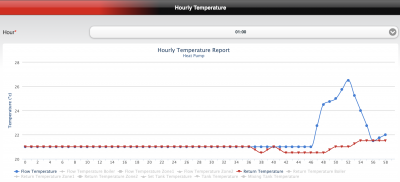

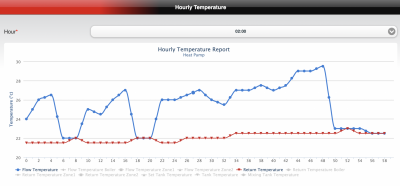

The Cycle Interval setting on the FTC had been set by the installer to 10mins with the default being 60mins. I had previously seen it cycling in the Hourly Temperature report up to 6 times each hour so I changed it back to 60 alongside the other changes above. Seems like the LWT is warmer than RWT for about an hour then drops to match it for the next hour. There does seem to be some cycling behaviour still present in the time where it should be staying on. I feel like im probably misinterpreting this though

Posted by: @sryan2525I feel like im probably misinterpreting this though

Its as if it reaches the target LWT, overshoots and shuts off for a bit, rinse and repeat. Much better than before though

-

Mitsubishi Ecodan 11kw Defrosting Issue.

2 weeks ago

-

Have Consumers Been Lied to About the Efficiency of Heat Pumps Made in China?

2 months ago

-

Ecodan consuming 100kwh per day in new build!!!

2 months ago

-

Help with understanding my Mitsubishi Ecodan air source heat pump

5 months ago

-

Efficiency Concerns on newly installed Mitsubishi Ecodan 8.5kW

5 months ago

Currently viewing this topic 2 guests.

- 26 Forums

- 2,177 Topics

- 47.9 K Posts

- 41 Online

- 5,748 Members

Podcast Picks

Latest Posts

-

@judith Applied for replacement from installer. If...

By cliffhanger , 38 minutes ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

The real answer is trial and error, because there are a...

By cathodeRay , 2 hours ago

-

@drei Id be wary of the reference in quote 1 to reattac...

By benson , 16 hours ago

-

RE: Renewable Heating Hub WhatsApp Channel

I clicked on the link and have WhatsApp on the computer...

By dgclimatecontrol , 17 hours ago

-

RE: Repiping and Reconfiguring our Heat Pump System Including Removing the Buffer Tank

@editor yeah i looked at those but id need 12+ for my p...

By AdamK , 17 hours ago

-

RE: Say hello and introduce yourself

Thanks for the warm welcome @editor and can't wait to b...

By Pirate Rich , 19 hours ago

-

RE: Powerwall 3 or Myenergi or something else?

Let's also bear in mind that Fogstar supply more than o...

By Majordennisbloodnok , 22 hours ago

-

RE: How to choose Towel Rails for an ASHP

@judith Yes I agree. They are extremely expensive. ...

By GrahamF , 1 day ago

-

RE: Which temperature sensor for a Steibel buffer and Ecodan?

@downfield I have never added a buffer sensor as we nev...

By ASHP-BOBBA , 1 day ago

-

Riello NXHM Monobloc Air Source Heat Pump

Hi, does anyone have any feedback on Riello NXHM Monobl...

By dgarvey , 1 day ago

-

RE: How to Zone with a Single Room with UFH

We have exactly what you describe, one utility room wit...

By Judith , 2 days ago

-

RE: Who's your electricity provider and what's your tariff?

@agentgeorge Come the Ist of October, the Cosy cheapest...

By Toodles , 2 days ago

-

RE: Boxt Heat Pump Installation Experience

@ashfp Mine does have a buffer tank. That was my experi...

By Andrew J H , 2 days ago

-

RE: Help me keep the faith with my air source heat pump installation

I'm sure you are right, I was just trying to understand...

By JamesPa , 3 days ago

-

RE: Preparing for 2nd winter in new build house.

Yuch! So that's basically just an on/off control. I...

By Transparent , 4 days ago

-

Good day everyone. I'm new here and have a few question...

By Edin67 , 4 days ago

-

RE: MCS certificate SCOP vs real-world performance

That may be contributing to lower than expected SCOP. ...

By JamesPa , 4 days ago

-

-

RE: Mitsu PAR-WT60R Wireless Controller - options

How it does it's job is something of a mystery although...

By Abernyte , 5 days ago