Do Heat Pumps need to start up at Full Power?

When our heat pump starts up, (Daikin EDLA08 8 kW Monobloc controlled via a Homely Smart Controller) the cycle starts with a high power burst and very quickly lowers the power consumption so that within minutes, it is running on ~600 Watts or less. Now the consumption will be greater in cold weather than in mild and, particularly in mild conditions, cycling may well happen.

Thinking about the above start-up procedure, I would be curious to know from anyone knowledgable in such matters, is the high power start-up a requirement for all the mechanical mechanisms to initiate and run efficiently? With smart controllers able to monitor performance and compare OAT, IAT, temperature drop (therefore the heat loss) and probably other factors I have not mentioned, I would imagine that such control might be exerted over the start-up of the cycle to curtail such abrupt surge demands replacing them with ‘soft start-ups’. I may be missing some fundamental law of the physics involved in the compressor mechanism so that what I am suggesting is wholly undesirable or even impossible. However, it does seem to me that if the IAT is constantly monitored and trends indicate a slight drop below required comfort level, a soft-start might be employed and just tick over rather than waiting for a greater drop in comfort level resulting in the need for a greater surge-start to restore the temperature to ‘normal’.

Maybe what I am suggesting would actually be counterproductive and result in more short cycling than ever, rather than a reduction in surge demand and wear and tear, I just don’t know. I ask the question purely out of curiosity really. Whimsically, Toodles.

Toodles, heats his home with cold draughts and cooks food with magnets.

I have noticed a similar behaviour in our Bosch unit. I don't know if it's a hardware-defined rule, or if it's a consequence of the controller on the unit. It looks to me like the high power burst is governed at least to some degree by the unit's response to a too-low flow temperature and dT.

When the unit starts up, the flow temperature is going to be lower than the target temperature, by some amount (in our case, the unit waits until the flow temperature is 2K below the target flow temperature). In general, I think most units will modulate upwards to close that gap. For this reason, we get a high spike in power use that lasts no more than a couple of minutes on start up. I have noticed that when the delta between the flow temperature and the target is much more than 2, it goes into even higher energy use state to make up the difference.

At the same time as that is happening, the pump is trying to broaden the dT to achieve its target of 3K, which it does by modulating very low. This makes it easy for the pump to achieve its flow temperature target, but almost immediately results in it overshooting a bit. It then modulates right down, and the pump turns its power up as it now sees a too-large dT.

Then we get a slow rising power phase as the unit goes a more gentle ramp up in power alongside the pump until both the dT and target flow temperature have been achieved, and then it starts to modulate down to maintain that state. In mild weather, and with low flow temperatures it's very possible for the flow temperature to overshoot before the pump can get to a point where it is happy with the dT, which is what tends to cause the unit to cycle off. For us, this is usually around 20 minutes.

It's possible I could use Home Assistant to manage the dT more intelligently, as that is something I can control through the EMS, but the weather is too cold at the moment for us to really see any cycling. Also, our current approach of using a minimum flow temperature just slightly above the level that tends to lead to cycling has already made a big improvement. In combination with a room influence, this forces a 28C flow temperature in warmer weather, and lets the unit overheat the flat by as much as a degree. The room influence then causes the unit to switch off (as it seems like it turns off whenever the target flow temperature falls below 26C, before the minimum is applied).

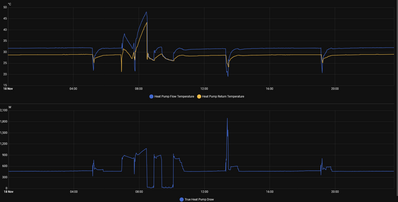

@steelbadger Attached is the plot for various parameters for our Daikin for yesterday Monday 17th. November; we had temps down to 4 degrees C. and I still see some cycling going on but you will observe the powerful starts. I had expected to see more ‘low and slow’ running than this, rather than bursts of high flow running and then turning off for intervals. With my sight, I can never be sure I am quite seeing what I think the plots are showing me though! Regards, Toodles.

Toodles, heats his home with cold draughts and cooks food with magnets.

@toodles That certainly doesn't look optimal, does it? It also looks worse than our unit. Our unit does have an initial spike, but seldom to more than 40% power while yours seems to be going all out right away. It then quickly blows past its target flow temperature and switches off again.

Do you have a buffer or low-loss header installed? I assume based on the dTs being produced and the speed with which things cool once the unit cycles off that it is primarily radiators that do the heating? If you have separation, is the flow rate in the graph the flow rate through the heat pump, or around the heating circuit? If it is the flow rate through the heat pump, is your heating circuit pump always on, or does it turn off with the primary pump (or cycle)?

Where are your flow and return temperature sensors? At the heat pump, or on the buffer/LLH if it is present?

My impression from looking at the graphs is that I'd expect most heat pumps to turn on at a higher power to hit their target temperatures and dTs, and if the heating circuit isn't able to moderate the heat gain by shedding it into the house quickly enough, that they'll end up cycling before they can self-modulate down. I have considered actively controlling the system target dT around startup in order to effectively force a higher rate of heat exchange in the emitters, giving the heat pump a little bit more time to find its equilibrium, but in the current weather we're no longer seeing any significant cycling.

@steelbadger We have an LLH with secondary pump; the secondary pump stops and starts with the heat pump system. The flow and return sensors must be contained within the monobloc as there is nothing else in the airing cupboard equipment. The system is all radiators (10 + towel rail). I don’t remember seeing this type of start up, run then stop last year but the style of plots used in the Homely installer app changed when it became Homely Connect. I think I’ll contact Homely for a check up on this behaviour, Regards, Toodles.

Toodles, heats his home with cold draughts and cooks food with magnets.

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 259 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

Struggling to get CoP above 3 with 6 kw Ecodan ASHP

I've been using this heatpump for two winters now and a...

By GoodbyeGas , 9 minutes ago

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

That would make sense. I've found the effects are prett...

By Majordennisbloodnok , 19 minutes ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@benson — as @tasos suggests, plotting multiple variabl...

By cathodeRay , 1 hour ago

-

@painter26 — as @jamespa says, it's for filling and re-...

By cathodeRay , 3 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 13 hours ago

-

RE: What determines the SOC of a battery?

@batpred Your BMS parameters will be the same as m...

By Bash , 14 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 15 hours ago

-

RE: Setback savings - fact or fiction?

I also need to correct something I said by mistake earl...

By cathodeRay , 15 hours ago

-

RE: Electricity price predictions

@judith Thanks for sharing, and nice to see how the ...

By Batpred , 16 hours ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 18 hours ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 19 hours ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 19 hours ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 20 hours ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 21 hours ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 22 hours ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 23 hours ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 23 hours ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago

-

RE: DIY solar upgrade - Considering adding more panels

I know this is a bit old, but it made me wonder what co...

By Batpred , 2 days ago

-

RE: New Vaillant aroTherm Plus in black - When will it come to the UK?

@majordennisbloodnok Daikin, take note! (In fact, I hav...

By Toodles , 2 days ago

-

RE: Midea ASHP – how to set weather compensation

@mk4 — good work! First, I agree, no evidence of cycl...

By cathodeRay , 2 days ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

I don't know about Solis inverters. It isn't a featur...

By Transparent , 2 days ago

-

Daikin Altherma 3 H HT - Freeze Prevention Threshold

Hi. We have an Altherma 3 HT (18kW I think) which, now ...

By RICHARDF5033 , 2 days ago