Is My Midea Heat Pump Inherently Defective?

There is no doubt that my heat pump fails to provide adequate heating at lower outside air temperatures. This is an 'MCS fail' - it can't keep the room temperatures at design temperatures when it is colder outside. This is despite the fact that on paper it should be able to do so. Given an empirical (measured not calculated) heat loss of around 9 to 10kW at -2 degrees outside, and a claimed (by Midea) output at that OAT (and LWT I have) of around 11.3kW, it should be able to cope, but it can't. It is a CQC heat pump - a Can't Quite Cope heat pump. It has been sub zero outside overnight, and this morning the room temp is 18 degrees where it should be 21 degrees.

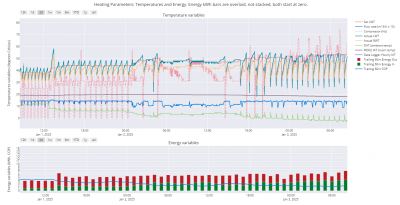

The last 48 hours has provided a very useful range of outside air temperatures (OATs), meaning I can plot my heat pumps behaviour over a wide range of temperatures over a short time frame, which makes it easier (but no necessarily easy, the plots are inevitably cluttered!) to see and compare what is going on. This is what I have (note the flow rate is plotted as true value x 10, to make it easier to see what is going on):

And there is indeed a lot going on here. Starting on the left, we have a 3 hour period of moderate OAT (just over 10 degrees). Here the heat pump does what it does most of the time: it runs with a fixed flow rate and appears to modulate its output by cycling, which in turn means much of the time the leaving water temperature (LWT) / returning water temperature (RWT) delta t is too low. This is not how a heat pump is supposed to run. That said, the trailing 60min COP of just over 4 is OK.

At around 1300 on 1st Jan, a day of storms, the OAT suddenly drops (cold front passing?). This happens to coincide with a timed DHW heating cycle (the high LWT spike), but once that is over the Set LWT increases, as it should, but the flow rate remain the same, and the heat pump continues to cycle, albeit with a marginally higher average LWT/RWT delta t, and the compressor (dotted line) can be seen to work a bit harder, and the trailing 60min COP drops to about 3. But it is still cycling, and this is not how a heat pump is supposed to work.

In the early hours of 2nd Jan, the OAT continues to fall, and the heat pump does something unusual for it, it starts running as it should. It modulates (in this case drops) the flow rate, the LWT/RWT delta t rises, and it stops cycling. The COP however continues to fall, as the heat pump is working harder. Note how relatively stable everything is between 0600 and 1200. This 'normal' steady running state is extremely rare on my heat pump, and only seems to occur at around 5 degrees OAT. Above that OAT, it cycles, below that OAT it starts robbing Peter to pay Paul (ie defrosting) as we can see on the right hand side of the chart. As the OAT drops to zero and then below on the evening of 2nd Jan, the heat pump starts using defrost cycles (the LWT drops below the RWT), and the heat pump sucks heat out of the building and dumps it in the garden (albeit doing a spot of defrosting on the way), as can be seen in the larger OAT upticks that coincide with the defrost cycles. All the while the compressor is working harder and harder. These defrost cycles are extremely damaging to performance. The energy out (red bars in lower chart) hardly rises from what it was in the previous 12 hours, despite the fall in OAT, the energy in rises, and the COP drops below two, and worst of all, because this is what really matters, the indoor air temp starts to fall. The heat pump is now firmly established in CQC mode, and it will stay in that mode until the OAT starts to rise. Until that happens, the indoor air temp will continue to remain cooler than it should be, and may well fall yet further.

I should perhaps add, because the flow rate is so central to what appears to happen, that the Midea reported flow rate is credible. Although it is calculated from unspecified 'electronic parameters', rather than directly measured, the reported values are very close to those seen on an independent analogue flow meter in the pipework.

As I said at the outset, this is an MCS fail. The question is why, and what can be done about it. We can effectively rule out heat pump under-sizing, because if we use real world heat loss and heat pump capacity values, the heat pump should, at least on paper, be able to meet the heat demand at low OATs (11kW supply to meet a 9-10kW demand). Instead the answer must lie in the way the heat pump is functioning, or rather not functioning.

It seems to me there are two problems. The first is that it fails to make use of its theoretical ability to modulate (vary) the flow rate. The almost always 1.4m^3/h flow rate is a striking feature of my heat pump (that drop seen in the middle of the chart is a very rare occurrence). Compare the extreme left and right hand ends of the plot. In both cases, the flow rate is effectively the same, despite the fact the OAT has gone from above 10 degrees to below zero degrees. According to the Midea manual, the flow rate can vary between 0.7m^3/h and 2.75m^3/h, but this never happens (or only very rarely, and then only by a limited amount, when the OAT is around 5 degrees). This has not one but two unfortunate consequences. The first is that the heat pump has to cycle at moderate and above OATs, and, the second, far worse, is that it can't up its output at lower OATs, and the end result is a failure to deliver sufficient heat. Until someone can persuade me otherwise, I consider this to be a defect of the heat pump.

The other problem, which is a general heat pump problem, though other manufacturers may manage it better, is the harmful effect of defrost cycles. Despite the compressor working harder than ever, and a rise in energy in, the energy out fails to rise, and the mean LWT, which is normally at around the set LWT, falls below the set LWT. The heat pump is thrashing itself, but getting nowhere. But defrost cycles are a given for heat pumps, which means they have to be designed to accommodate them, and that means adjusting other parameters - eg flow rate when not defrosting - to compensate.

And all the while, that flow rate stays stubbornly fixed. Recall the heat transfer equation, the heat transferred is directly proportional to the flow rate, if everything else stays the same, double the flow rate, and you double the heat transfer, half the flow rate and you halve the heat transfer. Yet my heat pump doesn't make use of that basic law of physics, and the result is that it cycles at moderate and above OATs, and fails to deliver sufficient heat at low OATs.

What can be done about it? I don't know. Freedom (who are effectively Midea Inc. in the UK) have yet to come up with anything useful so far. There has been a suggestion that the primary pipework is inadequate (too small), but I am not at all sure about this, because while it might explain the inability to raise the flow rate above 1.4m^3/h or thereabouts (that is the max the available pump can do given the available pipework), it fails to explain why the heat pump doesn't drop the flow rate at moderate OATs. In other words, if pipework resistance is a problem, then it should only restrict higher flow rates, lower flow rates should happen as expected - but it doesn't, the flow rate stays stubbornly fixed, it doesn't go down when it could and should do so (except for that odd 5 degrees OAT effect, and unfortunately Mother Nature does not oblige us with a constant 5 degree OAT).

It seems to me the first question that has to be answered in attempting to fix this is why does a heat pump that has PWM control (the ability to vary flow rate) not use variable flow rates? The effectively fixed flow rate can explain both the moderate OAT cycling and the low OAT poor performance. Or to put it the other way round, if the circulating pump did modulate it output, then it might both stop the moderate OAT cycling, and be able to deliver more heat when it is most needed, at low OATs.

The other option is to increase the size of the primary pipework, where this can be done without too much disruption, on a trial and error basis. But what if the pipework restriction isn't the problem, instead it is something else, like the failure to modulate the flow rate? That would mean a lot of expense and disruption to no benefit. That doesn't necessarily mean I rule out changing the pipework at some point in the future, instead, it just seems to me that we need a diagnosis before we start treatment.

Midea 14kW (for now...) ASHP heating both building and DHW

No answers here, just some observations.

Your flow temperature is reasonably high, which maybe indicates slightly smallish radiators and would give a lower max kw figure. I can’t find the manual for midea, for vaillant 12kw it is at -3C outside as per their manual:

40C: 13.4kw

50C: 12.1kw

55C: 11.2kw

What pipework do you have that you think it might need doing?

Another note is the odd correlation between the OAT and the defrost cycle. Is the sensor build into the heat pump or is it just mounted somewhere nearby? Probably doesn’t matter for this, but might confuse some algorithm slightly.

Overall it looks like your flow rate isn’t quit high enough.

1400l/h=0.4l/sec

0.4*4.2*5=8.16kW

From what I understand, there can be at least reasons for this:

The pump can’t push the water through fast enough, but I think that would lead to a high delta T, as the hot water would spend too much time in the radiators and cool down more.

or the radiators can’t get rid of the heat, so the heat pump reduces the flow rate to maintain the delta t (higher flow rate would result in lower delta t).

I’d check that all the radiators are on and hot and drained etc.

Posted by: @adrianNo answers here, just some observations.

Thanks. In reply:

The flow temps are high by design. The rads (all rads, no UFH) are as large as can be (and are are all bar two K3s) but the height and/or width is usually constrained by the building (small old cottage, low window sills etc) and aesthetics (my house is not a radiator showroom). To get sufficient heat delivery and keep the radiator sizes in bounds, we (my installer and I) had to accept the only way we could do this was by using high flow temps. That said, if the heat pump output is what it it should be then the (smallish) rads are nonetheless correctly sized at those higher flow temps.

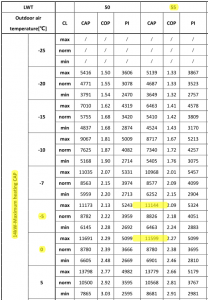

Here is the Midea manual data on outputs in Watts from my heat pump in the OAT/flow temp ranges we are looking at (CAP = capacity = output in Watts, COP = COP, PI = Power Input in Watts):

I have yet to determine what sets the output (CL, Capacity Level) to max, norm or min (flow rate???) but as can be seen, at 'max' level it has enough output to meet a 9-10kW load.

Posted by: @adrianWhat pipework do you have that you think it might need doing?

It's more Freedom (the heat pump supplier) who think this might need doing (ie enlarging). Their response so far has been it must be the installation that is at fault (I wonder why?). It is the primary circuit to the plate heat exchanger (yes, I have one), which is mostly but not all 28mm plastic (PEX). They may have a point, but before we go down that disruptive route, I want to be sure it is the cause of the problem. Another factor not mentioned in my earlier post for thinking the pipework is not the problem is that when the heat pump changes to DHW heating, the flow rate remains essentially the same (apart from a minute transient increase, see 1300 on 1st Jan in the chart). This suggests to me it is being controlled by something other than the circuit resistance, unless the DHW coil circuit has almost exactly the same resistance as the PHE circuit, which seems highly unlikely (but not impossible).

Posted by: @adrianAnother note is the odd correlation between the OAT and the defrost cycle. Is the sensor build into the heat pump or is it just mounted somewhere nearby? Probably doesn’t matter for this, but might confuse some algorithm slightly.

You are right, the OAT sensor is in the heat pump, and it is measuring the air intake temperature (AIT) rather than the true OAT. Since the defrost cycles use warm air to do the defrost, the local air temp warms a bit, and the air intake temp warms a bit. Something similar also happens during 'normal' cycles, but the other way round. If you look at the left had side of the chart, eg around 1800 on 1st Jan, you can see that when the compressor is running, and cold air is being expelled, the OAT/AIT drops. @jamespa and I among others have had many discussions about this, and have yet to come to a definitive answer. In the meantime, I have been collecting OAT hourly data (not perfect, but better than nothing) from an independent temp logger placed in an improvised Stevenson screen on the other side of the house.

Posted by: @adrianOverall it looks like your flow rate isn’t quit high enough.

1400l/h=0.4l/sec

0.4*4.2*5=8.16kW

Absolutely, this is the crux of the whole matter. Note also the circulating fluid has glycol in it, specific heat capacity nearer 4 than 4.2, and mean delta t is usually less than 5, meaning the actual heat transfer is a bit less. Given the Midea manual says the circulating pump has a range from 0.7 to 2.75m^3/h, why is it fixed most but not all of the time at around 1.4m^3/h???

Posted by: @adrianFrom what I understand, there can be at least reasons for this:

The pump can’t push the water through fast enough, but I think that would lead to a high delta T, as the hot water would spend too much time in the radiators and cool down more.

Agree, and I think this is another reason for supposing the pipework isn't too restrictive, or the other side of the same coin, the pump isn't too feeble. But this does raise another question: if the flow rate was increased, might it's benefits be lost because of a resulting lower delta t?

Posted by: @adrianor the radiators can’t get rid of the heat, so the heat pump reduces the flow rate to maintain the delta t

There is no obvious reason why they can't get rid of the heat. They are large enough and all valves etc are fully open apart from lock shield valve adjustments for balancing. TRVs are all off (fully open). Also, if the heat pump was reducing the flow rate to maintain the delta t, we should expect to see at least some variation in the flow rate (fer example, at different mean delta t values) but we don't. Instead for almost all the time, the flow rate is fixed (that steady running period with the lower flow rate in the above chart is a very rare event, most of the time the flow rate is effectively fixed at around 1.4m^3/h, as seen in the rest of the chart).

Midea 14kW (for now...) ASHP heating both building and DHW

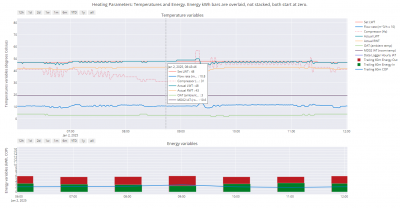

Perhaps the most interesting period in the chart is not when the heat pump is misbehaving, but when it is behaving, ie running at steady state, eg between 0600 and 1200 on the 2nd Jan:

Here, at an OAT of 3 degrees, and with the IAT (indoor air temp) steady ie the heat loss/supply is in balance (albeit a bit below target, but steady), we see the actual LWT is at the set LWT, the delta t is 5, and the flow rate is 1.08m^3/h (=0.3l/s) which gives an output of 0.3 x 4 (shc for glycol addition) x 5 = 6kW, which is suitably close to my empirically determined heat loss at this OAT (5kW, range 5.5 to 6.5kW). Although there might be a bit of self-fulfilling prophecy at work here (it is after all the same data over a long time period that determines the empirical loss), it is nonetheless interesting that the heat pump is running at a steady state, and is matching the heat loss. The question then becomes why can't it do this at other times?

Midea 14kW (for now...) ASHP heating both building and DHW

Posted by: @cathoderayAnd there is indeed a lot going on here. Starting on the left, we have a 3 hour period of moderate OAT (just over 10 degrees). Here the heat pump does what it does most of the time: it runs with a fixed flow rate and appears to modulate its output by cycling, which in turn means much of the time the leaving water temperature (LWT) / returning water temperature (RWT) delta t is too low. This is not how a heat pump is supposed to run. That said, the trailing 60min COP of just over 4 is OK

I don't think you can say 'This is not how a heat pump is supposed to run'. SOFAIK there is nothing wrong with operating a fixed flow rate (and thus variable deltaT); it has the interesting effect that a straight line WC curve is better matched to the 'ideal' curve than a fixed deltaT flow rate control. The principal means of modulating output of a heat pump is the compressor frequency and the fan speed.

As to cycling, at >10 its not that surprising. MyVaillant heat pump, sized pretty much to match the house loss, cycles above ~11C

Posted by: @cathoderayAt around 1300 on 1st Jan, a day of storms, the OAT suddenly drops (cold front passing?). This happens to coincide with a timed DHW heating cycle (the high LWT spike), but once that is over the Set LWT increases, as it should, but the flow rate remain the same, and the heat pump continues to cycle, albeit with a marginally higher average LWT/RWT delta t, and the compressor (dotted line) can be seen to work a bit harder, and the trailing 60min COP drops to about 3. But it is still cycling, and this is not how a heat pump is supposed to work.

I would agree that at this point (OAT~7-8) it should ideally stop cycling. But it could just be a bit oversized and/or there could be a restriction in taking the heat away imposed by the downstream system. I don't think this proves that the heat pump is faulty.

Posted by: @cathoderayIn the early hours of 2nd Jan, the OAT continues to fall, and the heat pump does something unusual for it, it starts running as it should. It modulates (in this case drops) the flow rate, the LWT/RWT delta t rises, and it stops cycling. The COP however continues to fall, as the heat pump is working harder. Note how relatively stable everything is between 0600 and 1200. This 'normal' steady running state is extremely rare on my heat pump, and only seems to occur at around 5 degrees OAT.

I was thinking about this effect in relation to my own heat pump. In reality (for me) there is a window between 11C and 4C where it runs continuously. Outside that window it either cycles (because it cant modulate down sufficiently) or defrosts (because it has to). I should add that I haven't yet observed the behaviour at well sub zero temps where it may not need to defrost. I think that its entirely plausible that you are seeing the same effect, but with a window that is narrowed because your heat pump is either oversized (which I still think it probably is) or restricted by the downstream circuit (which I still think it probably is). Again it doesnt prove the heat pump is faulty.

Posted by: @cathoderayThe other problem, which is a general heat pump problem, though other manufacturers may manage it better, is the harmful effect of defrost cycles. Despite the compressor working harder than ever, and a rise in energy in, the energy out fails to rise, and the mean LWT, which is normally at around the set LWT, falls below the set LWT. The heat pump is thrashing itself, but getting nowhere. But defrost cycles are a given for heat pumps, which means they have to be designed to accommodate them, and that means adjusting other parameters - eg flow rate when not defrosting - to compensate.

A possible explanation here is that the engaged system volume isn't sufficient (for defrost), due somehow to do with the PHE and flow rates. As we know the primary flow rate is insufficient for the system capacity, and so this also implies that it is restricted for defrost cycles. This will cause them to take longer and thus rob more time. Its just a theory so may be wrong.

Posted by: @cathoderayIt seems to me the first question that has to be answered in attempting to fix this is why does a heat pump that has PWM control (the ability to vary flow rate) not use variable flow rates? The effectively fixed flow rate can explain both the moderate OAT cycling and the low OAT poor performance. Or to put it the other way round, if the circulating pump did modulate it output, then it might both stop the moderate OAT cycling, and be able to deliver more heat when it is most needed, at low OATs.

Its a reasonable question although, as I say, I have yet to hear a coherent argument for flow rate modulation (although I can see an argument for the heat pump adapting the flow rate to the system at install time, which requires the same circuitry). I think the give- away is that, if you remove the PWM cable, the flow rate remains at the same (problematically low) value and its that which explains poor low OAT performance, not the fact it cant turn down. The manual to the pump clearly indicates that PWM only reduces the rate not increases it, so it follows that either the water pump is faulty or the system has too much back pressure. Neither would a fixed flow rate explain cycling at moderate OATs, what explains that is most probably modest oversizing (or restrictions in the rest of the system).

Posted by: @cathoderayThe other option is to increase the size of the primary pipework, where this can be done without too much disruption, on a trial and error basis. But what if the pipework restriction isn't the problem, instead it is something else, like the failure to modulate the flow rate? That would mean a lot of expense and disruption to no benefit. That doesn't necessarily mean I rule out changing the pipework at some point in the future, instead, it just seems to me that we need a diagnosis before we start treatment.

I dont think you have a choice as that is (you say) what Freedom want to do.

The fact is that all of the behaviours can be explained either without invoking a faulty heat pump, or by the fault with the heat pump being solely confined to the water pump. The possible exception to this is the fact that the pump speed doesn't reduce , however I cant see that is causing any actual problem.

So the next step is either

- replace the primary water pump and see if it pumps at a higher rate or

- replace at least some of the under-specified pipework (given that its likely your heat pump is a bit oversized, it may be sufficient to change out the accessible bits first - that's certainly what I would do if I were a plumber!

Until you have eliminated these two I cant see how it is worth investigating more complex explanations further, and anyway it seems unlikely freedom will contemplate this course of action.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

To I hope clear up some points:

Posted by: @jamespaI don't think you can say 'This is not how a heat pump is supposed to run'.

I can say what I like (within the usual limits) but equally I am open to refutation! This is actually a woolly bit of writing on my part, a dangling pronoun. 'This' refers to the near constant use of cycling, even at lower, but not very low OATs. I appreciate heat pumps have to cycle at higher OATs when they have reached the lower limit of their sustained output, but at moderate to low-ish OATs heat pumps are supposed to run 'low and steady', and cycling is not low and steady, it is the complete opposite.

Posted by: @jamespaThe principal means of modulating output of a heat pump is the compressor frequency and the fan speed.

There is a fair amount of chicken and egg stuff in this, as in what is actually responding to what, ie the actual control logic, and I am not sure we know what that is. I agree that ultimately it is varying the compressor frequency that varies the output, but does the heat pump primarily control the compressor, or does it primarily control something else (the rate of heat production/transfer, via delta t, flow rate?), and the compressor responds to that primary control? Why isn't the logic along these lines: low OAT > boost heat transfer (increase delta t and/or flow rate) > boost compressor output ie it is a secondary, not principal, response.

Posted by: @jamespaIn reality (for me) there is a window between 11C and 4C where it runs continuously. Outside that window it either cycles (because it cant modulate down sufficiently) or defrosts (because it has to).

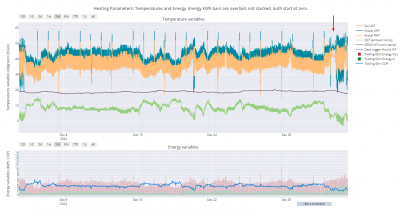

This is how a heat pump is supposed to work, but mine does not display this behaviour. Furthermore, OATs in the range are common in the heating season, meaning I suspect much of the time your heat pump will run continuously. However, the norm for my heat pump is the other way round, I mentioned the steady state running period seen in the chart in original post is extremely rare. Here is the last month's data. The OAT is between 4 and 11 degrees most of the time, and yet you have to look very hard to spot periods when it wasn't cycling (periods when the LWT/RWT stay apart). I can only see one, possibly two very short periods of non-cycling, apart from the 2nd Jan period which is visible (arrowed):

Posted by: @jamespaI think that its entirely plausible that you are seeing the same effect, but with a window that is narrowed because your heat pump is either oversized (which I still think it probably is) or restricted by the downstream circuit (which I still think it probably is). Again it doesnt prove the heat pump is faulty.

I am not sure I follow all the logic here. If the heat pump effectively always cycles (see above), then it must (by your logic) always be considerably oversized (and so can't modulate down low enough; the fact it has to cycle being the 'proof' it is over-sized). But at the same time, and my primary major concern is that in colder weather it under-delivers, either because it it is under-sized (which I think is unlikely, see notes earlier on measured heat loss and Midea's claimed capacities), or because of some failure to ramp up the output when it is needed. This failure can only really be down to one of two things (or possibly a combination of the two): the heat pump simply doesn't come up with the goods, or it could, but it can't deliver them because of a downstream restriction. I have said before I haven't yet ruled out either explanation, however there is a lot of circumstantial evidence as noted previously that suggests the pipework may not be restrictive.

I haven't proved anything (including the heat pump is faulty) yet! Note the title of the thread, it is a question not a proof!

Posted by: @jamespaA possible explanation here is that the engaged system volume isn't sufficient (for defrost), due somehow to do with the PHE and flow rates.

The 'engaged system volume' is presumably both circuits, albeit with a small choke effect allowance for the poor PHE, which always seems to get it in the neck. I do however agree with 'somehow to do with the...flow rates', that being in my view a very likely suspect. Even when defrosting, the flow rate remains steadfastly stuck at 1.4m^3/h. Why?

Posted by: @jamespaI think the give-away is that, if you remove the PWM cable, the flow rate remains at the same (problematically low) value and its that which explains poor low OAT performance, not the fact it cant turn down. The manual to the pump clearly indicates that PWM only reduces the rate not increases it, so it follows that either the water pump is faulty or the system has too much back pressure. Neither would a fixed flow rate explain cycling at moderate OATs, what explains that is most probably modest oversizing (or restrictions in the rest of the system).

I think you may be onto something here (for other readers, the PWM cable disconnection test happened behind the scenes: I disconnected the PWM lead which should have meant the pump ran at full speed, but it didn't, it stayed stuck at the 1.4m^3/h rate). But for the reasons given earlier, I remain as yet unconvinced that restrictions are the primary fault. Instead, I favour 'the water pump is faulty' (as you put it). My key point is that it is specifically described a a variable flow rate pump, yet most of the time it shows a remarkably unvariable fixed flow rate. The upper range might (or might not) be limited by system restrictions, but what stops it using it's lower range? By the way, the primary circulating pump is an integral part of a Midea heat pump, if that primary pump is faulty (either in itself, or though its controls), then the heat pump is faulty.

Posted by: @jamespaThe fact is that all of the behaviours can be explained either without invoking a faulty heat pump, or by the fault with the heat pump being solely confined to the water pump. The possible exception to this is the fact that the pump speed doesn't reduce , however I cant see that is causing any actual problem.

So the next step is either

- replace the primary water pump and see if it pumps at a higher rate or

- replace at least some of the under-specified pipework (given that its likely your heat pump is a bit oversized, it may be sufficient to change out the accessible bits first - that's certainly what I would do if I were a plumber!

Until you have eliminated these two I cant see how it is worth investigating more complex explanations further, and anyway it seems unlikely freedom will contemplate this course of action.

"by the fault with the heat pump being solely confined to the water pump" - the water pump is in my view as stated above an integral part of the heat pump, if it is faulty, then the heat pump is faulty. The failure of the water pump to reduce its speed is both a diagnostic pointer (suggests the water pump is not under any control) and a problem, albeit relatively minor, in its own right (it forces the heat pump to cycle almost all the time).

Next steps:

(a) there is an option for a slightly higher rated primary circulating pump, but for some not entirely clear reason Freedom don't want to try that option. I haven't asked about changing the current one like for like, but one way or another changing that pump is very much the first thing to try. I am still waiting for an explanation from Freedom of how a Freedom Midea heat pump should behave ie what flow rate and delta t patterns are to be expected. This surely is the first thing to look at.

(b) changing the pipework will be moderately disruptive. I will be the first to say it needs to be done, but only after either (i) it has been proven to be the cause of the poor low OAT performance or (ii) step (a) above has been tried, and made no difference.

Midea 14kW (for now...) ASHP heating both building and DHW

Posted by: @jamespaI don't think you can say 'This is not how a heat pump is supposed to run'.

I can say what I like (within the usual limits) but equally I am open to refutation! This is actually a woolly bit of writing on my part, a dangling pronoun. 'This' refers to the near constant use of cycling, even at lower, but not very low OATs. I appreciate heat pumps have to cycle at higher OATs when they have reached the lower limit of their sustained output, but at moderate to low-ish OATs heat pumps are supposed to run 'low and steady', and cycling is not low and steady, it is the complete opposite.

OK wrong wording on my part. Please read 'infer' instead of 'say'.

Regarding the rest of this quote please read again this comment

Posted by: @jamespaPosted by: @jamespaI think that its entirely plausible that you are seeing the same effect, but with a window that is narrowed because your heat pump is either oversized (which I still think it probably is) or restricted by the downstream circuit (which I still think it probably is). Again it doesnt prove the heat pump is faulty.

As I observe above the restricted window within which mine (which I would describe as not much more than critically sized - ie just big enough or a very tiny bit more) runs steadily is 5-11C (cycling at the high end, defrosting at the low). It doesn't need much additional oversizing for that to reduce to 5-8/5-7 or even 5-5C. You have produced, quite some while ago, evidence to suggest yours may be a bit oversized (say 8-9kW vs 11kW) which could easily explain your reduced window of steady operation and yet still be consistent with the problem at low OAT being caused by the low high end flow rate (which we know to be the case). Also I think your Midea is a downrated 16kW pump, so will possibly have a lower modulation depth than my pump which is not a downrate of a higher model.

Posted by: @cathoderayI disconnected the PWM lead which should have meant the pump ran at full speed, but it didn't, it stayed stuck at the 1.4m^3/h rate). But for the reasons given earlier, I remain as yet unconvinced that restrictions are the primary fault. Instead, I favour 'the water pump is faulty' (as you put it). My key point is that it is specifically described a a variable flow rate pump, yet most of the time it shows a remarkably unvariable fixed flow rate. The upper range might (or might not) be limited by system restrictions, but what stops it using it's lower range? By the way, the primary circulating pump is an integral part of a Midea heat pump, if that primary pump is faulty (either in itself, or though its controls), then the heat pump is faulty

As I say it could be system restriction or faulty pump that restricts the high end. As to what is stops it getting to the low end, either the Midea isnt in fact designed to modulate, despite the fact that the water pump is, or as you say there is a fault. However I cant see what negative consequence a failure to reduce in speed would cause. And yes I accept that the water pump is part of the heat pump, but its narrowing down the problem to an easily replaceable part. The give away, I repeat, is that removal of the pwm cable does NOT increase the speed which means either there is a system restriction or the pump is faulty pretty much for certain, without the need to invoke any other part of the heat pump (so this needs to be fixed even if something else is also wrong).

Posted by: @cathoderayThe 'engaged system volume' is presumably both circuits, albeit with a small choke effect allowance for the poor PHE, which always seems to get it in the neck. I do however agree with 'somehow to do with the...flow rates', that being in my view a very likely suspect. Even when defrosting, the flow rate remains steadfastly stuck at 1.4m^3/h. Why?

Most likely (but of course not certainly) because of a system restriction or faulty pump. The effect of removing the PWM cable confirms that its more or less certainly one of these, or at least that one of these is occurring even if there are also other faults.

Posted by: @cathoderayNext steps:

(a) there is an option for a slightly higher rated primary circulating pump, but for some not entirely clear reason Freedom don't want to try that option. I haven't asked about changing the current one like for like, but one way or another changing that pump is very much the first thing to try. I am still waiting for an explanation from Freedom of how a Freedom Midea heat pump should behave ie what flow rate and delta t patterns are to be expected. This surely is the first thing to look at.

(b) changing the pipework will be moderately disruptive. I will be the first to say it needs to be done, but only after either (i) it has been proven to be the cause of the poor low OAT performance or (ii) step (a) above has been tried, and made no difference.

Unfortunately I think you are stuck with what Freedom and or your installer will do. You can try to persuade them otherwise, but they will have an idea of what is likely to fail/easy to fix and doubtless will stick to it unless there is incontrovertible evidence to the contrary which, as I explain above, there currently isn't so far as I can see.

Assuming that the pump is fairly cheap and easy to change like for like (which is very probable) I would personally do the following

- swap the pump to rule it out or in. Swap back if no change found. I wouldn't have high expectations that this will make a difference, but its worth eliminating first if easy

- swap the accessible plumbing (and do the best job I could, oversizing by default). See what difference it makes. This may either be enough or indicate that you need to swap the rest, or reveal something else.

- Depending on the result of the above swap the inaccessible plumbing

The point I am trying, it seems unsuccessfully, to argue is that everything you have observed could be explained by either a faulty water pump (one which, for some reason, wont reach its max pumping speed) or a system restriction. That doesn't mean that this is the explanation but it is the simplest explanation consistent with all the facts. This being the case I can see that Freedom have a legitimate argument to try these first (and, even if they dont have a legitimate argument, will likely stick to their guns)

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

I should add to the above one other thing.

It is just possible that the Midea is designed for a deltaT higher than 5C at max output, high enough that the flow rate you see on the primary is adequate (implying in turn that the primary is functioning correctly). In this case it would indicate that the problem is with the PHE/Secondary not extracting sufficient heat from the primary. I think its unlikely, but Freedom should know what primary deltaT to design to (if they don't, they cant design) so that is worth asking!

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

I don't think we are far apart, what differences there are are down to semantics and writing styles. I note you tend to use explicit often bracketed caveats where as I leave them implied. For example, if I title a post 'Is My Heat Pump Inherently Defective?' I do that to signal I have not come to a foregone conclusion, and therefore I do not need to load every alternate sentence with caveats. I also know I will given a choice of words tend to use the shorter and/or more lively/accessible one. That said, despite my preference for precision in language, I am guilty of one major imprecision: I have used heat pump to mean my heating system. My only defence, if it is one, is that in the vernacular I think most people will use the terms interchangeably ('how are you getting on with you new heat pump?' - 'it's fine, except when it is very cold outside', where 'it' is in fact the heating system, not the heat pump on it's own, and 'fine' means I am warm and comfortable, not the dials on my heat pump are showing the right numbers). Furthermore, I am in a way asking whether the heat pump part of my heating system is defective, and so, by implication, if it isn't, then what is?

Summary of where we are now (and what I think we agree on):

(1) my heating system is defective. The evidence is that the room temperatures fail to reach their targets at low outside air temperatures.

(2) there is a second and unconnected concern that it almost always cycles. Given it is low frequency cycling it may be that this is in fact not much of a concern. Nonetheless, for my part, I would like to know if this is how it is meant to run, or not.

(3) given a defective system, we need to identify the cause of the defect if we are to correct the defect. We have considered and made some conclusions as follows:

(a) the heat pump is undersized: unlikely, if anything it may be a bit oversized. The extent to which this is the case, and what effect it might have, is open to speculation because we simply do not know how the heat pump is supposed to behave. In particular we know very little about how it is meant modulate its output, or even how low it can go, though that may in fact be in the Midea engineering data - if we can work out how to read it. We don't know what governs which row in the capacity (output) tables (the max/norm/min rows) the heat pump operates at. If, for example it normally operates in the norm or min row, then it may in fact be undersized. In passing, the heat pump was sold as a 14kW heat pump, it then subsequently turned out that the Midea 12 14 and 16kW models are in fact the same hardware, the badge output is set in software using dip switches. We may be able to determine the effect this has on range of output by comparing the capacity tables for the different models.

Note that much of the preceding paragraph is about the secondary problem (why the heat pump cycles all the time). Once we have established that the heat pump can meet and/or exceed the heat loss, then its theoretical 'at the compressor outlet' output is not the cause of the primary defect (the failure to reach room design temps in cold weather). However, it does still remain a possibility that while in theory (ie in the output tables) it can reach a certain output, say 11kW, in practice, for whatever reason, which may include the heat pump controls, the detail of which we do not know, it fails to reach that output. I don't think we have decisively ruled that possibility out, but for now I think we are agreed that while possible, this is not the most likely cause of the primary defect.

(b) the heat transfer system (that which gets the heat from the heat pump to the radiators) is defective: we both agree that this system is the most likely culprit. This system has three components: the circulating pump, the pipework and the plate heat exchanger (PHE), any or all of which could be the cause of the problem. Where we differ is on which is the most likely cause. I favour the pump, either in itself ie not man enough for the job, or in its controls, and I lean towards the latter because it is in effect (with rare exceptions) a modulated heat pump that fails to modulate. Yes I know there may be other explanations, but the failure to modulate is the standout observation, and given the primary defect is a failure to reach higher outputs then I can't help seeing a failure to modulate as at least a very good candidate for the reason for the failure.

I can of course see that pipework and/or PHE resistance might restrict flow (while at the same time noting that this just one side of a coin, the other side being an inadequate pump). However, various bits of circumstantial evidence - eg the fact the flow rate is the same for both the space heating and the DHW heating despite the fact they use different circuits which are extremely unlikely to have the same excessive resistance, and the fact there is no down modulation (if there was a restriction, I would expect an cap on higher flow, but not on lower flow, whereas what we actually see is a cap on both upper and lower flow rates, manifest as a fixed flow rate) - plus my assessment of circuit resistance, based on pipe sizes, circuit length and number of tight bends (they appear to be adequate, albeit not by very much) suggest, at least to me that this (excessive circuit resistance) is the second in line candidate, after the failure of the pump to modulate.

(c) the radiators are undersized: unlikely. All bar one were upgraded, and most are K3s, sized to be large enough at the design flow temps.

Given the above, we also agree on the next steps:

(1) rule out the circulating pump as the cause of failure. I also takes this a bit further: rule out its deficient modulation as the cause of failure, ie it fails not because it has failed, but because it fails to get the right instructions. To deal with that, we need more information on how it is supposed to modulate (or to put it another way, is it meant to run at a fixed flow rate, despite being a variable flow rate pump?).

(2) rule out the pipework as the cause of failure. The other reason why this is my second choice is the obvious one, replacing the pipework is disruptive. As wisecrack patients are wont to say about operations, a minor operation is one done on someone else.

Posted by: @jamespaThe point I am trying, it seems unsuccessfully, to argue is that everything you have observed could be explained by either a faulty water pump (one which, for some reason, wont reach its max pumping speed) or a system restriction. That doesn't mean that this is the explanation but it is the simplest explanation consistent with all the facts. This being the case I can see that Freedom have a legitimate argument to try these first (and, even if they dont have a legitimate argument, will likely stick to their guns)

The point I am making, I hope successfully, is that I have understood the points you are making, even to the extent we are both making the same point, its most likely either a faulty circulating pump and/or circuit resistance (but yes it could be something else altogether that has not occurred to us) all we differ on, if we differ at all, is on which of those two is the most likely.

None of this has been helped so far by the poor communication between me, the end user, and Freedom, the supplier, and one presumes the best source of technical expertise on Midea heat pumps in the UK, a direct consequence of Freedom's B2B (and BTC - choose you own words) policy. But that is where we are. I can only hope that come Monday when Christmas 2024 can be said to at last have become Christmas past that Freedom will be more forthcoming.

Have just seen your latest post:

Posted by: @jamespaI think its unlikely, but Freedom should know what primary deltaT to design to (if they don't, they cant design) so that is worth asking!

Indeed, but this is the problem, they won't (or at least haven't so far) talk to me! I do wonder sometimes how much they really know about Midea heat pumps. The only way that can be answered is for then to step up, and start talking!

Midea 14kW (for now...) ASHP heating both building and DHW

Posted by: @cathoderaySummary of where we are now (and what I think we agree on):

(1) my heating system is defective. The evidence is that the room temperatures fail to reach their targets at low outside air temperatures.

(2) there is a second and unconnected concern that it almost always cycles. Given it is low frequency cycling it may be that this is in fact not much of a concern. Nonetheless, for my part, I would like to know if this is how it is meant to run, or not.

(3) given a defective system, we need to identify the cause of the defect if we are to correct the defect. We have considered and made some conclusions as follows:

(a) the heat pump is undersized: unlikely, if anything it may be a bit oversized.

All agreed

Posted by: @cathoderayIn particular we know very little about how it is meant modulate its output,

In detail that is true. However its a dead cert that its primary control loop adjusts the compressor frequency and fan speed to achieve the flow temp demanded by the WC curve. Its these two variables which determine the amount of energy available to the water. Flow rate is secondary and, whilst it might choose to do so for reasons eg of efficiency, it doesn't need to adjust the flow rate as long as it is sufficient (which it isn't - but the PWM lead test proves that this is not because the water pump isn't receiving the correct instruction from the heat pump)

Posted by: @cathoderayI don't think we have decisively ruled that possibility out, but for now I think we are agreed that while possible, this is not the most likely cause of the primary defect.

Agreed

Posted by: @cathoderayI favour the pump, either in itself ie not man enough for the job, or in its controls, and I lean towards the latter because it is in effect (with rare exceptions) a modulated heat pump that fails to modulate.

This is where we maydiffer a bit. Since the PWM signal only reduces the pump speed, and since without the PWM signal the pump speed is what it is with the PWM signal, its most unlikely that the pump controls (other than those that are part of the pump itself) are causing the primary problem you have, namely insufficient output at low temps. So I think (folding in my afterthought about the secondary that reduces it to

- the pump is faulty (basically it doesn't, for some reason, get to its max output) or

- the pump and the system are mismatched (the pump not man enough for the system/the system has too much resistance - whichever way you wish to describe it)

- the pump and primary are matched, the heat pump is designed for a DT of 8-9 at its max output, and the phe/secondary is not matched to this

Posted by: @cathoderayGiven the above, we also agree on the next steps:

(1) rule out the circulating pump as the cause of failure. I also takes this a bit further: rule out its deficient modulation as the cause of failure, ie it fails not because it has failed, but because it fails to get the right instructions. To deal with that, we need more information on how it is supposed to modulate (or to put it another way, is it meant to run at a fixed flow rate, despite being a variable flow rate pump?).

(2) rule out the pipework as the cause of failure. The other reason why this is my second choice is the obvious one, replacing the pipework is disruptive. As wisecrack patients are wont to say about operations, a minor operation is one done on someone else.

As I say above I think 'not getting the right instructions' is ruled out by the pwm cable test.

The information we need to differentiate between 1/2 or 3 is what is the deltaT at which the Midea is expected to operate at max output.

Posted by: @cathoderayThe point I am making, I hope successfully, is that I have understood the points you are making, even to the extent we are both making the same point, its most likely either a faulty circulating pump and/or circuit resistance (but yes it could be something else altogether that has not occurred to us) all we differ on, if we differ at all, is on which of those two is the most likely.

Agreed.

Posted by: @cathoderayIndeed, but this is the problem, they won't (or at least haven't so far) talk to me! I do wonder sometimes how much they really know about Midea heat pumps.

I wouldn't want to speculate publicly (but I know what I suspect!)

Posted by: @cathoderay(2) there is a second and unconnected concern that it almost always cycles. Given it is low frequency cycling it may be that this is in fact not much of a concern. Nonetheless, for my part, I would like to know if this is how it is meant to run, or not.

This may change when the primary problem is fixed. If it doesn't I would put it down most likely to sizing/output modulation capacity as described above.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

@jamespa - all agreed, even most of the part in the middle about the PWM cable connection/disconnection test, with the minor difference that while the pipework resistance may cap the max flow rate, I am still perplexed why we don't see any down modulation with the lead connected.

Meanwhile, a bit more rather useful information! Freedom did send me an email by mistake on Christmas Eve (from the wording, it was meant to go to my installer, but nonetheless I replied as at the time my installer was on leave, but I haven't had a reply yet). Looking at it again (I had forgotten what it said, Christmas Eve was a long time ago, and as I said I am not really expecting an answer until next week), it turns out they have in fact already answered your design delta t question:

"When the PWM lead is connected the pump will modulate along with the compressor to maintain a delta T (flow and return) of between 4 and 5 degrees, until the flow temperature gets close to the target flow temperature. If the delta T is greater than 5 then the compressor and flow rate will ramp up and if it is less than 5 degrees its will ramp down."

From this I infer the design delta t is between 4 and 5 degrees, achieved by modulating both the compressor and the circulating pump ('the pump will modulate'), which means we should see a mostly steady delta t between 4 and 5 most of the time, which we definitely don't, and we should see evidence of both compressor modulation (which we do see, indeed it would be extraordinary if we didn't see that) and circulating pump modulation ('flow rate will ramp up...ramp down'), which almost all of the time we don't see (apart from the cyclic short dips plus very very occasionally a period of down modulation, at around 5 degrees OAT).

They also have this to say:

"If the flow rate never goes higher than 1.4 cubic meters per hour then it could be that the either the delta T is constantly around the 4/5 degrees so the flow should slowly increase until target flow temps are met, or the maximum flow the internal pump can achieve due to resistances in the pipework is the 1.4."

What I actually see is the opposite - my delta t constantly changes and most of the time less than 4/5 degrees, and the flow rate doesn't vary let alone slowly increase, it is instead effectively fixed. In so far as I can make sense of this, I should see the flow rate vary, but in practice I don't. The final part of the statement just reiterates what we all agree, the pipework resistances may be part of (or indeed all of) the problem.

In summary, I think what Freedom have said here is that we should see a mostly steady 4-5 degree delta t, with/controlled by circulating pump (and compressor) modulation. While the compressor does modulate, what we see with the delta t and circulating pump modulation is the opposite: the flow rate is fixed, and the delta t constantly changes, and most of the time is less than 4-5, sometimes considerably less. Bottom line as I see it: it appears the heat pump is not behaving (modulating) as expected.

Midea 14kW (for now...) ASHP heating both building and DHW

Posted by: @cathoderay@jamespa - all agreed, even most of the part in the middle about the PWM cable connection/disconnection test, with the minor difference that while the pipework resistance may cap the max flow rate, I am still perplexed why we don't see any down modulation with the lead connected.

Meanwhile, a bit more rather useful information! Freedom did send me an email by mistake on Christmas Eve (from the wording, it was meant to go to my installer, but nonetheless I replied as at the time my installer was on leave, but I haven't had a reply yet). Looking at it again (I had forgotten what it said, Christmas Eve was a long time ago, and as I said I am not really expecting an answer until next week), it turns out they have in fact already answered your design delta t question:

"When the PWM lead is connected the pump will modulate along with the compressor to maintain a delta T (flow and return) of between 4 and 5 degrees, until the flow temperature gets close to the target flow temperature. If the delta T is greater than 5 then the compressor and flow rate will ramp up and if it is less than 5 degrees its will ramp down."

From this I infer the design delta t is between 4 and 5 degrees, achieved by modulating both the compressor and the circulating pump ('the pump will modulate'), which means we should see a mostly steady delta t between 4 and 5 most of the time, which we definitely don't, and we should see evidence of both compressor modulation (which we do see, indeed it would be extraordinary if we didn't see that) and circulating pump modulation ('flow rate will ramp up...ramp down'), which almost all of the time we don't see (apart from the cyclic short dips plus very very occasionally a period of down modulation, at around 5 degrees OAT).

They also have this to say:

"If the flow rate never goes higher than 1.4 cubic meters per hour then it could be that the either the delta T is constantly around the 4/5 degrees so the flow should slowly increase until target flow temps are met, or the maximum flow the internal pump can achieve due to resistances in the pipework is the 1.4."

What I actually see is the opposite - my delta t constantly changes and most of the time less than 4/5 degrees, and the flow rate doesn't vary let alone slowly increase, it is instead effectively fixed. In so far as I can make sense of this, I should see the flow rate vary, but in practice I don't. The final part of the statement just reiterates what we all agree, the pipework resistances may be part of (or indeed all of) the problem.

In summary, I think what Freedom have said here is that we should see a mostly steady 4-5 degree delta t, with/controlled by circulating pump (and compressor) modulation. While the compressor does modulate, what we see with the delta t and circulating pump modulation is the opposite: the flow rate is fixed, and the delta t constantly changes, and most of the time is less than 4-5, sometimes considerably less. Bottom line as I see it: it appears the heat pump is not behaving (modulating) as expected.

OK, so (assuming Freedom are correct) you actually have two problems. The principal one is that the max pump rate is insufficient, leading to your output deficit at low OAT, the secondary one is that the pump rate doesn't modulate down (with no apparent negative consequences, but nonetheless relevant).

I would say that this new information makes it quite a bit more likely that the water pump is at fault. It could be somehow 'stuck' at a particular speed, which is insufficient for the demand.

If its not the water pump then there are (at least) two actual faults, one accounting for the capped upper speed and the second accounting for the failure to modulate the water pump speed down (which could be as simple as a failed lead)

Either way there is apparently something to do with the water pump or its control wrong, and then possibly (definitely f it turns out to be the water pump control not the pump itself) something to do with the circuit/pump capacity.

That said, when there are multiple faults in an electronic circuit, the first port of call is usually the power supply. I suppose its just possible that the primary power supply to the water pump (or the reference signal for the PWM if there is one) is faulty, accounting for both a failure to modulate and the cap. I suspect a multimeter on the appropriate points with reference to the water pump manual would tease this out, but you probably (and quite understandably) would rather leave this to your installer/Freedom.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 485 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Testing new controls/monitoring for Midea Clone ASHP

Here’s a current graph showing a bit more info. The set...

By benson , 2 minutes ago

-

RE: Setback savings - fact or fiction?

True there is a variation but importantly it's understa...

By RobS , 2 minutes ago

-

Below is a better quality image. Does that contain all ...

By trebor12345 , 29 minutes ago

-

Sorry to bounce your thread. To put to bed some concern...

By L8Again , 31 minutes ago

-

@painter26 — they (the analogue gauges) are subtly diff...

By cathodeRay , 1 hour ago

-

RE: What determines the SOC of a battery?

The answer from Fogstar was crisp. My hypothesis, su...

By Batpred , 1 hour ago

-

RE: Electricity price predictions

I am always impressed with how you keep abreast of so m...

By Batpred , 2 hours ago

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

@majordennisbloodnok I’m glad I posted this. There see...

By AndrewJ , 2 hours ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 5 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

Just to wrap this up here for future readers: The S...

By Batpred , 8 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 8 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 9 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 24 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 1 day ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 1 day ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 1 day ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 1 day ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago