Migrating from boiler to heap-pump; balancing radiators and UFH

@tomasmcguinness I saw your YouTube video about radiator balancing and I'm looking forward to seeing developments

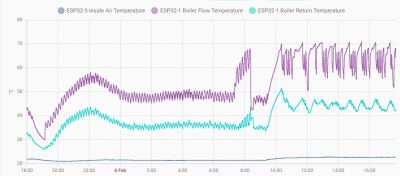

I attach my boiler flow and return temperatures over the last 24 hours. The left-hand side is operation with my Drayton controller and the right-hand side with no Drayton controller. DHW came on around 7am. The Drayton controller is now obsolete and Drayton will shortly be stopping cloud services so it will then become 'dumb' and I am trying to decide whether or not to replace it.

That looks about right. The Drayton slowly increased the temp by firing the boiler for short periods before it settled down. On the other side, the boiler just goes to full blast and cycles when the return temp gets too high.

Have you compared the gas usage on either side? It would be interesting to see the cost of letting the boiler cycle vs letting the Drayton turn it on and off.

Owner of a ridiculously oversized 35kW boiler and trying to make it as efficient as possible. 4.8kW solar PV with 5.4kWh storage. EV driver.

Follow my journey at https://www.youtube.com/@tomasmcguinness

Next big project is a heat pump!

@tomasmcguinness My concern with operation via the Drayton is the wear on the gas valve considering it turns on and off every 10 minutes. Regarding operation without the Drayton, I thought modulation in a boiler was supposed to produce a variable flame, not a boolean one. I know this boiler has a variable speed fan in it.

Gas consumption is certainly more stable with the Drayton. It's difficult to say from the attached graph alone, but I'd say consumption is slightly more. This correlates with the indoor temperature increase, too. If I can bring the indoor temperature down then I suspect there would be little if any difference in cost (it's difficult to assess on a day-to-day basis). Incidentally, I've realised that the usual running cost comparisons of boiler versus heatpump are rather more complicated when on agile and gas tracker tariffs. This will obviously change as energy policy taxes change in the future.

Modulation is supported in most boilers, but they have limits. My boiler, for example, can go between 35kW and 5.5kW. That's a range of 100% to 15%.

The boilers job is to lift the temperature of the water coming back into it up to the desired temp. In a condensing boiler setup, it will usually try and lift the water from say 50 to 70 as that's your desired flow temperature.

When the boiler starts, the return will be quite cold (most likely ambient temp) so the boiler will work hard to get it from 20 up to 70.

As the return temperature starts to rise, the boiler will reduce the amount of heat it needs to put into the water, maintaining flow temperature e.g. 70.

However, if the return temperature starts to get too high (because your radiators cannot dissipate enough heat), the boiler will turn the flame off. It will keep circulating the water until the return temperature drops far enough before the flame turns on. This is cycling.

It's bad in a boiler but it's terrible in a heat pump!

Owner of a ridiculously oversized 35kW boiler and trying to make it as efficient as possible. 4.8kW solar PV with 5.4kWh storage. EV driver.

Follow my journey at https://www.youtube.com/@tomasmcguinness

Next big project is a heat pump!

@tomasmcguinness a thermal store can help to reduce cycling / increase utilisation. Using dual stats top and bottom is helpful - appliance comes on only when the high stat goes below limit, and then off when bottom stat goes over limit (or when the return to the appliance is satisfied).

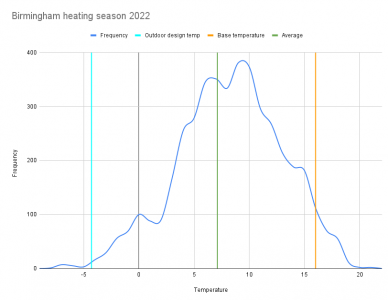

Looking at our heating season temperatures is interesting (well to me anyway 😀 ) - here I've marked the outdoor design temp as defined in BS12831. It leads to a lower temperature than if using the Cibse method. It's also calculated over 20 years and climate change has a definite effect over that period. Base temperature isn't accounted for when calculating the peak load using 12831 - so that all contributes to oversizing, even when the appliance is "correctly" sized.

(MCS framework currently refers to 12831, apart from the outdoor design temp which refers to Cibse.)

Great to hear about the changes you're making to your system in preparation, and your youtube channel looks excellent although so far I've only found time to look at one of the many uploads. I imagine that your control system will be able to track electricity prices and adjust the flow temperatures of a heat pump once you get to that stage?

Planning your dream house? Book a simple one-to-one consultation to get you on a good path - here.

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 415 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

Without knowing it, @andrewj, you've laid down the gaun...

By Majordennisbloodnok , 4 minutes ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@tasos and @cathoderay thanks. I have some history grap...

By benson , 8 minutes ago

-

I am having my existing heat pump changed to a Vaillant...

By trebor12345 , 41 minutes ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 1 hour ago

-

RE: Setback savings - fact or fiction?

@cathoderay The input power is largely determined by...

By RobS , 2 hours ago

-

RE: Electricity price predictions

@transparent Im impressed by all your work on this. ...

By JamesPa , 3 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

Just to wrap this up here for future readers: The S...

By Batpred , 4 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 4 hours ago

-

RE: What determines the SOC of a battery?

I agree. Fogstar confirmed that the Seplos BMS does ...

By Batpred , 4 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 5 hours ago

-

@painter26 — as @jamespa says, it's for filling and re-...

By cathodeRay , 9 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 20 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 22 hours ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 1 day ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 1 day ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 1 day ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago

-

RE: DIY solar upgrade - Considering adding more panels

I know this is a bit old, but it made me wonder what co...

By Batpred , 2 days ago