Secondary pump speed - how much slower should it be?

I now know that the secondary heat pump connected to the LLH should run more slowly than the primary pump - but how much slower please? I think that the faster the pump runs, the more the water circulates and has an opportunity to deliver ‘fresh’ hot water to the emitters but.. I’m also told that the slower the water circulates, the greater amount of heat can be transferred to the emitter. Maybe I have it wrong or there is a compromise (or should I say balance?) somewhere between these two settings? Regards, Toodles.

Toodles, heats his home with cold draughts and cooks food with magnets.

the smallest amount slower that you can reliably engineer. The thing you are trying to tune out is mixing of hot and cold flows within the LLH, which is done by trying to achieve identical flow rates each side. If one side has to be slower, its better for it to be the secondary.

In a system with no LLH or buffer just a single loop the tuning reason is different, in that case the faster the flow the more heat you can move (for the same DT).

That is also true for an LLH / buffer system but its more crucial to get the flow rates both sides close to the same. one side going noticeably faster than the other will cause mixing and that will kill efficiency.

"slower it moves more heat can be emitted" : no. the water will come out of the radiator colder, but that doesn't mean more heat was emitted. emitted heat is related to average water temp in the radiator - which is (input temp + output temp)/2 . reduce the cold output side you reduce that value.

My octopus signup link https://share.octopus.energy/ebony-deer-230

210m2 house, Samsung 16kw Gen6 ASHP Self installed: Single circulation loop , PWM modulating pump.

My public ASHP stats: https://heatpumpmonitor.org/system/view?id=45

11.9kWp of PV

41kWh of Battery storage (3x Powerwall 2)

2x BEVs

@iancalderbank Thank you Ian, I have attempted to tweak the pump as close to ‘just slower than the average speed of the primary pump; and will content myself that I have done all I can to optimise this setting then! Regards, Toodles.

Toodles, heats his home with cold draughts and cooks food with magnets.

Posted by: @toodles@iancalderbank Thank you Ian, I have attempted to tweak the pump as close to ‘just slower than the average speed of the primary pump; and will content myself that I have done all I can to optimise this setting then! Regards, Toodles.

Going back one step, what's the llh there for?

Buffers of a sufficient size correctly plumbed can be made to work (as in not materially compromise performance) by implementing a feedback loop so that on average the primary and secondary pumps run at exactly the same rate. The buffer then remains stratified and no mixing occurs. Many heat pumps have the functionality to do this built in.

An llh is surely just a very small buffer. As far as I am aware it's essentially impossible to avoid at least some mixing and thus loss of efficiency. This being the case they are best avoided unless there is a very specific reason for their presence.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

@jamespa I think the question was from the point of view of "toodles has an LLH, no prospect to do anything different , what should the pump tuning be"

I'm intrigued by your comments about a feedback loop. What would that be in practice, how would it work?

My octopus signup link https://share.octopus.energy/ebony-deer-230

210m2 house, Samsung 16kw Gen6 ASHP Self installed: Single circulation loop , PWM modulating pump.

My public ASHP stats: https://heatpumpmonitor.org/system/view?id=45

11.9kWp of PV

41kWh of Battery storage (3x Powerwall 2)

2x BEVs

Really interested in this topic and I am having to change secondary pump to get variable speed. However, I can't see why we should be talking about relative speed when I would have thought that it is relative flow that matters.

Also interested in "feedback loop" suggestion.

342sq m "Upside down" house in Algarve. Portugal

Mitsubishi PUHZ-120YUK 16kW ASHP

12 Solar Panels Growatt Inverter

2 x Growatt 7.5kW Batteries

Fronius EV Charger

Kia e- Niro 64kW

Hi @toodles I have a Daikin Altherma HT with a LLH feeding two 'zones' - one for UFH and one for rads. I have two DAB secondary/ circulating pumps immediately after the LLH which I've played around with for the past few years more on a trial and error basis informed by internet research. Where they currently are - and that may change - is one pump set to 3 (max of 3) on the UFH loop, constant pressure; and 1 (lowest of 3) on the rads, proportional pressure. The flow rates at the manifold for the UFH refused to hit even 1 l/m with the pump on anything other than 3 (I've seen someone else state similar here but can't recall who); whereas if I put the pump for the rads on anything other than 1 I get a whooshing sound in the radiators which the valve manufacturer tells me that means the pump needs to be dialled down. With the LLH, this probably isn't ideal but if I ran both pumps at the same speed one 'zone' seems to suffer.

I'm a bit unsure about having the rads pump set on proportional pressure...Grundfos say that for UFH 'the pump should be set to the constant pressure setting where the differential pressure is kept constant, securing a constant flow in each individual zone, independent of other zones' and for rads with TRV's 'pump should be set to the proportional pressure setting where the differential pressure adjusts proportionally to the required flow in the system'. Now, I have TRV's on my rads but they are all locked at 5 so in my layperson's world that suggests that constant pressure may be a better setting since there are no valves or such downstream of the circulating pump which could alter the pressure (I think!) - whether changing this would make any practical difference I have no idea.

Posted by: @iancalderbankI'm intrigued by your comments about a feedback loop. What would that be in practice, how would it work?

Temp sensor (or two) in buffer monitor where the thermocline is, heat pump adjusts the flow from the heat pump accordingly, thus keeping the separation between flow and return and avoiding mixing. It is, as I understand it, the fundamental basis on which a correctly plumbed and controlled buffer works and if its not done this way then it hasn't been done correctly.

Here is text I posted a few weeks ago on how buffers should work.

"I think its worth rehearsing the theory of how buffer tanks are supposed to work.

Firstly as @derek-m says any temperature drop between the primary and secondary flow will reduce efficiency. Very, very roughly the reduction is 2-3% per degree C which is why Im saying a 4C drop will cost 10% or maybe a bit more. You can check the COP curves for your machine at the actual flow temperatures to get a more precise value.

The flow-flow temperature drop is caused by mixing between flow and return in the buffer tank. In a sufficiently well designed, sufficiently tall, sufficiently large and sufficiently well controlled buffer tank there is negligible mixing, in the worst case of one which is poorly designed/set up the mixing will cause a flow-flow temperature drop equal to the temperature drop across the emitters (which is close to the situation you have). It definitely is possible for a buffer tank to operate correctly, people have posted actual measurements, but its probably more likely that it doesn't unless the installer really knows what they are doing!

This desired situation is achieved because hot water enters ands leaves at the top and cold water enters and leaves at the bottom at, on average, exactly the same rate. A temperature gradient establishes top to bottom and, while it may gently move up and down the tank, it never reaches the bottom or the top because both secondary and primary pumps are either a)operating at exactly the same speed (which of course wont in practice happen) or b) modulated on and off by the heat pump controller (or another mechanism) so that the average flow rate is the same and the difference in instantaneous flow rate never causes the tank either to be dominated by secondary water or dominated by primary water.

Additional to the above if, as @derekm says, the secondary runs a bit faster than the primary, then its the secondary which turns on/off to achieve this state, thus avoiding the throttling of the heat pump output which would occur if it were the primary that is turned on/off. However without the control/feedback loop described above, you might actually be better having the secondary operating very slightly slower than the primary, so that flow water dominates the content of the tank not return water (@derek-m do you agree or is this wrong?)

The above also depends on the buffer tank being tall enough that the thermal gradient can establish (horizontal buffer tanks don't work properly for this reason), the inlets/outlets being sufficiently well designed internally that there is little internal turbulence, and of course the heat pump being correctly connected to the pumps and thermocouples in the buffer tank that it can control both correctly (In principle a pair of thermostats connected to the call for heat of the heat pump could also control the pump on/off, but I think that this is a bit difficult with WC also operating - others may correct me though).

The ecodan controller expressly supports buffer tanks (I dont have the connection diagram to hand nor do I know exactly how it controls and to what extent it achieves the ideal situation described above). I think it also needs to be set up on the FTC unit in installer mode. From the sounds of it, I doubt your installer has bothered to implement the control properly. This is, in my view, unforgivable - if you are going to impose a (very likely superfluous) buffer tank at least have the decency to ensure that its properly connected and controlled!

(BTW the establishment of a temperature gradient also happens in DHW tanks which is why you can get close running all the hot water out before it starts to run cold.)

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

Posted by: @jamespaTemp sensor (or two) in buffer monitor where the thermocline is, heat pump adjusts the flow from the heat pump accordingly, thus keeping the separation between flow and return and avoiding mixing. It is, as I understand it, the fundamental basis on which a correctly plumbed and controlled buffer works and if its not done this way then it hasn't been done correctly.

that makes total sense in terms of buffer theory. I wasn't aware though that any HP vendor had a control setup that takes care of this and I've not seen any buffer setup posted anywhere ever that uses this? but I don't tend to read the ecodan threads in detail. Are you saying ecodans have this builtin and every ecodan should be done this way?

My octopus signup link https://share.octopus.energy/ebony-deer-230

210m2 house, Samsung 16kw Gen6 ASHP Self installed: Single circulation loop , PWM modulating pump.

My public ASHP stats: https://heatpumpmonitor.org/system/view?id=45

11.9kWp of PV

41kWh of Battery storage (3x Powerwall 2)

2x BEVs

Posted by: @iancalderbankPosted by: @jamespaTemp sensor (or two) in buffer monitor where the thermocline is, heat pump adjusts the flow from the heat pump accordingly, thus keeping the separation between flow and return and avoiding mixing. It is, as I understand it, the fundamental basis on which a correctly plumbed and controlled buffer works and if its not done this way then it hasn't been done correctly.

that makes total sense in terms of buffer theory. I wasn't aware though that any HP vendor had a control setup that takes care of this and I've not seen any buffer setup posted anywhere ever that uses this? but I don't tend to read the ecodan threads in detail. Are you saying ecodans have this builtin and every ecodan should be done this way?

Thats my understanding and how it has been described to me by someone who has a buffer tank set up properly, and has demonstrated so with fully convincing measurements (in the course of convincing me that buffers can work).

I confess I haven't verified it personally, but the fact is that any buffer not set up this way is effectively operating open loop, so is bound to mix at least to some extent.

I enclose two clips below from Mitsubishi which illustrates that there is some capability, some other heat pumps also say they do buffer control. They don't make it clear what that means so far as I can recall, however the obvious is simply to use the mid tank thermistor either to modulate the pump or switch it on and off, which will achieve whats needed provided that the relative pump speeds are biased correctly. Its possible I have made too many assumptions about what the heat pumps actually do, but if I have then buffer tanks really are the work of the devil!

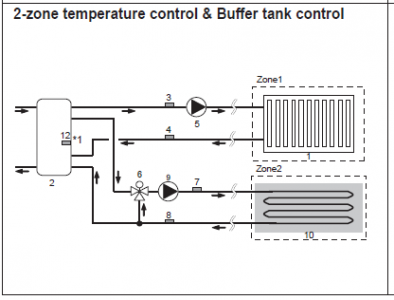

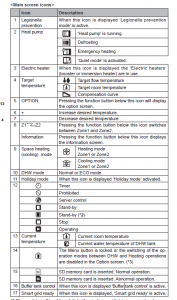

See this diagram

and item 16 on this

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

@jamespa when I read up on this way back, before being convinced that a buffer was totally unnecessary, I was pretty sure I learned that some heat pumps can work in a "buffer control" design in that they use the value of the temperature in the buffer, to determine what the HP does, . i.e the HP's control loop keep the buffer temperature within a band. a demand-side thermostat controls whether the 2ary side pump runs. That design wouldn't stop mixing.

What I didn't find any evidence of was any HP clever enough to balance 1ary and 2ary flow rates either side of a buffer automatically. I can't see how it would be able to without having either flow rate meters or precise DT measurement, and PWM control of pumps, on both sides. I think @rachel-lee has been trying to do this on their system as a DIY design. If there's someone's system out there that you've learned about , that does this out of the factory I'd be really interested to see its data.

My octopus signup link https://share.octopus.energy/ebony-deer-230

210m2 house, Samsung 16kw Gen6 ASHP Self installed: Single circulation loop , PWM modulating pump.

My public ASHP stats: https://heatpumpmonitor.org/system/view?id=45

11.9kWp of PV

41kWh of Battery storage (3x Powerwall 2)

2x BEVs

Posted by: @iancalderbank@jamespa when I read up on this way back, before being convinced that a buffer was totally unnecessary, I was pretty sure I learned that some heat pumps can work in a "buffer control" design in that they use the value of the temperature in the buffer, to determine what the HP does, . i.e the HP's control loop keep the buffer temperature within a band. a demand-side thermostat controls whether the 2ary side pump runs. That design wouldn't stop mixing.

What I didn't find any evidence of was any HP clever enough to balance 1ary and 2ary flow rates either side of a buffer automatically. I can't see how it would be able to without having either flow rate meters or precise DT measurement, and PWM control of pumps, on both sides. I think @rachel-lee has been trying to do this on their system as a DIY design. If there's someone's system out there that you've learned about , that does this out of the factory I'd be really interested to see its data.

I will be quite frank and admit that your questions had me re-evaluating my assumptions. I will have to look back a long way on the buildhub forum (which I will do) and see if I can find the thread

update - its here https://forum.buildhub.org.uk/topic/31313-what-are-the-design-principles-informing-the-which-pump-and-ufh-design-question/page/4/ The other main protaganist was ReedRichards

It was an interesting discussion where I was challenging the poster on the practicality of making a buffer tank work with approx. zero mixing and he successfully convinced me it can having posted both a coherent explanation and evidence to match (or so it seemed at the time). I remain convinced, at least for now, but also a bit questioning. I had the distinct impression that it was controlled by his heat pump, noted that several heat pumps feature buffer control, and made the connection, perhaps incorrectly that they (the heat pumps) do the sensible thing.

Contrary to what you are saying above I can see how it can work. Ideally there are two thermocouples in the buffer tank, say one third and two thirds in the height. The heat pump then modulates its own pump (or turns it off if needed) to ensure that the transition from flow temperature to return temperature happens between the two. But even with one thermocouple it can still do it. It knows the flow temperature, and it knows that this is approximately the temperature at the top of the tank. It knows the return temperature, and it knows that this is the temperature at the bottom of the tank. So it can control the flow driven by its pump such that the temperature at the middle thermocouple is kept somewhere between these two with a bot of a guard band. Stratification takes care of the rest provided that the buffer is tall and the flow rates/inlet designs don't cause too much turbulance. This then guarantees that the thermocline, where flow water meets return water, remains between the inlets and the outlets. Note that there is absolutely no need to match primary and secondary flow rates on an instantaneous basis, only on average (averaged over the time it takes for any difference in instantaneous rates to amount to say 3/4 of the volume of the buffer tank).

Re-reading key parts of the thread in question, whilst ReedRichards appears to agree that it works as I describe above, he finishes off by saying that his heat pump doesn't know about the buffer tank! So Im now wondering how it does in fact keep things working in the way we want in his case, and what Mitsubishi and other pumps that do know about the heat pump actually do with the additional information (hopefully control their water pumps effectively to match average flow!).

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

- 26 Forums

- 2,417 Topics

- 54.8 K Posts

- 186 Online

- 6,096 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Octopus Cosy 12 Heat Pump Regret: Incredibly Loud, Poor Heating & Constant Hum - Help!

So, after much anguish, and even visiting the neighbour...

By razz , 51 minutes ago

-

MLCP (Multi-Layer Composite Pipe) for ASHP

@editor nope. The info you reported was sufficient for ...

By iotum , 3 hours ago

-

RE: Advice for a novice on Mitsubishi Ecodan 6kW

@robs Quick response while I'm in stationary traffic le...

By Sheriff Fatman , 3 hours ago

-

RE: Setback savings - fact or fiction?

Maths looks right to me, my only question about this ca...

By JamesPa , 4 hours ago

-

RE: Ideal HP290 14kW ASHP - how to optimise

@jamespa I wasn’t offended at all. You are very knowled...

By Davesoa , 4 hours ago

-

RE: Experience - New Build / Complete New Heating System

@vincro I would be surprised if it is much above 5 to 6...

By ASHP-BOBBA , 4 hours ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

Yes, certainly not enough could have been tested in any...

By Batpred , 5 hours ago

-

RE: Post-Traumatic Heat Pump Stress Disorder

Yes bang on and maybe I can illustrate that by way of e...

By iotum , 7 hours ago

-

-

RE: Replacing my 18 month old Hitachi Yutaki ASHP

A big thank you to @jamespa for all his efforts online ...

By trebor12345 , 10 hours ago

-

RE: GSHP WOES! Midland based engineer recommendations?

@editor It is indeed for servicing. My current service ...

By Morgan , 10 hours ago

-

RE: Sunsynk Whole House Backup Issue

Hi @lostandconfused , I agree that topic/thread is the ...

By Batpred , 11 hours ago

-

RE: Speedcomfort radiator fans

In case it helps Andrew Kuhne on openenergy monitor has...

By JamesPa , 11 hours ago

-

Things have gone quiet with you @drei. Any updates?

By Mars , 14 hours ago

-

RE: Passiv Smart Thermostat - Help & Forum Support

Thanks @tim441. Interesting timing, as Passiv are a cur...

By Mars , 16 hours ago

-

Hi everyone, I have a two year old Marlec Solar iBoos...

By Tallmarc , 19 hours ago

-

RE: Please help with the settings ecodan

Are you trying to address any particular performance is...

By Sheriff Fatman , 1 day ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

🤣 Well, I never managed to get the HA solis "...

By Batpred , 1 day ago