Octopus Energy Heat Pump Quote

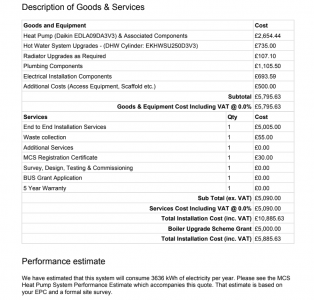

I thought some of you might be interested to see the quote we've received from Octopus for my mum's 4 bed detached house in Cambs.

I was really impressed with the service and survey process, not least because they don't charge you for the privilege of completing the survey and receiving a quote!!

This is actually the first proper quote we've received and I'm really pleased and suprised by the cost being quoted - other guide prices we've recieved have been 50-100% more!!

I also like that they worked with us in regards with heating the conservatory - because it's still seperated from the house by double glazing we weren't being pushed to upgrade the radiators. We still may anyway, but this customer focussed approach was very refreshing to see.

Love to hear your thoughts or comments.

I currently asking questions to try to find how flexible they are with customising the design slightly, so that will be interesting to see!

We're hoping they can install or allow us to install collaboratively a mixergy tank and plinth heaters in the kitchen.

Watch this space...!

This is a similar quote from the internet, I wonder when the £3k advertised cost comes to fruition as both these have minimal radiator upgrade required.

Description of Goods & Services

Goods and Equipment Cost

Heat Pump (Daikin EDLA08E2V3) & Associated Components £2,335.20

Hot Water System Upgrades - (DHW Cylinder: TCEMVI-0200SFC) £1,027.00

Radiator Upgrades as Required £618.06

Plumbing Components £855.14

Electrical Installation Components £479.38

Subtotal £5,314.78

Goods & Equipment Cost Including VAT @ 0.0% £5,314.78

Services Qty Cost

End to End Installation Services 1 £5,005.00

Waste collection 1 £55.00

MCS Registration Certificate 1 £30.00

5 Year Warranty 1 £0.00

Sub Total (ex. VAT) £5,090.00

Services Cost Including VAT @ 0.0% £5,090.00

Total Installation Cost (inc. VAT) £10,404.78

Boiler Upgrade Scheme Grant £5,000.00

Total Installation Cost (inc. VAT) £5,404.78

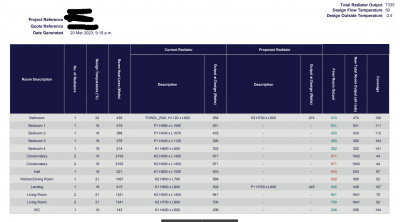

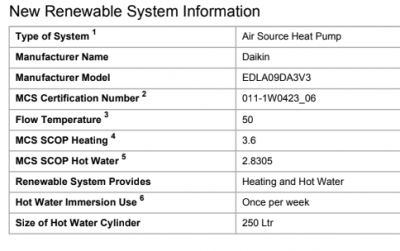

I had all my 22 rads replaced with mostly triples and a few double. I see P1 rads listed above. My Midea 12kW ASHP mostly runs at 40c leaving as the target. I see your flow temperature is quoted at 50c. Does anyone know if MCS require this?

My heat loss calculations came to 12kW so there was no slack. The alarming thing about the heat loss calculations was the allowance for air leakage from the building, which almost doubled the heat loss. Most new buildings are required to be significantly better.

Your installation labour is quite high. Normally the heat pump is ground mounted, so £500 for scaffolding is odd. However, it is good that you see Octopus as a lot less expensive.

I would ask questions about the controls and monitoring being provided so you can assess how efficiently the system is running.

Phil

@squeakysim - that seems like a good quote. We installed an 8.5kw Ecodan and a Mixergy tank (more expensive than the normal system tank) at a cost of £12,500, and then had the £5k grant so paid £7500 total. That included some new and some replacement radiators. We went through a quoting process with Octopus - we were quite specific with what we wanted to do, so we didn't proceed with them because they didn't want to do a complicated install. Hopefully they are a bit more amenable (we were talking with them while they were developing their approach) - essentially their model was about simple replicable installations, which makes sense for bringing costs of installation down. We wanted pipe runs from the heat pump to the tank to go under the floor, they wanted to run the pipes around the outside of the house. We didn't get as far as whether they would work with Mixergy. I was impressed with the level of detail they went into for the heat loss calc and their communications.

Good luck!

Octopus seem to get it. I moved to them for electricity and their Cosy tariff really works for us. Great customer service.

This is a well detailed and itemised quotation, which looks very reasonably priced. Room design temperatures are realistic, not all based on 22-24degC, which would result in an oversized ASHP selection. Octopus has large purchasing power, and you can see that evident in the price of the Daikin ASHP unit, which is well below most retailers' list prices.

I would challenge Octopus on the 50degC design temperature. Ask for an option for 45degC design temperature.* It will cost more, and you will need to upgrade more radiators for bigger heat emitters. But 50degC is too high a design temperature for retrofit ASHP. The uplift in cost for 45degC design will be recovered within 1-2 years through lower energy consumption and electricity costs. You are unlikely to achieve the MCS predicted SCOP for heating & hot water on a retrofit. There are inefficiencies inherent in a retrofit, such as less than optimal pipe sizes, additional circulating pumps sometimes needed, pre-plumbed cylinders with rather restrictive pipework and motorised control valves, heat losses from existing pipework under-floors and in floor voids, etc.

Also bear in mind that, even with power flushing, older emitters and radiators will have degraded thermal performance over time. All software used for heat loss assessments assumes the emitter provides original condition heat output, which is seldom so. This is where good old fashioned experience & engineering judgement comes into play. Radiators are quite cheap to upgrade & replace.

* I had a retrofit ASHP system designed for 50degC flow temperature, but with commissioning and control tweaking, including proper climate compensation, opening up all TRVs, ditching the 3rd party on/off room thermostat, and upgrading a few extra radiators is now running at 42degC flow temperature to keep the house at 18-20degC on pure climate compensation control. The difference in running cost is significant with much less wear and tear on the ASHP as it is not being switched on and off multiple times each hour by some dumb room thermostat.

Posted by: @fazelI wonder when the £3k advertised cost comes to fruition

Are you referring to their target of getting close to gas boiler install costs?

@filipe the 50C will be why we haven't needed to change many radiators I guess. I'm keen to try and improve the 50C a maybe look to change some other radiators which could bring it down. Particularly as the radiator cost seems extremely good value too, and compared with the quote @Dandee posted it looks like installation is a fixed fee...!(?)

The scaffolding is because the water tank location is the airing cupbaord in the centre of the house upstairs, meaning pipes need to be run up through the loft and down into airing cupboard. I'll be taking the feedback on controls and monitoring into account too, thanks!

We have received some feedback on the plinth heaters and they stated that they don't install them, and that hydronic one's don't work with heater pumps...! Does anyone have any information that can counter this?!

My understanding is that as long as they are sized correctly (like radiators) that they should work, and potentially even perform better than a radiator of the same output because of the fan distributing the air. Any thoughts?

Posted by: @squeakysimWe have received some feedback on the plinth heaters and they stated that they don't install them, and that hydronic one's don't work with heater pumps...! Does anyone have any information that can counter this?!

My understanding is that as long as they are sized correctly (like radiators) that they should work, and potentially even perform better than a radiator of the same output because of the fan distributing the air. Any thoughts?

Plinth heaters will work with any heat source, boiler, ASHP, etc. Heat output is purely a function of water inlet temperature, room air temperature, water and air mass flows. They can be prone to getting dirty, dusty, blocked up and needing a bit of maintenance due to location, but a good option where there's no wall space for larger or additional emitters.

https://www.grantuk.com/about/news/grant-launches-solo-fan-convector-range/

@allyfish thanks for the feedback, I definitely will be exploring what design temp might be possible with a few more rads!

Doesn't look like Grant do the plinth heaters anymore unfortunately! I was keen to see if they had a thermal cut in switch for the fan, as other models I've seen only have the fan coming on at 35-40C.

Posted by: @squeakysimWe have received some feedback on the plinth heaters and they stated that they don't install them, and that hydronic one's don't work with heater pumps...! Does anyone have any information that can counter this?!

My understanding is that as long as they are sized correctly (like radiators) that they should work, and potentially even perform better than a radiator of the same output because of the fan distributing the air. Any thoughts?

I thought your quote looked not too bad. with a possible ponder on "whats the labour rate / number of days", "is there a buffer / whats the design / what are the controls" . However that kind of thing "our system says we don't do plinth heaters" is the possible downside of going with bigco like octopus (who I have a lot of time for, I'm a long-standing customer) . As their installs will be templated for simplicity and repeatability, it may be difficult to get them to go outside template. The person/team who designed and tested the template won't be the one doing the install. But it should be a well designed and tested template if octopus are putting their repuation on it.

Plinth heaters work really well provided the cut-in temp is low enough for your design LWT . I've run my boiler at 45 for a large part of this winter and my old myson hydronic plinth heater (with a boiler level cut-in temp, I think 42) runs fine. Being fan driven way better output space for space than a radiator and of course they work really well in kitchens. I have one and thinking about adding another. Don't forget there are FCU's from various people which are basically the same thing but in a different form factor , usually for wall mount - and those are often marketed specifically at heat pumps systems by heat pump suppliers. New Plinths and FCU's will have cut-in temps that are entirely suitable for the LWT in a heat pump circuit with radiators. so .. TLDR: their logic to refuse to use hydronic plinths, doesn't make sense.

suggest talk to https://kitchenheaters.co.uk/ they have been very helpful although I've not bought anything from them yet. they have options to vary the cut-in / cut-out temperatures or even bypass the thermostat - treat it like an always on radiator and just electrically switch the fan via other means. and the highest outputs space for space that I've seen vs myson/smiths etc.

the other thing I noticed on your quote was the relatively low number of rad changes, particularly some P1's being left. even if those are deemed adequate and so to not need changing based on output as per the survey, you'll get a better system in the end if you upgrade them to at least K1, even if you haven't the room to go K2. Its not the high cost part of the work (or shouldn't be).

My octopus signup link https://share.octopus.energy/ebony-deer-230

210m2 house, Samsung 16kw Gen6 ASHP Self installed: Single circulation loop , PWM modulating pump.

My public ASHP stats: https://heatpumpmonitor.org/system/view?id=45

11.9kWp of PV

41kWh of Battery storage (3x Powerwall 2)

2x BEVs

I asked some follow upi questions after your feedback and received this a promising response - so it's not an outright 'no' after all!!

"

- If your considering a mixergy tank we would be more than happy to have a third party install this for you however, it would need to be done after the installation. Furthermore, would need you to send over the details of mixergy tank before going ahead.

- Would you be able to give us a little more detail as to why you would want a mixergy tank or any concerns our cylinder won't be able to provide that a mixergy would.

- The hot water cylinder is a standard cylinder however you would be able to schedule/monitor with the Daikin app.

- We certainly would be able to bring the design temperature down to 45C for you but anything below (such as 40C) would mean we would need to look at upgrading more radiators than what we've scheduled for and they would need to be bigger meaning there would be a price increase.

- Plinth heaters do work with heat pump systems however we would recommend using an electric system rather than wet as wet designs will only turn on when a certain temperature is met, often lower than the heat pump creates. However your more than welcome to send over the details to me so that i can get this checked with our tech team.

- The buffer is part of the design and i have attached an example below of the design layout.

- You can monitor the heat pump by using a open energy monitor and i have linked details below. We would be able to install one of these for you for an extra charge of £200.00 and if you were happy we would love to access the data from this so we can create a testimony from your results.

https://docs.openenergymonitor.org/applications/heatpump.html

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 419 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

@painter26 — they (the analogue gauges) are subtly diff...

By cathodeRay , 21 minutes ago

-

I cannot see the complete rcbo, since the photo is cut....

By Batpred , 34 minutes ago

-

RE: What determines the SOC of a battery?

The answer from Fogstar was crisp. My hypothesis, su...

By Batpred , 44 minutes ago

-

RE: Electricity price predictions

I am always impressed with how you keep abreast of so m...

By Batpred , 54 minutes ago

-

RE: Setback savings - fact or fiction?

I fully understand your reasoning, same steady inputs s...

By cathodeRay , 1 hour ago

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

@majordennisbloodnok I’m glad I posted this. There see...

By AndrewJ , 1 hour ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@tasos and @cathoderay thanks. I have some history grap...

By benson , 3 hours ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 4 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

Just to wrap this up here for future readers: The S...

By Batpred , 7 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 7 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 8 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 23 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 1 day ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 1 day ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 1 day ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 1 day ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago

-

RE: DIY solar upgrade - Considering adding more panels

I know this is a bit old, but it made me wonder what co...

By Batpred , 2 days ago