Vaillant flow rates, Delta T, buffer sizing - trying to get ASHP running well but hit a brick wall.

Posted by: @iancalderbank@squonk run the system in DHW mode and with your thermometers, see if the water going through the diverter valve, on what should be the Hot input to the DHW tank, is actually the hot ?

that tells you more about where the crossed pipe is.

That’s a good thought, I’ll need to work out how it should be, will try that when I’m next off work.

Posted by: @squonk@iancalderbank I assume it does have glycol … but I also assumed the guy knew what he was doing, and look where that got me! There are numerous other problems with the install, so I have asked a proper company to quote for a complete re-install, I think that’s the only way I’ll know it’s done right.

yes. hanging on till the summer for a reinstall sounds like the right option. Although make sure you understand exactly what company #2 are going to do as well, you don't want to be in the same boat twice! heacol on this forum and his company seem to be acknowledged masters of fixing other peoples badly done ASHP installs so you could try them.

couple of things you mentioned much earlier in the thread - lower flow rate than ideal. components like the diverter valve and magnetic filters can have a very significant negative effect on the flow rate if they are the wrong spec. The size of the input pipe doesn' mean anything. what matters is the pressure loss. Worth you checking out exactly what those parts are in your current setup, and make sure they are replaced with properly specced ones if needed.

also if you're going for re-installing would suggest you give serious thought to going for a single loop with volumiser rather than two loops with buffer. There's an article by heacol that explains this way better than I can. On the articles section of this forum, here

My octopus signup link https://share.octopus.energy/ebony-deer-230

210m2 house, Samsung 16kw Gen6 ASHP Self installed: Single circulation loop , PWM modulating pump.

My public ASHP stats: https://heatpumpmonitor.org/system/view?id=45

11.9kWp of PV

41kWh of Battery storage (3x Powerwall 2)

2x BEVs

@iancalderbank Thanks, that's an interesting article. My installation matches Option 1 (the least efficient one) so there is clearly scope for improvement. When I spoke to Vaillant they stated that the buffer tank is in fact a volumiser. I must admit I'm a little sketchy on the difference, might have to read the article again! The reason they gave for having it was that the heat pump needs a minimum circulating volume of 150l to work efficiently, and for the defrost cycle to work. I did some rough calculations and I reckon we've got about 85l in the floor and 45l in the buffer, so still a bit low by that measure. The Vaillant design documents also specify that weather compensation should be off for the system layout which I have, although I've never found a satisfactory explanation for that one.

Posted by: @squonk@iancalderbank Thanks, that's an interesting article. My installation matches Option 1 (the least efficient one) so there is clearly scope for improvement. When I spoke to Vaillant they stated that the buffer tank is in fact a volumiser. I must admit I'm a little sketchy on the difference, might have to read the article again! The reason they gave for having it was that the heat pump needs a minimum circulating volume of 150l to work efficiently, and for the defrost cycle to work. I did some rough calculations and I reckon we've got about 85l in the floor and 45l in the buffer, so still a bit low by that measure. The Vaillant design documents also specify that weather compensation should be off for the system layout which I have, although I've never found a satisfactory explanation for that one.

The volumiser, as the name implies adds volume to the system, and if my understanding is correct would normally be placed in the return pipework to the heat pump. It has one input, normally at the top, and one output at the bottom, so it contains warm water at the same temperature as the return water to the heat pump. This store of heat energy can therefore be used during any defrost cycle.

A buffer tank has at least four connections, a flow in near the top from the heat pump, a flow out near the top to the heat emitters, the return water from the heat emitters flows in at the bottom section of the buffer tank, with the final connections being the return water flowing out, near the bottom of the tank, to the heat pump. Unless the pipes are connected correctly and the flow rates are balanced, there may be mixing of the flow and return within the tank, which can seriously affect overall efficiency.

Posted by: @squonk@iancalderbank Thanks, that's an interesting article. My installation matches Option 1 (the least efficient one) so there is clearly scope for improvement. When I spoke to Vaillant they stated that the buffer tank is in fact a volumiser. I must admit I'm a little sketchy on the difference, might have to read the article again! The reason they gave for having it was that the heat pump needs a minimum circulating volume of 150l to work efficiently, and for the defrost cycle to work. I did some rough calculations and I reckon we've got about 85l in the floor and 45l in the buffer, so still a bit low by that measure. The Vaillant design documents also specify that weather compensation should be off for the system layout which I have, although I've never found a satisfactory explanation for that one.

your system as built has a minimum circulating volume of 45L. i.e. just the buffer. so that must be the min vol needed by vaillant. In your system its entirely possible for the secondary to be all off, and the buffer is the only thing in play. in fact thats why this system design was arrived at (plenty of other manufacturers have the exact same) - the ashp-to-buffer loop by itself is designed to satisfy the min volume and min flow rate, so that the ASHP doesn't cut out due to low flow, or struggle to defrost, regardless of how bad or good the min volume and min flow rate are on the buffer-to-emitters loop. but now people are realising that the mixing in the buffer is a heavy tax to pay on efficiency so are designing it without the buffer - but in doing so you have to be aware of the volume flow rate needs of the heat pump.

A buffer tank used as volumiser only has 2 pipes, one in one out. Logically speaking it makes one section of pipework very very fat and thats all. your buffer, whilst its adding volume, is not "a volumiser" in the classic sense, as it has 4 pipes: 2 in 2 out (one pair of which we know is the wrong way round).

pages 2 and 3 of this schematic from midsummer wholesale for samsung(yes I know you have a vaillant, but the basics are the same) are a pretty good simplified view of a 2 loop "buffer system" (page2) versus a 1 loop volumiser system (page 3).

given that you need to get a professional in anyway, I'd really recommend you speak to heacol's company as they should be able to sort all of it for you. message heacol on this forum or contact via https://ultimaterenewables.com/

My octopus signup link https://share.octopus.energy/ebony-deer-230

210m2 house, Samsung 16kw Gen6 ASHP Self installed: Single circulation loop , PWM modulating pump.

My public ASHP stats: https://heatpumpmonitor.org/system/view?id=45

11.9kWp of PV

41kWh of Battery storage (3x Powerwall 2)

2x BEVs

Posted by: @iancalderbankA buffer tank used as volumiser only has 2 pipes, one in one out. Logically speaking it makes one section of pipework very very fat and thats all. your buffer, whilst its adding volume, is not "a volumiser" in the classic sense, as it has 4 pipes: 2 in 2 out (one pair of which we know is the wrong way round).

Apologies for late arrival to this thread.

Accepting the obvious and hidden problems with this installation… Is it fare to say it may be easier to put right than first thought? For a knowledgable person?

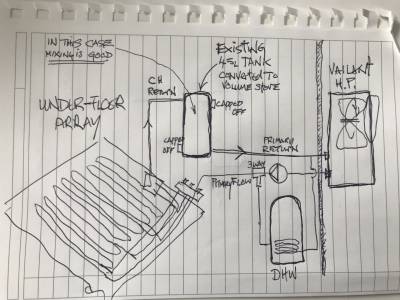

Forgiving the reverse piping and illogical header flow, couldn’t the “fat pipe” header be re-piped with just 2 connections providing a warm volumized tank with deliberate mixing occurring to balance the return temps? Just capping off the other two connectors.

The position of this tank on the primary return (as suggested above) makes sense as it means there is a reservoir of warm water closest to the heat pump ready to defrost the heat pump when required.

see sketch

Obviously it’s not that simple regarding the existing underfloor zones or secondary pumps (if there are any added complications) but I don’t think that’s been discussed in detail as yet.

one other thought I had was the spacing of the underfloor pipes since 100mm is now being recommended and if the spacing is wider this may also add to the under-performing heating. Although, since the system hasn’t worked properly yet this might not be an issue at all, but worth mentioning as a precautionary check.

@sunandair yes . your diagram is exactly what we are suggesting to the OP should be their target state - to be reached when a decent period of system downtime is possible. All quite do-able. They want to get a "knowledgeable person" in to do it for them, which is fair enough.

I don't know about the UFH spacing, not qualified.

I also suggested a quick-fix interim approach of the outdoor pipe swap to get them out of the current "wrong flow" situation with the 4 pipe buffer - but given that the crossed pipe maybe between the diverter and the buffer, rather than between the ASHP and the diverter (to be confirmed by thermometer testing around the diverter that the OP is yet to have time to do) , that may not be of any value.

My octopus signup link https://share.octopus.energy/ebony-deer-230

210m2 house, Samsung 16kw Gen6 ASHP Self installed: Single circulation loop , PWM modulating pump.

My public ASHP stats: https://heatpumpmonitor.org/system/view?id=45

11.9kWp of PV

41kWh of Battery storage (3x Powerwall 2)

2x BEVs

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 417 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

Just to provide some alternative feedback to balance th...

By Bash , 16 seconds ago

-

RE: What determines the SOC of a battery?

@batpred Ironically you didn't have anything good to...

By Bash , 8 minutes ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

Here’s a current graph showing a bit more info. The set...

By benson , 22 minutes ago

-

RE: Setback savings - fact or fiction?

True there is a variation but importantly it's understa...

By RobS , 22 minutes ago

-

Below is a better quality image. Does that contain all ...

By trebor12345 , 49 minutes ago

-

Sorry to bounce your thread. To put to bed some concern...

By L8Again , 51 minutes ago

-

@painter26 — they (the analogue gauges) are subtly diff...

By cathodeRay , 1 hour ago

-

RE: Electricity price predictions

I am always impressed with how you keep abreast of so m...

By Batpred , 2 hours ago

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

@majordennisbloodnok I’m glad I posted this. There see...

By AndrewJ , 2 hours ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 5 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 8 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 10 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 24 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 1 day ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 1 day ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 1 day ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 1 day ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago