ASHP choice help - 55C flow temperature required

Hello all. We live in a large Victorian house in North London. I am looking to get off gas and stabilise our energy costs more generally. ASHPs seem the best option. I am about to put in 10MW of solar PV (expected annual yield 7MW). There is a large main space, double-height, running the full length of the house. This was thermally upgraded 10 years ago, and fitted with UFH under an insulated floating engineered wood floor. The emitter value of the floor is on the low side, and it was specified at 55 degrees (although the flow rate indicates a speed of around 0.5 m/s). Heat loss for the room is probably 7kW and -2 degrees ambient, and the UFH at 55 degrees produces around 6kW. There’s also a wood burning stove on the mezzanine living room. We tend only to heat the room to 18 degrees, and burn some wood in the evenings to keep it warm in the living room.

The rest of the house is in practice heated to a very modest degree, but the total heat loss is 43kW. Most of the rooms have large cast iron radiators. We have some towel rails.

I have two questions that I would really appreciate help with. First, the 55 degree specification is quite important. If we go much lower than that the emitter value of the UFH drops significantly, so it seems critical to identify the ASHP with the best COP at this flow temperature, for various ambient temperatures. I have found this information very hard to come by. Samsung give excellent technical specs, but most of the rest seem content only to offer broad SCOPs, or figures which don’t take account of the defrosting cycle. At 55 degrees flow, the 14kW Samsung EHS Mono HT has an integrated COP of 2.16, 2.45 and 3.35 for ambient -2, 2 and 7 respectively. I found those figures are a bit disappointing, but perhaps I’ve just got used to reading overblown sales pitch. Are there any ASHPs which do materially better than this?

The second question relates to DHW. Do I upsize an external ASHP to heat up a cylinder, or do I use a dedicated internal heat pump cylinder? There is an uninsulated loft on the top floor which will rarely get colder than, say, 14 degrees. I could put something like the Vaillant Isostor in there. It would take a bit of heat from the building, but produce 270L of 50 degree water for around 2.2kWh per day. My instinct is that that will be more economical than using an external heat pump working at ambient temps, but I’ve struggled to find figures.

Depending on the best DWH solution it might be best to get a pair of smaller pumps, one attached only to the UFH, the other doing DHW and the radiators.

Any thoughts regarding the above would be hugely appreciated. I am in awe of the rigour and expertise with which issues like these have been discussed on these forums.

Stiebel Eltron WPLA07 7kW ASHP. 26 x 400W PV. 10kW Sunsynk 3-phase inverter. 6 x 4.8kWh Pylontech US5000C batteries.

If possible, I would suggest that you start by improving the level of insulation, since better energy efficiency will reap increased benefits long into the future.

@derek-m There may be some improvements that can be done in future in the bedrooms, but the main space already has triple-glazing, wall insulation etc.

Stiebel Eltron WPLA07 7kW ASHP. 26 x 400W PV. 10kW Sunsynk 3-phase inverter. 6 x 4.8kWh Pylontech US5000C batteries.

Posted by: @wintergreen@derek-m There may be some improvements that can be done in future in the bedrooms, but the main space already has triple-glazing, wall insulation etc.

I would suggest that you carry out room by room heat loss calculations, since so many other factors will be dependent upon the results.

I do have heat loss calculations for all the rooms, but while they may inform the required heat pump capacity, the point remains that I will need a device that can output 55 degrees at a market-leading COP. Hence the first question.

Stiebel Eltron WPLA07 7kW ASHP. 26 x 400W PV. 10kW Sunsynk 3-phase inverter. 6 x 4.8kWh Pylontech US5000C batteries.

@wintergreen, at a flow temperature of 55C, you're edging towards the realm of HT heat pumps, and COPs tend to suffer as a consequence. You may want to look at some of Daikin's models, as they have a reputable line of HT heat pumps. Having said that, most reputable heat engineers and heat pump installers, will still be adamant that a 'conventional' ASHP, designed and installed correctly, will get the job done. Why does the "emitter value of the UFH drops significantly?" – what are you basing this on?

Based on your description of your property and your daily hot water requirements, it seems like using a dedicated internal heat pump cylinder such as the Vaillant Isostor could be a more economical option.

Get a copy of The Ultimate Guide to Heat Pumps

Subscribe and follow our YouTube channel!

Posted by: @wintergreenI am about to put in 10MW of solar PV (expected annual yield 7MW).

Hmmm. Do you have the figure for the max output of the solar panels, as opposed to the annual accumulation?

By my quick reckoning, this sounds like your roof is going to have 27kW of PV panels on it.

That's very high

The maximum permitted export to the Distribution Grid is 16A (per phase), which equates to 3.68kW.

So if this PV installation is to use the common grid-tied 'string' inverters, then you'd expect to require a 3-phase connection.

Alternatively, a better option is to not export anything, but store it instead.

In that case we need to be discussing storage batteries... which aren't (yet) on your shopping list above.

I've posted a brief overview of the two main approaches to battery storage from PV panels over on the Hello topic.

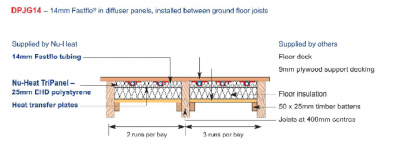

Posted by: @wintergreenfitted with UFH under an insulated floating engineered wood floor. The emitter value of the floor is on the low side, and it was specified at 55 degrees

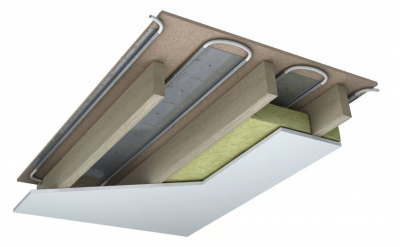

Ouch! I've used three different types of engineered wooden floor with UFH in my house.

To avoid the boards warping and the tongue & groove joints separating, the surface temperature shouldn't exceed 25°C.

That means the aluminium heat-spreader plates shouldn't be receiving water higher than 45°C.

This photo shows construction detail of those plates in position and the PEX pipe being clipped into place.

Is this how your floor was installed?

As you'll notice, 45°C is a very good match for the output from a heat-pump.

You shouldn't require 55°C 😲

Neither of the above points fits within the title of this topic.

So if we need to discuss these further, we'll move these elements to categories where others will find them.

Save energy... recycle electrons!

Right, on the PV front, we anticipate 10.1kW of panels, zero shading, largely south-facing. I have confirmed the yield calculations from a separate source, so they look ok to me. I intend to install around 30kWh of batteries alongside that. We're on a 3 phase supply.

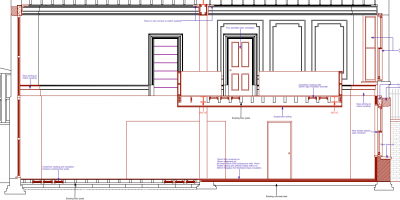

As for the design of the UFH, the only construction detail I have is shown below. Apologies for the quality.

Short of digging up the floor, we're stuck with the 55 degrees. It may well be unavoidable anyway, because it's a massive space:

It's an amazing room, but it's probably an example of architects not paying enough attention to heating design. In any event, it seems clear that the performance of an ASHP at 55 degrees is a critical constraint for getting rid of the gas boiler (massively overspecced at 46kW!).

Stiebel Eltron WPLA07 7kW ASHP. 26 x 400W PV. 10kW Sunsynk 3-phase inverter. 6 x 4.8kWh Pylontech US5000C batteries.

Firstly you've gone with NuHeat for the UFH components.

That's good. They're a reputable company, based in Axminster, Devon.

Ignore the concrete floor for the moment.

The detail of the suspended floor states that there's a 9mm plywood layer overlaying the joists.

Have you got an engineered floor on top of that?

Save energy... recycle electrons!

The detail of the suspended floor states that there's a 9mm plywood layer overlaying the joists.Posted by: @transparentHave you got an engineered floor on top of that?

Yes. That was the design Nu-heat came up with to go under an engineered wood floor.

Stiebel Eltron WPLA07 7kW ASHP. 26 x 400W PV. 10kW Sunsynk 3-phase inverter. 6 x 4.8kWh Pylontech US5000C batteries.

Oh dear! 😥

Firstly, I'm not 100% certain that your suspended floor is compliant with Part A of the Building Regulations (structural elements).

If your floor joists are the usual 400-450mm spacing, then a wooden floor requires a thickness of 20-22mm.

You're achieving that only by adding together the thickness of the 9mm plywood and the (14mm?) engineered floor boards.

Secondly, the 14mm diameter FastFlo tubing is effectively surrounded by insulation on all sides.

How the heck is that meant to work? 🤔

Let's look at these elements individually:

A. the pipe is called FastFlo because it's a smaller diameter than the more commonly-used 16mm PEX UFH pipe.

Given the same pump pressure, the water in FastFlo pipe willhave a higher velocity.

14mm with a 2mm wall thickness gives a bore of 10mm and a circumference of 44mm through which the heat is radiated.

A 1m length contains 0.31 litres of water, and has an external surface area of 0.044m²

16mm with a 2mm wall thickness has a 12mm bore and 50mm circumference.

A 1m length contains 0.45 litres, and has a 0.05m² area.

So you've got 30% less fluid trying to radiate through 12% less surface area.

That's not a great start.

B. The pipe is resting in 25mm thick polystyrene board, Nu-heat Tri-Panel.

Polystyrene is an insulator.

C. The diagram you posted suggests that the 'heat transfer plates' are below the polystyrene layer.

I doubt that.

It's more likely that the arrows have been displaced, and that the FastFlo pipe is actually clipped into 900mm lengths of radiating surface like this:

Compare the flat surface area of that with the 400mm-wide aluminium heat diffusers which I've used:

D. Above the narrow heat-transfer plates, you've then got 9mm plywood before the heat even reaches the floor itself.

What conclusion shall we arrive at regarding the efficiency of that heat-transfer design?

You can ignore the maths; what does common sense tell us?

Look at the larger heat-transfer surface which Nu-Heat themselves offer by using their ClippaPlate system when installing from below.

Save energy... recycle electrons!

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 351 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

@jancold I only discuss data.. Fogstar were not impress...

By Batpred , 10 minutes ago

-

RE: What determines the SOC of a battery?

@batpred Ironically you didn't have anything good to...

By Bash , 44 minutes ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

Here’s a current graph showing a bit more info. The set...

By benson , 58 minutes ago

-

RE: Setback savings - fact or fiction?

True there is a variation but importantly it's understa...

By RobS , 58 minutes ago

-

Below is a better quality image. Does that contain all ...

By trebor12345 , 1 hour ago

-

Sorry to bounce your thread. To put to bed some concern...

By L8Again , 1 hour ago

-

@painter26 — they (the analogue gauges) are subtly diff...

By cathodeRay , 2 hours ago

-

RE: Electricity price predictions

I am always impressed with how you keep abreast of so m...

By Batpred , 3 hours ago

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

@majordennisbloodnok I’m glad I posted this. There see...

By AndrewJ , 3 hours ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 6 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 9 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 10 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 1 day ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 1 day ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 1 day ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 1 day ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 1 day ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago