Posted by: @iancalderbankBut have they actually said, they will tell you to remove it, if you self-install or install with a non MCS installer, in such a way that would have been compliant(0.6m3, noise, 1m etc?) if you'd used an MCS installer? Given that exactly this is what pretty much every other self-installer in the country has done

I think @jamespa stated his home is a listed building…. Without knowing the nature of the listing it’s unclear how protected the house and location is.

neighbours have a habit of knowing that Permitted Development isn’t allowed on many listed buildings. Whereas in another street perhaps nobody would question a new hp installation if it complied to the usual PD rules.

And since James appears to have had some coms with the LA it may be more difficult to hope they will turn a blind eye to an installation now.

Incidentally I’ve done 2 listed building schemes for Heat Pumps in the last 2 years.

one for a front garden location. Close to the boundary and a second on a 2*listed farmhouse with Crested Newts in the garden and bats in the outbuildings. Both schemes needed desktop surveys and statements of avoidance of harm. Neither required 3rd party field survey studies. However immediate risk to habitats were easily explained that a metre high heat pump was not in conflict with immediate habitats or bat roosts. Explained with terrain sketches and pre existing gardening activities in the HP site with habitat ponds some considerable distance away and ditches not within the draught area of the Heat Pump fan.

Posted by: @iancalderbankI think what one really needs to get this empirical "heat pump size" is for the house to be run with the fossil based heating reconfigured as close to "heat pump steady state mode, MCS design conditions " that can be achieved (lowest flow temp that can get away with, all rooms heated, long run times ) for 2-3 days in cold weather (needs a decent duration to reach fabric steady state), and measure the heat throughput on a frequency of no less than hourly. That , IMO, gives a reasonable number for the upper limit for heat pump size.

I think that sounds like a good empirical approach, but I am not sure my old oil boiler could be controlled to that extent, ie a low flow temp, as it was designed primarily as an on/off boiler with high but normal for the era LWTs. But as a general guide for others, who can control their fossil fuel boiler output sufficiently, this may well be the gold standard test (though it is quite a lot of work, but if it gets you the right answer, then worth doing). We will have to wait until next autumn/winter to get cold enough conditions, and find a willing experimenter, to see how well it works in practice.

Midea 14kW (for now...) ASHP heating both building and DHW

@cathoderay I had the same problem; the BG installed gas guzzling boiler was set (by BG default) to the maximum rating setting of 16 kW/h and no means of controlling water temperature other than by turning the one control down which affected DHW heating as well. NBG for any system in my opinion! Regards, Toodles.

Toodles, heats his home with cold draughts and cooks food with magnets.

Posted by: @iancalderbankPosted by: @cathoderayPosted by: @jamespaIf the house is heated by gas or oil then its known how much energy is used in a year and from this an estimate of the design load can be calculated, given a bit of info about intermittent heating patterns

But don't forget what happened to me: seemingly not great changes necessitated by the way heat pumps work (chiefly, pivot (the word one loves to hate) from timed heating to 24 hour heating with comforts levels seeming similar) plus assumptions about efficiencies leading to all manner of confusion. I am not sure 'a bit of info' about heating patterns would have cut it. If I had just used my oil use to sanity check my heat pump sizing I would have got a very small heat pump, perhaps one third of the size I really needed, and would probably have ended up having to pivot back to oil.

I think what one really needs to get this empirical "heat pump size" is for the house to be run with the fossil based heating reconfigured as close to "heat pump steady state mode, MCS design conditions " that can be achieved (lowest flow temp that can get away with, all rooms heated, long run times ) for 2-3 days in cold weather (needs a decent duration to reach fabric steady state), and measure the heat throughput on a frequency of no less than hourly. That , IMO, gives a reasonable number for the upper limit for heat pump size.

the yearly burn number has too many variables for it to be accurate.

Don't forget to add a bit - at least 15% - for defrosts. And hot water. And make sure the manufacturer's 'size' is deliverable when it's actually cold outside because some aren't.

Running the gas/oil heating like this may help inform in some cases. However it wouldn't have helped me in my last two houses. The current one didn't have central heating pre-ASHP and the previous one would have struggled to make double figures at heat pump radiator temperatures.

Posted by: @iancalderbankref your planning thing - I appreciate you appear to have had a lot of exchange with your LPA which is of course private to you. But have they actually said, they will tell you to remove it, if you self-install or install with a non MCS installer, in such a way that would have been compliant(0.6m3, noise, 1m etc?) if you'd used an MCS installer? Given that exactly this is what pretty much every other self-installer in the country has done (including me) , and I haven't read on the forums of there being lots of self-installers / non-MCS installs being told to de-install by over-zealous planners? better not to ask permission?

They haven't told me that they would enforce, but they have told me that, if I go ahead without permission, they cant guarantee not to enforce.

Here is the scenario - a neighbour complains about noise, the EHO investigates and asks the planning officer whether there is planning consent, the planning officer says no. The EHO issues a noise abatement order on the back of that and the complaints, which you are obliged to comply with or face a £1000 fine, meanwhile the planning department starts enforcement proceedings with the threat to make you remove you heating source. Neither takes your word that you have followed 'equivalent' standards because you have no certificate to prove it and no amount of logic will convince the planning officers who have absolutely no knowledge of engineering whatsoever.

So you end up in court with MCS supporting the LPA to prove that you haven't followed 'equivalent standards.

Do you, as perhaps a climate change agnostic (or just a normally slightly selfish and financially prudent person) want to take this risk (given that you are already taking a risk by installing a HP) - No of course you don't. So you won't, and will replace your failing gas boiler with a new gas boiler at one third of the cost!

Posted by: @iancalderbankthat graph is awful. even ignoring the ones where the installer estimate is zero, it's awful. could you please check that link reference? I wanted to have a read, it doesn't work for me.

Having looked at this many times I now realise its energy consumption not peak load, but (estimated) energy consumption is calculated in practice from peak load so its not a bad proxy, albeit influenced by use profiles. However I apologise if anyone was mislead. I don't know if the graph we ideally need exists (if anyone finds it please post!).

Posted by: @fazelPeter Miller, he is an unhappy HP customer turned MCS accredited designer that uses professionals to put in practice his ideas. His mantra is the lowest cost to the customer and without oversizing.

It looks like he is based in Suffolk, check his twitter feed, he is involved in conversations with John Cantor and probably on the community.openenergymonitor.org/latest as well.

Maybe this is the person you are looking for.

twitter.com/PeterEastern

Thanks, I will contact him!

Posted by: @sunandairI think @jamespa stated his home is a listed building…. Without knowing the nature of the listing it’s unclear how protected the house and location is.

I dont think I said this. Its not, nor is it in a conservation area so normal PD rules apply. I apologise if I said anything to suggest it might be listed.

Posted by: @cathoderayI'm leaning towards the idea that heat loss and so heat demand assessments are probably pseudo-science. They look impressive because there are lots of calculations, but hidden in those calculations are a wide array of assumptions, meaning many such calculations are no more than whatiffery (what if my walls are 16 inch solid stone etc). Some important variables only get a scant look in eg old leaky draughty buildings - do the air changes take that into account?

Spot on IMHO. The science is sound but as you say there are too many unknown variables. Fabric variables are one, particularly in retrofits that have been upgraded and extended piecemeal (like mine) but the biggest is probably air change. MCS makes some sweeping assumptions which have no basis in design reality and, I suspect, massively overestimate air changes in many, if not most, cases. In a tolerably well insulated house (even mine - a 1930s solid brick construction) ventilation loss is 30-50% of the load which makes a massive difference if you get it wrong.

Unfortunately, for decades, we didn't bother with system sizing, we just slapped in a well overspecified gas boiler and left it to do its stuff. Now it matters we really don't know how to do it, and dont seem to be thinking about it either. Almost whenever I suggest system sizing (or at least sense checking of system sizing) based on experimental data I am labelled a heretic! The pseudo science gives comfort and an impenetrable barrier against complaint. So it has an advantage for the installer ... but nobody else!

Posted by: @iancalderbankI think what one really needs to get this empirical "heat pump size" is for the house to be run with the fossil based heating reconfigured as close to "heat pump steady state mode, MCS design conditions " that can be achieved (lowest flow temp that can get away with, all rooms heated, long run times ) for 2-3 days in cold weather (needs a decent duration to reach fabric steady state), and measure the heat throughput on a frequency of no less than hourly. That , IMO, gives a reasonable number for the upper limit for heat pump size.

The problems with this are (a) is that it relies on the customer (and there will be a fair number of installers that live by the motto 'never trust the customer') and (b) it relies on a period of relative temperature stability, which is not common in the UK (although last December we had 5 days in a row where it was about -3 in the South East day and night - but this is rare).

Posted by: @iancalderbankthe yearly burn number has too many variables for it to be accurate.

On its own I agree, as a sense check (supplemented by a customer questionnaire which the customer is required to sign) maybe, if its whats available.

I don't think there is a single answer to this but there are several options:

If half hourly smart meter data is available then this can surely be combined with hourly temperature data from the nearest weather station. A regression analysis will, I would be pretty sure, find the best fit both for the load and also for the house heat capacity (thermal mass). The half hourly data tells you about intermittent heating patterns so there is no need to trust what the customer tells you!

This can then be used to size the system and (using the calculated house heat capacity) to tweak the setback parameters accurately to reflect the building parameters. This seems to me to be the gold standard, based on data that cannot easily be manipulated by the customer and is available in many cases

If half hourly data is not available then one of the following could be done

a. set up a specific measurement over a few days with calibrated inputs and temperature monitoring (I have been told that there are companies that do this)

b. use annual data as a sense check to the pseudo science calculation, investigate material discrepencies

c. monitor the fossil fuel CH over a few days as suggested by @iancalderbank

This is the sort of thing that engineering departments of universities can study to good effect. A forward thinking, engineering minded, solution orientated government would sponsor such studies. Meanwhile the Honourable Member for the 18th Century is wittering on about... OK I don't actually know and really don't care about what somebody who was plumbed in reverse (rather like a PHE mentioned upthread) says, other than that it seems to affect what others think.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

You could try operating you present fossil fuel system in a similar manner to how we operate our present gas boiler system in the Winter. At the moment will still have an old gas boiler, which even when adjusted to its lowest setting raises the water temperature over 50C, and consumes 16.5kW of gas according to the smart meter.

The original thermostat has been replaced with an industrial type controller, which measures both the indoor temperature and the temperature of the radiator in my study. This achieves quite constant indoor temperature control by varying the radiator temperatures.

Whilst I am not suggesting that you install such a controller, you could use a similar technique to control the radiator temperatures, and in this way be able to better monitor the effect of changing outside temperature, varying indoor temperature and energy consumption.

If you were to fit a capilliary type thermostat, as detailed below, taped to a convenient radiator, under suitable insulation, it should be possible to control and vary the average radiator temperature. The electrical switch on this thermostat would need to be wired in place of your present thermostat, such that it would start and stop your present boiler.

The system should therefore operate in the following manner:-

When the radiator temperature falls below the setting, and differential, the boiler will be switched on.

The boiler heats the water and pumps it around the system, warming the radiators in the process (our system takes approximately 4 minutes). When the capilliary thermostat reaches the temperature setting it switches off the boiler and ideally the water pump.

The temperature of the radiator will initially continue to increase and then start to fall. The rate at which the radiator cools will be dependent upon the temperature differences between radiator, indoor temperature and outside temperature.

Whilst the period of time for which the boiler is switched on may only vary by a matter of seconds, the off period should vary quite considerably with the rate of heat loss of your home.

By trying different temperature settings on the new thermostat, under varying outside air temperatures, it should be possible to obtain fairly detailed data on how the overall heat loss varies under operating conditions similar to those of a heat pump.

I hope that this helps, but please get in touch if you require more detail.

https://www.bes.co.uk/amfile/file/download/file/1889/product/29295/

@derek-m thanks for the suggestion. I'm actually quite confident about sizing of my own installation, having taken lots of measurements. My personal issue now is that MCS installers refuse to take any notice and my LPA insists on an unachievable and unnecessary noise spec.

My interest above is in how experimental techniques could work more generally to fix up what appears to be a serious problem in the market.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

So if you go to LPA with an MCS quote (that includes an over specified heat pump), and you tell them you want to install the same brand/model but of lower power/noise, in order to give you permission to install they still require to follow the process of documenting the noise measures...? I mean, most of the HP's on the market are MCS certified.

I understand there is a due process, but the lack of common sense puts you in the position to wait until you find the right installer.

@fazel Zero chance your entirely sensible suggestion will work.

By now most will have fitted a a gas boiler, indeed I would if my existing one had failed.

The only light on the horizon is that the LPA is now a green/lib dem coalition not Tory. So I might just have some leverage with the councillors.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

Posted by: @jamespaMy personal issue now is that MCS installers refuse to take any notice and my LPA insists on an unachievable and unnecessary noise spec.

Have you been told that you cannot have a heat pump in your property location for some reason? Does your property and outside space meet the Permitted Development criteria for an Air Source Heat Pump? And is it only size specification that makes you want to do a non MCS installation?

on another point: From a planning pout of view, there is good logic why the MCS or equivalent approval mechanism exists… whether it works or not that’s another subject.

In view of the numbers of installations envisaged the MCS route means all the regulatory expertise is contained in one outside agency. This means planning authorities do not have to have multiple in-house expertise trained up to deal with individual applications. It also means there would be consistency on best practice.

The above deliberately excludes any caveat about the quality and depth of knowledge of the individuals doing the installation.

Posted by: @fazelPeter Miller, he is an unhappy HP customer turned MCS accredited designer that uses professionals to put in practice his ideas. His mantra is the lowest cost to the customer and without oversizing.

It looks like he is based in Suffolk, check his twitter feed, he is involved in conversations with John Cantor and probably on the community.openenergymonitor.org/latest as well.

Maybe this is the person you are looking for.

twitter.com/PeterEastern

Posted by: @jamespaThanks, I will contact him!

If half hourly smart meter data is available then this can surely be combined with hourly temperature data from the nearest weather station. A regression analysis will, I would be pretty sure, find the best fit both for the load and also for the house heat capacity (thermal mass). The half hourly data tells you about intermittent heating patterns so there is no need to trust what the customer tells you!

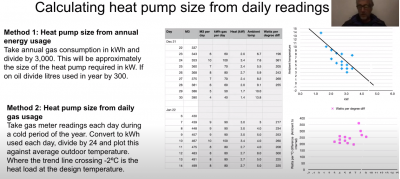

I sat through peter's youtube, this appears to be the method he's using. a better version of what I said to monitor the fossil fuel burn - using regression fit because outside temperature varies over the period.

snip from his youtube below

this interesting bit to me is to find out how he's managed to get himself registered as MCS using a significantly different assessment method and way of working with local PH Engs.

because I might try and do the same myself!

My octopus signup link https://share.octopus.energy/ebony-deer-230

210m2 house, Samsung 16kw Gen6 ASHP Self installed: Single circulation loop , PWM modulating pump.

My public ASHP stats: https://heatpumpmonitor.org/system/view?id=45

11.9kWp of PV

41kWh of Battery storage (3x Powerwall 2)

2x BEVs

Posted by: @kev-mDon't forget to add a bit - at least 15% - for defrosts. And hot water. And make sure the manufacturer's 'size' is deliverable when it's actually cold outside because some aren't.

Running the gas/oil heating like this may help inform in some cases. However it wouldn't have helped me in my last two houses. The current one didn't have central heating pre-ASHP and the previous one would have struggled to make double figures at heat pump radiator temperatures.

@kev-m I didn't mean that gives you simplistically the size of the HP. I mean it gives you the heat loss of the house. The size of the HP itself of course may have to include allowance for DHW, defrosts, and of course the good old made up "Name plate rating number". the method PeterMiller is using is basically this, but better , with regression fit to readings taken with varying outside temps.

The method should still work if the flow temp has to be higher, if you can get a reasonably steady state . The house with no CH, would there have been anything that could be measured or was it wood burning or something?

My octopus signup link https://share.octopus.energy/ebony-deer-230

210m2 house, Samsung 16kw Gen6 ASHP Self installed: Single circulation loop , PWM modulating pump.

My public ASHP stats: https://heatpumpmonitor.org/system/view?id=45

11.9kWp of PV

41kWh of Battery storage (3x Powerwall 2)

2x BEVs

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 645 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Electricity price predictions

@toodles @skd Then there is not going to be much from t...

By ChandyKris , 16 minutes ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

@batpred I reckon Andy might know a thing or 2 about...

By Bash , 45 minutes ago

-

RE: What determines the SOC of a battery?

@batpred Ironically you didn't have anything good to...

By Bash , 2 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

Here’s a current graph showing a bit more info. The set...

By benson , 2 hours ago

-

RE: Setback savings - fact or fiction?

True there is a variation but importantly it's understa...

By RobS , 2 hours ago

-

Below is a better quality image. Does that contain all ...

By trebor12345 , 2 hours ago

-

Sorry to bounce your thread. To put to bed some concern...

By L8Again , 2 hours ago

-

@painter26 — they (the analogue gauges) are subtly diff...

By cathodeRay , 3 hours ago

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

@majordennisbloodnok I’m glad I posted this. There see...

By AndrewJ , 4 hours ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 7 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 10 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 11 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 1 day ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 1 day ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 1 day ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 1 day ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 1 day ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago