On a positive note, something of a breakthrough on the energy in calculations, and the need for a 1.18 correction factor. Against expectations based on my past experience, Freedom Heat Pumps have replied to my email (credit very much due where credit is due, and a very welcome change) and it turns out the 'amps_in' (modbus register address 118) variable is indeed just the compressor current. I was unsure/confused about this because in the modbus tables it is labelled as 'Outdoor unit current (Outdoor unit operating current, in A)' and 'Outdoor Unit' suggests, at least it did to me, the whole unit, but then again there is the 1.18 anomaly. It turns out (by comparing in real time what appears in the minute data file with what is displayed on the wired controller), the value at register address 118 is the same as the value shown on the wired controller on Operational Parameter page 6/9 under COMP CURRENT, which FHP have confirmed is indeed the moment by moment real time compressor current, and only the compressor current.

This explains the anomaly between the calculated energy in and the energy in recorded by the external kWh, and thereby why a correction factor is needed, and further confirms that it is not just valid, but necessary, to use a correction factor. That said, it is not ideal, because the correction needed does vary, meaning I have to use an average correction factor. Nonetheless, that is better than not using the correction, and using a current value that I know is too low.

It may also mean we have a general indication of what the standing load (circulating pumps, ancillaries etc) is, the difference between the compressor current and the corrected total amps in figure (which is close to but not identical to, the external kWh meter figure), very roughly, on average, and only applies to one installation in one house that has two circulating pumps that run continuously when the heating is on, even when the compressor is off, of the order of 250W. That doesn't seem too unreasonable to me.

All this somewhat adds weight to the case for getting a modbus enabled external kWh meter. I shall give it some thought.

Midea 14kW (for now...) ASHP heating both building and DHW

Posted by: @sunandairThere have been many people over the past year, shocked and surprised at how quickly heat is lost from a hot water tank.

Me too, but I fear it is a fact of life that modern DHW tanks aren't in fact that well insulated. Mine drops most days by about ten degrees, from 50 degrees (the set temp) to 40 degrees, which is the trigger for a reheat, even with only minor hot water use, which means most days I have a reheat cycle. My DHW is on a timer, to come on between 1300 and 1400 every day.

I try to console myself that the heat lost, at least in winter, is partly lost to the house, so it isn't all wasted. In summer, it surplus to requirements and so it is a waste.

I have the target set to 50 degrees not because I need 50 degrees, but so that I will still have warm enough water towards the end of the cooling down period. I think if I set it any lower than this, and then have an evening bath/shower, I will be left with water too cold for the next morning.

Midea 14kW (for now...) ASHP heating both building and DHW

Posted by: @cathoderayMe too, but I fear it is a fact of life that modern DHW tanks aren't in fact that well insulated. Mine drops most days by about ten degrees, from 50 degrees (the set temp) to 40 degrees,

this shouldn't be the case. If its modern, it has to be well insulated or they can't sell it. Mine has only dropped 1C over 8 hrs. Have you insulated all the pipework around the tank? particularly the hot ones which will be acting as radiators. Doing that made a huge measurable difference for me.

My octopus signup link https://share.octopus.energy/ebony-deer-230

210m2 house, Samsung 16kw Gen6 ASHP Self installed: Single circulation loop , PWM modulating pump.

My public ASHP stats: https://heatpumpmonitor.org/system/view?id=45

11.9kWp of PV

41kWh of Battery storage (3x Powerwall 2)

2x BEVs

Posted by: @iancalderbankthis shouldn't be the case. If its modern, it has to be well insulated or they can't sell it. Mine has only dropped 1C over 8 hrs. Have you insulated all the pipework around the tank? particularly the hot ones which will be acting as radiators. Doing that made a huge measurable difference for me.

I agree, it does seem high, and I get reminded every time I see the DHW tank temp chart. It's the fairly common I think Telford Tempest Heat Pump model, 200L, and the entry and exit pipework is all lagged, though not 100% perfectly eg some of the mitres on bends are a bit free form. It's energy ERP rating is only C.

The manual that came with it gives the standing loss as 2.04 kWh / 24h, say the same as having a 1 kW heater on for 2 hours a day. That doesn't seem trivial to me. I'm not sure if there is an easy way to convert that quoted standing loss into an expected drop in degrees C per 24 hours with minimal/no hot water use, if there is, then that would be a way of checking whether the temp drop is consistent with the quoted standing loss.

Midea 14kW (for now...) ASHP heating both building and DHW

@cathoderay yes you echo what many people do and it’s how we have done so.

@jamespa the upload might work now....

However I’m trying to isolate and prove - in principal... which part of the heating cycle is most efficient and how to possibly only use the most efficient part of it. This might not suit a large family who use a lot of hot water but it would make sense to smaller HW consumption like our family is on occasion.

The other advantage of what I’m working on is that there’s nothing to stop a second reheat say in the evening to take the remaining HW temperature up to the upper limit as and when it’s needed.

With our system we can manually start a DHW heat up WITH JUST TWO presses of a button on our controller. so it’s very convenient to only heat enough for say 2 showers in a 30 minute DHW cycle. And I’m convinced the most inefficient heating period is the last 20 minutes of a typical full reheat to, as an example;50C.

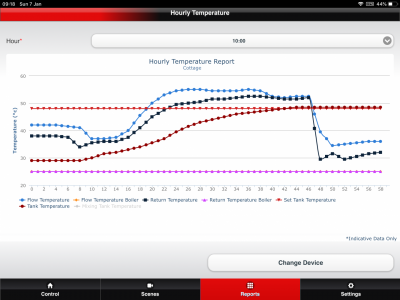

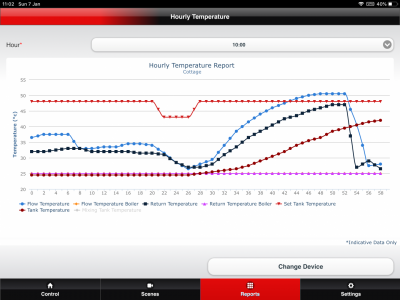

So here is a full cycle DHW Reheat Andy as you can see - even though we have a proper HP ready cylinder with 3 mitre coil heat exchanger the deltaT between 5 and 8 at a recommended flow rate of 18 lpm. Now let’s be clear we are not changing the cylinder James. There are thousands of this type so I’m looking at this characteristic energy signature.

So my assertions are:

The first 30 minutes is the fastest heat exchange period

The widest deltaT (gap between blue and black lines) is a visual indication of the fastest heat exchange period.

the longer the heating period is in the high temperature (55c plus) the more inefficient the hearing process will be so by removing the back end of the heating process the more efficient the process will be.

I realise I am attempting to interpret energy consumption from a standard graph which lacks actual kWh consumption but a graph which does show clearly deltaT, flow temp minus return temp which with the usual calc which you probably know (Lpm/60 x 4.2X DT) the general efficiency can I believe be seen.

So ive done a new reheat with a truncated heating period and we achieved a happy 43c in 30 minutes with a much lower Flow temperature in the process.

As you can see I have not lowered the target temperature but simply reduced the period of DHW cycle. This allows for a second reheat later in the day if a higher store of water is needed. This to me is simple and quite elegant.

I am not quite sure how’s to represent the inefficiency of a high flow temperature and perhaps James you might see a way of illustating this base day on the image s you can see. But it’s something that would be nice to illustrate numerically.

what do you think

addd...

we can activate a DHW cycle from all room controllers, or the wireless thermostats and also from a phone anywhere while we are out and about so this is a very convenient thing to do.

@cathoderay your cylinder mfr quotes 2kwh/24h = 83 watts. (FYI Mine's a 300L advance appliances, 69 watts, B rated)

the maths is easy, umpteen online calculators for heat capacity of water. 210L of water needs 2.44kwh to raise its temperature by 10C. to put it the other way, for a loss of 2kwh, the temp of 210L of water should drop by 8C over 24h.

so if its dropping 10C over 24h that's 2C worse than it should be , not great but could be down to the install . If the time period is a lot less than 24h, its not close to spec at all.

My octopus signup link https://share.octopus.energy/ebony-deer-230

210m2 house, Samsung 16kw Gen6 ASHP Self installed: Single circulation loop , PWM modulating pump.

My public ASHP stats: https://heatpumpmonitor.org/system/view?id=45

11.9kWp of PV

41kWh of Battery storage (3x Powerwall 2)

2x BEVs

@iancalderbank - thanks - looking at the chart for days with minimal hot water use, it is almost always 10 degree drop per 24 hours, so I suppose within tolerable but not great limits. Re-checking the lagging, I noticed the 3 inch or so outflow vertical riser coming out of the top of the tank isn't insulated, and as that is likely to be the hottest bit of pipework, I will add insulation there. The rest is OK until it disappears below the floor boards when I can't get at it, but it is presumably much cooler at that point and onwards.

I suppose the other thing to bear in mind is that is the standing loss, with no hot water use. Most days it does get some, albeit low, use eg washing up. Perhaps that explains the extra 2 degrees drop over the expected drop. I only have a bath once a month, whether I need it or not.

Midea 14kW (for now...) ASHP heating both building and DHW

Just to clarify your energy saving calculation method.

So you run your heat pump initiating a 6 hour setback, provided the weather is not too cold. You then measure and calculate the electrical energy used by your heating system during the remaining 18 hour period when the heat pump is operational.

Then using the regression method, you calculate the electrical energy consumption that would have been used by your heating system, had the setback not been initiated. Using simple approximation I assess the electrical energy consumption during this 6 hour period would have hypothetically been in the region of 1kW per hour.

You then add the total hypothetical electrical energy consumption, to the real electrical energy consumption measured during the 18 hour period when the heat pump was operating.

To obtain the electrical energy saving, you then subtract the electrical energy consumption during the real setback 24 hour period, from the hypothetical electrical energy consumption calculated for a 24 hour period without a setback.

The result being approximately 6kWh.

Is that correct?

@derek-m - broadly, I think you have got it, apart from this paragraph:

Posted by: @derek-mYou then add the total hypothetical electrical energy consumption, to the real electrical energy consumption measured during the 18 hour period when the heat pump was operating.

I am not sure where that comes from or what it does.

Boiled down to its absolute barest essentials, the method is:

(1) get the regression equation for predicting expected energy in from OAT as measured at the heat pump using only non-setback data

(2) collect the observed hourly OAT as measured and observed energy in data during a period (min 24 hours) of setback running in a spreadsheet

(3) add a column to (2) that gives the expected hourly energy in for the current given OAT as measured without a setback using equation from (1)

(4) use a pivot table to get the 24 hour totals, then subtract the observed column from the expected, the result is the saving, if any

Note that for the energy in, the observed value will include any recovery boost, while the expected will not. This is how it should be, recovery boosts are not used in non-setback running (except in exceptional circumstances too rare to matter), as we want to know what the expected energy in would have been, had there been no setback (and so no recovery boost).

Midea 14kW (for now...) ASHP heating both building and DHW

Since you seem reluctant to release the actual data, could you please clarify the source and detail of the non-setback data in item (1).

Posted by: @cathoderayOn a positive note, something of a breakthrough on the energy in calculations, and the need for a 1.18 correction factor. Against expectations based on my past experience, Freedom Heat Pumps have replied to my email (credit very much due where credit is due, and a very welcome change) and it turns out the 'amps_in' (modbus register address 118) variable is indeed just the compressor current.

18% is a lot particularly if it's actually a fixed ish load thus more significant at low power outputs.

Do you happen to know what happens if you run your regression method of estimating saving on the raw data before the 18% uplift is applied? It might just tell us something as the compressor power is the actual power in to the heat engine.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

- 27 Forums

- 2,520 Topics

- 58.6 K Posts

- 743 Online

- 6,800 Members

Join Us!

Worth Watching

Latest Posts

-

@editor has said a lot but let me address this one head...

By JamesPa , 6 hours ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

Well I've had an interesting few days and would like to...

By giganto , 7 hours ago

-

RE: Peak Energy Products V therm 16kW unit heat pump not reaching flow temperature

Yes, here's mine. From the service manual parts numbers...

By bobflux , 11 hours ago

-

RE: Underfloor Heating Installation Issues with Heat Pump

Thanks for sharing your observations, both of you. From...

By Jonatan , 11 hours ago

-

Had to learn the hard way 🤣 now I'm sharing T...

By bobflux , 11 hours ago

-

RE: Issue with a Grant Air Source Heat Pump & Tado Smart Thermostat

Im assuming from your original post that hysterisis ref...

By JamesPa , 12 hours ago

-

RE: Heat Pump vs New Gas Boiler for Inherited House - Worth the Extra Cost?

Hi @fretless6 Mike, I have experience with Taggas (Re...

By Old_Scientist , 14 hours ago

-

RE: Daikin Altherma 3 LT compressor longevity question

@bobflux With my limited HA skills I can't ad...

By Ubert767 , 15 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

Now seems a good time to summarise the costs and effici...

By benson , 19 hours ago

-

RE: Tell us about your Solar (PV) setup

@mk4 Charge to 100%, discharge down to 10%.

By bobflux , 20 hours ago

-

RE: Connecting Growatt SPH5000 over wired ethernet rather than wireless

The simplest wired option is usually the Growatt Ethern...

By Jonatan , 1 day ago

-

RE: Electricity price predictions

@jamespa And it seems some of the nasty public cloud...

By Batpred , 1 day ago

-

RE: Jokes and fun posts about heat pumps and renewables

Technology is rapidly advancing. BBC News reported th...

By Transparent , 1 day ago

-

RE: Do Fridges and Freezers have COP ratings?

@editor Thank you all for your replies and submitted in...

By Toodles , 2 days ago

-

I know and yes. The secondary deltaT wont necessaril...

By JamesPa , 2 days ago

-

RE: Designing heating system with air to water heat pump in France, near Lyon

Just love the way you put it! 🤣

By Batpred , 2 days ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thank you for sharing. So it seems that your Schneid...

By Batpred , 2 days ago

-

RE: Forum updates, announcements & issues

@upnorthandpersonal thanks for the thoughtful, consider...

By Mars , 3 days ago

-

RE: Solar Power Output – Let’s Compare Generation Figures

@mk4 All 21 panels have their own Enphase IQ7a microinv...

By Toodles , 3 days ago

-

RE: Setback savings - fact or fiction?

Great, so you have proven that MELCloud is consistently...

By RobS , 3 days ago

-

RE: Mitsu PUHZ120Y 'Outdoor Temp 'error?

Thanks David & James It almos...

By DavidAlgarve , 4 days ago

-

RE: Surge protection devices SPDs

@trebor12345 - your original Topic about the right type...

By Transparent , 4 days ago

-

RE: Help needed with Samsung AE120RXYDEG

@tomf I’ve been sent this from a service engineer at Sa...

By Mars , 4 days ago