Adventures in DIY Smart Thermostating

Over the past 5 months or so, I've been experimenting with my own "Smart Thermostat" algorithm. There are two parts to this: (1) the algorithm itself, and (2) the implementation using Home Assistant and a bunch of python scripts/cron jobs. However, I'll just stick with the algorithm for now, as the implementation part is boring to me! The goals of this are as follows:

- Exploit cheap rate electric tariffs (my Octopus Go rate is 7.5p/kWh between 12:30AM and 04:30AM)

- Run the heat pump harder during the day when it is warmer outside (and therefore more energy efficient for the HP)

- Have a more consistent flow temperature (which I think makes for less cycling and a more consistent "feel" in the room from the radiators)

- Have a more consistent room temperature (objectively, as measured by a thermometer)

- Have fun. (Frankly this is the biggest motivator for me. I just like making stuff work the way I want it to.)

I start with a Weather Compensation curve that I've been tweaking for a while. Nothing special here, just something that gives me a solid baseline. However, from this base, I'll be adding and subtracting "offsets" or otherwise modifying the standard WC calculation to achieve the above goals.

The first offset is a simple one: add X degC to my flow temperature during the cheap overnight rate period. Currently I use an offset of +5C, but I change this frequently. That raises my house's temperature overnight, which I'd imagine for most people would be kind of annoying, but for me it works for two reasons. First is that we have a baby and we often are awake between 12:30AM and 04:30AM. The second is for efficiency of the heat pump – more on that later.

The second modification of the standard WC calculation addresses points 2 and 3. During the course of a 24 hour period, the temperature rises and falls gradually, peaking in, say, mid-afternoon, and troughing some time at night (and usually staying low til morning). This does two things. First, the delta-T between required indoor and actual outdoor temperature changes cyclically throughout the day, resulting in the heat loss rate (and therefore heating requirement) of the house to change throughout the day. Second, the amount of energy required to pump the same amount of heat into the house changes cyclically throughout the day. And to make matters worse, these to cycles are in phase; that is, the heat loss from the house is highest when the amount of energy required to pump heat into the house is also at its highest. The two temperature gradients compound to make an even steeper efficiency gradient for the heat pump.

For example, if it's 3pm and the outdoor temperature is 12C, but it's forecast to drop to –2C in the night (a massive swing that happened quite a lot in Feb/March!!), a normal WC curve will run at a relatively low flow temperature (say, 30C) as the outdoor temperature is low. But this leaves the house vulnerable to the cold at night, and when it's –2C outside, the WC curve will tell the heat pump to run at say 45C, struggling to pump heat against two steep temperature gradients (higher flow temp AND lower outdoor temp). Wouldn't it be better to pump more heat when it's 12C, store it in the house for the night, then let the heat pump relax a bit when it's –2C?

Normally, the Weather Compensation curve has "Outdoor Temperature" as its x-axis, and "Flow Temperature" as its y-axis. My second modification alters the x-axis, so that instead of looking up the outdoor temperature right now, it instead takes the average outdoor temperature forecast for the next 24 hours and looks that up on the WC curve. In the above example, let's say the average temperature for the next 24 hours was 5C. At 3pm, when it's 12C outside, instead of looking up 12C against the WC curve and instructing 30C for the flow temperature, we instead look up 5C, giving a flow temperature of, say, 37.5C. This results in more heat being pumped into the house than is lost by the house, causing the average temperature of the house to rise a bit. Then, in the night, when it's –2C outside, instead of looking up –2C on the WC curve and getting a flow temp of 45C, we again look up 5C and get a flow temp of 37.5C. This results in less heat being pumped into the house than is lost by the house, causing the average temperature of the house to fall a bit.

Overall, over the full 24 hour period, if we make the false but simplifying assumption that the heat loss of the house is linear with the delta-T between indoor and outdoor temperature, there is no net change in the total amount of heat being lost by the house, and therefore no net additional heating requirement for the house. In reality, as the relationship is not linear, there will be some additional heating requirement. However, as the heat pump is operating at a flow temperature of 37.5C for the full 24 hour period, the heat pump uses less energy in total than if it were operating at 30C in the day and 45C at night. I admit I haven't done the full maths on this but I suspect this outweighs the extra heating requirement due to the non-linearity of the house's heat loss.

Now, we can tweak this further and add more considerations. For example, I don't just take the average forecast temperature for the next 24 hours -- I actually do a weighted average of this with the current outdoor temperature as I've found this gets less grief from my wife saying it's too hot during the day. And with the above logic we can go further and actually set a higher flow temperature when it's 12C outside using another offset. However, I haven't decided how to implement that yet. I'm currently mulling over including "outdoor temperature in 12 hours' time" into the calculation: a phase shift that should make the flow temperature counter-cyclical with outdoor temperature, but which would be in opposition to the "wife adjustment factor" above.

The final modification is my version of "room adaptation", though it would be more accurate (and fun) to call it "weather compensation compensation". I have a temperature sensor in the room, and I want that temperature sensor to read 21.0C (my "set temp"). Now, I have an offset that is something like a running total or "bank" - let's call it my "WC Offset". Every hour, I read the room temperature sensor. Let's say it's saying 20.0C, so I'm 1.0 degree C too low. That means that my WC curve is "wrong" by a small amount, and needs to be bumped up a bit. So I add, say, 0.2C to my offset. Now the offset is 0.1C. When I run my WC curve algorithm, and I get a final flow temperature (after accounting for all the above), I add my WC Offset of 0.1C to it. So in the above example, instead of running at 40C, I run at 40.1C. This probably isn't enough to make a difference to the rate at which I lose heat from my house, so probably my house temp will fall further below the set temp. So, an hour later, I again look at the temperature sensor. Let's say the temperature is 19.8C -- so I'm 1.2C below my target set temp. Now I add 0.3C to my offset. My offset is now 0.2 + 0.3 = 0.5C. So when I do my WC curve calc, it will now set the flow temp to 40.5C. Let's say this arrests the decline in the house temperature, but doesn't cause it to increase. So the temperature sensor still says 19.8C (1.2C below the set temp). Again, I'm going to add 0.3C to my offset, bringing the offset total up to 0.8C, and the flow temp up to 40.8C. Maybe this is enough to slowly increase the temperature of my house, and the temperature of my house rises back to 20.0C. Now I'm 1.0C below my set temp, so I add 0.2C to my offset, bringing the total to 1.0C and flow temp up to 41C. Hopefully you can see how this goes, and that there is a cycle here that runs, perhaps, slightly counter to the logic in my previous modifications. You can also imagine that it overshoots and undershoots – but how much?

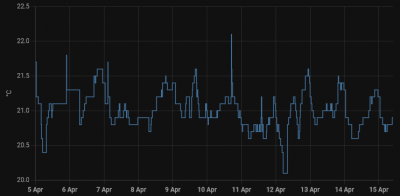

This is a 10 day period where the weather outside was fairly consistent, the heat pump was running 24/7, and we were mostly in the house – so kind of the best-case scenario for my hypothesis. This results in the temperature fluctuating by +/- 0.5C over the course of the day, in what I feel is a nice cadence that follows the course of the day: highest in the afternoon when we're having family time, coolest at night – but still not too cold when we have to get up to comfort/feed the baby. A theory I have is that your brain "expects" it to be warmer during the afternoon, and so it's fine that the house is objectively warmer as that's what you expect (vice versa at night).

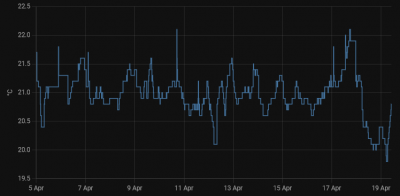

A non-ideal scenario is what happened a few days later, where it got to 19C outside and 22C inside, followed by a day of rubbish weather when the indoor temp dropped to 20C:

Part of that is our fault, however: we turned the heating off but were a bit late turning it back on.

Now, it's clear that a lot of what I'm doing with all these modifications is undoing things I've done in earlier modifications. But for me that's fine – there's no silver bullet or magic algorithm, and the push/pull of these different factors results in, for me at least, a pretty consistent feel for the house. For the months of Feb through April, I've been leaving these algorithms more or less untouched, only modifying the offsets manually if my wife says she's too hot or too cold, to give a bit of a boost to the heating.

It's also clear that I'm reinventing the wheel, and that I'm missing some basic things that industrial control systems use (e.g. I have the "P" and the "I" but not the "D" in a "PID" control – I suspect this would be useful). But again, for me that's fine. My fifth and most important goal is to have fun, and I just like doing this stuff myself, learning what works, and getting everything just the way I want it.

This forum is full of people who enjoy thinking about the operation of heat pumps, and who bring a wealth of experiences to the conversation. I would love to hear people's thoughts on this. One thing I've learnt is that everyone's experience is different and there's no one-size-fits-all solution for getting your heat pump to work just the way you want it, so I'd be keen to hear what elements of the above you would keep, what elements you would remove, and what other elements you might consider adding, in order to get it "just right" for your house.

ASHP: Mitsubishi Ecodan 8.5kW

PV: 5.2kWp

Battery: 8.2kWh

This looks very interesting, not disimilar to "homely" I would think. I havent got time to read it carefully now but I would be interesting in exploring this with my own system 🙂

House-2 bed partial stone bungalow, 5kW Samsung Gen 6 ASHP (Self install)

6.9 kWp of PV

5kWh DC coupled battery

Blog: https://thegreeningofrosecottage.weebly.com/

Heatpump Stats: http://heatpumpmonitor.org/system/view?id=60

@scrchngwsl - very interesting, and thanks for writing it up in so much detail. A couple of thoughts:

(a) at the end of the day, there is really only one 'thermometer' that matters - us. If we are comfy and cosy (used both words because not sure which is the right word), then everything is working. It sounds as though you have achieved that, congratulations.

(b) I'm sure you know this, maybe even like it, but your system is complicated. It also relies partly on forecasts, and they are notoriously variable in accuracy, though they may get near enough some of the time. I do like your idea of anticipating future heat demand (I think Homely also tries to do the same thing), but only time will tell how useful and effective that proves to be in practice, and there are other weather complications to consider, things like solar gain (a forecast temp won't tell you much if anything about that, might be warm but overcast, or room aspect, faces north or south etc) and wind chill, which is significant in old leaky buildings.

When I finally get round to it (rather missed the timing for this heating season), I plan to start with a much simpler approach: measure that delta t between the kitchen actual temp and desired temp, and then offset one or both ends of the weather compensation curve, up if the actual is less than the desired and down if the actual is above the desired. It will inevitably lag, and forever be playing catch up, and in no way is as smart as your approach, but it does have the virtue of simplicity, hopefully making it easier to manage, and possibly less prone to errors. But it won't be as 'smart'.

These are just my thoughts on a different approach, nothing more or less than that. If your system is working, then, as I say, congratulations.

Midea 14kW (for now...) ASHP heating both building and DHW

Posted by: @scrchngwslNormally, the Weather Compensation curve has "Outdoor Temperature" as its x-axis, and "Flow Temperature" as its y-axis. My second modification alters the x-axis, so that instead of looking up the outdoor temperature right now, it instead takes the average outdoor temperature forecast for the next 24 hours and looks that up on the WC curve

Thanks for posting this, what HP as a matter of interest.

I have a feeling there quite a lot in 'look ahead'. At either end of the cold snap last year, during which I was monitoring my gas usage particularly carefully (to verify my HP calculations) it became abundantly clear that the house took about 24 hours to react. Also my scattergram of 'degree days' vs 'total gas used' for the period Sept 2022-Apr 2023 shows a better correlation if I offset one by 24 hrs relative to the other.

Obviously the response time of the house will vary a lot from house to house.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

@scrchngwsl I've had similar ideas myself, as I also have temp sensors in almost all rooms, all going into home assistant, and wish to (eventually) optimise in ways that share some ideas with yours. My gas boiler smart system (evohome) tried to do some of these things already. Eventually I think there'll be an open source "heating optimiser" that can work off all the various inputs you refer to.

the key thing I'd like to ask you to explain first is the part 0 - before the algorithms , how are you enacting these changes? what type of heatpump is it, what protocol or method are you using to communicate with the heat pump to tell it what you want to do, what parameter(s) are you changing on the heatpump, what hardware and software are you using for that?

I ask this not just out of idle interest - I have a samsung g6 heat pump and I am able to read lots of data from it over Modbus, but I haven't yet been able to get it to change any of its settings (LWT being the one I'm after) via that Modbus route.

My octopus signup link https://share.octopus.energy/ebony-deer-230

210m2 house, Samsung 16kw Gen6 ASHP Self installed: Single circulation loop , PWM modulating pump.

My public ASHP stats: https://heatpumpmonitor.org/system/view?id=45

11.9kWp of PV

41kWh of Battery storage (3x Powerwall 2)

2x BEVs

Posted by: @iancalderbank@scrchngwsl I've had similar ideas myself, as I also have temp sensors in almost all rooms, all going into home assistant, and wish to (eventually) optimise in ways that share some ideas with yours. My gas boiler smart system (evohome) tried to do some of these things already. Eventually I think there'll be an open source "heating optimiser" that can work off all the various inputs you refer to.

the key thing I'd like to ask you to explain first is the part 0 - before the algorithms , how are you enacting these changes? what type of heatpump is it, what protocol or method are you using to communicate with the heat pump to tell it what you want to do, what parameter(s) are you changing on the heatpump, what hardware and software are you using for that?

I ask this not just out of idle interest - I have a samsung g6 heat pump and I am able to read lots of data from it over Modbus, but I haven't yet been able to get it to change any of its settings (LWT being the one I'm after) via that Modbus route.

I haven't looked in detail at the Samsung controller capabilities recently, but I suspect that whilst required LWT is an input for the compressor speed control algorithm, it is an output derived from the WC calculations. Whilst you may be able to externally write to an output over Modbus, there is always the possibility that it will then be overwritten by the controller program on its next pass.

One way that it may be possible to change the required LWT value, would be by putting the system into fixed LWT mode and then changing the fixed value setting via Modbus. If this works, it would then be necessary to also incorporate WC into the calculation.

If your controller supports applying an offset when in WC mode, it may be possible to change the required LWT by changing the offset via Modbus.

If the controller does not support WC offset, then as CathodeRay has suggested, changing the WC settings via Modbus may also work.

I would be interested to know if any of these suggestions work.

@derek-m I know you've made this same conversation on the other thread so I prefer not hijack this one if we can avoid? other people on the other thread have this working (for samsung). I just need one of them to tell me how. for this thread, I'm interested in what the OP is changing and how.

My octopus signup link https://share.octopus.energy/ebony-deer-230

210m2 house, Samsung 16kw Gen6 ASHP Self installed: Single circulation loop , PWM modulating pump.

My public ASHP stats: https://heatpumpmonitor.org/system/view?id=45

11.9kWp of PV

41kWh of Battery storage (3x Powerwall 2)

2x BEVs

Posted by: @cathoderay(b) I'm sure you know this, maybe even like it, but your system is complicated. It also relies partly on forecasts, and they are notoriously variable in accuracy, though they may get near enough some of the time. I do like your idea of anticipating future heat demand (I think Homely also tries to do the same thing), but only time will tell how useful and effective that proves to be in practice, and there are other weather complications to consider, things like solar gain (a forecast temp won't tell you much if anything about that, might be warm but overcast, or room aspect, faces north or south etc) and wind chill, which is significant in old leaky buildings.

I agree it's rather complicated. In my experience with automating stuff, generally you only want to start automating things after you've been doing them manually for a while. All of the things in the above are things that I would do myself, e.g. if it's too hot, turn down the WC offset on the control panel; if it's going to be cold tonight, turning the WC offset up on the control panel during the day. I learnt the sort of "rules" I was following based on how I was manually doing it, and implemented them one at a time. So from my perspective it wasn't that complicated, as I ate the elephant one bite at a time, as it were. It might be hard to maintain/improve going forward though...

Solar gain is absolutely the biggest problem, and I find myself manually adjusting the offsets when it's sunny. Something to improve on for sure.

When I finally get round to it (rather missed the timing for this heating season), I plan to start with a much simpler approach: measure that delta t between the kitchen actual temp and desired temp, and then offset one or both ends of the weather compensation curve, up if the actual is less than the desired and down if the actual is above the desired. It will inevitably lag, and forever be playing catch up, and in no way is as smart as your approach, but it does have the virtue of simplicity, hopefully making it easier to manage, and possibly less prone to errors. But it won't be as 'smart'.Posted by: @cathoderay

I had considered this actually either as an alternative to or as a supplement to the WC offset - a sort of permanent set of offsets where the WC curve itself is adapting. I think it's a smart approach actually, and again it mimics what I (and I assume most of us here) did when we first got the heat pump and realised the installers' WC curve was in need of constant adjustment. In the end I couldn't decide whether I wanted to do as you describe and keep the curve's form fixed but change one or both ends of it, or to alter the form of the curve as well. For example, you could have a lookup table that maps outside temp to flow temp, and offset the values in that table. That way you're not limited to a straight line or a x^(1/a) curve or whatever. Please do post about it on the forum if you ever do this as I'd be very interested to know what your experience is.

I believe you had posted about this before, and that conversation was in mind when I did this.

Posted by: @derek-mIt would appear that you have created a basic PID controller, without the D. The D would be of no use since the 'rate of change' of the temperatures are very slow.

Good to know that I'm not missing out on much by not having the D! The "room adaptation" part is indeed a PID controller without the D, so that the "look ahead"/"heat battery" parts of the algorithm don't go too wild and cause us to bake/freeze. The "I" part is particularly useful when combined with the "look ahead"/"heat battery" part, as it sort of automatically compensates for the fact that you've dumped more heat into the house over the past N hours than you need, so for the next M hours you don't need the HP to work as hard.

BTW I must thank you as I first learnt about what a PID controller was from a post you made here some months ago.

Posted by: @jamespaThanks for posting this, what HP as a matter of interest.

Mitsubishi Ecodan (more details below).

That's really interesting - I might do the same for my data and see what sort of phase shift gives the best correlation. That way I'd have a better idea how far to look ahead.I have a feeling there quite a lot in 'look ahead'. At either end of the cold snap last year, during which I was monitoring my gas usage particularly carefully (to verify my HP calculations) it became abundantly clear that the house took about 24 hours to react. Also my scattergram of 'degree days' vs 'total gas used' for the period Sept 2022-Apr 2023 shows a better correlation if I offset one by 24 hrs relative to the other.Posted by: @jamespa

Posted by: @iancalderbank@scrchngwsl I've had similar ideas myself, as I also have temp sensors in almost all rooms, all going into home assistant, and wish to (eventually) optimise in ways that share some ideas with yours. My gas boiler smart system (evohome) tried to do some of these things already. Eventually I think there'll be an open source "heating optimiser" that can work off all the various inputs you refer to.

the key thing I'd like to ask you to explain first is the part 0 - before the algorithms , how are you enacting these changes? what type of heatpump is it, what protocol or method are you using to communicate with the heat pump to tell it what you want to do, what parameter(s) are you changing on the heatpump, what hardware and software are you using for that?

I ask this not just out of idle interest - I have a samsung g6 heat pump and I am able to read lots of data from it over Modbus, but I haven't yet been able to get it to change any of its settings (LWT being the one I'm after) via that Modbus route.

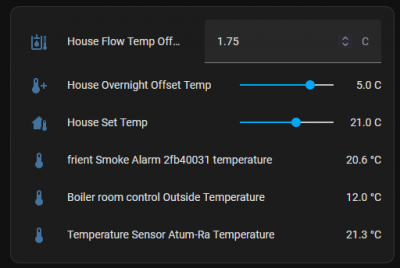

Mitsubishi Ecodan, using the pymelcloud python library to communicate. I'm running the HP in "fixed flow temperature" mode (i.e. ignoring the Weather Compensation settings built into the controller), and altering the "fixed" flow temperature via a python script. The python scripts are on my home server (an ARM-based SBC), and the main script runs every 4 hours via cron. It pulls in the weather forecast from the Met Office API, and all other parameters (including indoor and outdoor temps) from Home Assistant, runs the algorithm, and then sets the flow temperature on my heat pump using pymelcloud. (The outdoor temperature gets into HA from the heat pump via the MELcloud integration.) Home Assistant keeps track of the offsets as well as the set temperature for my home:

Does your Samsung heat pump have an app or website that can control your flow temps? If so you might be able to "pretend" to be the app and send commands in the same way (that's more or less how pymelcloud works - it basically sends the same URL requests that the app sends as there's no official API).

ASHP: Mitsubishi Ecodan 8.5kW

PV: 5.2kWp

Battery: 8.2kWh

Posted by: @iancalderbank@derek-m I know you've made this same conversation on the other thread so I prefer not hijack this one if we can avoid? other people on the other thread have this working (for samsung). I just need one of them to tell me how. for this thread, I'm interested in what the OP is changing and how.

I cannot state for definite, since I doubt that I would be able to inspect the program inside a Samsung controller, even if I had one, but I suspect that it will operate in a similar manner to an industrial controller.

A controller performs three distinct functions, it reads the inputs and stores the values in specified memory locations, it performs any necessary calculations on the data obtained, then it writes the outputs to specified memory locations for possible use by other circuitry. This process repeats probably 50 times per second.

It is therefore quite easy to read both inputs and outputs via Modbus without any effect, but writing to either may soon be overwritten by the controller program.

I think that it should be possible to write to inputs that are set manually on the HMI, such as fixed LWT or WC parameter settings, since their values in memory are only likely changed by an interrupt initiated by the HMI, so the values in memory will remain the same until changed via the HMI or possibly using Modbus.

The O/P to which you refer is the required LWT value, which as far as I am aware can be set from the HMI when in fixed mode, or is set by the WC algorithm when in WC mode. This output acts as an input to the compressor speed control algorithm, such that if the required LWT value is increased, the speed of the compressor will be increased, to raise the actual LWT until it matches the required value.

I hope this answer your question.

I am pleased to read that you are not only learning, but enjoying the experience, it was my pleasure for over 50 years, in fact the first PID controllers on which I worked were analogue rather than digital, and there were even pneumatic ones.

You mentioned solar gain. My wife, who is keeping a solar powered garden lights giga - factory in China in full production, allowed me access to one of her older versions, when I was investigated ways in which to increase the output from solar panels. During testing I quickly came to the conclusion that a small solar panel could easily be used as a solar intensity detector. In open circuit mode the output voltage increases quite quickly to the maximum value, but when loaded using a simple resistor network, the output voltage is very much dependent upon the level of irradiance.

My home heating system incorporates an industrial type PID controller, and I also have a data logger which monitors various temperatures. I strongly suspect that solar gain not only affects the internal areas by direct sunlight through the windows, but also by heating the external fabric of the building. In doing so it reduces the rate of heat loss, which in turn causes an increase in the indoor temperature leading to a reduction in the heating requirement. This effect continues long after the Sun has gone down.

@derek-m by OP I meant original poster (of this thread) 🙂 a TLA I've used in forums before that I thought was common usage, but I guess not! I am trying to avoid a hijack here... I am doing some work to try to understand why I can't change the parameters on mine yet - I'll report back in the other thread if I ever figure it out.

@scrchngwsl I was going to say same thing as derek - if you have PV, surely the output of that gives you a decent proxy for solar irradiance? even if you don't have PV you can pretend that you do , setup HA's solar forecast integration to give you predicted output for a PV array that you don't have ?

the samsung does have an app (which requires a separate wifi gateway hardware that I don't own), no one on this forum that I've found so far uses it either. those who are trying to hack it and make it dance to our tune, are all using modbus. some have got it (modbus control) working, but not me (only modbus data reading so far - which is really really useful in itself). personally I would also prefer a purely local system of control so bouncing off a cloud is something I prefer to avoid. I design large bits of the internet for a living, so not afraid of clouds, but architecturally I prefer to keep this kind of thing on-premises if possible.

My octopus signup link https://share.octopus.energy/ebony-deer-230

210m2 house, Samsung 16kw Gen6 ASHP Self installed: Single circulation loop , PWM modulating pump.

My public ASHP stats: https://heatpumpmonitor.org/system/view?id=45

11.9kWp of PV

41kWh of Battery storage (3x Powerwall 2)

2x BEVs

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 485 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Testing new controls/monitoring for Midea Clone ASHP

Here’s a current graph showing a bit more info. The set...

By benson , 8 seconds ago

-

RE: Setback savings - fact or fiction?

True there is a variation but importantly it's understa...

By RobS , 30 seconds ago

-

Below is a better quality image. Does that contain all ...

By trebor12345 , 27 minutes ago

-

Sorry to bounce your thread. To put to bed some concern...

By L8Again , 29 minutes ago

-

@painter26 — they (the analogue gauges) are subtly diff...

By cathodeRay , 1 hour ago

-

RE: What determines the SOC of a battery?

The answer from Fogstar was crisp. My hypothesis, su...

By Batpred , 1 hour ago

-

RE: Electricity price predictions

I am always impressed with how you keep abreast of so m...

By Batpred , 2 hours ago

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

@majordennisbloodnok I’m glad I posted this. There see...

By AndrewJ , 2 hours ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 5 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

Just to wrap this up here for future readers: The S...

By Batpred , 7 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 8 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 9 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 24 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 1 day ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 1 day ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 1 day ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 1 day ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago