Posted by: @upnorthandpersonal- You stop charging at 55V. If this is a 16s pack (which it should be) that means you stop at 3.437 V per cell. You also don't absorb there. This means that you won't charge to 100%, and your balancer can't do its job. You will lose capacity over time because of this (but you can recover this with balancing).

All that is being done is the inverter is set to stop charging when soc reaches 100%.

This battery has a JK balancer, I just use the default values Fogstar made. I am not sure if the JK balancer is being triggered, since the battery is in almost permanent use (only an hour or so overnight where it may sit still).

Posted by: @upnorthandpersonal- Your temperature hits 30C. That's about the upper limit I ever use for my cells. Is there inadequate cooling? Are you sure this is cell temperature and not BMS temperature? If it's the BMS, you're fine. I highly doubt it's cell temperature actually: cells have a large thermal mass, and it takes quite long to heat 16 cells from 20C to 30C. There should be more than one temperature sensor in most batteries like this.

The cells are inside a vertical box with the Seplos and JK boards on the top section. No cooling was specified..

I assumed it could only be cell. The BMS has a lot of temperature parameters to be able to consider the cell temperature. Via the inverter modbus, there are other temperature readings. I don't know what they are from. They are higher readings.

Posted by: @upnorthandpersonal- The voltage drop is normal. Cells settle at 3.375V on their own. You're at 3.23V per cell under load. Especially since you're not fully charged, I consider this ok for now.

Do you mean it is reasonable to expect 8,000 cycles?

Posted by: @upnorthandpersonalPersonally, I would fully charge the pack (say, 3.5V to 3.55V per cell, 56V to 56.8V pack voltage). Can you monitor individual cells? Once you reach this voltage, you really want to check for cell imbalance (and also cell protection, maybe you won't reach this voltage at all because the BMS goes in protection when one cell goes too high). It would also be nice to be able to monitor the balancer. If you can't get to this voltage in one go, you definitely have an imbalance in which case you should gradually increase the voltage so the balancer can fix this without the BMS going in protection.

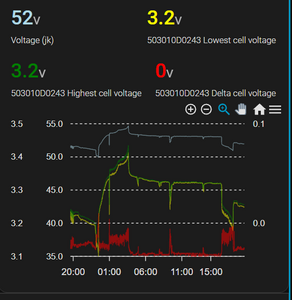

From what I remember, the JK board is meant to balance it. Below is a graph from it... The BMS display has 4 temperature readings that tend to be room temperature. I assume they will go up to 30C overnight when it is charging..

8kW Solis S6-EH1P8K-L-PLUS hybrid inverter; G99: 8kw export; 16kWh Seplos Fogstar battery; Ohme Home Pro EV charger; 100Amp head, HA lab on mini PC

Posted by: @batpredAll that is being done is the inverter is set to stop charging when soc reaches 100%.

This battery has a JK balancer, I just use the default values Fogstar made. I am not sure if the JK balancer is being triggered, since the battery is in almost permanent use (only an hour or so overnight where it may sit still).

Yes, but the issue is that 100% the inverter gets from the BMS is not really 100%, it's likely reaching 100% because one cell in the pack goes over a certain voltage, or the BMS is just wrong. All those BMS (Seplos, JK, etc.) have issues with measuring state of charge. More recent versions are somewhat better, but I would have to see the parameters on the BMS etc. to know what it's actually reporting to the inverter as 100%.

Posted by: @batpredThe cells are inside a vertical box with the Seplos and JK boards on the top section. No cooling was specified..

I assumed it could only be cell. The BMS has a lot of temperature parameters to be able to consider the cell temperature. Via the inverter modbus, there are other temperature readings. I don't know what they are from. They are higher readings.

The BMS has multiple temperature sensors. Some go to the cells, others are on the MOSFETs doing the switching. These can get warm, the cells likely not. The round trip efficiency of LFP is well into the 90%, meaning that you don't get heat development in the cells from charging/discharging. It must be a different temperature you're getting.

Posted by: @batpredDo you mean it is reasonable to expect 8,000 cycles?

LFP, especially in solar applications or home storage where you typically have low C rates can definitely reach that. If you see loss of capacity over time, the first suspect in your set-up is cell imbalance. I've cycled LFP cells thousands of times in my lab (I co-run a battery test lab here at the university lab) at all kinds of conditions without noticeable life cycle issues, except at high temperatures.

Posted by: @batpredFrom what I remember, the JK board is meant to balance it. Below is a graph from it... The BMS display has 4 temperature readings that tend to be room temperature. I assume they will go up to 30C overnight when it is charging..

I wonder if the temperature sensors are actually placed on the cells and not just bundled together on top of the case...

My blog where I write about all the systems in place and decisions made for my off-grid house at 63 degrees north in Finland.

Posted by: @batpredThe BMS display has 4 temperature readings that tend to be room temperature. I assume they will go up to 30C overnight when it is charging

Why?

Are you suggesting that all four temp sensors are in the same location?

As @upnorthandpersonal suggests, the BMS may well get warm during charging, but I wouldn't expect the LiFePO₄ cells to reach 30°C.

I also agree with his observation that 55v peak across a 16S battery may be insufficient to trigger cell balancing by the JK BMS.

Is the inverter set upo to deliver a particuklar current until it 'sees' the BMS report 100% SoC?

Or does it slowly reduce the current as it reaches the point you've configured?

If it charges at the same (high) current until it thinks 100% SoC has been attained, and then abruptly stops, then it won't have achieved 100% SoC. The SoC reading is incorrect because it's being measured at full charge-current.

Save energy... recycle electrons!

Posted by: @transparentIs the inverter set upo to deliver a particuklar current until it 'sees' the BMS report 100% SoC?

Or does it slowly reduce the current as it reaches the point you've configured?

My guess at this point is that the BMS communicates state of charge to the inverter, and the inverter switches off based on that. If the 100% trigger is wrong in the BMS (and it likely is based on these types of BMS), the battery never truly reaches full.

My blog where I write about all the systems in place and decisions made for my off-grid house at 63 degrees north in Finland.

Posted by: @upnorthandpersonalYes, but the issue is that 100% the inverter gets from the BMS is not really 100%, it's likely reaching 100% because one cell in the pack goes over a certain voltage, or the BMS is just wrong. All those BMS (Seplos, JK, etc.) have issues with measuring state of charge. More recent versions are somewhat better, but I would have to see the parameters on the BMS etc. to know what it's actually reporting to the inverter as 100%.

Thanks, I made some adjustments as per yours and @transparent advice, to slow the charging rate as it approaches 100% (since I have not tried to use any clever AI methods from the inverter, so the rate is fixed per period).

Posted by: @upnorthandpersonalThe BMS has multiple temperature sensors. Some go to the cells, others are on the MOSFETs doing the switching. These can get warm, the cells likely not. The round trip efficiency of LFP is well into the 90%, meaning that you don't get heat development in the cells from charging/discharging. It must be a different temperature you're getting.

I remember placing some sensors on some of the cells. But essentially I just followed some YT video from Fogstar, they have to written instructions, so will need to double check.

Posted by: @upnorthandpersonalLFP, especially in solar applications or home storage where you typically have low C rates can definitely reach that. If you see loss of capacity over time, the first suspect in your set-up is cell imbalance. I've cycled LFP cells thousands of times in my lab (I co-run a battery test lab here at the university lab) at all kinds of conditions without noticeable life cycle issues, except at high temperatures.

Sounds promising!

Posted by: @upnorthandpersonalI wonder if the temperature sensors are actually placed on the cells and not just bundled together on top of the case...

This I can be pretty sure about, I would not left any loose cables when assembling it!

There are four temperature readings on the display and they are all slightly different.

8kW Solis S6-EH1P8K-L-PLUS hybrid inverter; G99: 8kw export; 16kWh Seplos Fogstar battery; Ohme Home Pro EV charger; 100Amp head, HA lab on mini PC

Posted by: @transparentPosted by: @batpredThe BMS display has 4 temperature readings that tend to be room temperature. I assume they will go up to 30C overnight when it is charging

Why?

Are you suggesting that all four temp sensors are in the same location?

No as the temp readings are not the same..

Posted by: @transparentI also agree with his observation that 55v peak across a 16S battery may be insufficient to trigger cell balancing by the JK BMS.

And additionally the JK BMS may need a quiet period before doing its job. Will need to study this a bit better. Anyway, it is working pretty well and the BMS reading is reporting more than 17kwh charge..

8kW Solis S6-EH1P8K-L-PLUS hybrid inverter; G99: 8kw export; 16kWh Seplos Fogstar battery; Ohme Home Pro EV charger; 100Amp head, HA lab on mini PC

I have been trying to get my head around what this all means for the battery life? Like others I want to get the best out of my system (Solis 8Kw and Fogstar 2* 16 KWH with Pace BMS on the Intelligent octopus go). Are there battery charge settings in the Solis box I could check? I have reduced the charge to 80A as that easily charges ( according to the Solis) the batteries in the cheap period and allows a time for them to sit before discharging to the house.

Daikin 6Kw ASHP.

MG4 EV, Solis 8KW inverter, 32KWh battery

1926 Semi with loft and wall cavity insulation, all radiator.

Posted by: @batpredThanks, I made some adjustments as per yours and @transparent advice, to slow the charging rate as it approaches 100%

It would be useful to @jancold if you could specify what change(s) you've made to achieve lower charge-rates as the cells reach capacity.

If that is a feature of the Solis inverter, then it's a strong point in favour of that manufacturer.

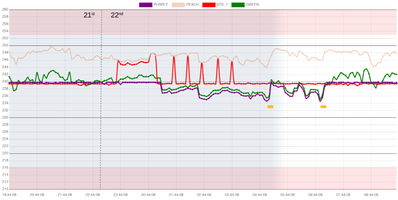

I have been trialing the effects of reducing current towards the end of the charging period, but doing so using an external micro-controller, rather than a protocol built into an inverter.

Here a timeline showing two grid-monitors (green and purple) measuring grid voltage as the charge current is slowly reduced over 3 or 4 minutes.

Look at the sections of the graph above the two orange rectangles.

Save energy... recycle electrons!

Posted by: @transparentIt would be useful to @jancold if you could specify what change(s) you've made to achieve lower charge-rates as the cells reach capacity.

If that is a feature of the Solis inverter, then it's a strong point in favour of that manufacturer.

The Solis inverter has an amp setting on each period. I currently have mine set to 50A for the main cheap rate period then at 0A for the first half hour as it doesn't need the whole 6 hr window to fully charge the battery but there is no point using the battery during the off peak.

I have noticed that it still charges slightly during this period so I will try reversing them and having the slow charge during the last half hour. I was thinking that the less time the battery sits at 100% the better but maybe not, when it is only for a short time.

Posted by: @jancoldI have been trying to get my head around what this all means for the battery life? Like others I want to get the best out of my system (Solis 8Kw and Fogstar 2* 16 KWH with Pace BMS on the Intelligent octopus go). Are there battery charge settings in the Solis box I could check? I have reduced the charge to 80A as that easily charges ( according to the Solis) the batteries in the cheap period and allows a time for them to sit before discharging to the house.

My advice with LFP: stop worrying about battery life. You're talking 4000 cycles, from 0% to 100% before you reach 80% of original capacity. That's almost 11 years. Keep our voltage limits within reason (say 3.0V per cell at the low end and 3.5V at the high end), manage the temperature (25C is the sweet spot, high temperature kill the battery fast). Calendar aging (the battery just being a battery) will likely kill the battery before cycles will. With typical applications like this you're no where close to the 0.5C test current (140A with typical 280Ah cells) so that won't impact either.

Make sure your cells get balanced once in a while, so that's why the 3.5V per cell. If you don't want to go to 3.5V all the time, do this a few times a month and leave it at 3.45V per cell otherwise.

If a cell should fail down the line for some reason, just replace it. They're well under 80 Euro per cell in single cell quantities... I just bought another 32kWh to add to my 120kWh, and total cell costs for that was under 2000 Euro including shipping to Finland.

My blog where I write about all the systems in place and decisions made for my off-grid house at 63 degrees north in Finland.

I know there are a number of charging periods but had not thought of using them that way. My assumption was that the inverter had automatic charge phases, bulk, absorb, float like a battery charger which information it must get from the BMS or its own current measurement? If an inverter just pumps in say 100A and stops dead on being told battery 100% that is mad.

Daikin 6Kw ASHP.

MG4 EV, Solis 8KW inverter, 32KWh battery

1926 Semi with loft and wall cavity insulation, all radiator.

From my observations the Seplos V3 BMS that comes in the Fogstar Seplos units ramps down the charge rate as it approaches capacity.

This leaves plenty of time for the cells to balance.

Mine are perfectly balanced at 3.600v

Just make sure you have the JK Active balancer in yours as the Seplos one supplied in the past aren't good at balancing the cells (actually quite bad).

I replaced the Seplos Active balancer to a JK 2A (that Fogstar now fit in the current batteries).

Fogstar were great in supplying me the JK Active balancer and cable for a nominal amount and it was easy to change.

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 870 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

Actually, it’s better for wooden furniture – or at leas...

By Majordennisbloodnok , 6 hours ago

-

This is absolutely standard for any sealed pressurised ...

By JamesPa , 8 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 8 hours ago

-

RE: What determines the SOC of a battery?

@batpred Your BMS parameters will be the same as m...

By Bash , 9 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 10 hours ago

-

RE: Setback savings - fact or fiction?

I also need to correct something I said by mistake earl...

By cathodeRay , 10 hours ago

-

RE: Electricity price predictions

@judith Thanks for sharing, and nice to see how the ...

By Batpred , 11 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@tasos the OAT is incorporated into the control logic. ...

By benson , 11 hours ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 13 hours ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 13 hours ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 14 hours ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 15 hours ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 16 hours ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 17 hours ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 18 hours ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 18 hours ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 1 day ago

-

RE: DIY solar upgrade - Considering adding more panels

I know this is a bit old, but it made me wonder what co...

By Batpred , 1 day ago

-

RE: New Vaillant aroTherm Plus in black - When will it come to the UK?

@majordennisbloodnok Daikin, take note! (In fact, I hav...

By Toodles , 2 days ago

-

RE: Midea ASHP – how to set weather compensation

@mk4 — good work! First, I agree, no evidence of cycl...

By cathodeRay , 2 days ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

I don't know about Solis inverters. It isn't a featur...

By Transparent , 2 days ago

-

Daikin Altherma 3 H HT - Freeze Prevention Threshold

Hi. We have an Altherma 3 HT (18kW I think) which, now ...

By RICHARDF5033 , 2 days ago

-

RE: Passiv Smart Thermostat - Help & Forum Support

@petch We are not yet compatible with the R290 from Gra...

By Will H , 2 days ago