It does sound as if your ASHP is about the right size. It might be worth checking the specs to see if your ASHP is capable of producing 5.3kW at low temperatures but I'd be surprised if it can't.

If your ASHP is the right size then that leaves the radiators. If they can't heat the house at 48 deg flow then they are undersized. Are they really reaching 48 deg? - that will feel distinctly hot to the touch. My rads only get to 42 degrees at 0 deg or below outside.

At 48 deg your COP isn't going to be great but shouldn't be that bad.

Kev

Hi @howiewsl

From the assessments that I have carried out on quite a number of ASHP's from different manufacturers, I estimate that the output capacity should be at least 1.5 times that of the heat loss calculation, which assuming that your heat loss calculation is correct, would be 7.95kW.

Of course, having the correct sized heat pump is only half the battle, in that it is still necessary to get the heat energy from the heat pump and distribute it around your home. Totaling the specified output capacity of your radiators gives a value of approximately 15.5kW, at a delta T of 50C. Based upon the information provided, I estimate that to heat your home to 21C, with an outside air temperature of 2C, would require a water flow temperature of approximately 40C. But this would only be true if all the heat energy is being transferred from your heat pump to your radiators and distributed in a fairly even manner.

If you do not already have one, I would suggest that you invest in one or more suitable thermometers, so that you can measure and record the various temperatures around your system.

Measure the temperature of each radiator in turn, taking a measurement at the top and the bottom. Measure the temperature of the flow and return pipes at each radiator, and note how they vary when the heat pump is running or stopped. Measure the temperature of the pipes entering and leaving the buffer tank, to see if there is any mixing of the warmer and cooler water taking place.

Try to draw a diagram of how your system is installed, so that you can add the temperature measurements, which may indicate where the heat energy is being dissipated.

There seem to be two issues:

£5 a day

It's not warm enough

Taking the first of these - 'since you've a 5p/24p tariff, the number of kWh depends on when you use the ashp. Using the EPC values of 2135kWh for DHW, and assuming this is at 5p/kWh, means (2135kWh/365)*5p/2.5 = 12p/day

Again from EPC, I would expect average winter heating bill to be (11487kWh/180)*24p/3 = 510p/day

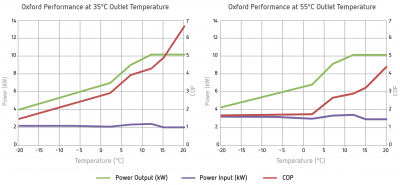

The COP comes from the snip below, which shows two graphs with the higher output temp one on the right giving lower COPs. It's normal to get in the range of 5 down to 1.5 depending on flow temp and whether the dreadful inbuilt immersion kicks in. My calc. above though seems very close to what you are actually paying I'm afraid. To make it cheaper, you would need to do one of the following:

Insulate the house more to reduce demand heat. Reduce the flow temperature to increase the COP, so less electricity is needed to provide the heat. Operate more during the cheap period of day, so that the electricity provided costs less.

As to why isn't it warm enough - that seems odd, given 8kW > 5.3kW. Doubly odd, if it only heats for 7 hours a day. Have you got the "Oxford" 8kW ashp by GES - I think the heat drops off as it's cold out, down to 6kW at 0C (snip from their datasheet). Why doesn't it keep heating until the setpoint though? Do you have anything throttling the heat - eg. thermostatic radiators that are switching off? Given you have glycol, there is often a heatexchanger somewhere so the house rads run on water not glycol, and an indoor pump for this. Is that what you have - if so this indoor pump may be slaved off the GEC ashp (which has a pump in it), or it might be independently controlled?

I suggest that you invest in an infra red thermometer - they're only £10 or so from ebay. It can quickly check all of the radiator temperatures. I know it's warmer now, but I suggest turning all TRV's to high, and the main thermostat high. Wait for the system to stabilise, then record the temp of every radiator in a few places - some may be blocked, some TRVs may be broken. What we want is all the radiator surfaces to be at the output temperature of the ASHP, effectively transmitting the heat, giving more future scope to reduce the temperatures and improve the COP. What we do not want, is something dropping that 48C ashp flow temperature; the buffer, a heat exchanger, TRV etc.

In general though I think the optimum way to operate your system is likely to be:

Never use the immersion

All common room (downstairs?) radiator TRVs on high

Heating set to run 24/7

DHW set to run at cheap rate elec

Drop the flow temperature, such that on the coldest day the system can only just keep up. Ideally we want this <40C, to get the COP higher.

I second the point and shoot IR thermometer suggestion, they are very useful. You need to be aware that they come set to a certain 'emissivity' which works for many surfaces but not copper pipes (and other shiny metal surfaces). This can be fixed to some extent by attaching a piece of black insulating tape where the measurement is to be taken. Also bear in mind the measurement cone isn't where the laser dot shows up at close range. I just place the measurement aperture in contact with whatever i am measuring and take the reading.

Mysterious heat losses are definitely a thing. My leaving water temperature (temp of water leaving the heat pump) ranges up to around 51 degrees but the rads never get anywhere near this. On one occasion whens I measured them, they ranged between 20-something and 30-something degrees (at the top), when the LWT was 50 degrees). This was on a recent cool morning, so it seems reasonable to assume the the system was in steady state, as it is on 24hours/day. The returning water temp was 45 degrees.

This suggests the primary heat pump circuit was doing pretty much as expected, with water at between 45-50 degrees, but the heat was not getting to the secondary rad circuit, which was on average around 30 degrees, far far cooler than the water in the primary circuit. I still think the plate exchanger (which I have) is responsible to the failure to transfer the heat, and measurements taken off the pipework using the insulating tape trick seem to confirm this: PHE leaving water temp 41 degrees, returning water temp 31 degrees. Despite being in steady state, these measurements can be quite volatile, so I am not sure how much reliance can be placed on them, but a sanity check by putting a hand on the pipework and rads suggests these readings are not that far out.

Which brings us back to the debate about the need for buffers and heat exchangers... I can still see pros (protect primary circuit) and cons (inefficient transfer, need for another circulating pump (£££) which might also be a plus as well, as heat pump circulating pump has less hard work to do), and then there is the Freedom lack of clarity about whether they are needed for the guarantee. I'm still waiting for my installer to come back from his extended holiday (it was planned ages ago, not a response to attempting to install my heat pump!), and will discuss it with him then.

@howiewsl - I wonder what kind of insulation etc your property has, as a total heat loss of 5.3kW at -2.2C seems on the low side? My 3 bed house has a loss of over 12kW at -2, but is an old listed building with solid stone walls etc. As mentioned earlier, heat loss calcs in practice vary. Do you have a copy of the room by room calcs, which you can check makes sense? If not, Freedom's heat pump tool (an Excel spreadsheet) has a heat loss calculator worksheet (copies available via links in various posts on this forum), and @batalto has generously made his version available in his signature.

Midea 14kW (for now...) ASHP heating both building and DHW

Hi @cathoderay

I would suggest that you check the specification of your PHE to confirm that it is of adequate size for your system.

Usually heat exchangers used in plumbing are bphe (brazed plate heat exchangers). They have two connections at each end, and should always be used in counterflow. So at one end it’s fluid1 in and fluid2 out. The orientation doesn’t matter -it does if there is a gas-liquid phase change, but not for plumbing.

The heat transfer can be calculated based on size and number of parallel internal plates, and assuming glycol:water turbulent heat transfer of around 1000W/degC/m^2. The total heat transfer area is A*B*(n-2). The number of plates is normally printed on it, or you can count them on the side.

So as an example, a small £50 bphe of 7cm by 18cm with 24 plates will have total heat transfer area of 0.07*.18*(24-2)=0.277m^2, and a conductivity of 1000*0.277 =277W/degC.

If 6000W were transferred through it, it would suffer a temperature drop of 6000/277=22degC. I would consider this too high, as it’s forcing a higher heatpump temperature to be used, dropping the COP, so causing more electrical power to be used. I would aim as a guess for around a 5C drop.

That 1000 factor could be different, eg. clever patterns in the bphe increase turbulence which increase it. Measuring the temperature drop is better than calculating it, it avoids all the unknowns.

Posted by: @roblUsually heat exchangers used in plumbing are bphe (brazed plate heat exchangers). They have two connections at each end, and should always be used in counterflow. So at one end it’s fluid1 in and fluid2 out. The orientation doesn’t matter -it does if there is a gas-liquid phase change, but not for plumbing.

The heat transfer can be calculated based on size and number of parallel internal plates, and assuming glycol:water turbulent heat transfer of around 1000W/degC/m^2. The total heat transfer area is A*B*(n-2). The number of plates is normally printed on it, or you can count them on the side.

So as an example, a small £50 bphe of 7cm by 18cm with 24 plates will have total heat transfer area of 0.07*.18*(24-2)=0.277m^2, and a conductivity of 1000*0.277 =277W/degC.

If 6000W were transferred through it, it would suffer a temperature drop of 6000/277=22degC. I would consider this too high, as it’s forcing a higher heatpump temperature to be used, dropping the COP, so causing more electrical power to be used. I would aim as a guess for around a 5C drop.That 1000 factor could be different, eg. clever patterns in the bphe increase turbulence which increase it. Measuring the temperature drop is better than calculating it, it avoids all the unknowns.

I'm not sure I understand; are you saying if you have a PHE then water out is 5 deg less (or even 22 deg less) than water in? Where does all that energy go? My water return flow is 5 deg less than output but that's after heating the whole house.

If you have a PHE, then there will be a temp drop between the two separate liquids, and this temp drop is what pushes the heat flow from one liquid to the other. It’s the same heat; you haven’t lost any ‘power’, but the same heatflow(actually power in Watts not in temperature units) is at a lower temperature so is less useful. I admit it’s not intuitive, that you haven’t lost power somewhere. In contrast the temp diff into and out of the heatpump (*flow rate) is the same fluid and does show the power. So too does the temp difference *flow rate through radiators.

You just want the temp drop to be low, when the unit is working at full power. It has a similar effect as making radiators smaller, or putting blankets on them - the heatpump will need to be run hotter so less efficiently to get the same average heat into the room to keep it warm.

To be clear- we ideally want the radiators to be within 5C of the heatpump output. If it’s a long way off, it could hopefully be improved somehow (bigger bphe, open up rad valves, faster water flow). Ultimately we want to be able to drop the HP temp, to get the best COP we can.

I have sometimes seen power ratings on a PHE, but not with an associated temperature drop. And I’m sure it will be with water:water, which is fully twice the transfer rate, so twice the power of glycol:water for a given temperature drop. In my above example bphe, water:water would have DT=11C at 6kW.

I don't have much to add. There is a lot of good information and suggestions already posted by others. I won't attempt to comment on your actual ashp setup.

There are so many things that might need adjustment/upgrading/adding/removing to get the optimum setup. It can sound overwhelming (to me anyway).

My overriding general initial thought was that the EPC and separate heat loss numbers for a Victorian house with 80% of the external solid brick walls sounds low. Of course it may be fine. EPC data is of variable quality though as is the MCS heat loss numbers. You can look online for EPC reports for properties so you could look at neighbouring houses etc as a comparison.

https://www.gov.uk/find-energy-certificate

We found that useful.

You say you have good insulation in the suspended floors and roof. Is this something you fitted yourself or was that the previous occupant? For example our EPC said our roof insulation was good, i would say it was mixed....

As well as looking at EPCs for similar houses, chatting to neighbours might also be useful to understand their energy use and setups and what they have done to the fabric of their home. We found it useful.

We have 2 power showers in our house, obviously not the greenest of appliances... the temperature of the water in the tank makes a dramatic difference in our case to the length of showers you can have, especially if you like hot showers. Just wondering what sort of showers you have?

It would be useful to know how many kWh the ashp has used per month since it was installed. Even proxy monthly figures from the smart meter if nothing else is available historically. I am not sure the £5 figure is helping other posters get an idea of the scale of the issue which may help.

Doing your own comprehensive as possible room by room heat loss calculation feels like a good idea. By using the information from your installers, neighbours, other EPCs, the knowledge you have gained about your house since you moved in etc. Of course it won't be perfect but it might give you some pointers to inform other things to investigate and change that have been highlighted by others.

Getting the right setup to heat old homes and figuring out what to improve regarding the building fabric can be challenging in my experience. It is possible with patience and some compromises and investment irrespective of your heat source (we have stuck to our mains gas boiler for now so are yet to go through yet another learning curve).

The PHE has been one of the goblins in my system. Initially I accepted it as the (now known to be older) Freedom installation manual said it or a buffer had to be fitted otherwise there would be no guarantee. The initial installation was completed at 5pm on a Friday and at that point the DHW worked, but all the rads were cold, despite pumps circulating, and the primary circuit being warm. My installer and his plumber said the problem was airlocks/sludge blocked pipes but this seemed unlikely as previously the oil fired boiler had warmed all the rads normally on the rare occasions I used it. I spent the following weekend trying to make sense of things and then realised the PHE had been plumbed in with same direction flow ie both circuits in at one end, both out at the other, ie not contraflow, which, as @robl says, is how they should be set up (its obvious if you think about it, it maintains the maximum temp gradient throughout the PHE). I then confirmed with the PHE manufacturer that it should be contraflow, and also incidentally that although best practice was to have the PHE orientated vertically (helps clear air from the PHE), they can sometime be OK horizontally, as mine was. My installer said horizontal installation was his normal practice, and PHE was a generic one supplied I'm pretty sure by Freedom on a one size fits all basis ie it was a big enough exchanger to cover any and all AHSPs up to 16kW. Unfortunately there is no easy way to identify the model/rating of the PHE, as it has been plumbed in in a very tight space with an insulation jacket around it which could only be removed by breaking it up. Even accurate external dimension are impossible to determine because of the limited access.

The flow in the secondary rad circuit was reversed (circulating pump rotated 180 degrees), and the rads started to warm up, but erratically. A powerflush was done (should really have been part of the original installation), without much effect. Over time most rads seemed to warm up a bit (luke warm at best), and on a second visit the plumber flushed the ground floor rad circuit using mains pressure (and in the process somehow managed to trip the pressure relief valve (the circuit is unvented) so at least we now had a pressure test, and no leaks evident (the pipework is unchanged, still the original 28/22/15mm flow and return pipes). Now most of the rads warm up some of the time. I have tried to balance them, but difficult to do when they behave erratically. All TRVs are fully open, and the rad circulating pump is set to max constant pressure.

Ad hoc readings just now with 4 degrees ambient outside and room stat at 21.0 and system in (presumably) steady state:

All rooms at or a degree or two below design temp (but we are not at -2 ambient...)

All rads luke warm, range 22 to 36 (these are outliers, most are in the upper 20s)

Midea controller reports LWT 47/RWT 42 (this is about right, both for current weather comp settings and differential between LWT/RWT)

IR temp on black insulating tape on PHE pipes: primary flow (in) 40 return (out) 31, secondary flow (out) 42 return (in) 31

Ditto, about 10 mins later: Midea controller 50/44, primary pipework 47/43, secondary pipework 47/41

These figures are actually some of the best from the PHE, the secondary flow out temp is close to/matches the primary flow in (40=>42 !?! and 47=>47). They also show how volatile the readings are, both from the independent measured Midea controller and IR thermometer, ie 'steady state' is not very steady.

But: the rads are nowhere near the heat pump LWT, rads say an average of 28-29, LWT 47-50 degrees, around 20 degrees difference. At the moment some of the loss appears to be happening between the heat pump and the PHE (pipes are all lagged throughout), the PHE isn't doing too badly (which is unusual) and the oddity is the difference between the average of the secondary flow and return (~35, then ~ 44) and the rads (~28). Conventional theory has it that the rads should be ~ half way between the flow and return, ie 35 to 44 degrees, but they are far cooler, ~28 degrees. The rad temps are all top middle warmest panel readings, many of the three panel K£s (not a typo...) have noticeably cooler front panels, and all rads are only warm at the top.

I don't know what to say. Given the above readings, the PHE can at least on occasions function as it should, degrees C in the primary in get transferred to degrees C in the secondary out (but it is not always so), but there is something odd about the transfer of heat from the circulating water to the rads: average circulating water temp 35 - 44 degrees, rads around 28 degrees. It shouldn't be possible...

@robl - just seen your reply which you posted while I was writing the above. Yes, I do get we are using a sort of proxy/shorthand, degrees C instead of watts (power) and kWh (energy), but that is perhaps because it is more intuitive, and also it is what we can measure without fancy equipment. I also know you can't 'disappear' energy, it has to go somewhere (unless and until e = mc2 kicks in). "To be clear- we ideally want the radiators to be within 5C of the heatpump output" - exactly, and that is what we haven't got, but the reasons are not immediately apparent.

PS I appreciate this is a partial highjack of @howiewsl's thread, but it is the same general topic, under-performing systems. FWIW, my current weekly energy use for the heat pump on its own meter is ~250kWh, or £62.50 a week at 25p/unit, or just under £9/day. Ouch. And the weather over the last week has been mild.

Midea 14kW (for now...) ASHP heating both building and DHW

@cathoderay I feel for you. Our total power use for the month so far is just over 800kw and that's everything in the house and the ASHP.

https://renewableheatinghub.co.uk/do-air-source-heat-pumps-really-need-glycol?amp=1

Just posting as there has been mention of glycol.

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

2 days ago

-

Rodents! A word of warning for heat pump owners

3 weeks ago

-

Ecodan Pump Issues… Circulation pump turns off when heat pump compressor turns off

1 month ago

-

Running my new Nibe ASHP efficiently

1 month ago

-

Weather compensation- why you should use it

1 month ago

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 217 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

No you arent, because you dont need any, and furthermor...

By JamesPa , 25 minutes ago

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

Can you link them to Home Assistant so they can be inte...

By JamesPa , 30 minutes ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@tasos ignore the set LWT value on the graph before aro...

By benson , 34 minutes ago

-

RE: Electricity price predictions

I have often thought the same. In Italy (I am told) th...

By JamesPa , 36 minutes ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

As I mentioned earlier most radiators have a power outp...

By JamesPa , 59 minutes ago

-

RE: Our Experience installing a heat pump into a Grade 2 Listed stone house

@travellingwave Looking forward to hearing the rest ...

By MK4 , 2 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

As a side note I observed the the charge/discharge time...

By Bash , 2 hours ago

-

RE: What determines the SOC of a battery?

@batpred Ironically you didn't have anything good to...

By Bash , 12 hours ago

-

RE: Setback savings - fact or fiction?

True there is a variation but importantly it's understa...

By RobS , 13 hours ago

-

Below is a better quality image. Does that contain all ...

By trebor12345 , 13 hours ago

-

@painter26 — they (the analogue gauges) are subtly diff...

By cathodeRay , 14 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 20 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 22 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 2 days ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 2 days ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 2 days ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 2 days ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 2 days ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 2 days ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 2 days ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 2 days ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 2 days ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 3 days ago