Posted by: @sunandairI guess one advantage of a PHE over a LLH is that there won’t be any mixing between Flow and Return. However is there a quantifiable energy loss through the plates of the PHE?

Even a lossless PHE will reduce the system efficiency because the flow on the CH side is necessarily colder than the flow on the CH side and thus the HP has to increase its flow temp to achieve the same flow temp at the radiators. In the @cathoderay case this difference was measured at 5C, corresponding (crudely) to a 10% reduction in HP efficiency.

Posted by: @sunandairis it fair to say that the industry stated these were required particularly for the retrofit business as some sort of guarantee that the system would work EVEN WITH bad or unknown existing pipework?

Not really sure how it guarantees that. @cathoderay reports that he does not know how the pump speed (or anything else) on the CH side is controlled. This being the case, what guarantees that the two sides are properly matched to avoid unnecessary cycling on the HP side or other potential issues. If the existing pipework is not sufficiently large etc for the flow required to get sufficient heat transfer at the chosen deltaT, adding in a PHE doesn't fix this (it might of course mask it - but that's a bad thing).

What a PHE does do of course is reduce the amount of glycol needed in the system (if you are using glycol), which seems to be a significant reason for fitting them. I guess its open to debate whether the use of glycol is to be preferred over antifreeze valves and whether the saving in glycol if you fit a PHE is worthwhile.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

@cathoderay You stated in an earlier post on your other thread, quote "I think the heat loss as the house currently is (I am slowly improving insulation/draft-proofing where I can) is something just over 12kW. The rads are matched plus ~10% to the room heat losses at a flow of 55 degrees. "

So just like your radiators need to be hotter than the room you are heating ( to create a heat differential), when incorporating a heat exchanger the primary primary circuit needs to be at least 5 deg C hotter than the secondary circuit (radiator circuit) in order to transfer the desired heat quantity across (on a cold night you need as much of that 11 to 12 kW as possible). So when you need 55degC supplying the radiators you are going to need 60degC from the heat pump primary circuit.

Your weather compensation curve has to take this into account, which it doesn't at the moment.

Remember that most who are commentating on this forum about their weather compensation implementations don't have a PHE and therefore their selection criteria will be always be slightly different to yours.

A better matched weather compensation curve will improve you experience during cold spells as well as reducing cycling, all be it at a higher running cost. The choice is yours of course.

Posted by: @derek-mThere is no bog standard control philosophy that meets all requirements throughout the whole year.

I can certainly agree with that. I reckon that there are a fair few PhDs in 'optimised' control of heat pump central heating systems under various sets of conditions. Cross disciplinary ones at that, as it is both engineering and human psychology!

Perhaps central heating control systems should have a dial, in addition to 'ideal temperature' allowing you to choose the relationship between tolerance to deviation (from temperature) and efficiency, much like investments ask about your tolerance to risk vs potential reward. In my own case Im also convinced that humidity is another factor which affects the 'perceived' temperature.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

Posted by: @iaackSo when you need 55degC supplying the radiators you are going to need 60degC from the heat pump primary circuit.

Your weather compensation curve has to take this into account, which it doesn't at the moment.

Remember that most who are commentating on this forum about their weather compensation implementations don't have a PHE and therefore their selection criteria will be always be slightly different to yours.

A better matched weather compensation curve will improve you experience during cold spells as well as reducing cycling, all be it at a higher running cost. The choice is yours of course.

Surely its more likely that @cathoderay adjusted his wc curve with the PHE in place, so the settings already take account of its effect. Of course, assuming that this is the case, he will be able to rack it down if he removes the PHE, improving system efficiency.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

Posted by: @jamespaYou are mixing up cause and effect. The heat delivered by the heat pump to the system absolutely is equal to (mass) flow rate * specific heat capacity of the medium x deltaT. Thats just basic physics and its not dependent on steady state.

However this is a result of heat lost at the emitters which is dependent on the temperature difference between the emitter and the room (in the case of the radiator, raised to the power 1.3). The HP adjusts the amount of heat it delivers to the water to match the heat lost by the radiators and maintain the delta T it targets.

I don't doubt the physics, I've even applied the equation to two conditions, but am still left confused, and I'd bet the house on the fact that I am not the only one confused!

Sometimes analogies work for me. Maybe we can see the transfer/delivery of energy as happening like a goods train. The amount of goods - lets say coal - a train can deliver is determined by its speed (which is the flow rate), the capacity of the wagons (the specific heat) and how much coal actually gets off loaded at the destination (the delta t). Increase any one of those parameters, and more coal gets delivered.

Now comes the bit where I get stuck: how can we extend this analogy (assuming it can be done) to cover the same delta t (amount of coal off loaded) at different flow temps. Logically the analogous situation to a higher LWT is a train carrying more coal (say 100 tons instead of 50) but the delta t (coal off loaded remains the same (say 5 tons). But it is still delivering the same amount of coal (energy).

For a moment, I thought your second paragraph above made everything clear: the heat pump has to put more heat in when the rad/room delta t is larger (the yard has to load more coal on the train) - but then the train hits the buffers again, whatever the LWT/preload of coal, the basic physics means that at a constant LWT/RWT delta t, the heat pump always delivers the same amount of energy (because, at least in a Midea heat pump, the flow rate is constant, and the specific heat is also constant).

To further complicate things (for me), the Midea data charts I have posted (eg 3rd April 2023) appear to show the heat pump adjust both the LWT and the delta t (indeed, delta t is the only thing in the equation that it varies): on the left hand side, with ambients just above zero, the LWT is mostly around 49 degrees (when not fluctuating), and the delta t is around 5, while on the right hand side, with ambients over ten, the LWT averages out at about 38 degrees, and the delta t is around 3 to 4. because the delta t is just a simple multiplier in the equation, a 1-2 degree drop from 5 degrees reduces the energy transferred by 20 and 40% respectively.

Maybe this is what happens: the ambient goes up, and the LWT goes down, and this is what lowers the LWT/RWT delta t: because the room temp remains fairly constant, the lower LWT means less heat/energy is transferred to the room, 20 to 40% less in the 3rd of April left hand/right hand side comparison, and as a consequence the LWT/RWT delta t drops. I am mindful of the fact that the only variable in the equation a Midea unit changes is the LWT/RWT delta t, but it seems to me it doesn't do that directly, instead, it alters the LWT, and as a consequence the LWT/RWT delta T changes.

Sorry to be so thick about this, and persistent in trying to be less thick, but I have always been one who has to understand the basics. It used to drive some (but thankfully not all) of my teachers mad, just as I fear it will be driving some of you mad.

Posted by: @iaackSo just like your radiators need to be hotter than the room you are heating ( to create a heat differential), when incorporating a heat exchanger the primary primary circuit needs to be at least 5 deg C hotter than the secondary circuit (radiator circuit) in order to transfer the desired heat quantity across (on a cold night you need as much of that 11 to 12 kW as possible). So when you need 55degC supplying the radiators you are going to need 60degC from the heat pump primary circuit. Your weather compensation curve has to take this into account, which it doesn't at the moment.

At the design stage, when my installer completed the Freedom Heat Pump calculator, there was no mention of the PHE, it appeared at installation time. Prior to the installation, I understood the system would need a LWT of 55 degrees at -2 ambient, but even that is an oversimplification, because a LWT of 55 at the heat pump does not mean 55 degrees arriving at the rads, which is what on paper they needed to heat the rooms to design temp at - 2 outside. I suspect this is 'accommodated' (on paper) by the fact the rads are ~10% over-size.

I absolutely get that if there is a 5 degree drop across the PHE, then to get the necessary temp at the rads, then the LWT at the heat pump needs to be increased by whatever the drop is, in this case 5 degrees, giving a LWT (at the heat pump) of 60 degrees. Had I known this at the time, I might have asked whether this is a good idea, given heat pump efficiency drops at high LWTs.

My weather curve does in fact partly take this into account, I changed the low ambient end from 55 @ -2 to 58 @ -4. At the time, I did it mainly to extend the range over which there was a gradient, because the Midea curve flat lines either side of the two set points, but it also took the LWT closer to 60 degrees at the low ambient end. I was loathe to take it any higher for fear of what it might do to running costs.

Posted by: @jamespaSurely its more likely that @cathoderay adjusted his wc curve with the PHE in place, so the settings already take account of its effect. Of course, assuming that this is the case, he will be able to rack it down if he removes the PHE, improving system efficiency.

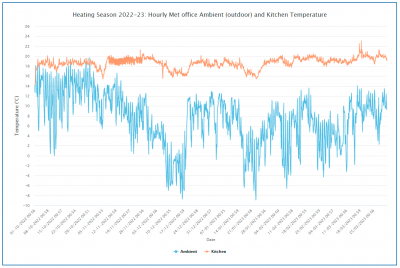

See the above, that was me adjusting the low ambient end of the curve with the PHE in place, so it did take the PHE into account, insofar as it was in place. I have to say after the adjustment, done on 24 Jan 2023, the curve worked pretty well, most of the time the house (or rather kitchen, which is what I monitored) was within a degree or so of design temp, and perhaps a bit over as it got milder:

I do agree all this amounts to a compelling reason to remove the PHE. As I said earlier, I am going to talk to my installer about this. Once I have been persuaded AF valves are fail-safe in practice (or if they are not, how you manage that), then I will have the glycol removed, which will both make the system easier to manage (and cheaper to fill), but will also of course increase the specific heat of the circulating fluid, with consequent benefits.

Midea 14kW (for now...) ASHP heating both building and DHW

Posted by: @cathoderayMaybe we can see the transfer/delivery of energy as happening like a goods train. The amount of goods - lets say coal - a train can deliver is determined by its speed (which is the flow rate), the capacity of the wagons (the specific heat) and how much coal actually gets off loaded at the destination (the delta t). Increase any one of those parameters, and more coal gets delivered.

Its not a bad analogy

Posted by: @cathoderayNow comes the bit where I get stuck: how can we extend this analogy (assuming it can be done) to cover the same delta t (amount of coal off loaded) at different flow temps. Logically the analogous situation to a higher LWT is a train carrying more coal (say 100 tons instead of 50) but the delta t (coal off loaded remains the same (say 5 tons). But it is still delivering the same amount of coal (energy).

However the coal is offloaded at the radiators through the bottom of the truck, so the amount offloaded (deltaT) depends on how full the truck is in the first place (temperature difference between the radiator and the room).

The driving force for the delta T is the radiators not the heat pump. The heat pump can maintain a given delta T by varying either the flow rate or the flow temp, but all its doing is 'keeping up' with the heat lost from the radiators.

To extend the analogy further, as well as the hole in the bottom of the waggon, each radiator has an aperture at the top which fits snugly against the hole. You can adjust the size of the aperture thus adjusting the rate at which coal is emptied for any given level of fill. That's balancing the radiators.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

Posted by: @jamespaHowever the coal is offloaded at the radiators through the bottom of the truck, so the amount offloaded (deltaT) depends on how full the truck is in the first place (temperature difference between the radiator and the room).

Brilliant extension of the analogy, thank you very much.

Midea 14kW (for now...) ASHP heating both building and DHW

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

Posted by: @cathoderaySee earlier reply (secondary pump is very basic, internally controlled). So far as I can see, the primary and secondary flow rates are totally independent of each other, neither has the slightest clue what the other is doing. Furthermore, it looks as though the primary pump, although it can be externally controlled isn't, or if it is, it is controlled to have a constant flow rate (as seen on the charts).

IF the above statement still holds currency then this is more and more pointing to your PHE as the cause of both Low cop and increased cycling. One event may be compounding another.

Going back to basics the fundamental efficiency of a PHE is when the flow rates on either side of the plates are equalised. If your secondary pump even slightly slows it will immediately narrow the DT And so lowering your cop. If it slows further then it will be closely followed by stopping the HP.

so from what theory I have learned, if your secondary pump does operate independently of flow rate of your HP pump speed as you say, then this wiil be mounting up several stages of energy losses.

Using your analogy.

The train has 10 coal trucks, each carrying 10 tonnes, so 100 tonnes total. At the loading end (heat pump) the trucks can be loaded at a variable rate up to a maximum of 150 tonnes per hour.

At the unloading end the trucks are emptied into a 20 tonne hopper, but the coal can be removed from the bottom of the hopper at a variable rate between 0 and 100 tonnes per hour.

The train is initially loaded with 100 tonnes of coal which it takes to the unloading hopper, which as the train arrives holds 10 tonnes of coal. Coal is being removed from the bottom of the unloading hopper at a rate of 50 tonnes per hour. The first truck is unloaded into the hopper, which brings the quantity up to the maximum 20 tonnes, so no further trucks can be unloaded for the time being. After 12 minutes, 10 tonnes have been removed from the hopper so a further truck can be emptied.

This continues for 1 hour, so 5 trucks have been emptied, but now the train driver is told to return to the loading hopper. So the train goes back with 5 empty trucks and 5 that are still full. At the loading end it is therefore only necessary to fill the 5 empty trucks before the train goes back to the unloading hopper.

The rate at which the coal is supplied is therefore dependent upon the rate at which it can be unloaded from the train, not the rate at which the train can be loaded.

Posted by: @derek-mThis continues for 1 hour, so 5 trucks have been emptied, but now the train driver is told to return to the loading hopper. So the train goes back with 5 empty trucks and 5 that are still full. At the loading end it is therefore only necessary to fill the 5 empty trucks before the train goes back to the unloading hopper.

....But because you have a plate heat exchanger the coal on the train from MeashamLWTCB has to change trains mid journey to a different train running on a different track in order to get the coal to its final Destiny - GWR Emitterville.

not all the coal can be offloaded at Station PHE being controlled by a notoriously intransigent workforce who will only come in to offload the train when they know there is a partially empty train returning from GWR Emitterville. And even then they will only offload enough coal to fill the empty wagons on the train. If there are no empty wagons the workforce will have no option but to park the full train from MeashamLWTCB. Until the Emitterville train returns with some empty wagons.

Now, is this the right point to start discussing the calorific value of the coal? 😉 Regards, Toodles.

Toodles, heats his home with cold draughts and cooks food with magnets.

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 486 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Testing new controls/monitoring for Midea Clone ASHP

Here’s a current graph showing a bit more info. The set...

By benson , 1 minute ago

-

RE: Setback savings - fact or fiction?

True there is a variation but importantly it's understa...

By RobS , 2 minutes ago

-

Below is a better quality image. Does that contain all ...

By trebor12345 , 28 minutes ago

-

Sorry to bounce your thread. To put to bed some concern...

By L8Again , 30 minutes ago

-

@painter26 — they (the analogue gauges) are subtly diff...

By cathodeRay , 1 hour ago

-

RE: What determines the SOC of a battery?

The answer from Fogstar was crisp. My hypothesis, su...

By Batpred , 1 hour ago

-

RE: Electricity price predictions

I am always impressed with how you keep abreast of so m...

By Batpred , 2 hours ago

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

@majordennisbloodnok I’m glad I posted this. There see...

By AndrewJ , 2 hours ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 5 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

Just to wrap this up here for future readers: The S...

By Batpred , 8 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 8 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 9 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 24 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 1 day ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 1 day ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 1 day ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 1 day ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago