[Solved] Ecodan. How to run this efficiently with zero understanding.

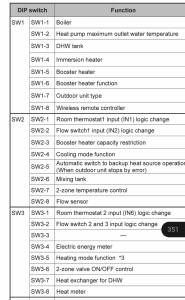

@mjr no, you are right. Dip switch 1 has 8 switches and 7 & 8 only are on for me.

I still don't understand how 192=11000000 though but not to worry. At least your theory is correct! Although don't know what the readout problem with my dip switch 5 is.

As humans we have been taught to count using the decimal (denary) systems as shown below.

(100's) (10's) (1's)

1 9 2

For operational reasons, computers count, and store data, using the binary system as shown below.

(128's) (64's) (32's) (16's) (8's) (4's) (2's) (1's)

1 1 0 0 0 0 0 0

So 192 in decimal is actually stored as 11000000 in binary in a computer.

Since 8 bits equals 1 byte, it is possible for a computer to store the position of 8 switches using just 1 byte of memory, rather than using 1 byte for each switch. Human's are not too happy counting in binary, so on the computer display a number would normally been shown in decimal.

In your particular screen display I am surprised that the developer did not lay it out differently. Had I been creating the display I would have done it as shown below.

Posn

DipSwitch (8) (7) (6) (5) (4) (3) (2) (1)

1 On On Off Off Off Off Off Off

2 On Off Off Off Off Off Off Off

3 Off Off Off On Off Off Off Off

4 Off Off Off Off Off Off Off Off

5 Off Off Off Off Off Off Off Off

6 Off Off Off Off Off Off Off Off

Simples. 😎

Posted by: @derek-mAccording to the wiring diagram on page B35 of the large manual, the control signal for the main water pump should be connected to CNPWM, which is located in the upper right-hand section of the circuit board.

What is this large manual of which you speak? I've looked at the Installation Manuals for the FTC5 and FTC6. Both have circuit board illustrations that feature the CNPWM connector but no description of its use. It has three terminals which suggest it might be suitable for pump control. I'm looking with colleagues at a FTC5 installation with a Grundfoss pump which is PWM capable but doesn't currently have a PWM cable connected. The system provides underfloor heating in a museum building and we're keen to reduce our running bills.

What is this large manual of which you speak? I've looked at the Installation Manuals for the FTC5 and FTC6. Both have circuit board illustrations that feature the CNPWM connector but no description of its use. It has three terminals which suggest it might be suitable for pump control. I'm looking with colleagues at a FTC5 installation with a Grundfoss pump which is PWM capable but doesn't currently have a PWM cable connected. The system provides underfloor heating in a museum building and we're keen to reduce our running bills.

The large manual is the 'AIR TO WATER HEAT PUMP SYSTEMS' Data Book, which unfortunately I can no longer post a copy on the forum. It is now deemed too large.

To help reduce running bills it would probably be useful to improve insulation if at all possible. The heat pup should be operated in weather compensation mode, with the lowest water temperature that meets the heat loss.

Posted by: @derek-mThe large manual is the 'AIR TO WATER HEAT PUMP SYSTEMS' Data Book, which unfortunately I can no longer post a copy on the forum. It is now deemed too large.

To help reduce running bills it would probably be useful to improve insulation if at all possible. The heat pup should be operated in weather compensation mode, with the lowest water temperature that meets the heat loss.

Looks like this may be it: Air to Water Heat Pump Systems Databook Vol. 5.3 R32

Download it as a PDF if you want to be able to search it.

The building is a recent refurbishment of an industrial unit. Almost everything replaced apart from the steel frame and (substantial) concrete floor. Good insulation and underfloor heating. The heat pump seemed to be using quite a lot of electricity during the summer when it should have almost nothing to do (It doesn't supply DHW).

Pump appears to be a Grundfoss UPS3. Mitsubishi provide minimal information about PWM. Would it just work if a cable was connected from the pump to CNPWM or is there more configuration required?

@john-connett PWM control has been discussed elsewhere and I think the opinion is that it is not functional in the Mitsubishi system. Perhaps the board was designed with it mind, possibly it is just residual having been adapted from another product, but either way unless the software is written to use it, it won't function. The FTC settings have an option to set 5 different pump speeds but nothing referring to PWM.

If you are taking energy use from the readings on the FTC controller, then just don't! There seems to be a minimum recorded level of energy consumption even when less is being used, this is particularly noticeable over summer when no heating is being done. This can amount to a reading of 90kWh per month even though only around 15kWh has actually been drawn.

Mitsubishi EcoDan 8.5 kW ASHP - radiators on a single loop

210l Mitsubishi solar tank

Solar thermal

3.94kW of PV

Posted by: @john-connettPosted by: @derek-mThe large manual is the 'AIR TO WATER HEAT PUMP SYSTEMS' Data Book, which unfortunately I can no longer post a copy on the forum. It is now deemed too large.

To help reduce running bills it would probably be useful to improve insulation if at all possible. The heat pup should be operated in weather compensation mode, with the lowest water temperature that meets the heat loss.

Looks like this may be it: Air to Water Heat Pump Systems Databook Vol. 5.3 R32

Download it as a PDF if you want to be able to search it.

The building is a recent refurbishment of an industrial unit. Almost everything replaced apart from the steel frame and (substantial) concrete floor. Good insulation and underfloor heating. The heat pump seemed to be using quite a lot of electricity during the summer when it should have almost nothing to do (It doesn't supply DHW).

Pump appears to be a Grundfoss UPS3. Mitsubishi provide minimal information about PWM. Would it just work if a cable was connected from the pump to CNPWM or is there more configuration required?

Don't quote me on this, but I assume that the system may work in the following manner:-

The 240v ac supply is provided to the water pump from TBO.1 terminals 1 & 2, or from connector CNP1. This will start and stop the water pump as required.

If the installed water pump is capable of PWM control, a second control cable would be connected to connector CNPWM to vary the water pump speed. It may be that the pump speed is not continually variable, but can be set to one of five speed settings.

Don't forget that there will probably be water pumps associated with the UFH system, which may entail balancing flow rates.

The attached youtube video clearly shows that the pump speed can be varied, provided that the correct equipment has been installed.

As far as energy usage is concerned, how are you operating your system? Are you operating the heat pump in weather compensation mode? How are you controlling the UFH?

Posted by: @harriupThe FTC settings have an option to set 5 different pump speeds but nothing referring to PWM.

PWM is how the pump speed step(1-5) is controlled from the controller.

Version 5.8

https://library.mitsubishielectric.co.uk/pdf/book/Ecodan_ATW_Databook_R32_Vol5_5

Posted by: @fazelPosted by: @harriupThe FTC settings have an option to set 5 different pump speeds but nothing referring to PWM.

PWM is how the pump speed step(1-5) is controlled from the controller.

The Grundfoss UPS3 is a smart pump with a number of control modes, including three fixed speeds, proportional pressure and underfloor mode. PWM makes some sense with the fixed speed modes but, maybe, not with the others. I wonder if the pump is smart enough to ignore the PWM signal when it is working to its own priority to maintain proportional pressure (for radiators without an automatic bypass) or constant pressure (for underfloor mode)? I don't know which mode the museum's UPS3 is using, the underfloor mode might be the best match. Perhaps the UPS3 is smarter than the FTC5?

The Grundfoss ALPHA3 is even smarter and can be programmed using Bluetooth from an app on a mobile phone.

Posted by: @john-connettPosted by: @fazelPosted by: @harriupThe FTC settings have an option to set 5 different pump speeds but nothing referring to PWM.

PWM is how the pump speed step(1-5) is controlled from the controller.

The Grundfoss UPS3 is a smart pump with a number of control modes, including three fixed speeds, proportional pressure and underfloor mode. PWM makes some sense with the fixed speed modes but, maybe, not with the others. I wonder if the pump is smart enough to ignore the PWM signal when it is working to its own priority to maintain proportional pressure (for radiators without an automatic bypass) or constant pressure (for underfloor mode)? I don't know which mode the museum's UPS3 is using, the underfloor mode might be the best match. Perhaps the UPS3 is smarter than the FTC5?

Oops! Wrong pump. I have been informed that we have Grundfoss UPM3 HYBRID 25-70 180 ACA pumps. Sorry for the confusion. According to UPM3 Installation and operating instructions, page 13, the UPM3 HYBRID offers a choice of 19 control modes, including three constant pressure modes. Interesting that This item is no longer in production! We are sorry, but we did not find a replacement in our online catalogue.

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 291 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

@majordennisbloodnok I’m glad I posted this. There see...

By AndrewJ , 9 minutes ago

-

RE: Electricity price predictions

i only know about Intelligent Octopus Go ToU, where acc...

By SKD , 50 minutes ago

-

RE: What determines the SOC of a battery?

@batpred I didn't write the Seplos BMS software, I a...

By Bash , 1 hour ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@tasos and @cathoderay thanks. I have some history grap...

By benson , 2 hours ago

-

I am having my existing heat pump changed to a Vaillant...

By trebor12345 , 2 hours ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 3 hours ago

-

RE: Setback savings - fact or fiction?

@cathoderay The input power is largely determined by...

By RobS , 4 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

Just to wrap this up here for future readers: The S...

By Batpred , 6 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 6 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 7 hours ago

-

@painter26 — as @jamespa says, it's for filling and re-...

By cathodeRay , 11 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 22 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 24 hours ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 1 day ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 1 day ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 1 day ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago

-

RE: DIY solar upgrade - Considering adding more panels

I know this is a bit old, but it made me wonder what co...

By Batpred , 2 days ago