Samsung Gen6 16kW tribulations

Samsung 16kW Gen6 installed 3 years ago. Primary circuit 28mm pipework, primary pump Grundfos UPM4XL 25-90 130, 250l HW tank, 50l buffer, 2 secondary pumps for UFH and rads with separate heatmiser thermostats.

About a year ago, compressor failed and Samsung repaired, but said that the installation (by a Samsung registered installer) voided the warranty, saying the flow rate and system volume too low. After a lot of reluctance and buck-passing between Samsung/supplier/installer, the 50l buffer was installed, but primary pipework left at 28mm and flow rate still 30lpm instead of 46lpm Samsung insist is mandatory. They say low flow leads to cycling and compressor failure, which seems not unreasonable.

Previously the running costs were just about tolerable, but now they have become stupid (x 2-3). Samsung just say all the problems are due to low flow rate, but we no longer trust their advice, and don't want expense of 35mm pipework until the excessive energy use has been resolved.

-We can't remember figures from before change, but it can't be correct for ASHP to sit at 7kW input when OAT 10deg and LWT 33deg? (we gave up after 10hours !)

-It seems sometimes the primary valves for both HW and Heating are open at the same time. Surely that can't be correct?

Anybody any ideas as to the most likely causes of these? Or what else we should look out for?

-12kW would be more than enough for the house and only needs 36lpm flow, but Samsung refuse to change EPROM without voiding the warranty. If we give up on Samsung and change EPROM ourselves, is it very difficult to set up the new one? Would it be a good idea?

Hi. Im not an installer but as no one else has answered you, I will try and help.

28mm copper pipes can move about 10 kW of heat at 0.9 m/s so would seem unsuitable for a 16 kW heat pump. Adding a buffer vessel should help your flow rate issue but will have a knock on effect of lowering your efficiency and increase your bills.

Do the 28mm pipes connect your heat pump to the cylinder/heating system? If so they are too small if you actually need 16kW, but if you think your house doesn't need that much heat it could maybe work.

The energy usage you quote is eye watering, and no the heat pump should not be heating the hot water and space heating at the same time!

Do you have any kind of monitoring on the system? That would be very helpful in trying to find out the best way forward. If you dont then investing in some might be a good idea. Something like this would tell you what was happening and costs about £550. There are other cheaper alternatives.

House-2 bed partial stone bungalow, 5kW Samsung Gen 6 ASHP (Self install)

6.9 kWp of PV

5kWh DC coupled battery

Blog: https://thegreeningofrosecottage.weebly.com/

Heatpump Stats: http://heatpumpmonitor.org/system/view?id=60

@bontwoody Hi, thanks for reply. System has settled to 0.9 kW, but is difficult to be sure which, if any, of our many fiddlings worked and so how likely to recur. I wonder if maybe was sticky zone valve somehow released?

Do you happen to know (for combinations of LWT and RWT), the logic ASHP uses to decide when to switch on/off and what power to apply?

@emceed I assume you have a 3 way valve controlling the direction of water flow to either the space heating or DHW. Its possible that they can stick I think. There is also something called a mid position valve which can do both at the same time but thats not what you want. I believe a mid position valve can be used as a three way if its connected correctly. Might be worth checking if you think it was heating both at the same time.

If that was occuring then it would account for the ridiculous energy usage as you would be sending hot water around your heating pipes. If it happens again feel the pipes leaving the valve and see if all are hot or not. The space heating pipe should be cooler.

Have a serious think about some kind of monitoring as a badly set up system can waste a lot of money very quickly.

House-2 bed partial stone bungalow, 5kW Samsung Gen 6 ASHP (Self install)

6.9 kWp of PV

5kWh DC coupled battery

Blog: https://thegreeningofrosecottage.weebly.com/

Heatpump Stats: http://heatpumpmonitor.org/system/view?id=60

@emceed A heat pump will have sensors monitoring the LWT and the RWT and when the difference is close to zero, the pump should stop applying energy to the water. A good Delta T for a heat pump is 5 degrees C.; when the returned water is nearly the same as the LWT, this indicates (all else being equal) that the emitters (radiators in many cases) are no longer emitting sufficient heat to cool the returning water. At this point, the Delta T is probably less than 1 degree C. I think. Hope that clarifies things a little. Regards, Toodles.

Toodles, heats his home with cold draughts and cooks food with magnets.

Posted by: @emceedDo you happen to know (for combinations of LWT and RWT), the logic ASHP uses to decide when to switch on/off and what power to apply?

I am glad to hear that your consumption problem has resolved. On starting, it seems that the compressor ramps up to close to 100% and then modulates down after 20-30 minutes, depending on the target LWT. As long as the emitters can match the minimum ASHP heat output, then the ASHP should just continue to run at target LWT. In mild conditions, if the emiiters cannot match the minimum ASHP heat output, then either LWT rises above target or Delta T falls below an acceptable limit and the compressor will stop. From my observations, I think it is the rise in LWT that triggers the compressor to stop rather than a low Delta T, but this is probably academic.

If cycling on and off frequently due to the above mechanism is a problem, then it is worth altering your FSV settings (2091/2092 if using an external stat and 2093 if using the wired remote controller's stat). You can set these so that the compressor only switches off if the stat is no longer calling for heat. LWT will rise with these settings if the emitters cannot match the minimum ASHP heat output because the compressor cannot modulate any lower, but in my experience the electricity consumption stays at its minimum value.

Again thanks for replies.

Is not a 3-way valve. ASHP output tees to 2 Honeywell zone valves, HW directly to HW coil and returning via buffer. The heat zone goes thro buffer then tees to rads/UFH. Not so easy to be certain what water flows are doing. I know we should buy/install/learn monitor but are so cheesed off with poor design and installation that we may have to make other costly decisions first.

We have 2091/2092 so already. It would make sense that RWT and Δ(5) eventually try to drive the LWT over target which stops ASHP. Presumably there is then some hysteresis setting to trigger restart. Can anyone confirm this logic, especially in situations where (1) heating slab from cold and (2) LWT/flow just balancing emission so maintaining heating at maximum efficiency ?

(We do need LWT over 33 or inadequate emission causes cycling - at 7kW !)

@emceed even something like these taped to your pipes with insulation over the top will give you some idea what’s going on if you don’t want to spend a lot.

House-2 bed partial stone bungalow, 5kW Samsung Gen 6 ASHP (Self install)

6.9 kWp of PV

5kWh DC coupled battery

Blog: https://thegreeningofrosecottage.weebly.com/

Heatpump Stats: http://heatpumpmonitor.org/system/view?id=60

@emceed, can you please give us an update on your system and what happened with the warranty issues?

Get a copy of The Ultimate Guide to Heat Pumps

Subscribe and follow our YouTube channel!

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 355 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

@jancold I only discuss data.. Fogstar were not impress...

By Batpred , 11 minutes ago

-

RE: What determines the SOC of a battery?

@batpred Ironically you didn't have anything good to...

By Bash , 46 minutes ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

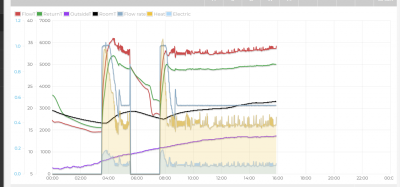

Here’s a current graph showing a bit more info. The set...

By benson , 59 minutes ago

-

RE: Setback savings - fact or fiction?

True there is a variation but importantly it's understa...

By RobS , 60 minutes ago

-

Below is a better quality image. Does that contain all ...

By trebor12345 , 1 hour ago

-

Sorry to bounce your thread. To put to bed some concern...

By L8Again , 1 hour ago

-

@painter26 — they (the analogue gauges) are subtly diff...

By cathodeRay , 2 hours ago

-

RE: Electricity price predictions

I am always impressed with how you keep abreast of so m...

By Batpred , 3 hours ago

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

@majordennisbloodnok I’m glad I posted this. There see...

By AndrewJ , 3 hours ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 6 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 9 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 10 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 1 day ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 1 day ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 1 day ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 1 day ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 1 day ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago