Posted by: @alan-mI'm afraid the data I am collecting is only at the granularity of days. An OpenEnergyMonitor installation might be my next step.

I fear this is a common problem, inadequate data because it is just so bloody hard to get good data. The manufacturer's apps are in my experience useless, because the manufacturer only tells you what they want you to know, and that won't include anything bad. I think most people know my views on Home Assistant, too complex for all but HA enthusiasts to use, and much the same applies to the other open source monitoring systems. What this means in practice is that most heat pump owners have no idea what their true heat pump COP/SCOP is, or if they have a figure, it comes from manufacturers marking their own home work data. They also have no idea what their actual LWT is, no idea weather their heat pump is cycling. I suspect this is why trying to get a simple answer from @filipe on the evidence his heat pump isn't cycling (which he claims to be the case) is like trying to get water out of a stone, he doesn't have the data, or if he does, for some peculiar reason, he won't post it. The reason I am pursuing this is because I am beginning to wonder if Midea and Midea clone heat pumps default to cycling. If that is the case, I think it would be useful for current and prospective Midea/Midea clone heat pump owners to know.

Posted by: @filipeI don’t find it helpful to criticise installers for not knowing all the ins and outs of plate heat exchangers

I am not sure why you think this, given in almost all cases the supplier/installer is the designer. It a bit like saying it isn't helpful to criticise car manufacturers for not knowing all the ins and outs of car radiators. A heat pump/car engine is part of a system, and the whole system (including PHE/car radiator) needs to be taken into account and properly understood is the system (central heating/car) is to work well.

Your next suggestion (all that is needed is for MCS to tighten things up) is unfortunately a triumph of hope over experience. As has been documented here and elsewhere so many times, their requirement are all too often a hindrance rather than a help, and adding further MCS requirements would only make things worse. As for regulation, a toothless bearded hag would make a better regulator than MCS. At least she could put a strap right across the backs of miscreant installers (and what gas that would be!).

Posted by: @filipeI show the temperature cycles, you ask about the electric, I say the electric cycles like the temperature, you continue….it’s all simple.. watch John cantor.

I'm sorry, but that looks precious close to a word salad to me. If 'I say the electric cycles like the temperature' means what it appears to mean, then your heat pump is cycling, in the usual meaning of the term (compressor switching on and off over relatively short periods of minutes rather than hours) which means it is not running continuously, unless by running you mean on at the mains rather than actually producing heat.

Posted by: @filipeYou have seen my power data before.

I have searched the forum high and low but can't find any chart posted by you showing your power data. Either my search failed, and you have posted it, or you haven't. Nonetheless, I think 'the electric cycles like the temperature' probably clears it up, your heat pump, as noted above, is cycling. The extent to which cycling is detrimental is still open to debate.

Posted by: @filipeWhy should anyone be interested in Midea’s integer compressor current data? If i want the instantaneous COP i just read the output power from the controller and power from the Energy monitor. It does require I trust Midea, but I find there is consistency with their Engineering data.

My running cost is lower than gas despite a colder winter. Given similar heat loss assessment mine has used 2992kWh in 12 months for DHW and CH and yours 8000. Comfort levels are of course very personal.

I’m glad you are now considering not running 24/7. Personally I don’t like a warm bedroom when sleeping. It’s only a matter of being comfortable the rest of the day rather than warm. John Cantor explains how reducing the flow temperature can help to reduce cycling. It’s not me that runs with a target flow temperature of 55-58c and wonders why the COP is low and the pump cycles a lot. I don’t run mine 24/7 except when a modest setback in really cold weather brings it on. It makes sense to heat the house when the the outside temperature is warmest rather than coldest. Mostly our house only drops a few degrees overnight, but -9c is a challenge. WC doesn’t really help with getting comfortable temperatures and in winter is more likely to increase the flow temperature.

I'm afraid again that if this isn't another word salad, then it is at the very least all over the place. We've previously agreed 'each to his own' and reading between the lines you heat your house to lower temps than I do (my target in daytime use rooms is 18 degrees, which I usually get, perhaps you could mention your targets and achieved temperatures?). If that is the case, a formal heat loss calculation doesn't apply (because your actual heat loss will be less) and your energy use will be less. Without knowing what you are actually heating (and by how much) a statement that you have used 2992 kWh in 12 months means very little. Had you used that to heat a shoe box at the end of your garden to 12 degrees, I might suggest that looks like rather an excessive use!

I run the system with relatively high flow temps at the lower ambient end of the weather curve because that is how it was designed to run. If I lower the LWTs, the house will not, can not, reach design temps at low ambients, full stop. I knew full well, at design stage, prior to installation, that this was the case. The only way to be able to run with lower LWTs was to have even larger radiators than the large ones that were to be installed as part of the upgrade, and that wasn't practical because of the physical constraints of the building (shortage of wall space). Knowing I would be running with higher LWTs meant I also knew I couldn't not expect top end COPs. Consequently, I am not left wondering 'why the COP is low' - it happens to be about where I expected it to be, at about 3 or a bit above most of the time. That is, given all the constraints, 'good enough' for me. Since I like evidence, here is a chart, subject to the usual caveats about using Midea data, showing 24 hour trailing COP (the COP given the last 24 hours data) over recent weeks based on the Midea total energy in/out data (top chart) and calculated using the flow x specific heat x delta t equation (bottom chart). I have not been able to find out why the latter is usually a bit higher than the former, it may be to do with glycol assumptions (glycol effects are not trivial, typically about 10% less energy (sp ht 3.8 vs 4.2, 0.4 is near enough 10% of 4.2). And yes, I do still have HA:

My lifetime (of the heat pump, not me) COP (lifetime energy out / lifetime energy in) by the way is 2.8, but I think this figure is probably distorted by some rather erratic running in the commissioning period last spring, including periods when the PHE was running with parallel rather than contra flow, and a period when I had the pump running with a fixed LWT (ie weather comp off) which was definitely detrimental to performance.

"I don’t run mine 24/7 except when a modest setback in really cold weather brings it on." I'm afraid you lost me here.

"It makes sense to heat the house when the the outside temperature is warmest rather than coldest." This suggests you heat the house in summer, and turn off the heating in winter, which I am sure is not the case. Perhaps you are getting at the fact the heat pump will likely run more efficiently in the warmer part of the day, and so, when the heating is in use, you prefer to have it on during the warmer part of the day?

"Mostly our house only drops a few degrees overnight, but -9c is a challenge." Indeed it is, not least to understand what this means. I think you mean when the house drops by 9 degrees overnight. If on the other hand, it means what it actually says (an actual temperature of -9 degrees), then if that is your indoor temperature then you really do have a challenge. Clarity matters...(as indeed does this subject, actual temperature drops during setbacks, and how well a heat pump can recover after a setback).

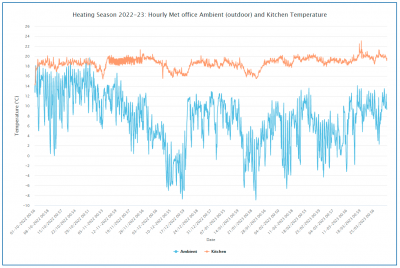

"WC doesn’t really help with getting comfortable temperatures and in winter is more likely to increase the flow temperature." I am again afraid I am not sure what you are getting at here. In my experience, weather compensation does get comfortable temperatures for me. Here is a chart I posted earlier showing indoor (kitchen) and outdoor temperature for Oct 2022 to Mar 2023 inclusive:

I did some minor tweaks to the curve, notably changing the low ambient end from 55 @ -2 to 58 @ -4 in late January as it seemed to me the heat pump struggled to reach target room temp in cold weather. But the main point is that by and large, the room temp was where I wanted it to be, I was comfortable, and this was done running the heat pump with weather compensation. Again, without seeing your data, it is all but impossible to make sense of your statements. It is not enough to declare as if by decree "WC doesn’t really help with getting comfortable temperatures" - you need to back up the statement with data. We both know that, because we have both been trained in scientific methods.

Of course weather compensation is likely to increase the flow temperature in winter, that is the alpha and the omega of weather compensation, its raison d'etre, its beginning and its end. It is exactly what the curve plotted on paper shows, higher LWT when outdoor ambient temp is lower, lower LWT when the outdoor ambient is higher. I'm glad to say that at least on that point, we can agree.

Midea 14kW (for now...) ASHP heating both building and DHW

Posted by: @kev-mAt least ASHPs keep running as long as you want them to. Imagine having an ASHP that stopped after using 30kWh and required you to faff around with various apps and wait in an online queue before starting it up again an hour or two later.

Range and charge speed are both increasing and taking a break after 3 or 4 hours driving is good for safety. The number of charge points is also increasing. You are comparing a steady state with a transition; during a transition some things will inevitably get out of step but, once its well underway, it will be the old technology that feels, and is, awkward. Remember when digital cameras were large, expensive, had extremely low resolution and very short battery life! Is anyone going back to film - no - that's why Kodak went bust!

ASHPs may keep running as long as you want them to but do have their own challenges, or rather the system into which they are fitted presents challenges. Unfortunately we got lazy in the UK with central heating, fuel was too cheap and it was just too easy to shove in a well-oversized boiler unnecessarily left on the max flow temp (without weather compensation) and sod the running cost, matched to radiators sized to fit the window opening without regard to output. So we didn't bother with system design.

Now we are forced to, we discover we don't actually have many system designers around, so instead we invent a set of rigid rules and process that someone with little or no understanding can follow, but which all too often doesn't deliver yet, unfailingly protects the installers, even if what they deliver is rubbish. Then we continue to justify this in the name of 'standards'. We also tie it to an incentive scheme which is half-baked, because the government doesn't believe in such things anyway and there are too few scientists/engineers in the civil service, and further compound it by making it extremely difficult to circumvent the closed shop by imposing unnecessary planning rules none of which apply to gas or oil boilers.

Fortunately there are countries that do better than us, and some people who can, in fact, think and they will show us the way whilst, in parallel, engineering advances reduce the system design task. We would speed up this process (and allow those who can think to come to the fore) if we opened the installation market up to competition and innovation, rather than restricting it to the current closed-shop union as we currently do.

There was a time when we were world leaders in science and engineering. Sadly, decades during which we neglected any concept of an industrial strategy and sat on the laurels of empire, having 'won the war', being the only country not obliged to put its name on stamps, and being permanent members of the Security Council (in short - 'exceptionalism'), have led us to the rather sad position we occupy today. The baby-boomers (of which I am one) selfishly squandered resources and created a society which is not sustainable.

However we still have many very good and capable people, a functioning democracy (just, although that is fast being eroded) and the advantage of at least a reasonable scale. So we mustn't give up and instead demand higher standards of ourselves, government and our institutions in order that our children, and their children, can enjoy at last some of the pleasures to which we have become so accustomed.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

Your mention of oversized boilers rings very true here; British Gas surveyed and installed a condensing boiler and all the plumbing associated with it, new radiators etc. about 17 years back. It wasn’t until last year when I interrogated the ‘BG ‘Engineer’ who came to carry out the annual service that I discovered that they had just installed a 16 kW/h system - set on maximum without any adjustment at all; 8 kW/h would have sufficed but, of course, they weren’t paying the gas bill! Being a ‘one control’ system, any adjustment to temperature setting would affect the DHW system as well; the consequence, I could not really turn the temperature down below 50 degrees C on a ‘set and leave’ basis. That system has now gone and I am consuming far less energy* with the ASHP than the gas guzzling boiler did. *Yes, even allowing for the approximately ‘3 times’ less energy required for equivalent output. Regards, Toodles.

Toodles, heats his home with cold draughts and cooks food with magnets.

Posted by: @toodlesYour mention of oversized boilers rings very true here; British Gas surveyed and installed a condensing boiler and all the plumbing associated with it, new radiators etc. about 17 years back. It wasn’t until last year when I interrogated the ‘BG ‘Engineer’ who came to carry out the annual service that I discovered that they had just installed a 16 kW/h system - set on maximum without any adjustment at all; 8 kW/h would have sufficed but, of course, they weren’t paying the gas bill! Being a ‘one control’ system, any adjustment to temperature setting would affect the DHW system as well; the consequence, I could not really turn the temperature down below 50 degrees C on a ‘set and leave’ basis. That system has now gone and I am consuming far less energy* with the ASHP than the gas guzzling boiler did. *Yes, even allowing for the approximately ‘3 times’ less energy required for equivalent output. Regards, Toodles.

The sad thing is that its still happening with heat pumps. I have had in total 10 quotes and 2 full (3 hour) surveys. The two full surveys both estimate my house load as 16kW, because they ignore fabric upgrades and, in the case of one for certain (and presumably the other) double count room to room losses.

My own calculation, with the correct fabric u values and leaving out the double counting (but otherwise using MCS assumptions), comes to 10.5-11kW and the actual measured value during a prolonged cold spell (day and night) is 7.5kW.

The difference between a system design based on a 16kW unit and a system design based on an 11kW unit, is material in cost, disruption and engineering challenges.

The crazy thing is that a simple calculation based on amount of gas consumed annually (which is of course accurately measured) could have been done by the surveyors as a sense check, and would have come out at 8.5kW, which would surely have triggered alarm bells for the company (one of those which did a full survey!) that suggested I install 2 16kW Mideas to take the load. But they don't even ask this question, let alone act on the information, and are fully protected because they have followed the MCS rules to the letter.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

Posted by: @jamespaPosted by: @toodlesYour mention of oversized boilers rings very true here; British Gas surveyed and installed a condensing boiler and all the plumbing associated with it, new radiators etc. about 17 years back. It wasn’t until last year when I interrogated the ‘BG ‘Engineer’ who came to carry out the annual service that I discovered that they had just installed a 16 kW/h system - set on maximum without any adjustment at all; 8 kW/h would have sufficed but, of course, they weren’t paying the gas bill! Being a ‘one control’ system, any adjustment to temperature setting would affect the DHW system as well; the consequence, I could not really turn the temperature down below 50 degrees C on a ‘set and leave’ basis. That system has now gone and I am consuming far less energy* with the ASHP than the gas guzzling boiler did. *Yes, even allowing for the approximately ‘3 times’ less energy required for equivalent output. Regards, Toodles.

The sad thing is that its still happening with heat pumps. I have had in total 10 quotes and 2 full (3 hour) surveys. The two full surveys both estimate my house load as 16kW, because they ignore fabric upgrades and, in the case of one for certain (and presumably the other) double count room to room losses.

My own calculation, with the correct fabric u values and leaving out the double counting (but otherwise using MCS assumptions), comes to 10.5-11kW and the actual measured value during a prolonged cold spell (day and night) is 7.5kW.

The difference between a system design based on a 16kW unit and a system design based on an 11kW unit, is material in cost, disruption and engineering challenges.

The crazy thing is that a simple calculation based on amount of gas consumed annually (which is of course accurately measured) could have been done by the surveyors as a sense check, and would have come out at 8.5kW, which would surely have triggered alarm bells for the company (one of those which did a full survey!) that suggested I install 2 16kW Mideas to take the load. But they don't even ask this question, let alone act on the information, and are fully protected because they have followed the MCS rules to the letter.

Don't forget that an ASHP will spend 15-20% of its time defrosting when it's cold outside. And you'll still want hot water. 11kW sounds about right.

I can sort of understand the installers; a complaint that the ASHP doesn't heat the house in winter is more serious (and sue-able) than a gripe about slightly high running costs. And of course it wouldn't be MCS compliant...

Posted by: @kev-mPosted by: @jamespaPosted by: @toodlesYour mention of oversized boilers rings very true here; British Gas surveyed and installed a condensing boiler and all the plumbing associated with it, new radiators etc. about 17 years back. It wasn’t until last year when I interrogated the ‘BG ‘Engineer’ who came to carry out the annual service that I discovered that they had just installed a 16 kW/h system - set on maximum without any adjustment at all; 8 kW/h would have sufficed but, of course, they weren’t paying the gas bill! Being a ‘one control’ system, any adjustment to temperature setting would affect the DHW system as well; the consequence, I could not really turn the temperature down below 50 degrees C on a ‘set and leave’ basis. That system has now gone and I am consuming far less energy* with the ASHP than the gas guzzling boiler did. *Yes, even allowing for the approximately ‘3 times’ less energy required for equivalent output. Regards, Toodles.

The sad thing is that its still happening with heat pumps. I have had in total 10 quotes and 2 full (3 hour) surveys. The two full surveys both estimate my house load as 16kW, because they ignore fabric upgrades and, in the case of one for certain (and presumably the other) double count room to room losses.

My own calculation, with the correct fabric u values and leaving out the double counting (but otherwise using MCS assumptions), comes to 10.5-11kW and the actual measured value during a prolonged cold spell (day and night) is 7.5kW.

The difference between a system design based on a 16kW unit and a system design based on an 11kW unit, is material in cost, disruption and engineering challenges.

The crazy thing is that a simple calculation based on amount of gas consumed annually (which is of course accurately measured) could have been done by the surveyors as a sense check, and would have come out at 8.5kW, which would surely have triggered alarm bells for the company (one of those which did a full survey!) that suggested I install 2 16kW Mideas to take the load. But they don't even ask this question, let alone act on the information, and are fully protected because they have followed the MCS rules to the letter.

Don't forget that an ASHP will spend 15-20% of its time defrosting when it's cold outside. And you'll still want hot water. 11kW sounds about right.

I can sort of understand the installers; a complaint that the ASHP doesn't heat the house in winter is more serious (and sue-able) than a gripe about slightly high running costs. And of course it wouldn't be MCS compliant...

The responsible manufacturers include defrost time in their system specs and give you the net output. However as you say 11kW sounds about right allowing a bit of leeway and Im personally glad I did the comparison.

My basic point however is that this over-engineering really matters even if it does 'protect' the installer (which in the long time must be questionable if it gives the industry a bad name). Its not just about the cost of the unit, its all the knock on effects. A 16kW unit in a 8-11kW house is unlikely to modulate down sufficiently far and so will be cycling at relatively low temperatures. Some will argue that split 22mm primaries need, as a result, to upgraded to 28mm, involving massive disruption. Some will also argue that feeds to the DHW will likely also need upgrading from 22mm to 28mm again because of insufficient modulation depth from 16kW. And one installer who did a survey wanted to fit 2 16kW units, requiring express planning consent and most likely resulting in unachievable noise constraints and, by the time those have been challenged, 12 months delay. How is that justifiable? Yet this is all MCS quality controlled.

I have installers say, in all serious, 'never listen to the customer'. However if you aren't going to listen to the customer when it comes to fabric upgrades, how will you know about them. Its not beyond the wit of man to come up with a way to protect the installer if they have used some necessary information from the customer, nor to check it by experiment for example in the way I did. Nor for that matter is it an absolute disaster if you have to use a supplementary heater for the very few days of the year when the outside temperature comes anywhere close to the design temperature.

The market, at least where I live, is sick, very sick, and its MCS and grants that are making it ill. Something has to change!

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

Posted by: @cathoderayI suspect this is why trying to get a simple answer from @filipe on the evidence his heat pump isn't cycling (which he claims to be the case) is like trying to get water out of a stone, he doesn't have the data, or if he does, for some peculiar reason, he won't post it. The reason I am pursuing this is because I am beginning to wonder if Midea and Midea clone heat pumps default to cycling. If that is the case, I think it would be useful for current and prospective Midea/Midea clone heat pump owners to know.

I don’t find it helpful to criticise installers for not knowing all the ins and outs of plate heat exchangers

I am not sure why you think this, given in almost all cases the supplier/installer is the designer.

I object to you taking everything out of context. I certainly won’t waste time explaining anything to you. Please don’t quote me in misleading ways.

Phil

@filipe - I think if you read what I have written you will find that rather than taking everything out of context, I have tried to put things in context, or alternatively asked you to do so. For example, your 12 month 2992kWh use given a 'similar heat loss assessment' doesn't make much sense without context ie how you are actually heating your property. Likewise, I remain confused about your remark that "there is nothing wrong with this as long as the system under load can run continuously, which mine does when it is cold" (emphasis added) when the only chart you have posted shows what looks very like short cycling to me, which means it (it being the compressor) isn't running continuously. I'm pursuing this because, as I said in an earlier post, I think this tendency to short cycle might be a default Midea/Midea clone characteristic, in which case it is useful to know, and we can try to find ways to reduce it, as indeed we have been doing, eg by removing PHEs and similar contraptions. Even if you don't want to waste time explaining anything to me, you might do other readers the courtesy of giving them some context.

Midea 14kW (for now...) ASHP heating both building and DHW

@cathoderay This thread has been very long, informative and in the most part extremely useful in extending my understanding of the whole heat pump subject; it would be a great shame to sour the matter now and I suspect deprive others of some very useful knowledge s it has done so far for me. At one point, I had started to wonder if I should unsubscribe from the thread as it was extending in length so ‘thick and fast’ that I though I would never be able to keep up! So far, I have just about managed to continue reading - thank you to ALL contributors - it is by such means we extend our understanding of such complex matters via the free exchange of information and knowledge. Regards, Toodles.

Toodles, heats his home with cold draughts and cooks food with magnets.

To identify what is going wrong with so many of our heat-pump installations, we need the range of approaches and analysis which is occurring in this topic.

It is inevitable that there will be significant differences of opinion, and ongoing frustration with the lack of data available from the controllers and apps designed by the manufacturers themselves.

We need to hear the views of 'free thinkers', whether or not they come from an engineering background.

Solutions to the inefficiencies and ineffectiveness of heat pump installations aren't likely to emerge from a tame discussion, nor a reticence to challenge ideas.

Taking just the matter of poorly-applied (or non-existent) pipe insulation...

Who is more likely to get this right?

- a qualified installer with MCS-approval and training certificates from a dozen major manufacturers/suppliers?

- a young fella with autism and OCD, which blighted his school education, but who relishes issues requiring attention to detail?

The latter totally lacks the official approach to training professional installers... and yet is better suited for the task.

Amidst the difficulties emerging within these discussions, please persist.

I value reading the differences of opinion and analysis.

It doesn't matter so much to me whether a comment is 'right', but that it gets made.

Save energy... recycle electrons!

Posted by: @toodlesit is by such means we extend our understanding of such complex matters via the free exchange of information and knowledge

I couldn't agree more, which is why I have sought clarification from @filipe on the statements of his that baffle me. Indeed in science, it is often the peculiar that leads to insights. I do appreciate my writing style sometimes isn't 100% formal, but surely we are all grown up enough to take banter, rather than clam up in a huff. I should of course add that what I find baffling is what @filipe writes, not the man himself. There are no ad hominen attacks here, real or implied, and I apologise if any have been imagined.

Edit, now that I have seen @transparent's post: again, couldn't agree more. I also like your approach of matching the person to the task.

Midea 14kW (for now...) ASHP heating both building and DHW

Posted by: @transparentTo identify what is going wrong with so many of our heat-pump installations, we need the range of approaches and analysis which is occurring in this topic.

It is inevitable that there will be significant differences of opinion, and ongoing frustration with the lack of data available from the controllers and apps designed by the manufacturers themselves.

We need to hear the views of 'free thinkers', whether or not they come from an engineering background.

Solutions to the inefficiencies and ineffectiveness of heat pump installations aren't likely to emerge from a tame discussion, nor a reticence to challenge ideas.

Taking just the matter of poorly-applied (or non-existent) pipe insulation...

Who is more likely to get this right?

- a qualified installer with MCS-approval and training certificates from a dozen major manufacturers/suppliers?

- a young fella with autism and OCD, which blighted his school education, but who relishes issues requiring attention to detail?

The latter totally lacks the official approach to training professional installers... and yet is better suited for the task.

Amidst the difficulties emerging within these discussions, please persist.

I value reading the differences of opinion and analysis.

It doesn't matter so much to me whether a comment is 'right', but that it gets made.

Posted by: @cathoderayI also like your approach of matching the person to the task.

Definitely.

In the UK 1.4M gas boilers are retrofitted each year, the task is to make that 1.4M heat pumps. That's a major task which will not be accomplished by closed -mind thinking.

On another forum I have been disputing a view held by a couple of contributors that the only way forward is to train a whole load of young people and leave local plumbers and electricians completely out of the equation. Yet its local plumbers and electricians that deliver 1.4M retrofits per year and they value their reputations.

I completely accept that we need to train a whole load of people (young or old) in system engineering for the retrofit business. What I cant accept is that local plumbers and electricians cannot play a significant part. Although efficient retrofit system engineering is key (and is undoubtedly the principal missing skill), and people doing it must understand and have lived the real world of lifting floorboards and being bent double in cupboards/under sinks to make that final connection, it doesn't have to be done wholly by the same people who do the actual installation work. Local plumbers and electricians are the workforce we have, and excluding them in the way that MCS does is criminal (and also builds resistance to change).

If this problem is to be fixed we need to open it up and, as you say, match the person to the task. As well as plumbers and electricians, there are lots of engineers from other areas who understand problem solving and system engineering, have doubtless done some plumbing, but who perhaps don't want to spend the rest of their days in the awkward physical positions that plumbing inevitably forces you into. They may lack sector specific knowledge, but that's easily acquired. They too are excluded by the MCS stranglehold, and doubtless have absolutely zero motivation to learn by rote a whole load of rigid rules that they know will prevent them from doing a good job.

If you ran an engineering company tasked with ramping up over say 10 years to deliver 1.4M somewhat customised widgets (heating systems) per year, each of which took about half to one man day to design and a few man days to make on-site, would you go about it the way the UK is going about its heat pump roll out? I don't think so. And would you plan to do it by excluding and/or jettisoning the entirety of your existing, fairly loyal, workforce who are well trained in the onsite work, again I don't think so. Yet the current regime does exactly that.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 607 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

That’s my pleasure, @andrewj. The only challenge now is...

By Majordennisbloodnok , 9 minutes ago

-

RE: Electricity price predictions

@toodles @skd Then there is not going to be much from t...

By ChandyKris , 54 minutes ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

@batpred I reckon Andy might know a thing or 2 about...

By Bash , 1 hour ago

-

RE: What determines the SOC of a battery?

@batpred Ironically you didn't have anything good to...

By Bash , 2 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

Here’s a current graph showing a bit more info. The set...

By benson , 3 hours ago

-

RE: Setback savings - fact or fiction?

True there is a variation but importantly it's understa...

By RobS , 3 hours ago

-

Below is a better quality image. Does that contain all ...

By trebor12345 , 3 hours ago

-

Sorry to bounce your thread. To put to bed some concern...

By L8Again , 3 hours ago

-

@painter26 — they (the analogue gauges) are subtly diff...

By cathodeRay , 4 hours ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 7 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 10 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 12 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 1 day ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 1 day ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 1 day ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 1 day ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 1 day ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 2 days ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 2 days ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago