Delta T with a Low Loss Header

My installer told me that the Delta T attaining 5 degrees was not so critical when employing an LLH, I have been tinkering with the speed of the secondary pump in our Daikin based system and would appreciate the views of members in this forum.

I have a Wilo Pico pump and have been trying to achieve DT 5 but find generally that with the pump at mid speed, I achieve approx DT 2.5; slowing the pump makes little difference on most of the 10 radiators (plus a dual fuel towel rail) though one achieves approx 5.2, the others are still 2-3 at best. I would like to know two things:

1. Does the degree of ‘openess’ (i.e. how much constriction the lockshield valve applies) affect the DT across that radiator?

2. How critical is achieving a DT of 5 when using an LLH after all? Is my installer right?

Slightly Curious, Regards, Toodles.

Toodles, heats his home with cold draughts and cooks food with magnets.

Posted by: @toodlesMy installer told me that the Delta T attaining 5 degrees was not so critical when employing an LLH, I have been tinkering with the speed of the secondary pump in our Daikin based system and would appreciate the views of members in this forum.

I have a Wilo Pico pump and have been trying to achieve DT 5 but find generally that with the pump at mid speed, I achieve approx DT 2.5; slowing the pump makes little difference on most of the 10 radiators (plus a dual fuel towel rail) though one achieves approx 5.2, the others are still 2-3 at best. I would like to know two things:

1. Does the degree of ‘openess’ (i.e. how much constriction the lockshield valve applies) affect the DT across that radiator?

2. How critical is achieving a DT of 5 when using an LLH after all? Is my installer right?

Slightly Curious, Regards, Toodles.

1. yes (provided that its open enough for some flow!). The more open, the bigger the flow through the rad, the lower the DT on that rad.

2. I don't think it is critical. with the LLH its more important to try to balance the flow rates on each side of the LLH (for which the primary tool is pump speed) to optimise for LLH distortion (see heatgeek). Are you able to do that?

balancing for same DT across all radiators is really a boiler thing.

In a HP setup (unless you have perfect plumbing and perfect radiator sizing), your DT across each rad will be slightly different : you want to balance the radiators so they all get the right amount of flow to output the amount of heat that the room needs when HP is running constantly. which will inevitably mean not all radiator DT's are the same.

My octopus signup link https://share.octopus.energy/ebony-deer-230

210m2 house, Samsung 16kw Gen6 ASHP Self installed: Single circulation loop , PWM modulating pump.

My public ASHP stats: https://heatpumpmonitor.org/system/view?id=45

11.9kWp of PV

41kWh of Battery storage (3x Powerwall 2)

2x BEVs

@iancalderbank Thank you Ian, I’ll look for that heat geek presentation later; I have watched many of Adam’s presentations and they are very informative - even if his flamboyance does run away with him occasionally! Regards, Toodles.

Toodles, heats his home with cold draughts and cooks food with magnets.

I have had a look at Heat Geek’s presentations and articles that I could find and the nearest to the topic of llh distortion was a quote “Another issue that might arise from the process of hydraulic separation is distortion. This is when higher temperatures are needed at the boiler as a means of getting the emitters (e.g., radiators or/and underfloor heating) to an appropriate temperature should the flow rates differ on either end of the low loss header.” I’m not quite sure how to interpret this but assume one should aim to balance rather than distort (i.e., reduce any difference in temperature differences between the heat pump input to the LLH and the emitter-side of the LLH) I have probably got this completely wrong! Am I aiming to set the secondary pump speed to reduce the differential on the LLH ‘sides’ or set speed to achieve a certain difference please? Regards, Toodles.

Toodles, heats his home with cold draughts and cooks food with magnets.

Posted by: @toodlesI have had a look at Heat Geek’s presentations and articles that I could find and the nearest to the topic of llh distortion was a quote “Another issue that might arise from the process of hydraulic separation is distortion. This is when higher temperatures are needed at the boiler as a means of getting the emitters (e.g., radiators or/and underfloor heating) to an appropriate temperature should the flow rates differ on either end of the low loss header.” I’m not quite sure how to interpret this but assume one should aim to balance rather than distort (i.e., reduce any difference in temperature differences between the heat pump input to the LLH and the emitter-side of the LLH) I have probably got this completely wrong! Am I aiming to set the secondary pump speed to reduce the differential on the LLH ‘sides’ or set speed to achieve a certain difference please? Regards, Toodles.

If my understanding of the theory is correct, the flow from the heat pump into the LLH needs to be slightly higher than the flow coming out of the LLH and going to the heat emitters. That way the temperature of the water going to the heat emitters should be the same as that coming from the heat pump, and the heat pump controller will regulate the quantity of thermal energy it produces to match the heat demand from the heat emitters.

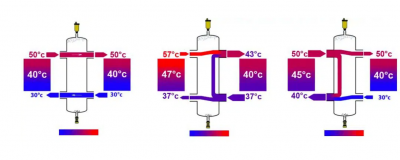

@toodles this diagram

flow rates the same = temperatures the same.

flow rate higher on the radiator side: has to pull from one of the lower (cold) inputs to serve the rads -> rad temps lower - > heat to house lower - > have to run higher LWT on heat pump -> much lower efficiency in the HP

flow rate higher on the heat pump side: RWT to heat pump goes up so heat pump may back off (stop producing heat) as it "sees" a reduced load and so think its has no work to do. But so long as they are not too close, and flow rate is high enough , it won't back off.

optimal: the same

next best thing (given that optimal is nigh on impossible) : bit higher on the heat pump side.

i.e. what derek-m said

My octopus signup link https://share.octopus.energy/ebony-deer-230

210m2 house, Samsung 16kw Gen6 ASHP Self installed: Single circulation loop , PWM modulating pump.

My public ASHP stats: https://heatpumpmonitor.org/system/view?id=45

11.9kWp of PV

41kWh of Battery storage (3x Powerwall 2)

2x BEVs

@iancalderbank Ok, I get the gist of the requirement now, ideally matching - probably impossible, especially as the primary pump is variable speed itself. Slightly lower flow on the emitter side should produce a reasonable compromise that keeps efficiency near the ideal. Looks like I need to see what flow rate the primary pump produces (on average) and set the secondary just below this figure. ‘`fun for the whole family’ might ensue! Regards, Toodles.

Toodles, heats his home with cold draughts and cooks food with magnets.

@toodles so the other gotcha with dropping the pump power on the secondary side is that it will run at lower head , which means your "harder to reach" radiators become less likely to stay in the active circuit. there might not be enough push for the flow to reach them. unless you have really well balanced rads and low head-loss plumbing this can be a factor. one to be aware off. if you know which rads is the "furthest away in plumbing terms" (a.k.a index radiator) make sure you check that if/when you lower pump power.

I'm actually tuning my own system to a slightly higher flow rate at the moment (I have no LLH of course) for this exact reason.

My octopus signup link https://share.octopus.energy/ebony-deer-230

210m2 house, Samsung 16kw Gen6 ASHP Self installed: Single circulation loop , PWM modulating pump.

My public ASHP stats: https://heatpumpmonitor.org/system/view?id=45

11.9kWp of PV

41kWh of Battery storage (3x Powerwall 2)

2x BEVs

@iancalderbank I’m reasonably confident this won’t be a problem on my system; the furthest point has had to be throttled well back on the lockshield valve to the point that it is perhaps an eighth of a turn from fully shut. Some radiators are fully open* and others at various degrees (pun intended!) of open. I have spent some hours over the months tweaking these radiators and none are near straining to heat the area fortunately. Of course, I have had umpteen changes as the system was commissioned in mid-February in mild weather so I have had a number of rounds of tweaks, no radiator runs out of puff so to speak. Homely has probably noticed some of my tweaks and so time is allowed to elapse between tweaking and evaluation of the results!

*We like a warm bathroom, so this radiator is totally unrestricted providing us with 24.5 - 25.5 degrees in the evenings. ‘Fun’ will be had! Regards and Thanks, Toodles.

Toodles, heats his home with cold draughts and cooks food with magnets.

Fun has been had, and the Daikin pump reports that it is pumping ~ 15 litres/min. The Wilo pump works in cubic metres/h so….. taking 60 x 15 litres =900 litres so I have set the secondary pump (radiator side of the LLH) for 0.8 cubic metres/hour for the present. Strange though it may seem, this is the speed I had set the pump after the commissioning and I was balancing the radiators initially! Some may wonder why me not the installlers? Well, I wanted the settings ‘finessed’ to my own satisfaction and they were commissioning late on a Friday afternoon - need I say more? Regards, Toodles.

Toodles, heats his home with cold draughts and cooks food with magnets.

I've been bending my brain trying to balance my LLH (Grant install one by default these days it seems - I suspect to ease the installer's job from what I've read) and didn't really follow the Heat Geek article. I've found this web-page easier to understand (maybe Heat Geek borrowed from it, or vice versa) and it explains how the ratio of temperatures on either side are affected by the flow rates.

Grant Aerona 3 10kW

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 301 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Electricity price predictions

I am always impressed with how you keep abreast of so m...

By Batpred , 2 minutes ago

-

RE: Setback savings - fact or fiction?

I fully understand your reasoning, same steady inputs s...

By cathodeRay , 11 minutes ago

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

@majordennisbloodnok I’m glad I posted this. There see...

By AndrewJ , 33 minutes ago

-

RE: What determines the SOC of a battery?

@batpred I didn't write the Seplos BMS software, I a...

By Bash , 2 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@tasos and @cathoderay thanks. I have some history grap...

By benson , 2 hours ago

-

I am having my existing heat pump changed to a Vaillant...

By trebor12345 , 3 hours ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 3 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

Just to wrap this up here for future readers: The S...

By Batpred , 6 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 6 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 8 hours ago

-

@painter26 — as @jamespa says, it's for filling and re-...

By cathodeRay , 11 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 22 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 24 hours ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 1 day ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 1 day ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 1 day ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago

-

RE: DIY solar upgrade - Considering adding more panels

I know this is a bit old, but it made me wonder what co...

By Batpred , 2 days ago