Samsung Launches the EHS Mono HT Quiet – A High Temperature, Low Noise Heat Pump Ideal for Home and Building Renovations

@derek-m yes absolutely, I'm not unread on the subject, I've watched many of these videos, and I understand the physics. I have done detailed heat loss calculations for my house , and upgraded some of my rads based on this. I know more about my heating system than most installers - I'm yet to find one who is a proper heating engineer (as supposed to a gas safe trained plumber) that I can "just trust to get on with it", so until that point (and to be honest, afterwards as well) I will continue to want to be fully clued up about how my system works and be involved in the design and selection decisions.

There is an assumption behind "don't use thermostats" statement that has been written in many articles that I've read on the "heat pump" subject which I believe is not valid in my (and many similar) cases for the below reasons:

1. I have a large closed-plan house, with widely differing heat losses in different rooms, and different temperature requirements based on what those rooms are used for and when. Some rooms are unused on most days. So, I use a large programmable TRV system, as most do who have this situation. Honeywell Evohome in my case. That aggregates up the demand from all rooms into a relay that signals on/off. This gives me and my family the comfort that we need in our house, where and and when we want it, whilst minimising energy use as much as possible. The argument of "just leave it on all the time everywhere" doesn't work for my use case. I therefore want a heat pump that is capable of taking this kind of input - whether that is "optimal" isn't the question.

2. My heat source at the moment (a mod-con heat only gas boiler) already has weather compensation (which I fitted myself, the installers didn't bother) and it works well. On most days the flow temp is below 50, so I know my house is well enough insulated for a heat pump - although it could be better, in my case that would mean EWI which has been costed at north of £30k.

3. I'm prepared to tolerate a less than perfect heat pump deployment because at least it would be moving away from burning gas - which is desirable both to reduce carbon emissions and to increase one's energy security in the current geopolitical climate. For me, its about reaching "good enough" in a short time, rather than "perfect" in a long time.

however (The reason I came in here in the first place 🙂 is that the DT of 5C means really rather fat primary pipes for a 14-16kw requirement - so I would be interested in any pointers to particular (air source) heat pumps that can run at slightly wider DT?

ta

Ian

My octopus signup link https://share.octopus.energy/ebony-deer-230

210m2 house, Samsung 16kw Gen6 ASHP Self installed: Single circulation loop , PWM modulating pump.

My public ASHP stats: https://heatpumpmonitor.org/system/view?id=45

11.9kWp of PV

41kWh of Battery storage (3x Powerwall 2)

2x BEVs

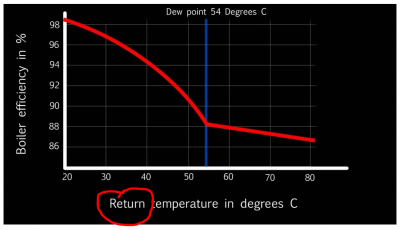

Gas boilers can have a high DT as the efficiency of them is governed mostly by the return water temperature. So long as the return temperature is low, I think the flow can be 0C-20C, it could even be higher still depending on the heat exchanger design, and it will not change the efficiency significantly. Graphs you find of gas boiler efficiency show return v efficiency. The source of heat they have starts very high (burning gas), and heat is available to be extracted as that gas is cooled in the heat exchanger. Pic of boiler efficiency:

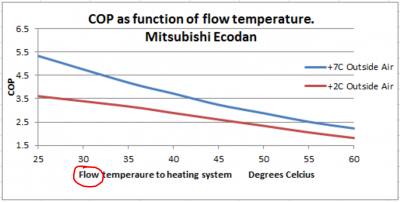

In contrast, single molecule fluid heatpumps (I think domestic ashp generally use these, R290, R22, etc, but there are blended refrigerants available) have a refrigerant fluid which changes from gas to liquid at a precise temperature. Almost all of the heat is available at this temperature alone. There is a bit of "superheat", but I think it's inefficient to have much of this. What this means is that it is the flow water temperature which determines the efficiency, not the return. The result of this, is that a high DT on a heatpump will simply reduce the COP. Pic of typical ashp COP:

@robl thanks, but whilst that is an explanation for why lower flow temps are good for COP, it doesn't say anything about DT? by the logic of the comment that its only the flow temp that matters, the return temp could be anything (very low) with a very wide DT?

My octopus signup link https://share.octopus.energy/ebony-deer-230

210m2 house, Samsung 16kw Gen6 ASHP Self installed: Single circulation loop , PWM modulating pump.

My public ASHP stats: https://heatpumpmonitor.org/system/view?id=45

11.9kWp of PV

41kWh of Battery storage (3x Powerwall 2)

2x BEVs

What i would find interesting is a graph or table that shows COP or some measure of efficiency for a variety of Delta T (flow vs return temp).

I think i now know that the domestic heat pump controls try and get to a target delta T (flow vs return) of 5 for the gases commonly used as it is doing its thing with weather compensation at the same time. Although given the quality of the installation of some sensors i do wonder what actually goes on sometimes.

I don't personally know just how bad things are if the Delta T gets to 6,7,8 9,10 for a prolonged period of time.

Also i don't know if any heat pumps let you tweak what the heat pump uses as a target Delta T in any way.

It is just a curiosity thing for me.

I can't imagine i would ever use the information to be honest but i can see why Ian is interested.

I can only assume no such efficiency data exists else i am sure someone would have found it. Interesting no one has posted any examples of being able to vary delta t given the variety of heat pumps and hence manuals people on the forum will have, including the installers on the forum. Best bet is probably phone up Samsung and ask if they can find out if the target Delta T can be altered and what impact it might have? I suspect you will get some strange response that doesn't answer the question....

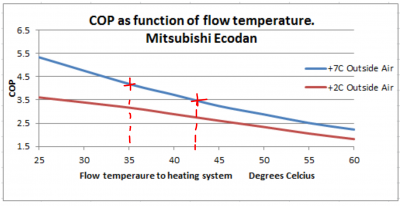

DT is just the temperature of flow-return, and Heatpumps only care about the flow temperature - if you would like a DT of 20C, you will find that your radiators will, on average, be halfway between flow and return - so to get the same heat out of them as at DT=5, the flow temperature will need to increase by 7.5C, so the COP will be worse. For the Ecodan, that would take you from COP=3.8 to COP=3.5:

DT=5 is I think a generally suggested compromise between COP (lower is better as the flow temp can be lower for a given set of radiators at a given power), and the water circuit used (pipework diameter, circulation pump power).

Having said all this, there's a variety of ways that heatpumps can be set up - often with an extra heat exchanger or 4 port buffer tank in the house, and an extra circulation pump indoors - this added complexity is so that glycol can be used outdoors, not inside due to cost. Under these conditions I don't think heatpumps generally have any useful control mechanism to give DT=5 around your rads, as this is controlled by an extra pump which is I think generally single speed.

My suggestion generally, by the way, would be to use a single circuit without glycol, and instead anti-freeze valves. Try and get DT=5 or close, but that's a question of upfront cost (swapping rads, pipes, or insulating and having a smaller heatpump - the best approach) versus long term elec running cost. There is no magic.

@robl thanks. I think a lot of the discussion confuses the two DT's though. With the output power of the Rad coming from (((Flow+Return)/2)-Room) DT, there's a bit of a gain from the fact that the average rad temp is a bit higher with lower (F - R) DT, but its not the main driver - the main driver is the F to Room delta as that's the big number.

whereas the Flow to Return DT is what I'm trying to find out about. Combined with primary flow rate, that (only) is what determines the heat transfer coming from the heat pump's primary circuit....and there we re-enter the discussion on enormous primary pipes. I'm well aware with glycol of course it gets worse (so yes I am looking for a single circuit no-glycol approach). Although I do want to hydronically split the circuits (close-T, buffer, LLH, whatever), because a single circulation loop in my house, at the flow-rates needed for a heatpump, is beyond the head of any normal domestic pump and I don't want a jet engine in the utility room 😉

I still don't think we've collectively answered the question though, is it possible to run a heatpump at slightly wider DT (at the same peak power output, accepting a lower COP) in order to be able to use a lower primary flow rate and thus not have to run monstrous , expensive, primary piping? Bearing in mind that this is only about it happening in the worst case scenario, when heat pump needs to to run flat out those days in MCS coldest day scenario, I see this as acceptable compromise (its about good enough not perfect) - if it works... I don't want the heat pump to pack up when its -3...

My octopus signup link https://share.octopus.energy/ebony-deer-230

210m2 house, Samsung 16kw Gen6 ASHP Self installed: Single circulation loop , PWM modulating pump.

My public ASHP stats: https://heatpumpmonitor.org/system/view?id=45

11.9kWp of PV

41kWh of Battery storage (3x Powerwall 2)

2x BEVs

I think I read off the COP numbers wrongly from the graph in my last post- trying a bit harder, it's COP=4.2 down to 3.5 from a 5C DT to 20C DT. It might not seem like much, but that represents a 20% increase in the expected heatpump electricity bill, every year, forever.

You can do what you say, and I suspect it's commonly done (keeping existing radiators, and too thin pipes). In some cases (mine), the extra retrofit insulation means a smaller HP can be used and all is well - we use a 1960s radiator system, DT=6, as the HP power is only 2.5kW. The lower DT will result in lower bills, that's all. I agree, it is only really significant on the colder days, when everything must run the hardest. Do you have a schematic in mind?

@robl just to be clear, I've already done numerous rad upgrades to K2 over the summer, based on heat loss calculations and the Rad temp (I'm working off avg(50,45)=47.5) to Room temp DT , and my secondary pipe work is big enough, its 22mm to several intermediate points and 15mm to the rads. That is not my area of concern.

also, which DT do you mean can be increased to 20C? Flow-Return? do you believe that implies that particular heat pump can run at Flow-Return DT = 20? sounds overly large to me?

My area of concern is entirely focused on primary pipe work, from the pump, to the location (airing cupboard) where all the 22mm branches come off (3 pipework zones).

I have a 210m2 1973 built house. I have done the MCS worst day calculations myself (using heatpunk.co.uk), and I get 14-16kw (depending on what temp I pick for which room, 18 vs 21 for different usage). I don't believe I will ever need to hit that , because I have monitored the 30-min gas usage of my boiler for the last 2 years and the worst I ever saw was 12kw (of GAS, not heat used by the house, so maybe 10.5 for the house at most) for a short period. But every heat pump installer wants to know that it will work at the rated spec otherwise they won't do it.

Heat/mass flow rate maths says that 14kw at DT5 needs 14kw needs 40l/min. Then I do the hazen-williams maths, with the pipe inner diameter sizes, to work out flow rate, and with distance added I get the head loss. To keep it down to acceptable levels that aren't going to be noisy (sub 1.0m/sec) and head loss within that of a sane pump, that requires 35mm copper over shortest distance I can use (20m ish). But its not actually do-able in copper over the 20m route (too wiggly...) so it goes up to 30m ish to go round in 35mm. cost goes even more bonkers. Or it can work in 40mm plastic but thats even bigger to make fit through the holes available and also pricy and specialist pipe. Either way both are crimp fit so outside the land of "normal domestic" pipework and not all the transition fitting sizes are easy to come by and it only comes in 3-5 m lengths so loads of waste / joining fittings and and and.... I have been looking a lot. I don't like any of the options.

whereas a wider DT of just 7 drops the flow rate needed to 28.4 l/min and it becomes feasible in 28mm copper, and the nuance that I'm considering to split it into 4x 28mm plastic (2 per direction, half the flow rate per leg) to go through the "wiggly under roof valley shortcut" currently used by the boiler primary (which is in 2x 28mm plastic), becomes feasible as well, and all of a sudden it becomes quite do-able..

I curse the people who designed some of the aspects of my house's physical topology 😉

schematic: not drawn it neatly enough to share here but will describe hope it makes sense

primary side:

heat pump with circulating pump->(antifreezing+zone valves)-->primary pipework 20m(ish) loop -> (branch point to cylinder with Z.V)-> airing cupboard primary side of Close-couple T's, 3 or 4 pipe buffer, or LLH

secondary side:

airing cupboard secondary side of Close-couple T's, 3 or 4 pipe buffer, or LLH-> secondary circulating pump-> 22mm zone distributions (3 of) -> several branches and loops in 15mm into rads (22 of) : individual distances to rads over pipe work path are between 5 and 30m from airing cupboard

control:

relay output of evohome system (summing the demand from 22 rads) signals "need heat or not" to heat pump and/or secondary circulator. heat pumps sensors and controls responsible for the rest.

ta

Ian

My octopus signup link https://share.octopus.energy/ebony-deer-230

210m2 house, Samsung 16kw Gen6 ASHP Self installed: Single circulation loop , PWM modulating pump.

My public ASHP stats: https://heatpumpmonitor.org/system/view?id=45

11.9kWp of PV

41kWh of Battery storage (3x Powerwall 2)

2x BEVs

As I stated previously I remember reading that at least one of the controllers allowed the required DT to be set greater than 5. Unfortunately I cannot remember the manufacturer. I would suggest that you call the technical departments of the various manufacturers, to see if they can help.

Isn't it the other way around? That is, if you make the flow rate lower - either by changing pump speeds (i.e. turning them down) or physically restricting the flow with smaller pipes (i.e. don't install the huge pipes needed for a 5 deg delta T), then the heat pump will run at a higher delta T? Or are you asking if there are any ASHP controllers that can monitor delta T and adjust flow rate to maintain a set target delta T ? (I don't know if any do that)

The question 'why is my COP so low and my flow/return delta T so high' is often asked and the answer is usually because the flow rate is too low.

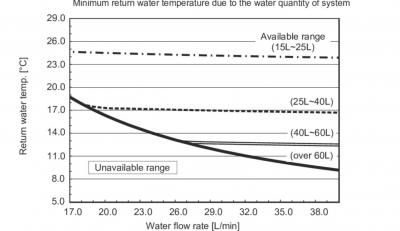

BTW you do have to be a little careful about making the return flow too low. This is for a 14kW Ecodan.

A further idea that you could possibly test with your present gas boiler would be to not supply all 3 zones at the same time, thereby reducing the required flow rate.

Our heating system, using an old gas boiler, and an industrial controller, basically heats up the radiators to a temperature calculated by the controller. The controller then switches off the gas boiler and the central heating pump until the radiator temperature falls slightly and the process is repeated.

The gas boiler is at its minimum setting and is heating the water in the region of 45C to 50C. The actual temperature of the radiators varies from probably 25C to 45C, dependent upon the heat loss of our home due the the outside air temperature. At this time of year the gas boiler is switched on for approximately 4 minutes, but then may not be switched back on for a further 1 hour. When it is below zero outside, the gas boiler may be on for just over 4 minutes, every 15 minutes, and heats the radiators to approximately 45C. Certainly in our case, it proves that the radiators do not need to be supplied continuously.

Dependent upon the thermal mass of your home, it may be possibly to have a system that feeds hot water to the larger of the 3 zones, but not the other two zones, and then switches over to supply the other two zones, but not the larger one. If you do not already have them, then fitting zone valves which are interlocked, so that when certain ones are open it prevents others from opening may just solve your problem. The heat pump may have to work a little harder at a slightly higher WFT, but that is already one of the things that you are considering. I leave you to do the maths.

@kev-m that graph looks pretty useful but not quite sure I can interpret it , what exactly is it the criteria for? is it saying that the ecodan will run perfectly fine (albeit maybe lower COP) with a return temp of 11C (as long there's more than 60L of water in the system) with a 33L/min flow rate? Mine is well over 100L volume so no issues there. I'm sure the that flow temp can't possibly be 16C as thats no use to anyone , lets say its even only 40C, that would make DT 30-ish, way over the 5, so do I understand the graph right?

what I'm asking is exactly what you said, but stated a different way - if the pipe isn't fat enough for 40L/min to be pushable by the circulation pump, will a 14kw heat pump run at a wider DT in order to still be able to output 14kw of heat? Say for the sake of simplicity the pipe/pump can handle no more than 20L/min, will it run at DT10? other people have said either it would always try to get down to 5C DT, and/or it would "have problems" at DT10.

I'm not asking for a heat pump that can maintain a particular delta T as its target - I'm asking if there's a 14kw one that will still supply its full power output if the pipe/pump combo won't do 40L/min. That implies that it would have to widen its DT in order to do that - but it would do that based on being continually asked for more heat , and the return temp staying low, rather than a specific DT target. If the heat demand is low, it can go ahead run at DT5 to optimise COP if it wants to. I find the available documentation and commentary contradictory as on the one hand there is "DT must be 5 otherwise it breaks" and on the other hand you have this implied "it'll still work but at a worse COP". Thats my basic question / problems - if it still works at 14kw at DT7, then I dont need to rebuild my house / spend a fortune to put in gigantic pipes for 40L/min. I can put in "normal" ones that'll do 30L/min.

My octopus signup link https://share.octopus.energy/ebony-deer-230

210m2 house, Samsung 16kw Gen6 ASHP Self installed: Single circulation loop , PWM modulating pump.

My public ASHP stats: https://heatpumpmonitor.org/system/view?id=45

11.9kWp of PV

41kWh of Battery storage (3x Powerwall 2)

2x BEVs

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 259 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Setback savings - fact or fiction?

@cathoderay The input power is largely determined by...

By RobS , 12 minutes ago

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

@editor, this is now an example of greenwashing in the ...

By Majordennisbloodnok , 23 minutes ago

-

RE: Electricity price predictions

@transparent Im impressed by all your work on this. ...

By JamesPa , 2 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

Just to wrap this up here for future readers: The S...

By Batpred , 2 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 2 hours ago

-

RE: What determines the SOC of a battery?

I agree. Fogstar confirmed that the Seplos BMS does ...

By Batpred , 3 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 4 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@benson — as @tasos suggests, plotting multiple variabl...

By cathodeRay , 6 hours ago

-

@painter26 — as @jamespa says, it's for filling and re-...

By cathodeRay , 8 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 18 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 20 hours ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 23 hours ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 24 hours ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 24 hours ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago

-

RE: DIY solar upgrade - Considering adding more panels

I know this is a bit old, but it made me wonder what co...

By Batpred , 2 days ago

-

RE: New Vaillant aroTherm Plus in black - When will it come to the UK?

@majordennisbloodnok Daikin, take note! (In fact, I hav...

By Toodles , 2 days ago

-

RE: Midea ASHP – how to set weather compensation

@mk4 — good work! First, I agree, no evidence of cycl...

By cathodeRay , 2 days ago